Trans. Nonferrous Met. Soc. China 20(2010) s931-s936

Simulation of semisolid diecasting process of

four-way valve of HPb59-1 alloy for air-conditioner

YAN Guan-hai(闫观海), ZHAO Sheng-dun(赵升吨), SHA Zheng-hui(沙郑辉)

School of Mechanical Engineering, Xi’an Jiaotong University, Xi’an 710049, China

Received 13 May 2010; accepted 25 June 2010

Abstract: There exist many problems in producing four-way valve of HPb59-1 alloy for an air-conditioner by traditional solid state hot forging, i.e. larger forming loads, lower material utilization, larger subsequent machining allowance and nonuniform microstructure. For this reason, based on the orthogonal test, the semisolid diecasting process of a certain type of four-way valve was simulated with FLOW-3D. The simulation results show that the optimized process parameters are: the pouring temperature of 897.25 ?C, the shot velocity of 2.0 m/s and the preheated die temperature of 260 ?C. The simulation results demonstrate that the cavity can be filled smoothly and completely, the surface defects are small, the temperature field and the pressure field are uniform, and the casting quality is satisfactory. The effectiveness and availability of applying this technology are well verified by the numerical simulation.

Key words: simulation; semisolid diecasting; four-way valve; orthogonal test

1 Introduction

The four-way valve of HPb59-1 alloy for air-conditioner is mainly processed by traditional solid state hot forging. But it has many problems, such as larger forming loads, lower material utilization, larger subsequent machining allowance and nonuniform microstructure, which hinders the application of the valve. So the semisolid metal processing becomes the most promising technology for metal forming in the 21th century[1-2]. It excels at near-net shape and low cost of energy and materials. The semisolid diecasting process presents a good growth momentum[3], which comprises the advantages of both traditional casting and forging technologies. With the progress of the semisolid diecasting process, its simulation technology which analyzes the temperature and pressure field in the filling process and then predicts the product defects is also paid a lot of attention.

Both the semisolid metal research and its simulation technology target at nonferrous metal, its alloy and steel. ATKINSON[4] reviewed the rheology background, mathematical theories of thixotropy and the simulation technologies for semisolid metal processing. HIRT and KOPP[5] summarized the latest research of semisolid metal processing technology concerning the material fundamentals, process technology, material and process modeling for aluminium alloys and steel. Semisolid forming of copper alloy mainly focuses on the thixoforming of rotor by numerical simulation and experiments[6]. The filling process of the key-shaped component was simulated based on the apparent viscosity model of semi-solid A356 aluminum alloy slurry[7]. ZHANG et al[8] did numerical simulation of thixomolding on the mobile phone housing in magnesium alloy using the governing equations and numerical models. Based on rigid visco-plastic constitutive model of semi-solid AZ91D alloy at different strain rates, the thixoforming process of semi-solid AZ91D alloy was simulated using finite element software DEFORM-3DTM[9]. JIANG[10] simulated the thixoforging process of magazine plates of AZ91D magnesium alloy and achieved the effects of the parameters on this process. At present, the simulation research concerning semisolid metal forming is mainly involved with aluminium alloys, magnesium alloys and steel. The research with respect to semisolid copper alloys is less presented.

In this work, the process of semisolid diecasting for a certain type of four-way valve was simulated by FLOW-3D based on the orthogonal test. The optimized values of three chosen parameters, i.e. the pouring temperature, the shot velocity and the preheated temperature of the die, were achieved. The excellent casting quality was well demonstrated.

2 Governing equations and rheology model 2.1 Governing equations

The semi-solid slurry of HPb59-1 is regarded as a homogeneous, continual, incompressible fluid. The filling flow of semisolid slurry behaves as a continuum and abides laws of mass, momentum and energy conservation. The governing equations describing the filling flow of semisolid slurry consist of continuity equation, momentum equation, energy equation and fluid volume equation.

1) The continuity equation is expressed as:

(1)

(1)

where u, v, and w are the velocity vector components in

and

and direction, respectively.

direction, respectively.

2) The momentum equation is expressed as:

(2)

(2)

where  is the fluid density; p is the pressure; m is the apparent viscosity; G is the acceleration of gravity; and

is the fluid density; p is the pressure; m is the apparent viscosity; G is the acceleration of gravity; and  is Laplacian operator.

is Laplacian operator.

3) The energy equation is expressed as:

(3)

(3)

where  is the thermodynamic temperature;

is the thermodynamic temperature;  is the specific heat; and

is the specific heat; and  is the thermal conductivity.

is the thermal conductivity.

4) The fluid volume equation can be expressed as:

(4)

(4)

where VF is the fraction of opening volume in elements.

2.2 Rheology model

The semisolid materials take advantage of the laminar flow of the materials into the die cavity[11-13]. The semisolid materials are non-Newtonian fluid, the rheological behavior of which governs the way they flow. Viscosity is the most important property that governs the rheological behavior. Here the Carreau model is used to describe the variation of the apparent viscosity, which can be expressed as:

(5)

(5)

where is the apparent viscosity of the slurry;

is the apparent viscosity of the slurry;  is the zero shear viscosity;

is the zero shear viscosity;  is the infinite shear viscosity;

is the infinite shear viscosity; is a time constant, which reflects the influence of time on viscosity;

is a time constant, which reflects the influence of time on viscosity;  is the shear rate; and

is the shear rate; and  is the power law index.

is the power law index.

3 Simulation 3.1 Model

The object of the research is an four-way valve of HPb59-1 alloy whose three-dimensional solid model and gating system are shown in Fig.1. Fig.2 shows the generation mesh, which is divided into three blocks using the multi-block technique. The total number of elements is 1 845 208. The chemical composition of HPb59-1 alloy is shown in Table 1.

Fig.1 Solid model of four-way valve with gating system

Fig.2 Multi-blocks based on generated mesh

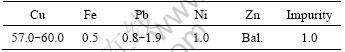

Table 1 Chemical composition of HPb59-1 alloy(mass fraction, %)

3.2 Selection of simulation parameters

Here three important parameters such as pouring temperature, shot velocity and preheated temperature of the die which have significant influence on filling ability of semisolid slurry and casting quality were chosen. In order to seek the optimal process parameters, based on the orthogonal test, simulations were carried out.

The three pouring temperatures were 895.60 ?C (fs=0.6), 897.25 ?C(fs=0.5) and 898.60 ?C(fs=0.4); the three shot velocities were 1.2, 1.6 and 2.0 m/s, and their corresponding ingate velocities were 11.76, 15.68 and 19.60 m/s, respectively[14-16]; the three preheated temperatures of the die were 260, 280 and 300 ?C. The factor-level table for orthogonal test is summarized in Table 2.

Table 2 Factor-level table for orthogonal test

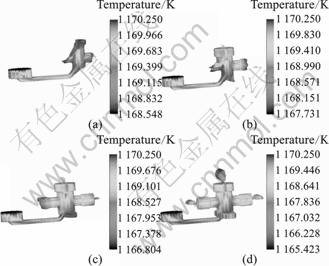

4 Results and discussion 4.1 Results of temperature field

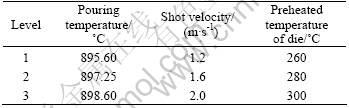

Fig.3 shows simulation results of temperature field on the nine groups from which it can be gained that the lowest temperature of the semisolid slurry occurs on the farther surface of casting, the last filling areas, and the outside of the ingate; while the highest temperature exists in the center of the ingate.

According to the simulation results, the slurry temperature varies with the process parameters. A great variation happens when the pouring temperature is low, the shot velocity is small, and the preheated temperature of the die is low. Generally speaking, the slurry temperature varies among 10 ?C, and its values are within the range from solidus temperature to liquidus temperature. The main reasons for phenomenon are as follows: The filling process is a transient nonisothermal process, and the filling time is 0.05 s, which leads to that the heat transfer process between semisolid copper alloy and die is inadequate. On the other hand, the smaller the variation of the temperature field, the closer the solidification rate of the slurry. This can avoid the shrinkage and the hot deformation caused by different cooling rates and big temperature difference. However, the bigger the variation of the temperature field, the more apparent the difference of the cooling rate with the increase of the solidification time. Given the temperature field, L3, L5, L6, L8, L9 should be considered in priority.

4.2 Results of pressure field

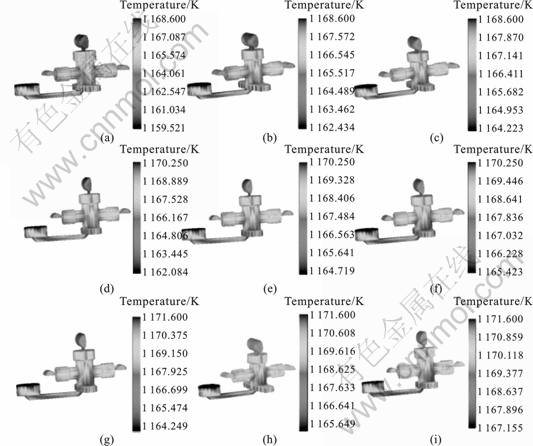

Fig.4 shows the results of pressure field for four-way valve when the filling is complete. According to the simulation results, pressure distribution changes in the casting and its gating system. In the runner and casting the pressure is higher, while it is lower at where is filled in the end. The pressure distribution is uniform in the casting under the nine groups of orthogonal parameters. There seems no local concentration of high pressure in the whole pressure field. The faster the shot velocity, the higher the pressure in the cavity. So decreasing the shot velocity can relieve the pressure of the cavity. From the pressure field aspect, the lower pressure can result in the profile of the casting surface rough, and even cannot make cavity filled up. However, the higher pressure causes the big impact of the slurry on the die and the turbulence in the filling process. Thus the shot velocity should be chosen in a compromise. In this work, the shot velocity is ideally 1.6 and 2.0 m/s.

Fig.3 Results of temperature field on nine groups orthogonal parameters: (a) Group L1, time frame: 0.043 601; (b) Group L2, time frame: 0.032 736; (c) Group L3, time frame: 0.026 193; (d) Group L4, time frame: 0.043 636; (e) Group L5, time frame: 0.032 724; (f) Group L6, time frame: 0.026 277; (g) Group L7, time frame: 0.043 704; (h) Group L8, time frame: 0.032 769; (i) Group L9, time frame: 0.026 091

Fig.4 Results of pressure field on nine groups orthogonal parameters: (a) Group L1, time frame: 0.043 601; (b) Group L2, time frame: 0.032 736; (c) Group L3, time frame: 0.026 193; (d) Group L4, time frame: 0.043 636; (e) Group L5, time frame: 0.032 724; (f) Group L6, time frame: 0.026 277; (g) Group L7, time frame: 0.043 704; (h) Group L8, time frame: 0.032 769; (i) Group L9, time frame: 0.026 091

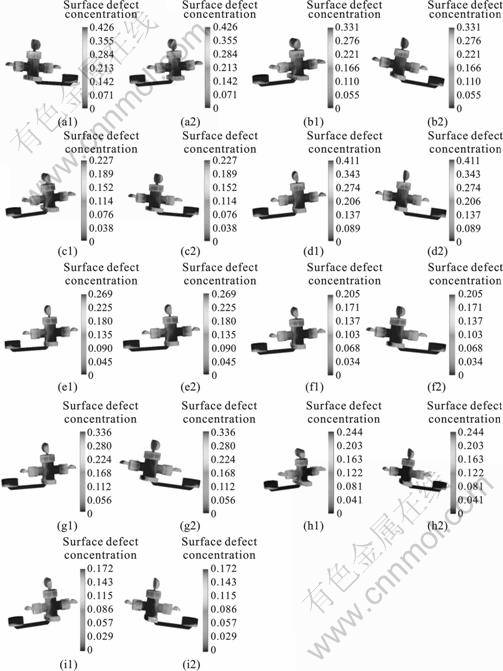

4.3 Results of surface defect concentration

In order to better achieve the goal of optimizing process parameters, Fig.5 shows the results of surface defect concentration. From these results, the values of surface defect concentration vary under the influence of process parameters of nine groups. It can be seen from the surface defect distribution that the die temperature has little influence on the distribution. At the same pouring temperature, a higher shot velocity brings about lower surface defect concentration. At different pouring temperatures, when the pouring temperature is high, the shot velocity increases, and thus the surface defect concentration gets its minimum. In addition, the order of the macro area of surface defect from large to small in the nine groups process parameters is: L7, L4, L5, L6, L8, L9, L2, L3, L1. Considering the surface defect concentration, L3, L5, L6, L8 should be prioritized.

4.4 Determining optimal process parameters

When selecting the optimal process parameters, the factors, such as the temperature field, the pressure field and the surface defect concentration, should be taken into account. If the temperature field is uniform, the solidification rates of the semisolid slurry in the cavity are close. The shrinkage and the hot deformation can be avoided. To prevent from the impact on the cavity caused by the over pressure and the roughness of the surface profile caused by the deficient pressure, the pressure distribution should be uniform and its value should be appropriate. The simulation results with low surface defect concentration and small surface defect macro area are preferred. Under higher pouring temperature, the fluidity of the slurry and the casting quality are better, but the gas and the oxidation in the slurry are increased, the die life is decreased, and the soldering of the copper alloy is generated. Under lower pouring temperature, the fluidity of the slurry and the casting quality are worse, but the small shrinkage helps to avoid the shrinkage cavity and bubble at the thicker part. This also helps to decrease the die corrosion and increase the die life. In addition, four-way valve of air-conditioner needs good air tightness, so a lower pouring temperature should be selected. The pouring temperature is selected as 897.25 ?C. Under lower preheated temperature of the die, the slurry is easily solidified in advance and the casting is easily cracked. Under higher preheated temperature of the die, the soldering will happen on the casting, the shrinkage is generated on the thicker part, and the microstructure is coarse. By conclusion, the optimized process parameters are: pouring temperature 897.25 ?C, shot velocity 2.0 m/s, preheated temperature of the die 260 ?C, which are helpful to decrease surface defects and improve the distribution of temperature field and pressure field. Fig.6 shows the filling processes and the variation of the temperature field. The flow of semisolid slurry in filling process is the laminar flow. Moreover, the cavity can be filled smoothly and completely.

Fig.5 Results of surface defect concentrationon nine groups orthogonal parameters: (a) Group L1, time frame: 0.043 601; (b) Group L2, time frame: 0.032 736; (c) Group L3, time frame: 0.026 193; (d) Group L4, time frame: 0.043 636; (e) Group L5, time frame: 0.032 724; (f) Group L6, time frame: 0.026 277; (g) Group L7, time frame: 0.043 704; (h) Group L8, time frame: 0.032 769; (i) Group L9, time frame: 0.026 091

Fig.6 Filling process of semisolid diecasting: (a) Group L6, time frame: 0.010 002; (b) Group L6, time frame: 0.015 001; (c) Group L6, time frame: 0.019 999; (d) Group L6, time frame: 0.026 227

5 Conclusions

1) Three process parameters, i.e., pouring temperature,

shot velocity and preheated temperature of the die, are selected. Based on orthogonal test, the semisolid diecasting process of a certain type four-way valve is simulated with FLOW-3D. The simulation results have achieved for the temperature field, the pressure field, and the surface defect concentration.

2) According to the simulation results, the optimized process parameters are obtained as that the pouring temperature is 897.25 ?C, the shot velocity is 2.0 m/s, and the preheated temperature of the die is 260 ?C. Using these parameters, the flow of semisolid slurry in filling process is the laminar flow. The cavity can be filled smoothly and completely, and the casting quality is excellent.

References

[1] FAN Z. Semisolid metal processing[J]. Int Mater Rev, 2002, 47: 49-85.

[2] KIRKWOOD D H. Semisolid metal processing[J]. Int Mater Rev, 1994, 39:173-189.

[3] FLEMINGS M C. Semi-solid forming: The process and the path forward[J]. Metall Sci Technol,2000, 18(2): 3-4.

[4] ATKINSON H V. Modeling the semisolid processing of metallic alloys[J]. Prog Mater Sci,2005, 50: 341-342.

[5] HIRT G, KOPP R. Thixoforming: Semi-solid metal processing [M]. Berlin: Wiley-VCH,2009: 1-42.

[6] LEE S Y, LEE S Y. Filling and solidification characteristics during thixoforming of copper rotor for the electrical motors[J]. Solid State Phenomena, 2006, 116/117: 652-655.

[7] BAI Yue-long, MAO Wei-min, XU Jun, XU Hong, HOU Hua. Numerical simulation on rheo-diecasting mould filling of semi-solid key-shaped component[J]. Transactions of Nonferrous Metals Society of China, 2008, 18: 682-685.

[8] ZHANG You-fa, LIU Yong-bing, CUI Xiao-peng, CAO Zhan-yi. Filling analysis for thixomolded process of AZ91D magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2006, 16: s117-s121.

[9] JI Ze-sheng, YAN Hong-hua, ZHENG Xiao-ping, SUGIYAMA S O, YANAGIMOTO J. Numerical and experimental investigations of semi-solid AZ91D magnesium alloy in thixoforming process[J]. Journal of Materials Processing Technology, 2008, 202: 212-218.

[10] JIANG Ju-fu. Research on preparing AZ91D semi-solid billets by new SIMA and its thixoforging[D]. Harbin: Harbin Institute of Technology, 2005: 32-48. (in Chinese)

[11] FLEMINGS M C, RIEK R G, YOUNG K P. Rheocasting processes[J]. AFS International Cast metals Journal, 1976, 1(3): 11-22.

[12] FLEMINGS M C. Behaviour of metal alloys in the semisolid state[J]. Metall Trans A, 1991, 22A(5): 957-981.

[13] MODIGELL M, KOKE J. Time-dependent theological properties of semi-solid metal alloys[J]. Mech Time-Depend Mat, 1999, 3: 15-30.

[14] YOUNG K P, RIEK R G, FLEMINGS M C. Structure and properties of thixocast steels[J]. Metals Technology, 2003, 18(1): 36-41.

[15] FLEMINGS M C, RIEK R G, YOUNG K P. Rheocasting[J]. Materials Science and Engineering, 1976, 25: 103-117.

[16] BROOK G B. Improving the quality of aluminium diecastings by novel techniques[J]. Materials & Design, 1982, 3: 558-565.

(Edited by YANG You-ping)

Foundation item: Project(50375117) supported by the National Natural Science Foundation of China

Corresponding author: YAN Guan-hai; Tel: +86-29-82668607; E-mail: guanhai.yan@stu.xjtu.edu.cn