Trans. Nonferrous Met. Soc. China 22(2012) 2124-2130

Effect of vacuum degree in VIM furnace on mechanical properties of Ni-Fe-Cr based alloy

Masoud MOSHTAGHI, Seied Mahdi ABBASI

Materials and Metallurgical Engineering Department, Khaje Nasir Tossi University, Tehran 19395-1999, Iran

Received 17 November 2011; accepted 21 March 2012

Abstract: In order to investigate the effect of the vacuum degree in vacuum induction melting (VIM) furnace on the mechanical properties of Ni-Fe-Cr based alloy, four samples were prepared under different conditions. The chemical analysis results show that under the argon atmosphere, there is more dissipation in Al and Ti, whereas it is reduced by establishing the vacuum atmosphere. The gas analysis results show that the oxygen and nitrogen contents of the samples decrease with increasing vacuum degree. However, there is no dissipation in the gas content of the samples in higher degree of vacuum. In addition, the thermodynamic calculations show that the probability of TiO2 and Al2O3 formation is high due to the small value of the equilibrium oxygen. Higher vacuum degree reduces the tensile and yield strength of the alloys, while it enhances the elongation and reduction of area values due to the lower amount of the inclusions and evaporation of Al and Ti under higher vacuum. On the other hand, increasing vacuum degree changes the fracture mode from brittle to ductile.

Key words: Ni-Fe-Cr based alloy; vacuum degree; VIM furnace; mechanical properties

1 Introduction

Fe-Ni based Inconel 718 alloy is an alloy precipitation hardened by γ′ and γ″ phases in an austenitic matrix. There are some other phases such as NbC and δ in the matrix. Among these phases, γ″ has the most significant role in the strengthening of the alloy [1]. Since the innovation of this alloy in 1960, it has been applied in many applications in high temperature industries due to its good workability and individual mechanical properties. Today, the Inconel 718 alloy is also one of the most utilized super alloys worldwide, though it could not be applied at temperatures higher than 650 ℃ due to the instability of the strengthening phase γ″ [2].

The alloying elements of the Inconel 718 alloy are divided into major and trace alloying elements groups. The major alloying elements include Al, Ti, Nb, Cr, Fe, and Mo as well as W and Co which are added in some cases to promote the properties. The trace elements in this alloy include Si, Mn, B, P, Cu, Ta, Mg, N and O [3].

Vacuum induction melting (VIM) is an important processes in melting and casting of the super alloys. It is necessary to use VIM for melting Ni and Ni-Fe based super alloys as well as other advanced alloys due to their high reactivity in oxygen and nitrogen containing atmospheres. Using this method along with further refining processes such as vacuum arc re-melting and electro slag re-melting (ESR) provides favorable properties for the super alloys [4, 5]. By investigating the effective parameters in vacuum melting processes including vacuum intensity in VIM furnace, the type of crucible, the dwelling time of melt in crucible as well as liquid-crucible reactions and optimizing them, homogenous composition with high purity and suitable mechanical properties for super alloy could be reached. This study was performed to investigate the effect of vacuum degree in VIM furnace on the mechanical properties of the Inconel 718 super alloy.

2 Experimental

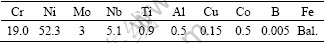

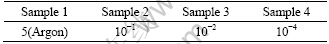

In order to prepare the melting and alloying process, a VIM furnace with capacity of 5 kg and an Al2O3 spinel crucible were used. Primary materials were ferrochromium (66.2%), ferromolybdenum (62.1%), ferroniobium (68.5%), ferrotitanium (70.8%), cobalt (99.99%) and nickel (99.99%). In addition, pure Al, Cu and Fe were used. Table 1 lists the chemical composition of the target alloy. Four samples were melted, alloyed and poured under different conditions in order to investigate the effect of the vacuum degree on the mechanical properties of the Inconel 718 super alloy as listed in Table 2. However, all of the alloys were produced under the same condition of melt dwelling time in the crucible.

Table 1 Chemical composition of target alloy (mass fraction, %)

Table 2 Vacuum degree (mbar) of VIM furnace for different samples of melting Inconel 718 alloy

ESR process was applied to reduce the segregations and inclusions and also eliminate the shrinkages and porosities. Before hot rolling the samples, they were homogenized at 1180 ℃ for 3 h and then quenched in cold water. The hot rolling process was conducted at 1095 ℃ with a total strain of 66% during several passes, and then samples were cooled in the air. Thereafter, the rolled samples were prepared for aging by exposing to solution annealing treatment at 980 ℃ for 1 h. Annealed specimens were cooled in the air and then exposed to the tow stages aging treatment. First, specimens were kept at 720 ℃ for 8 h and then cooled to 620 ℃ in the furnace at a cooling rate of 55 ℃/h. Afterward, they were kept at this temperature for 8 h and finally cooled in the air.

The chemical compositions of the prepared alloys were determined by Metal Lab 80-75J quantometer. In order to measure the oxygen and nitrogen content of the specimens, a Leco TC600 gas analyzer was used. According to the ASTM E8, two samples were prepared from each rolled specimen for the tensile test. Tensile test was performed by means of an Instron 8520 tensile instrument at a jaw’s rate of 2 mm/min. Quantitative assessments of the inclusions including the size, quantity, surface fraction and nodule count were conducted according to the ASTM E-11296 by means of a Unimet 8799 optical microscope equipped with an image analyzer software. The reported results were the average of six zones in each sample. In order to investigate the EDS analysis and fracture surfaces, a Cam Scan 2300NV SEM system was used.

3 Results and discussion

3.1 Effect of vacuum on chemical composition

Figure 1 shows the effect of vacuum on the Ti and Al contents and their loss. It should be noted that, increasing vacuum degree has no significant effect on the other alloying elements such as Nb, Ni, Mo, Cr and Fe.

Fig. 1 Effect of vacuum intensity on content (a) and dissipation value (b) of Al and Ti

It seems that the sample 1, produced under Ar atmosphere has higher Ti dissipation than the vacuum treated specimens, due to the more oxygen content of the surrounding environment of the melt, because of the higher probability of contacting the liquid with the atmosphere as well as existing oxygen with the Ar impurities. In addition of oxidation reactions, it could be related to the dissipation of Ti from the reactions of Ti with the crucible wall. Figure 1(b) shows the dissipation of Ti and Al in different vacuum intensities. The dissipation of Ti and Al is decreased by increasing the vacuum degree, due to the reduced oxidizing probability of the elements under higher vacuum conditions.

The major dissipating elements are Ti and Al due to their high reactivity and oxidizing ability. Increasing the soluble oxygen content of the melt might lead to promoting the formation of Al and Ti oxides. The produced oxides are sent to the slag and a large amount of Ti and Al are wasted [6].

The dilute solution of Ti and Al in molten nickel is considered for investigating the oxidation tendency of these elements. Therefore, the equilibrium pressure of oxygen is chosen as the criterion for the oxidation tendency. Since the considered solution is dilute, the constant activation coefficient γΘ is used instead of the activation coefficient γ. The oxidation relation of Al and the calculations for the equilibrium content of the oxygen are as follows [7,8]:

2Al+3/2O2=Al2O3

when ?G=0,

(1)

(1)

where ?G is Gibbs free energy; xi is the mole fraction of element i; R is the gas constant; T is the thermodynamic temperature; αi and hi are the activity of element i and  is the equilibrium pressure of oxygen in the melt of i. The oxidation relation of Ti and the calculations for its equilibrium oxygen content are as follows [7,9]:

is the equilibrium pressure of oxygen in the melt of i. The oxidation relation of Ti and the calculations for its equilibrium oxygen content are as follows [7,9]:

Ti+O2=TiO2

(2)

(2)

By considering Eqs. (1) and (2) and comparing  and

and  , it could be found that the required equilibrium pressure for the oxidation of Ti and Al is closed to each other, thus the formation of these two oxides is thermodynamically possible. Since the equilibrium pressure value is low and it could be simply provided, it could be proposed that they have high oxidation tendencies. However, Al has a little higher tendency for oxidation than Ti.

, it could be found that the required equilibrium pressure for the oxidation of Ti and Al is closed to each other, thus the formation of these two oxides is thermodynamically possible. Since the equilibrium pressure value is low and it could be simply provided, it could be proposed that they have high oxidation tendencies. However, Al has a little higher tendency for oxidation than Ti.

Equations (3) and (4) are related to the nitriding reactions of Ti and Al. They show the reactivity of the Al and Ti with nitrogen [7].

2Al+N2=2AlN

/kJ=-644.34+0.186T, T=273-923 K (3)

/kJ=-644.34+0.186T, T=273-923 K (3)

2Ti+N2=2TiN

/kJ=-676.55+0.191T, T=1115-1500 K (4)

/kJ=-676.55+0.191T, T=1115-1500 K (4)

By considering the temperature ranges of Eqs. (3) and (4) as well as the melting point (1623 K), it could be concluded that these nitrides are not formed thermodynamically. Therefore, it could be suggested that they are not presented in the alloy. However, due to the temperature variations during the cooling stages, TiN is more likely to form than AlN.

Here, the dilute solution of Ti and Al in molten nickel is considered to study the tendency of these elements for reacting with carbon. Therefore, the equilibrium activity of the carbon is taken into account as the criterion for the carbonizing tendency. The equations for the reaction of Al and C as well as calculation procedure of the equilibrium activity of the carbon are as follows [7,8]:

4Al+3C=Al4C3

(5)

(5)

The reaction of Ti and C and its equilibrium activity of the carbon are given as [7,9]:

Ti+C=TiC

(6)

(6)

By comparing  and

and  and considering Eqs. (5) and (6), it could be found that the required activity for the formation of Al4C3 is a large value, so reaching to this value is impossible. Consequently, the formation of TiC is more likely.

and considering Eqs. (5) and (6), it could be found that the required activity for the formation of Al4C3 is a large value, so reaching to this value is impossible. Consequently, the formation of TiC is more likely.

Another mechanism for wasting Ti and Al is evaporation. Generally, these two elements have very low vapor pressures and they would be wasted under vacuum condition. From Fig. 1(b) it could be found that Al has been wasted more than Ti under lower vacuums. At the end, it could be concluded that wasting via oxidation is far more than wasting via evaporation. It is due to the reduction of the dissipation by increasing the vacuum degree resulting from the reduction of oxidation under higher vacuums.

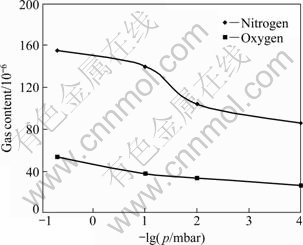

Figure 2 shows the effect of the vacuum of the chamber on the gas composition. It could be seen that by increasing the vacuum of the chamber, the oxygen content of the specimens is decreased. However, there is no significant difference in oxygen content of the specimens under higher vacuums. From this figure, it is found that enhancing the vacuum intensity leads to the reduction of the nitrogen content of the alloy though increasing vacuum intensity under higher vacuums has no influences on reducing the nitrogen content of the samples.

Fig. 2 Effect of vacuum of chamber on O and N content of alloys

It is illustrated that the oxygen and nitrogen contents of the specimens are reduced (due to increasing the vacuum) in the same way. In other word, the variation curves of the element contents verses vacuum intensity have the same shapes. According to the previous work [6], the reduction of the oxygen content of the heats lead to increasing de-nitrogenization of the melt. Also, it has been revealed that increasing the vacuum of the chamber to higher values has no significant effect on removing the contained gases of the alloy. The results of this study are also compatible with those mentioned before [6].

3.2 Effect of vacuum on mechanical properties

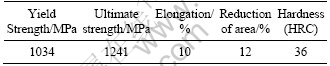

Table 3 summarizes the standard mechanical properties of the Inconel 718 alloy.

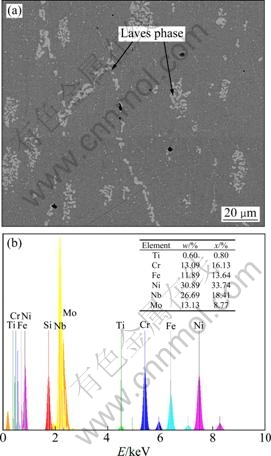

Figure 3 shows the effect of the vacuum degree on the mechanical properties of the samples. It is illustrated that increasing the vacuum degree results in decreased hardness, tensile and yield strength as well as considerable enhancement of the elongation and area reduction of the samples.

Table 3 Mechanical properties of Inconel 718 alloy according to AMS 5662L [10]

Fig. 3 Effect of vacuum degree on mechanical properties of alloys

From Fig. 3 it is observed that the melting and alloying processes under Ar atmosphere lead to promoting the hardness, tensile and yield strength as well as decreasing the elongation and area reduction values. This is due to two reasons. 1) since the vapor pressure of Ti and Al is high under vacuum conditions, some of these elements are wasted and it results in diminishing the amount of the strengthening phase γ″; thus the strength is higher under Ar atmosphere and the elongation and area reduction values are decreased. 2) In the casting under Ar atmosphere, inclusions are increased.

As mentioned above, enhancing the vacuum intensity leads to the reduction of C, O and N contents of the super alloy. It means that the probability of the inclusion formation is reduced and so the ductility is promoted. Figure 4 shows that increasing vacuum results in decreasing the surface fraction and the amount of the inclusions. The effectiveness of the vacuum increasing on the both mentioned parameters is considerable. As seen, these features are decreased by increasing the vacuum degree. On the other word, the higher the vacuum degree, the lower the inclusion formation probability. Under the higher vacuum intensities, due to the possibility of the evaporation of the elements such as Al and Ti, waste of these elements and the amount of Ti and Al containing inclusions (e.g. TiC, TiN, TiO2, AlN and Al2O3) would be increased in the microstructure. Considering the obtained results, it could be expressed that this value is negligible, because the amount of N, O and C would be decreased under higher vacuums and the probability of the formation of the inclusions would be declined dramatically.

Fig. 4 Effect of vacuum degree on amount (a) and area fraction (b) of inclusions

Refining and reducing the amount of inclusions results in decreasing stress concentration around the inclusions and so the resistance against crack growth is increased and the ductility of the super alloy is promoted. Uniform dispersion of the inclusions also leads to the improved ductility of the super alloy. The existing inclusions in the γ matrix might restrict the re-crystallization of the austenite in the grains during the hot rolling process. Hence, the grain growth of the γ phase is reduced considerably and the strength of the super alloy is increased.

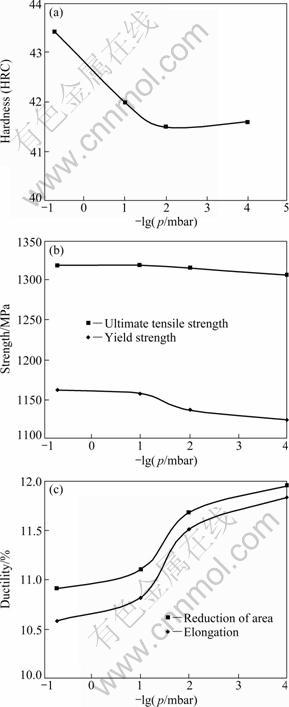

As observed, the relative elongation and area reduction values are lower than those reported in AMS 5662L (10% and 12%, respectively). It is found that this is due to the high Si content (0.8% in average) of the alloys. GUO and ZHOU [11] have investigated the effect of Si on the microstructure and mechanical properties of the casting Inconel 718 alloy. The results show that Si results in the segregation of niobium and the formation of Laves phase. Laves phase is an intermetallic compound which is formed in the presence of relative large amounts of metallic elements including Nb, Ta and Ti in the γ matrix. This phase is precipitated during the production of the alloy due to the segregation of Nb. It is brittle and can affect the mechanical properties. By increasing Si content in the alloy, the temperature of Laves/γ eutectic reaction is elevated. The tensile test results show that Si has detrimental effects on the tensile strength and ductility at ambient temperature. When the Si content is exceeded to 0.34%, the elongation would be decreased intensely [12]. Considering the results, it is suggested that the reason for decreasing the relative elongation and area reduction values is the high Si content of the alloy, which is due to the higher Si content of the primary materials. Figure 5 shows the SEM image of the sample 3 and EDS analysis of the phases. Laves phase consists of (Ni,Fe,Cr)2(Nb,Mo,Ti) intermetallic compounds [4]. Thus, the presence of the Laves phase in the microstructure from EDS results could be revealed.

3.3 Effect of vacuum intensity on fracture surface of tensile specimens

Figure 6 shows the fracture surface of the tensile test samples under two conditions of Ar and 10-4 mbar vacuum for aged alloys. In the comparison of these figures, it is found that by increasing the vacuum, the large and small pores in fractography images are increased and the amount of the smooth cleavage surfaces is decreased in fracture zone.

Fig. 5 SEM image (a) and related EDS analysis (b) of alloy sample 3

The fracture surface of sample 1 (Fig. 6(a)) shows that cleavage planes and cracks develop through a zigzag path. Since the dimples are rarely observed in the fracture surface of this sample, it could be stated that the ingot produced under the Ar atmosphere is fractured cleavagely and so it has the brittle mode of fracture.

Sample 4 which is age hardened has fractured in soft mode (Fig. 6(b)). It seems that fracturing and cracking of the inclusions and/or eliminating the matrix-inclusions and precipitates connection while applying the tensile load lead to the creation of several smooth cleavage surfaces in the fracture surface. The fracture surface of this sample has many dimples which is one of the soft fracture mode characteristics. Fracturing and cracking of the inclusions and/or eliminating the connection of the matrix with inclusions and strengthening precipitates while applying the tensile load result in the formation of some cleavage smooth surfaces in the fracture surface. The size of the created pores in the fracture surface is depended on the size of the produced inclusions and precipitates through aging treatment, the bearing ability of the matrix against the plastic deformation and the difference between elastic modules of the inclusions as well as precipitates and matrix. The pores could be formed on the micro-scaled inclusions such as carbides and nitrides or nano-scaled precipitates. Finally, it could be expressed that by increasing the vacuum intensity, the fracture mode is changed from brittle to soft due to the decreasing amount of the inclusions.

Considering the conducted analysis on the obtained results as well as the importance of reaching high ductility and high strength for Inconel 718 super alloy, the optimum vacuum of 10-2 mbar is recommended for melting and alloying processes.

Fig. 6 Fracture surface of tensile test samples under various vacuum intensities for aged alloys: (a) Sample 1 (under Ar atmosphere); (b) Sample 4 (under vacuum of 10-4 mbar)

4 Conclusions

1) Increasing the vacuum intensity leads to the loss of Al and Ti and the decrease of oxygen and nitrogen contents in the samples. At higher vacuum intensities, the reduction rates of Al and Ti decrease.

2) Thermodynamic calculations show that the probability of TiO2 and Al2O3 formation is high due to the small value of the equilibrium oxygen. The same calculations show that TiN is more likely formed than AlN.

3) Increasing the vacuum degree causes the decline of the yield and tensile strength of the specimens due to the decreasing inclusion amount.

4) The ductility is increased by elevating the vacuum intensity due to the reducing amount and size of the inclusions.

References

[1] CAI D, ZHANG W, NIE P, LIU W, YAO M. Dissolution kinetics of δ phase and its influence on the notch sensitivity of IN-718 [J]. Materials Characterization, 2007, 58: 220-225.

[2] FU S H, DONG J X, ZHANG M C, XIE X S. Alloy design and development of Inconel 718 type alloy [J]. Materials Science and Engineering A, 2009, 499: 215-220.

[3] DONG Y W, JIANG Z H, LI I B. Segregation of niobium during electroslag remelting process [J]. Journal of Iron and Steel Research, International, 2009, 16: 7-11.

[4] DONACHIE M J, DONACHIE S J. Superalloys: A technical guide [M]. ASM International, 2002: 27-71.

[5] CHOUDHURY A. State of the art of superalloy production for aerospace and other application using VIM/VAR or VIM/ESR [J]. The Iron and Steel Institute of Japan Internatoinal, 1992, 32: 563-574.

[6] SCHLATTER R. Vacuum induction melting [M]. New York: Elsevier Publishing Co., 1984: 7-12.

[7] GASKELL D R. Introduction to metallurgical thermodynamics [M]. New York: Hemisphere Publishing Corporation, 1981: 77-536.

[8] ISHII F, BAN-YAS, HINO M. Thermodynamics of the deoxidation equilibrium of aluminumin liquid nickel and nickel-iron alloys [J]. The Iron and Steel Institute of Japan International, 1996, 36: 25-31.

[9] DASHEVSKII V Y, ALEKSANDROV A A, KANEVSKII A G, MAKAROV M A. Deoxidation equilibrium of titanium in the iron–nickel melts [J]. The Iron and Steel Institute of Japan International, 2010, 50: 44-52.

[10] AMS 5662L [M]. Pennsylvania US: SAE International Corporation, 2000: 5-7.

[11] GUO J T, ZHOU L Z. The effect of phosphorus, sulphur and silicon on segregation, solidification and mechanical properties of cast alloy 718[C]//KISSINGER R D. Superalloys Pennsylvania, US: The Mineral, Metals and Materials Society, 1996: 451-455.

[12] KNOROVSKY G A, CIESLAK M J, HEADLEY T J, ROMING A D, HAMMETTER W F. Inconel 718: A solidification diagram [J]. Metallurgical Transactions A, 1989, 20: 2149-2158.

真空感应熔炼炉真空度对Ni-Fe-Cr基合金力学性能的影响

Masoud Moshtaghi, Seied Mahdi Abbasi

Materials and Metallurgical Engineering Department, Khaje Nasir Tossi University, Tehran 19395-1999, Iran

摘 要:为研究真空感应熔炼炉的真空度对Ni-Fe-Cr基合金力学性能的影响,在不同真空度条件下制备4个样品。化学分析结果表明:在氩气保护气氛下,Al和Ti的损耗较多,而在真空条件下其损耗较少。气体分析结果表明:样品中氧和氮的含量随真空度的增加而降低。而在更高的真空度下,样品中的氧和氮则没有损耗。热力学计算表明:由于平衡的氧含量值较低,TiO2和Al2O3生成的可能性高。高真空度使合金的拉伸强度和屈服强度降低,但是由于少量的杂质以及Al和Ti的损耗,合金的伸长率和断面收缩率增加。此外,提高真空度使合金由脆性断裂转变为韧性断裂。

关键词:Ni-Fe-Cr 基合金;真空度;真空感应熔炼炉;力学性能

(Edited by FANG Jing-hua)

Corresponding author: Masoud MOSHTAGHI; Tel: +98-9127216196; E-mail: masoud.moshtaghi@gmail.com

DOI: 10.1016/S1003-6326(11)61438-6