DOI:10.19476/j.ysxb.1004.0609.2019.11.13

退火态FGH96合金的热变形行为及热加工图

刘敏学1,吴 宏1,王 岩2,侯艺婷2,郑 聪2,程天威2,陈雅倩2,江者也2,江 亮1

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 中南大学 航空航天学院,长沙 410083)

摘 要:通过热模拟试验,系统研究热挤压-退火态FGH96合金在变形温度为1020~1110 ℃、应变速率为0.001~1 s-1条件下的热压缩变形行为,建立本构方程并构建热加工图;结合电子背散射衍射(EBSD)分析,优化合金的变形工艺参数。结果表明:合金在热变形过程中发生明显动态再结晶现象。利用摩擦修正后的峰值应力获得的该合金热压缩本构方程材料常数分别为:α=0.0071272、n=2.6417、A=6.6811×1015、Q=448.05 kJ/mol,较低的变形激活能与热挤压后初始晶粒尺寸的减小以及二次γ′相的粗化有关。利用构建的不同应变量ε下热压缩本构方程材料常数的五次多项式组对合金的流变应力进行了预测,预测数据与实验摩擦修正数据吻合较好。根据热加工图能量耗散效率并结合微观组织分析,对热挤压-退火态FGH96合金提出了建议的热加工参数范围:变形温度约为1075~1080 ℃、应变速率约为1×10-3~1×10-1.5 s-1的区域。

关键词:FGH96合金;热压缩变形;本构方程;变形激活能;热加工图

文章编号:1004-0609(2019)-11-2561-11 中图分类号:V256 文献标志码:A

FGH96合金是一种以面心立方结构(FCC) γ相为基体,以γ′相为强化析出相的沉淀强化型粉末高温合金,属于损伤容限型镍基粉末高温合金,其成分与Rene'88DT接近[1-2]。作为我国的第二代粉末高温合金,FGH96合金具有均匀的微观组织、较低的裂纹扩展率[3-4],热工作环境性能良好,最高使用温度可达750 ℃,已成为我国航空发动机涡轮盘的首选材料,但FGH96合金尚存在成本高、工艺周期长和制粉困难等缺点。目前,生产粉末高温合金的主要工艺路线为:真空感应熔炼(Vacuum induction melting, VIM)+等离子旋转电极雾化法(Plasma rotating electrode process, PREP)制粉/氩气雾化法(Argon gas atomization, AA)制粉+热等静压成形(Hot isostatic pressing, HIP)/热挤压(Hot extrusion, HEX)+等温锻造(Isothermal forging, ITF)+热处理。在粉末高温合金盘件的成型制备方面[5],国外相对成熟,主要包括以美国为代表的AA制粉+HEX+ITF工艺和以俄罗斯为代表的PREP制粉+HIP工艺。而我国主要采用PREP制粉+HIP工艺或者AA/PREP制粉+HIP+ITF工艺生产盘件。

等温锻造是制造FGH96合金涡轮盘件的关键工序。国内外学者目前已对FGH96合金的热压缩变形力学及其微观组织演化行为展开了一些研究[1, 3, 6-11]。ZHANG等[6]对比了不同制粉工艺(PRER和AA)下HIP态FGH96合金的热压缩变形行为,并分别建立了两种状态合金的热加工图。结果表明,PRER-HIP态FGH96合金对变形温度和应变速率更加敏感,而AA-HIP态FGH96合金具有更低的热激活能;AA-HIP态FGH96合金具有更好的热加工性能,应变对该合金的能量耗散率和失稳区域影响更为显著。刘建涛等[7]对HIP态FGH96合金的动态再结晶行为进行了研究。结果表明,应变速率对动态再结晶晶粒大小的影响最为显著;同时,建立了动态再结晶平均晶粒尺寸小与Z参数的关系,并构建了该合金的动态再结晶状态图。XU等[8]研究了HIP态FGH96合金的热压缩变形行为,利用双曲正弦函数建立了本构关系方程,获得的变形热激活能为693.21 kJ/mol;同时分别给出了动态再结晶动力学和动态再结晶平均晶粒尺寸公式。NING等[3]研究了HIP态FGH96合金经热处理后的热压缩变形行为,分析了其微观机理,构建了热加工图并给出了优化的热加工工艺条件。FANG等[1, 9]利用双道次热压缩变形试验研究了HIP态FGH96合金的动态再结晶临界应变,结果表明该合金二道次的动态再结晶临界应变量小于一道次的动态再结晶临界应变量,一道次和二道次热变形的动态再结晶模型也有所不同;研究者还建立了考虑应变量影响的热变形本构关系方程,并利用构建的热加工图讨论了不同应变量范围下合金的流变失稳区。王淑云等[10]建立了HIP态FGH96合金的热变形非线性本构关系方程,并引入有限元算法提高了模型的计算精度。

综上可知,目前对于FGH96合金等温锻造的基础研究多集中在HIP态FGH96合金,有关HEX态FGH96合金热压缩行为的研究还很少。HEX作为FGH96合金等温锻造前的一类重要备选工序,对该状态合金热压缩/热加工行为的研究具有十分重要的现实意义。杨川等[11]研究了热挤压态FGH96的热压缩变形力学行为,构建了热加工图、分析了其开裂行为并结合有限元方法对其热压缩变形过程进行了模拟。研究表明,随着应变速率的减小,裂纹产生的临界应变量逐渐减小;在低应变速率条件下,在宏观裂纹产生之前内部晶粒之间就已经产生了微观开裂现象。本文作者以热挤压态FGH96合金为研究对象,对其进行一定温度的退火处理,系统研究了热挤压-退火态FGH96合金在变形温度为1020~1110 ℃、应变速率为1×10-3~1 s-1范围内的热压缩变形行为,建立了合金的本构方程,构建了热加工图,并结合微观组织结果优化了热挤压-退火态FGH96合金的热加工工艺参数。

1 实验

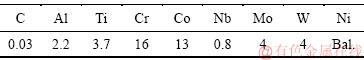

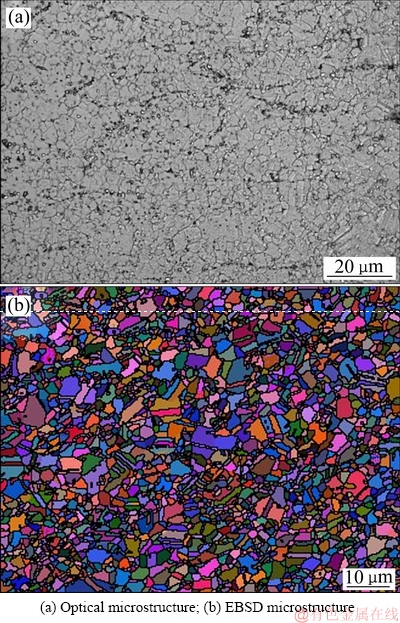

实验所用材料为国产挤压态FGH96高温合金,其化学成分见表1。将挤压态FGH96合金进行750 ℃、2 h退火处理,冷却方式为随炉冷却。图1所示为退火态FGH96合金的显微组织。由图1可见,热挤压态FGH96合金经低温退火后,其晶粒大多呈现等轴晶形貌,大晶粒与小晶粒相间分布,晶粒内存在一定数量的退火孪晶;没有观察到明显的粉末原始颗粒边界(Prior particle boundary, PPB)存在,这从侧面证明了热挤压对PPB的消除作用;晶粒取向分散,无明显的织构存在。经EBSD 统计分析,其晶粒尺寸在0.3~9.0 μm,平均晶粒尺寸为1.1 μm;孪晶含量达28.5%。

表 1 FGH96粉末高温合金的化学成分

Table 1 Nominal composition of FGH96 alloy (mass fraction, %)

图1 热挤压-退火态FGH96合金的显微组织

Fig. 1 Microstructures of hot extruded-annealed FGH96 alloy

利用线切割机从热挤压-退火态FGH96棒材半径的1/2处切取直径8 mm×12 mm的圆柱体热压缩试样,在Gleeble-3180D型热模拟实验机上进行等温压缩实验。热模拟实验温度分别为1020、1050、1080、1110 ℃,应变速率分别为1×10-3、1×10-2、1×10-1、1 s-1,最大真应变为0.7。将试样以10 ℃/s的速度加热到设定温度,保温2 min后进行压缩实验。实验过程中利用润滑油在试样两端粘贴石墨片以减小变形过程中的摩擦,实验结束后立即水冷以保留高温变形组织。通过热模拟实验机的微机系统进行实验数据的自动采集,绘制真应力-真应变曲线并进行数据修正,为本构方程的建立和热加工图的构建提供数据基础。

将热挤压-退火态试样和热压缩试样沿轴向剖开,经不同型号砂纸打磨、机械抛光后,采用Kallings溶液(5 g CuCl2+100 mL HCl+100 mL C2H5OH)进行腐蚀。腐蚀后的金相组织在REICHERTMe F3A型光学显微镜上进行观察和分析。将机械抛光后的试样进一步做振动抛光,抛光时间在6~8 h。制备后的样品在配有电子背散射衍射(EBSD)附件(Oxford, Aztec)的FEI Quanta 650型扫描电镜(SEM)下进行,步长设定为0.02~1.2 μm。利用Channel 5软件对数据进行后续处理及分析。

2 结果与分析

2.1 真应力-真应变曲线及其修正

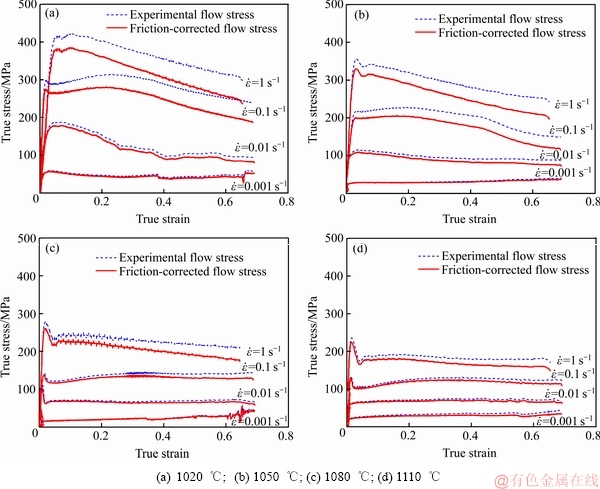

图2中虚线所示为不同变形温度和应变速率下,热挤压-退火态FGH96合金热压缩的真应力-真应变曲线。由图2可见,合金试样在变形初期处于加工硬化阶段,真应力随着真应变的增加而迅速增加;随着动态再结晶的发生,动态软化作用逐渐增强,真应力随真应变的增长速率逐渐减小;当加工硬化与动态再结晶软化达到动态平衡,真应力-真应变曲线逐渐趋于平稳。随着变形温度的升高或应变速率的降低,合金的流变应力有所减小。以上规律与文献报道[3, 6, 8, 11]的不同状态FGH96合金的热压缩变形流变应力变化规律一致。

尽管使用润滑剂和石墨片可以减小热压缩变形过程中试样与压头之间的摩擦,但是随着温度的升高和变形量的增加摩擦无法避免,因此本文利用EBRAHIMI等[12]提出的流变应力修正方法,对热挤 压-退火态FGH96合金的真应力-真应变曲线进行了摩擦修正,如式(1)所示:

(1)

(1)

式中:pave为压缩实验所测压力值(未修正的真应力); 为修正后的真应力值;R为瞬时半径;H为瞬时高度;其中,

为修正后的真应力值;R为瞬时半径;H为瞬时高度;其中, ,R0和H0分别为试样的原始尺寸;b为圆度系数,可表示为

,R0和H0分别为试样的原始尺寸;b为圆度系数,可表示为 ;其中,RM为最大鼓度半径、

;其中,RM为最大鼓度半径、 ;m是摩擦因子,可表示为

;m是摩擦因子,可表示为 。

。

图2 热挤压-退火态FGH96合金摩擦修正前后的真应力-真应变曲线

Fig. 2 True stress-true strain curves of hot extruded-annealed FGH96 alloy before and after friction correction

图2中实线所示为摩擦修正后的热挤压-退火态FGH96合金真应力-真应变曲线。由图2可见,修正后的曲线基本位于原始曲线的下方,这是由于摩擦力对材料径向流动的限制使得变形抗力增大的缘故,这与文献[13-15]报道的摩擦修正规律一致。

2.2 本构方程的建立

材料在高温塑性变形过程中,流变应力 、变形温度T和应变速率

、变形温度T和应变速率 之间的函数关系,按应力水平的不同可以分别用以下函数来表达[8]:

之间的函数关系,按应力水平的不同可以分别用以下函数来表达[8]:

(2)

(2)

(3)

(3)

(4)

(4)

式中:A1、A2、A、n、 、

、 均为与温度无关的常数,其中

均为与温度无关的常数,其中 、

、 和n之间满足

和n之间满足 ;

; 为稳态或峰值应力;R为摩尔气体常数,其值为8.314 J/(mol·K);

为稳态或峰值应力;R为摩尔气体常数,其值为8.314 J/(mol·K); 为应变速率;T为变形温度(K);Q为热变形激活能。其中式(2)和式(3)分别适用于低应力水平和高应力水平,而式(4)为Arrenius关系的一种修正形式,适用于较宽的应力水平。

为应变速率;T为变形温度(K);Q为热变形激活能。其中式(2)和式(3)分别适用于低应力水平和高应力水平,而式(4)为Arrenius关系的一种修正形式,适用于较宽的应力水平。

假定一定温度下,热变形激活能Q为常数,对式(2)和(3)两边分别取对数,有:

(5)

(5)

(6)

(6)

式(4)经变换,以Zener-Hollomonon(Z)参数表示 为[16]

(7)

(7)

对式(7)两边取对数,可得:

(8)

(8)

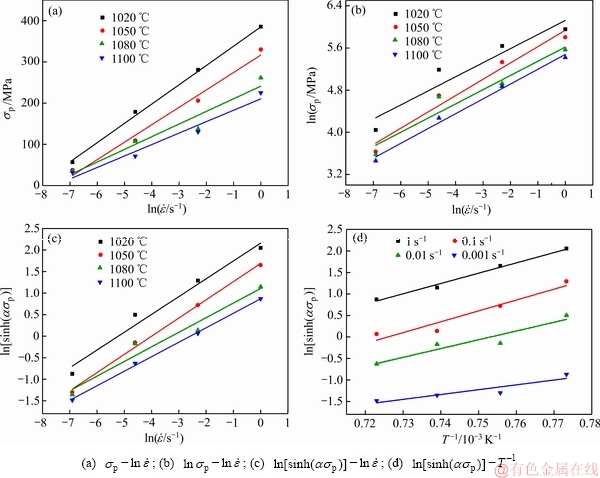

利用热挤压-退火态FGH96合金在一定温度下的峰值应力数据,绘制 -

- 和

和 -

- 关系曲线,如图3(a)和图3(b)所示。对图3(a)和图3(b)进行线性回归分析,并将回归分析数据分别代入式(5)和式(6)中,即可得出n1、

关系曲线,如图3(a)和图3(b)所示。对图3(a)和图3(b)进行线性回归分析,并将回归分析数据分别代入式(5)和式(6)中,即可得出n1、 和

和 值。进一步做

值。进一步做 -

- 和

和 -

- 关系曲线并进行线性回归,如图3(c)和图3(d)所示。利用式(8)及回归分析结果,通过计算机反复迭代,直至n值的平均偏差最小,即可得热挤压-退火态FGH96合金热压缩变形本构方程为

关系曲线并进行线性回归,如图3(c)和图3(d)所示。利用式(8)及回归分析结果,通过计算机反复迭代,直至n值的平均偏差最小,即可得热挤压-退火态FGH96合金热压缩变形本构方程为

(9)

(9)

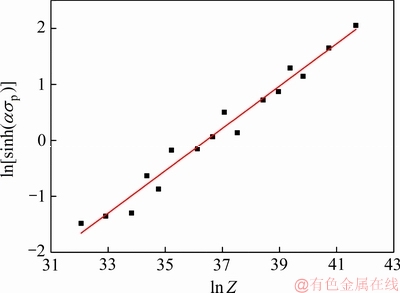

将变形参数和激活能Q值代入式(9),求出Z值,并绘制热挤压-退火态FGH96合金 -

- 关系图,如图4所示。由图4可见,其线性关系拟合较好,这也验证了利用双曲正弦函数关系建立FGH96合金流变应力本构方程的准确性。

关系图,如图4所示。由图4可见,其线性关系拟合较好,这也验证了利用双曲正弦函数关系建立FGH96合金流变应力本构方程的准确性。

图3 热挤压-退火态FGH96合金热模拟压缩峰值应力与应变速率和变形温度的关系

Fig. 3 Relationship between peak stress and strain rate or deformation temperature for thermal simulation compression of hot extruded-annealed FGH96 alloy

图4 热挤压-退火态FGH96合金热模拟压缩峰值应力与Z参数的关系

Fig. 4 Dependence of peak stress on Z parameter for thermal simulation compression of hot extruded-annealed FGH96 alloy

本实验得出的热挤压-退火态FGH96合金的热变形激活能为448.05kJ/mol,明显低于NIE等[17]报道的固溶时效态FGH96以及XU等[8]和张仁鹏等[18]报道的HIP态FGH96的热压缩变形激活能。分析其原因可知,这一方面与热挤压后初始晶粒尺寸的减小有关;另一方面还可能与二次γ′相在热挤压和退火过程中的粗化有关。由于热挤压工序较热等静压工序相比其晶粒细化作用明显,随着初始晶粒尺寸的减小,合金动态再结晶发生的临界应变量(ec)减小[15, 19],故动态再结晶晶粒形核和长大过程需要克服的势垒有所减小,从而导致FGH96合金的热变形激活能降低。同时,LI等[20]的研究也表明,在亚固溶温度下进行高温压缩,具有粗大γ′相的粉末高温合金其峰值应力和动态再结晶发生的临界应变量均低于具有细小γ′相的合金,因此,热挤压或退火过程导致的二次γ′相在一定程度上的粗化也对本实验合金热变形激活能的降低起到一定作用。

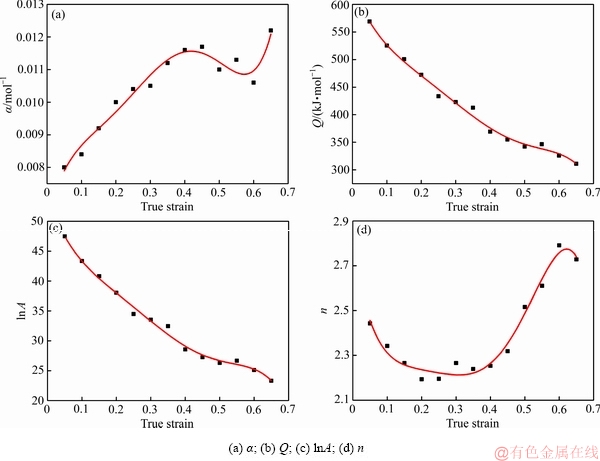

采用上述计算方法,在0.05~0.65应变范围内,计算每隔0.05的应变量时所对应的本构方程材料常数,如图5所示。利用五次多项式拟合各材料常数和应变之间的关系,可以得到以应变量为自变量的热挤压-退火态FGH96合金热压缩本构方程如下:

(10)

(10)

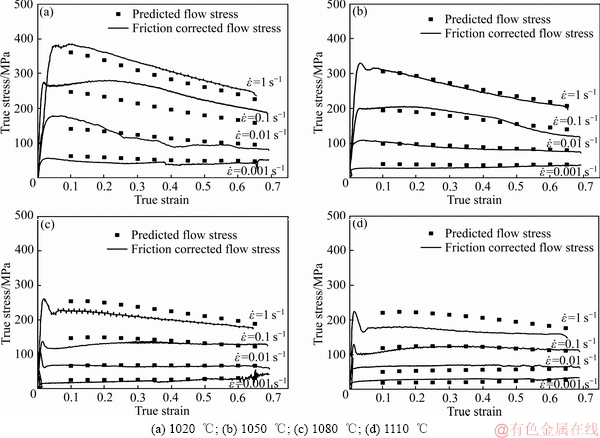

利用关系式(10)的函数模型,将对应的变形温度、应变速率和应变量值(每0.05格取一个应变量)代入式(10)中,计算出每个变形温度和应变速率下的真应力值,并与实验摩擦修正后的曲线作图进行比较,如图6所示。由图6可知,部分流变应力的预测值与摩擦修正值还存在一定的差异,尤其是在高应变速率条件下差异较明显。这主要是因为除了摩擦之外,在热压缩过程中产生的温升也会对流变应力有一定的影响[21],应变速率越大,温升引起的应力变化也越大。

2.3 热加工图及其分析

基于PRASADY等[22]提出的动态材料模型(Dynamic materials model,DMM)模型,绘制材料在变形过程中的能量耗散图和失稳图,最后把两个图叠加即可得到材料的热加工图。热加工图可以有效地描述热加工工艺参数对材料加工变形行为的影响,使变形参数与微观变形机制之间的联系可视化,有利于在加工前寻找和制定优化的加工参数。

图5 热挤压-退火态FGH96热模拟压缩变形本构方程材料常数与真应变的关系

Fig. 5 Relationship between material constants of constitutive equation and true strain for thermal simulation compression of hot extruded-annealed FGH96 alloy

图6 热挤压-退火态FGH96合金热模拟压缩真应力-真应变摩擦修正曲线与预测曲线对比

Fig. 6 Comparison of true stress-true strain curves between friction-corrected one and predicted one for thermal simulation compression of hot extruded-annealed FGH96 alloy

DMM理论把材料视为一个非线性的功率耗散体,将材料在变形过程中的耗散协量与理想耗散协量之间的比值定义为功率耗散因子η,其表达式如下:

(11)

(11)

式中:m为材料一定应力下的应变速率敏感指数,可以利用应力和应变速率之间的函数关系拟合得到:

(12)

(12)

根据DMM原理,进一步提出的热加工失稳参数 为

为

(13)

(13)

式中: 函数为负数的区域为热变形流变失稳区。

函数为负数的区域为热变形流变失稳区。

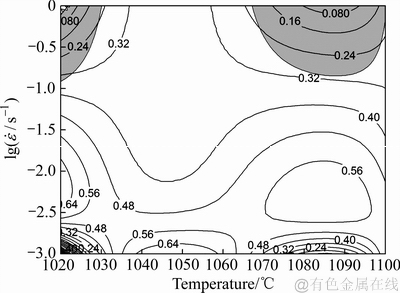

基于上述基本理论方法,结合本实验获得的高温压缩数据,在变形温度和应变速率的坐标平面内绘制耗散因子的等高线图,同时在该平面内做失稳函数 为负值的颜色填充(以灰色区域显示),即可得到热挤压-退火态FGH96合金热压缩变形热加工图,如图7所示。由图7可见,热挤压-退火态FGH96合金的耗散效率基本处于10%~65%之间。由于耗散效率的变化以及局部区域存在的耗散率极大值均与合金不同的高温变形机理密切相关,其中η值为30%~55%的区域通常为典型的动态再结晶区域,故对于热挤压-退火态FGH96合金来说,典型的动态再结晶基本发生在中到低应变速率区域。其中,局部的η极大值分别出现在3个区间(>55%):1) 应变速率为1×10-2.6~1×10-1.5 s-1、变形温度为1020~1030 ℃的区域;2) 应变速率为1×10-3~1×10-2.75 s-1、变形温度为1037~ 1071 ℃的区域;3) 应变速率为1×10-2.65~1×10-1.9 s-1、变形温度为1075~ 1110 ℃的区域。

为负值的颜色填充(以灰色区域显示),即可得到热挤压-退火态FGH96合金热压缩变形热加工图,如图7所示。由图7可见,热挤压-退火态FGH96合金的耗散效率基本处于10%~65%之间。由于耗散效率的变化以及局部区域存在的耗散率极大值均与合金不同的高温变形机理密切相关,其中η值为30%~55%的区域通常为典型的动态再结晶区域,故对于热挤压-退火态FGH96合金来说,典型的动态再结晶基本发生在中到低应变速率区域。其中,局部的η极大值分别出现在3个区间(>55%):1) 应变速率为1×10-2.6~1×10-1.5 s-1、变形温度为1020~1030 ℃的区域;2) 应变速率为1×10-3~1×10-2.75 s-1、变形温度为1037~ 1071 ℃的区域;3) 应变速率为1×10-2.65~1×10-1.9 s-1、变形温度为1075~ 1110 ℃的区域。

图7 热挤压-退火态FGH96合金的热加工图( )

)

Fig. 7 Hot processing map of hot extruded-annealed FGH96 alloy ( )

)

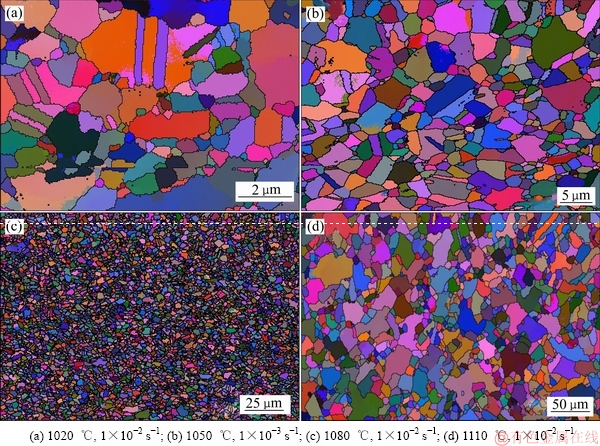

图8 热挤压-退火态FGH96合金在不同变形条件下热模拟压缩后的晶粒形貌图

Fig. 8 Grain morphologies of hot extruded-annealed FGH96 alloy after thermal simulation compression at different deformation conditions

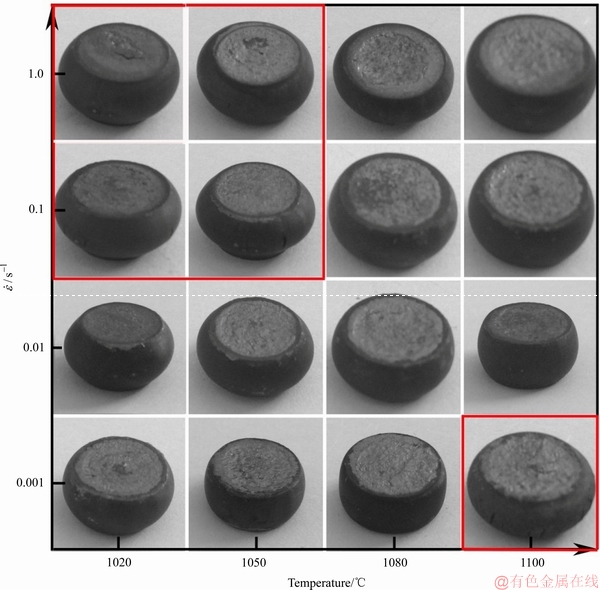

为验证热加工图的正确性,进一步优化工艺参数,利用EBSD对不同变形条件下热挤压-退火态FGH96合金的组织进行了观察。由图8(a)可以看出,经1020 ℃、1×10-2 s-1热压缩后,热挤压-退火态FGH96合金原始晶界周围已开始发生了动态再结晶;合金在1050 ℃、1×10-3 s-1条件下热压缩后,动态再结晶基本完全,且伴随着γ′相的逐渐溶解,再结晶晶粒有明显长大(见图8(b));经1080 ℃、1×10-2 s-1热压缩后,合金中的动态再结晶较均匀,平均晶粒尺寸约2.4 μm (见图8(c));提高变形温度至1110 ℃后,合金中的动态再结晶晶粒明显粗化(见图8(d))。图7中显示的热挤压-退火态FGH96合金的流变失稳区对应于0.1~1 s-1、1020~1032 ℃和1070~1110 ℃变形条件范围内。观察热变形试样的宏观形貌可以发现(见图9),热挤压-退火态FGH96合金的流变失稳与裂纹的形成有关(见图9中红色区域)。分析可知,合金中由碳化物、氧化物等有害脆性相形成的原始颗粒边界(PPB)和热诱导孔洞[23],在热变形过程中易成为潜在的裂纹源,导致裂纹的萌生;在高应变速率条件下,裂纹源迅速得以扩展从而引起宏观开裂。但由于挤压所产生的内应力经退火后得到了较好地消除,故在本实验条件范围内热压缩试样产生的宏观裂纹明显少于未经退火的热压缩试样[17]。综合上述结果,对热挤压-退火态FGH96合金建议的热加工参数为变形温度约为1075~1080 ℃、应变速率约为1×10-3~1×10-1.5 s-1的区域。在该动态再结晶区域内进行热加工,既具有较高的耗散效率又可获得较细小的动态再结晶晶粒。

图9 热挤压-退火态FGH96合金在不同变形条件下热模拟压缩后的宏观形貌图

Fig. 9 Macrographs of hot extruded-annealed FGH96 alloy after thermal simulation compression at different deformation conditions

3 结论

1) 热挤压-退火态FGH96合金在热压缩变形过程中发生了明显的动态再结晶;利用摩擦修正后的峰值应力数据获得的合金热压缩变形激活能为448.05kJ/mol;以Z参数描述的合金热压缩流变应力方程为

2) 构建了以应变量为自变量的热挤压-退火态FGH96合金热压缩本构方程,根据该方程预测的流变应力数据与实验摩擦修正数据基本相符吻合较好。

3) 热挤压-退火态FGH96合金典型的动态再结晶分别发生在应变速率为1×10-2.6~1×10-1.5 s-1、变形温度为1020~1030 ℃的区域,应变速率为1×10-3~ 1×10-2.75 s-1、变形温度为1037~1071 ℃的区域,应变速率为1×10-3~1×10-2 s-1、变形温度为1075~ 1110 ℃的区域;合金的流变失稳区对应于应变速率为0.1~1 s-1、变形温度分别为1020~1032 ℃和1070~ 1110 ℃的变形条件范围内。对热挤压-退火态FGH96合金建议的热加工参数为变形温度约为1075~ 1080 ℃、应变速率约为1×10-3~1×10-1.5 s-1的区域。

REFERENCES

[1] FANG Bin, JI Zhen, LIU Meng, TIAN Guo-feng, JIA Cheng-chang, ZENG Tian-tian, HU Ben-fu, CHANG Yu-hong. Study on constitutive relationships and processing maps for FGH96 alloy during two-pass hot deformation[J]. Materials Science and Engineering A, 2014, 590(2): 255-261.

[2] 秦子珺, 刘琛仄, 王 子, 何国爱, 刘 锋, 黄 岚, 江 亮. 镍基粉末高温合金原始颗粒边界形成及组织演化特征[J]. 中国有色金属学报, 2016, 26(1): 50-59.

QIN Zi-jun, LIU Chen-ze, WANG Zi, LIU Feng, HUANG Lan, JING Liang. Formation and microstructure evolution of precipitation on prior particle boundaries in P/M nickel-base super-alloys[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(1): 50-59.

[3] NING Yong-quan, YAO Ze-kun, GUO Hong-zhen, FU M W, LI Hui, XIE Xing-hua. Investigation on hot deformation behavior of P/M Ni-base superalloy FGH96 by using processing maps[J]. Materials Science and Engineering A, 2010, 527(26): 6794-6799.

[4] 刘小涛, 丁晗晖, 杨 川, 刘 锋, 黄 岚, 江 亮. 热挤压态FGH96 粉末冶金高温合金的显微组织与力学性能[J]. 中国有色金属学报, 2016, 26(2): 354-364.

LIU Xiao-tao, DING Han-hui, YANG Chuan, LIU Feng, HUANG Lan, JIANG Liang. Microstructure and mechanical properties of hot extruded FGH96 powder metallurgy superalloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(2): 354-364.

[5] 张义文, 刘建涛. 粉末高温合金研究进展[J]. 中国材料进展, 2013, 32(1): 1-11.

ZHANG Yi-wen, LIU Jian-tao. Development in powder metallurgy superalloy[J]. Materials China, 2013, 32(1): 1-11.

[6] ZHANG M J, LI F G, WANG S Y, LIU C Y. Effect of powder preparation technology on the hot deformation behavior of HIPed P/M nickel-base superalloy FGH96[J]. Materials Science and Engineering A, 2011, 528(12): 4030-4039.

[7] 刘建涛, 张义文, 陶 宇, 刘国权, 胡本芙. FGH96合金动态再结晶行为的研究[J]. 材料热处理学报, 2006, 27(5): 46-50.

LIU Jian-tao, HANG Yi-wen, TAO Yu, HU Ben-fu. Study on dynamic recrystallization behavior of FGH96 alloy[J]. Transactions of Materials and Heat Treatment, 2006, 27(5): 46-50.

[8] XU Wei, ZHANG Li-wen, GU Sen-dong, ZHANG Jian-lin. Hot compressive deformation behavior and microstructure evolution of HIPed FGH96 superalloy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(1): 66-71.

[9] FANG Bin, JI Zhen, LIU Meng, TIAN Guo-feng, JIA Cheng-chang, ZENG Tian-tian, HU Ben-fu, CHANG Yu-hong. Critical strain and models of dynamicrecry stallization for FGH96 superalloy during two-pass hot deformation[J]. Materials Science and Engineering A, 2014, 593(5): 8-15.

[10] 王淑云, 李惠曲, 张麦仓. FGH96合金等温变形力学性能研究[J]. 热加工工艺, 2002, 6(7): 16-18.

WANG Shu-yun, LI Hui-qu, ZHANG Mai-cang. A study of the mechanical properties of FGH96 alloy in isothermal deformation[J]. Hot Working Technology, 2002, 6(7): 16-18.

[11] 杨 川, 刘小涛, 司家勇, 刘 锋, 江 亮. 粉末冶金高温合金 FGH96的热加工图及热压缩变形过程的开裂行为[J]. 中国有色金属学报, 2015, 25(10): 2707-2719.

YANG Chuan, LIU Xiao-tao, SI Jia-yong, LIU Feng, JIANG Liang. Processing map and cracking behavior of powder metallurgy superalloy FGH96 during hot compression[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(10): 2707-2719.

[12] EBRAHIMI R, NAJAFIZADEH A. A new method for evaluation of friction in bulk metal forming[J]. Journal of Materials Processing Technology, 2004, 152(2): 136-143.

[13] 吾至岗, 李德富. GH625镍基合金的高温压缩变形行为及组织演变[J]. 中国有色金属学报, 2010, 20(7): 1321-1327.

WU Zhi-gang, LI De-fu. Hot compression deformation behaviors and microstructure evolution of GH625 Ni-based alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7): 1321-1327.

[14] LI Jian-bo, LIU Yong, WANG Yan, LIU Bin, LU Bin, LIANG Xiao-peng. Constitutive equation and processing map for hot compressed as-cast Ti-43Al-4Nb-1.4W-0.6B alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(11): 3383-3391.

[15] 陈 前, 王 岩. δ相时效态GH416合金热加工行为研究[J]. 中国有色金属学报, 2015, 25(10): 2727-2737.

CHEN Qian, WANG Yan. Investigation on hot working behavior of a delta-processed GH4169 alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(10): 2727-2737.

[16] WANG Yan, SHAO Wen-zhu, ZHEN Liang, ZHANG Bao-you. Hot deformation behavior of delta-processed superalloy 718[J]. Materials Science and Engineering A, 2011, 528(7): 3218-3227.

[17] NIE Long-fei, ZHANG Li-wen, ZHU Zhi, XU Wei. Constitutive modeling of dynamic recrystallization kinetics and processing maps of solution and aging FGH96 superalloy[J]. Journal of Materials Engineering and Performance, 2013, 22(12): 3728-3734.

[18] 张仁鹏, 李付国, 王晓娜. FGH96合金的热变形行为及其热加工图[J]. 西北工业大学学报, 2015, 25(5): 652-655.

ZHANG Ren-peng, LI Fu-guo, WANG Xiao-na. Determining processing maps of FGH96 superalloy[J]. Journal of Northwestern Polytechnical University, 2015, 25(5): 652-655.

[19] NA Y S,YEOM J T, PARK N K, LEE J Y. Simulation of microstructures for alloy 718 blade forging using 3D FEM simulator[J]. Journal of Materials Processing Technology, 2003, 141(3): 337-342

[20] LI Fu-lin, FU Rui, YIN Fa-jie, FENG Di, WANG Hai-zhou, DU Gang, FENG Yong. Impact of γ′(Ni 3(Al,Ti)) phase on dynamic recrystallization of a Ni-based disk superalloy during isothermal compression[J]. Journal of Alloys and Compounds.2017, 693(4): 1076-1082.

[21] TAN Li-ming, LI Yun-ping, HE Guo-ai, LIU Feng, NIE Yan, JIANG Liang. Optimized hot workability of a powder metallurgy nickel-base superalloy[J]. Materials Characterization, 2019, 147(1): 340-352.

[22] PRASADY V R K, GEGEL H L, DORAIVELU S M, MALAS J C, MORGAN J T, LARK K A, BARKER D R. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242[J]. Metall Mater Trans A, 1984, 15(10): 1883-1892.

[23] DONACHIEM J, DONACHIE S J, Superalloys: A technical guide[M]. New York: ASM International, 2002: 192-265.

Hot deformation behavior and hot processing map of as-annealed FGH96 alloy

LIU Min-xue1, WU Hong1, WANG Yan2, HOU Yi-ting2, ZHENG Cong2, CHENG Tian-wei2, CHEN Ya-qian2, JIANG Zhe-ye2, JIANG Liang1

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. School of Aeronautics and Astronautics, Central South University, Changsha 410083, China)

Abstract: Hot compressive deformation behavior of as hot extruded-annealed FGH96 alloy was systematically investigated at the temperatures from 1020 ℃ to 1110 ℃ with strain rates from 1×10-3 to 1 s-1 by thermal simulation experiments. The constitutive equation for hot compression of the alloy was established, and the hot processing map was also constructed. Combined with electron backscatter diffraction (EBSD) analysis, the deformation parameters of the alloy were optimized. The results show that apparent dynamic recrystallization occurs during hot deformation of the alloy. By using the friction-corrected peak stress data, the material constants of the constitutive equation for hot compression of the alloy are obtained to be α=0.0071272, n=2.6417, A=6.6811×1015, Q=448.05 kJ/mol, respectively. The lower activation energy of deformation is closely related to the decrease of initial grain size after hot extrusion and the coarsening of secondary γ′ precipitate. A group of five-order polynomials showing the relationship between material constants of the constitutive equation and strain is built up, by which the flow stresses are predicted. The predicted data are in good agreement with the experimental friction-corrected one. Considering the energy dissipation efficiency in the hot processing map and the microstructural analysis, the hot working parameters of the as hot extruded-annealed FGH96 alloy are suggested to be the deformation temperatures of about 1075-1080 ℃ and the strain rate of about 1×10-3-1×10-1.5 s-1.

Key words: FGH96 alloy; hot compression deformation; constitutive equation; deformation activation energy; hot processing map

Foundation item: Project(2016YFB0700304) supported by the National Basic Research Development Program of China; Project(CX20180050) support by Innovation and Entrepreneurship Project for College Students of Central South University, China

Received date: 2018-09-10; Accepted date: 2019-05-16

Corresponding author: WANG Yan; Tel: +86-731-88877495; E-mail: wangyan@csu.edu.cn

(编辑 龙怀中)

基金项目:国家重点研发计划资助项目(2016YFB0700304);中南大学大学生创新创业项目支持(CX20180050)

收稿日期:2018-09-10;修订日期:2019-05-16

通信作者:王 岩,教授,博士;电话:0731-88877495;E-mail:wangyan@csu.edu.cn