文章编号:1004-0609(2016)-05-1001-09

纤维预热温度对3D-Cf/Al复合材料显微组织及力学性能的影响

聂明明,徐志锋,徐 鹏,余 欢,王振军

(南昌航空大学 轻合金加工科学与技术国防重点学科实验室,南昌 330063)

摘 要:采用真空气压浸渗法制备纤维体积分数为51%的三维五向编织M40碳纤维增强铝基复合材料(3D-Cf/Al),研究纤维预热温度对3D-Cf/Al复合材料显微组织与力学性能的影响,并对比研究3D-Cf/Al复合材料与单向连续Cf/Al复合材料的差异。结果表明:复合材料致密度随着编织体预热温度的提高而增大,提高预热温度可有效减少复合材料内部孔洞和纤维偏聚等浸渗缺陷;复合材料的拉伸强度随纤维预制体预热温度的提高而显著降低。其中,在预热温度500 ℃、浸渗温度720 ℃、浸渗压力7 MPa和保压时间20 min的工艺条件下,所制备的3D-Cf/Al复合材料致密度为97.3%,拉伸强度为777.8 MPa,弹性模量为186.1 GPa。

关键词:三维编织;Cf/Al复合材料;纤维预热温度;力学性能;显微组织

中图分类号:TB331 文献标志码:A

3D-Cf/Al复合材料相较于2D、单向连续Cf/Al复合材料,除具有轻质、高比强度、高比刚度及耐磨性好等优良性能外,还具有耐冲击、不分层、抗开裂及耐疲劳等特点,表现出特有的整体性,因此备受航空航天部门的关注,并已发展成为现代国防高端技术领域最具战略性的结构材料之一[1-2]。真空气压浸渗是实现高性能三维编织复合材料复杂制件的近净成形最有效的制备方法,区别于3D纤维增强树脂基与陶瓷基复合材料,3D纤维增强金属基复合材料因纤维与金属之间存在的严重界面反应以及金属和纤维的不相容性,使其应用远远落后于前二种复合材料,而从制备工艺入手,也是合理控制界面反应,制备高性能3D金属基复合材料的最为高效、经济实用的方法之一。

KO[3]、MACANDER等[4]、YAU等[5]和SHIVAKUMAR等[6]等对3D-Cf环氧树脂复合材料的力学性能进行试验研究。通过改变纤维体积分数和编织角,用试验的方法研究碳-环氧树脂编织复合材料的弹性模量和强度的变化规律,并将试验结果与现有的平均应变和平均应力模型的预测结果进行比较,证明应变应力的加权平均模型给出的结果最接近试验结果。沈怀荣[7]、刘宁等[8]、王玉果等[9]和李嘉禄等[10]对三维编织碳纤维环氧(C-3D/EP)复合材料的冲击、蠕变、摩擦、疲劳、损伤等工程力学性能进行了研究,姚学锋等[11]利用数字散斑相关方法对玻璃纤维/环氧树脂编织复合材料在三点弯曲载荷作用下裂纹损伤演化增长的力学行为进行试验研究,张立同等[12-13]对三维编织陶瓷基复合材料的各项性能进行深入研究。然而,国内外对3D金属基复合材料的制备和性能研究相对较少。

为此,本文作者选用体积分数51%的三维五向编织M40预制体,预制体编织参数为周向花节为15~16 mm每10花节,母向花节为30~40 mm每10花节,采用的制备方法是真空气压浸渗法。研究不同纤维预热温度下3D-Cf/Al复合材料的致密度、显微组织、拉伸强度以及弹性模量,采用扫描电镜观察复合材料的拉伸断口,并对其进行分析,旨在为制备组织致密、力学性能良好的3D-Cf/Al复合材料提供借鉴,实现高性能3D-Cf/Al复合材料制备与成型一体化工艺,推动3D-Cf/Al复合材料的大规模化工程应用。

1 实验

1.1 实验材料

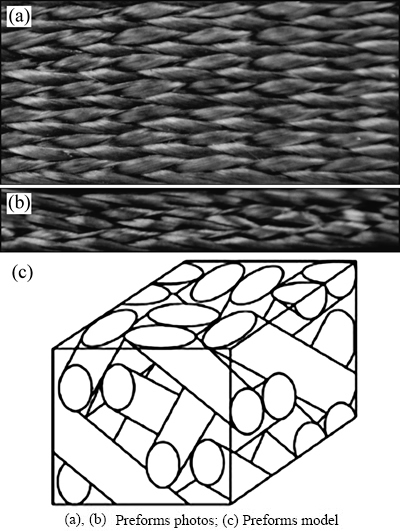

试样采用M40(6 K)高模量型石墨纤维编织得到三维五向编织预制体,编织预制体实物及模型如图1所示,其中图1(a)、(c)为编织预制体实物,图1(a)为试样预制体的宽面,图1(c)为试样预制体的厚面,图1(b)为三维五向编织预制体空间模型。M40(6 K)的主要性能指标见表1。三维五向预制体试样的尺寸为130 mm×20 mm×3 mm,M40纤维的体积分数为51%。基体合金采用ZL301合金,其中Mg含量为9.5%~11.0%(质量分数)。

表1 纤维的性能参数

Table 1 Performance parameters of M40-6K fiber

图1 三维五向编织预制体

Fig. 1 3D five-directional-woven prefabrication body

1.2 实验方法

采用真空气压浸渗法,选用不同的纤维预热温度(分别是500、560和600 ℃),工艺条件为:真空度小于210 Pa、浸渗温度720 ℃、浸渗压力7 MPa、保压时间20 min,3D-Cf/Al复合材料中M40纤维所占体积分数为51%。

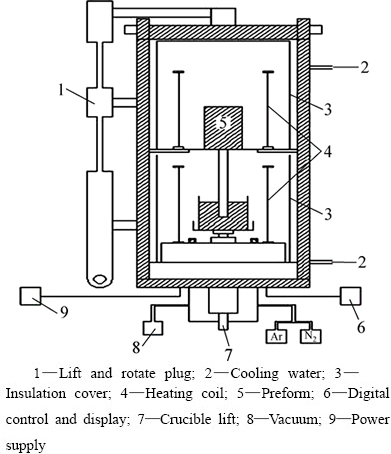

真空气压浸渗法是根据反重力浸渗的原理来实现复合材料的近净成形,其装置与模具示意图如图2所示。真空气压浸渗装置的温度和压力等都可通过控制系统控制,并实现全程自动控制。浸渗装置的主要技术参数为真空度210 Pa,最大充型压力10 MPa,最高设定温度1000 ℃;装置密封性好,气体充填卸压过程平稳,加压速率最小可调节至100 kPa/s,压力可在0~10 MPa内任意调节。装置内温度采用双热电偶进行控制,分别对炉膛与金属液进行控温,温度误差范围在±5 ℃。

图2 真空气压浸渗装置与模具示意图

Fig. 2 Schematic diagram of vacuum pressure impregnation method

制备出尺寸为130 mm×20 mm×3 mm的3D-Cf/Al复合材料板状试样,通过线切割将板状试样切割成标准板状拉伸试样,采用电子万能拉伸试验机Instron5569型进行复合材料的力学性能测试;采用排水法测定试样的实际密度,并计算其致密度;采用BrukerD8型X射线衍射分析仪(XRD)分析复合材料的相组成;采用Quanta200型扫描电子显微镜(SEM)对3D-Cf/Al复合材料的断口形貌和显微组织进行分析。

2 结果与分析

2.1 纤维预热温度对3D-Cf/Al复合材料显微组织的影响

复合材料的显微组织在很大程度上决定复合材料的性能[14]。3D-Cf/Al复合材料是一种人造的多相介质,复合材料内部的孔洞缺陷、增强体碳纤维在铝基体中的分布情况、碳纤维与基体之间的界面结合、基体中的弥散析出相等因素都会严重影响3D-Cf/Al复合材料的性能。

图3所示为纤维预热温度500 ℃条件下3D-Cf/Al复合材料不同截面方向的微观组织。从图3中可以发现,三维编织预制体碳纤维束与束之间浸渗完好,基体铝合金充满了纤维束之间的间隙。不同方向纤维束呈现出不同的形貌,图3(a)所示为横切面上纤维分布情况,由于采用的三维五向编织法编织的预制体纵向的纤维体积分数高达90%,所以制备出的复合材料横切面上纤维束基本呈现出均匀规律的分布;图3(b)和(c)所示为纵切面上纤维分布情况。从图3(c)中可以看出,同一个切面上存在被不同角度切断的纤维束,左边的A区域的纤维束被垂直切断,右边的B区域的纤维束被斜切断,产生这种现象的原因是三维编织的预制体中纤维之间存在交织。

图3 预热温度500 ℃下3D-Cf/Al复合材料微观组织

Fig. 3 Microstructures of 3D-Cf/Al composite at preheating temperature of 500 ℃

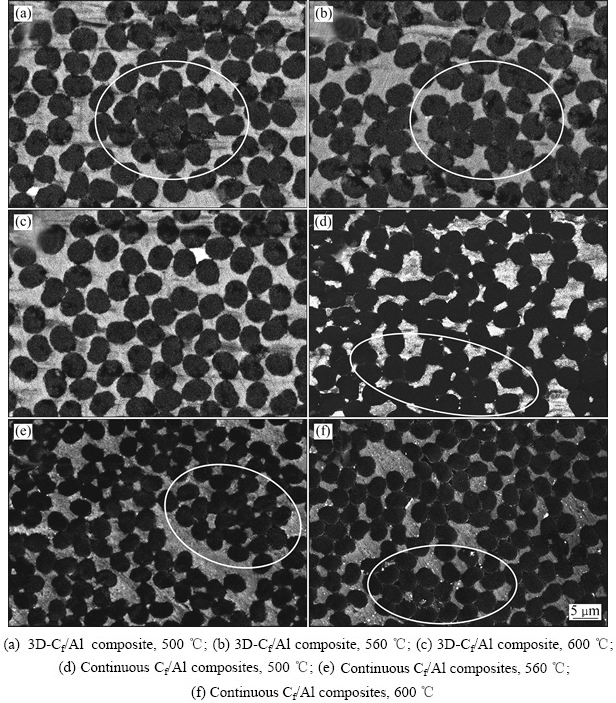

图4所示为不同预热温度下3D-Cf/Al复合材料和Cf/Al复合材料横切面显微组织。图4(a)、(b)、(c)分别为预热温度500、560和600 ℃下的3D-Cf/Al复合材料微观组织。从图4(a)~(c)中可以看出,纤维预热温度为500 ℃时,纤维预制体浸渗效果较差,纤维存在明显的团聚现象并且有孔洞产生;当纤维预热温度为560 ℃时,碳纤维预制体浸渗效果较好,但还是存在少量的纤维团聚;当纤维预热温度为600 ℃时,碳纤维预制体浸渗效果很好,纤维分布均匀。这是由于预热温度过低,浸渗前端熔融的铝液冷却速度较快,合金液流动性降低,铝合金液还未完全浸渗到纤维间较细小的孔隙中已经凝固,由此形成细微孔洞缺陷。同时,纤维预热温度较低,预热温度过低,金属液流动相对较弱,不利于纤维在基体中分散,导致纤维出现团聚现象。随着纤维预热温度的提高,铝合金液冷却速度降低,其流动性得到改善,使得纤维预制体的浸渗更为充分。同时,提高纤维预热温度可以提高纤维表面活性,从而改善铝液与碳纤维之间的润湿性,使得浸渗得以顺利进行。因此,随着纤维预热温度的提高,3D-Cf/Al复合材料的孔洞缺陷及纤维团聚现象逐渐减少。

图4(d)~(f)分别为预热温度500、560、600 ℃下单向连续Cf/Al复合材料的显微组织。从图4(d)~(f)中可以看出,单向连续Cf/Al复合材料出现更为严重的纤维团聚现象,3D-Cf/Al复合材料相比单向连续Cf/Al复合材料纤维分布更加均匀,这是由于三维编织而成的预制体纤维之间互相存在约束,浸渗过程中不易受到挤压偏移,而单向连续Cf/Al复合材料的纤维预制体在各个方向不受到约束,在浸渗过程中受到压力的作用,使得纤维更容易发生团聚。

2.2 纤维预热温度对3D-Cf/Al复合材料致密度的影响

复合材料的致密度是反映复合材料成型完整性的重要指标,本文作者根据阿基米德原理测算出复合材料的实际密度,结合该材料的理论密度计算出3D-Cf/Al复合材料的致密度。

王旭[15]通过实验测得碳纤维与熔融铝液之间的润湿角在130°~135°之间,浸渗过程不能自发地进行,铝合金液难以自发的浸渗进入碳纤维预制体。由于纤维束中每根纤维之间间距很小,浸渗过程中,会形成细小的管道,根据Yong-Kelvin方程:

(1)

(1)

图4 不同预热温度下3D-Cf/Al及连续Cf/Al复合材料横切面的显微组织

Fig. 4 Microstructures of 3D-Cf/Al and continuous Cf/Al composites under different preheating temperatures

式中:p为毛细作用力;σ为液-气界面上的表面张力;θ为润湿角;r为等效毛细管半径。

当管道半径很小时,要求的附加压力则会很大,碳纤维的平均直径为6~8 μm,碳纤维预制体的束内及束间的间隙均达到了亚微米和纳米级。同时,由于三维五向编织预制体内部纤维相互交织,纤维之间的间距相较于单向连续预制体更小,更容易形成浸渗不到位的孔隙,导致复合材料不能完全致密。

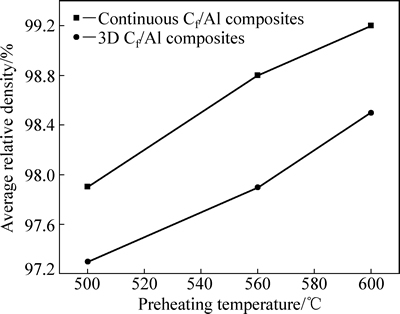

图5所示为纤维预热温度与复合材料平均致密度的关系曲线。由图5可看出,当预热温度分别为500、560和600 ℃时,制备的3D-Cf/Al复合材料的致密度都达到了97%以上,浸渗效果较好。预热温度为500 ℃时,3D-Cf/Al复合材料的致密度最小为97.3%,随着预热温度的升高,制备的复合材料致密度也逐渐提升;当预热温度为600 ℃时,3D-Cf/Al复合材料的致密度达到了98.5%。这是由于预热温度较低时,熔融的铝液温度降低速度快,铝合金液还未完全进入纤维间较细小的孔隙中就会开始凝固,由此形成的细微的孔洞缺陷导致复合材料致密度不高。提高预热温度,铝合金液温度降低速度减慢,充型的粘滞阻力和凝固阻力减小,铝液的充型能力随温度的升高而增强,能对纤维间细小的间隙进行充填,减少复合材料的孔洞缺陷,可获得更好的浸渗效果。同时,随着纤维预热温度升高,碳纤维的表面活性也随之增加,从而改善碳纤维与铝液之间的润湿性,降低毛细阻力和表面张力。由于纤维与铝液润湿性的改善,使得铝液能够渗入纤维之间更小的间隙中,减少复合材料内部的浸渗缺陷,使得复合材料浸渗得更加完全。因此,随着纤维预热温度的提高,3D-Cf/Al复合材料的致密度呈上升的趋势。

图5 预热温度与平均致密度的关系曲线

Fig. 5 Relationship between preheat temperature and average relative density

相较于单向连续Cf/Al复合材料的致密度(见图5),3D-Cf/Al复合材料在各个预热温度下的致密度都略低,这是由于三维五向预制体内的纤维在空间内存在交织,纤维束编织的节点处纤维间距较小,铝液难以浸渗到这些微小的间隙。同时,这些节点也使得浸渗通道不连续,不利于预制体的整个浸渗过程,而单向连续Cf/Al复合材料在浸渗过程中的浸渗通道是连续的,并且其纤维之间没有约束,有利于浸渗过程的进行,因此,其致密度要高于3D-Cf/Al复合材料的。

2.3 纤维预热温度对3D-Cf/Al复合材料拉伸强度的影响

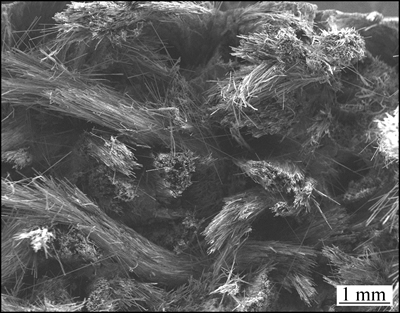

通过万能拉伸试验机对实验所制备的3D-Cf/Al复合材料试样进行拉伸测试,计算出不同工艺参数下的复合材料平均拉伸强度。图6所示为预热温度500 ℃的3D-Cf/Al复合材料的拉伸断口,其内部结构明显区别于单向连续Cf/Al复合材料的单一排布方式及层合复合材料的二维排布,在空间内呈现多个方向的排布,表现出特有的整体性。然而,对标准拉伸试样的机械加工中不可避免地破坏复合材料的整体性,使复合材料强度降低,因此,通过真空气压浸渗工艺实现复合材料构件的近净成形显得更为意义重大。

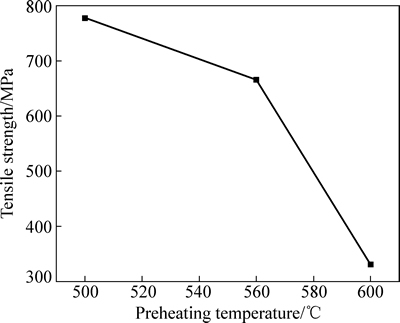

图7所示为不同预热温度下的3D-Cf/Al复合材料的拉伸强度。根据图7中的数据发现,3D-Cf/Al复合材料平均拉伸强度随着预热温度的升高显著降低,当预热温度为500 ℃时,复合材料的平均拉伸强度达到了最高值为777.8 MPa;随着纤维预热温度的升高,3D-Cf/Al复合材料拉伸强度降低至600 ℃时的330.4 MPa。造成这种现象的原因主要由于是随着预热温度的升高,碳纤维的表面活性增加,加剧了碳纤维与铝基体之间的界面反应,生成的Al4C3相的含量也增多。一般认为,适量的Al4C3相可以增强界面结合,但过多的Al4C3相会降低复合材料的性能。随着预热温度的升高,Al4C3脆性相含量增多,这些Al4C3脆性相偏析于晶界,从而导致晶界弱化,增加材料沿晶断裂的倾向,而且这些Al4C3脆性相也往往是裂纹萌生的地方,Al4C3脆性相断裂后容易将裂纹导入纤维,纤维呈现低应力破坏,使复合材料在早期失效。同时,随着预热温度的升高,碳纤维更容易氧化以及高温对碳纤维造成损伤,从而导致纤维承载能力的下降,导致复合材料强度下降。观察图8拉伸试样断裂后的断口形貌可以发现,当纤维预热温度为500 ℃时,试样断口处大部分纤维被拔出,而且以单丝纤维拔出为主,复合材料界面在拉伸过程中起到传递载荷的作用,界面结合强度比较好;当纤维预热温度为560 ℃时,断口处有相对较少的单丝纤维拔出,出现了较多整体被拉断的断面,复合材料界面结合更强;当纤维预热温度为600 ℃时,试样断口平整,没有纤维拔出现象,以整体拉断为主,表明复合材料界面结合过强。

图6 3D-Cf/Al复合材料拉伸断口形貌

Fig. 6 Tensile fracture morphology of 3D-Cf/Al composite

图7 预热温度与平均拉伸强度的关系

Fig. 7 Relationship between preheating temperature and average tensile strength

图8 不同预热温度下3D-Cf/Al复合材料的拉伸试样断口形貌

Fig. 8 Tensile fracture morphologies of 3D-Cf/Al composite at different preheating temperatures

在Cf/Al复合材料的制备过程中,碳铝界面处纤维与铝液发生如下反应,生成脆性相Al4C3:

(2)

(2)

(3)

(3)

式中: 为标准生成吉布斯自由能,kJ/mol;T为温度,K。脆性相Al4C3是离子型碳化物,往往在界面处呈针状或者片状,会降低界面对载荷的传递作用;同时易成为裂纹源,降低纤维的承载能力,使得复合材料的强度大幅度降低。

为标准生成吉布斯自由能,kJ/mol;T为温度,K。脆性相Al4C3是离子型碳化物,往往在界面处呈针状或者片状,会降低界面对载荷的传递作用;同时易成为裂纹源,降低纤维的承载能力,使得复合材料的强度大幅度降低。

图9所示为不同预热温度下3D-Cf/Al复合材料的XRD谱。发现不同预热温度下3D-Cf/Al复合材料中都有Al4C3相生成。

随着预热温度的升高,会使得界面反应更容易发生,生成的Al4C3相含量也逐渐增多。Al4C3相的含量适度时,能增强界面结合,使界面具有较好地传递载荷,但生成过量的Al4C3相会降低复合材料的性能。预热温度较低时,复合材料界面呈弱界面结合,受到载荷时,碳纤维易与基体脱粘,造成纤维拔出现象;随着预热温度的提高,复合材料界面结合逐渐变强,弱界面结合逐渐转变为强界面结合,受到载荷时,纤维难以与基体脱粘,而是表现为纤维与基体一同断裂,因此,试样断口平整,无纤维拔出,复合材料呈脆性断裂。

图9 不同纤维预热温度下3D-Cf/Al复合材料的XRD谱

Fig. 9 XRD patterns of 3D-Cf/Al composite at different preheating temperatures

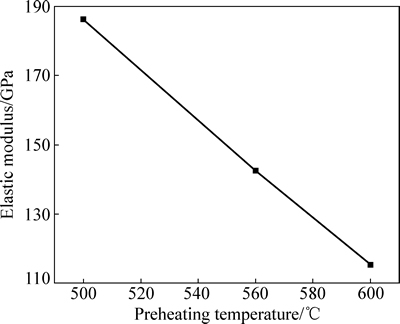

图10所示为不同预热温度下3D-Cf/Al复合材料的弹性模量。对比图7观察可发现,其变化趋势与拉伸强度的变化相对应,都呈现逐渐降低的趋势。其弹性模量由纤维预热温度为500 ℃时的186.1 GPa逐渐降低至115.3 GPa,几乎呈直线下降趋势。随着纤维预热温度的升高,复合材料的浸渗效果变好,但由于界面反应加剧,生成的Al4C3相也逐渐增加,纤维发生严重损伤。由于复合材料中纤维是载荷的主要承载体,因此,复合材料抵抗弹性变形的能力明显下降, 3D-Cf/Al复合材料的弹性模量会随着纤维预热温度的升高而逐渐降低。

图10 不同预热温度3D-Cf/Al复合材料的弹性模量

Fig. 10 Elasticity modulus of 3D-Cf/Al composites at different preheat temperatures

3 结论

1) 纤维预热温度是真空气压浸渗工艺的关键工艺参数,随着纤维预热温度的提升,3D-Cf/Al复合材料的致密度逐渐提高,在预热温度600 ℃、浸渗温度720 ℃、浸渗压力7 MPa、保压时间20 min的工艺条件下,所制备的3D-Cf/Al复合材料的致密度为98.5%。

2) 纤维预热温度对3D-Cf/Al复合材料的显微组织有明显的影响,预热温度过低容易在复合材料中产生孔洞缺陷,提高预热温度可使复合材料更致密;随着预热温度的提高,复合材料的纤维分布更加均匀,团聚现象减少。

3) 纤维预热温度对3D-Cf/Al复合材料的力学性能有决定性影响,随着纤维预热温度的升高,3D-Cf/Al复合材料的拉伸强度逐渐降低,预热温度500 ℃、浸渗温度720 ℃、浸渗压力7 MPa、保压时间20 min时制备的3D-Cf/Al复合材料抗拉强度达到了777.8 MPa,弹性模量为186.1 GPa。

4) 机械加工会破坏3D增强复合材料特有的整体性,降低复合材料的强度。通过真空气压浸渗工艺实现复合材料构件的近净成形具有重大意义,是实现3D金属基复合材料构件走向工程应用的一种有效手段。

REFERENCES

[1] 刘 兵, 彭超群, 王日初, 王小锋, 李婷婷. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(9): 1705-1715.

LIU Bing, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LI Ting-ting. Recent development and prospects for giant plane aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1705-1715.

[2] 王 涛, 赵宇新, 付书红, 张 勇, 曾维虎, 韦家虎, 李 钊. 连续纤维增强金属基复合材料的研制进展及关键问题[J]. 航空材料学报, 2013, 33(2): 87-96.

WANG Tao, ZHAO Yu-xin, FU Shu-hong, ZHANG Yong, ZENG Wei-hu, WEI Jia-hu, LI Zhao. Research progress and key issues of continuous fiber reinforced metal matrix composite materials[J]. Journal of Aeronautical Materials, 2013, 33(2): 87-96.

[3] KO F K. Tensile strength and modulus of a three-dimensional braid composite[C]//Composite Materials: Testing and Design. Philadelphia: American Society for Testing Material, 1986: 392-403.

[4] MACANDER A B, CRANE R M, CAMPONESCHI E T. Fabrication and mechanical properties of multi-dimensionally braided composite materials[C]//Composite Materials: Testing and Design (7th Conf.). Philadelphia: American Society for Testing Material, 1986: 422-443.

[5] YAU S S, CHOU T W, KO F K. Flexural and axial compressive failures of three-dimensionally braided composite I-beams[J]. Composites, 1986, 17(3): 227-232.

[6] SHIVAKUMAR K N, EMEHEL T C, AVVA V S. Compression strength and failure mechanisms of 3D textile composites[R]. AIAA-1995-1159, 1995.

[7] 沈怀荣. 三维编织复合材料冲击实验与分析[J]. 装备指挥技术学院学报, 2002, 13(2): 84-86.

SHEN Huai-rong. Impact experiment and analysis of three braided composite materials[J]. Journal of Institute of Command and Technology of Equipment, 2002, 13(2): 84-86.

[8] 刘 宁, 姚学锋, 陈俊达. 编织复合材料的冲击损伤与断裂行为研究[J]. 实验力学, 2002, 17(2): 184-189.

LIU Ning, YAO Xue-feng, CHENG Jun-da. Research on the impact damage and fracture behavior of braided composites[J]. Journal of Experimental Mechanics, 2002, 17(2): 184-189.

[9] 王玉果, 王玉林, 吴广顺. 三维编织复合材料在润滑条件下的摩擦性能[J]. 材料科学与工艺, 2005, 13(4): 365-367.

WANG Yu-guo, WANG Yu-lin, WU Guang-shun. Friction and wear characteristics of 3-D braided carbon composites under lubricated condition[J]. Materials Science & Technolgy, 2005, 13(4): 365-367.

[10] 李嘉禄, 杨红娜, 寇长河. 三维编织复合材料的疲劳性能[J]. 复合材料学报, 2005, 22(4): 172-176.

LI Jia-lu, YANG Hong-na, KOU Chang-he. Fatigue properties of three dimensional braiding composites[J]. Acta Material Composite Sinica, 2005, 22(4): 172-176.

[11] 姚学锋, 林碧森, 张志勇. 编织复合材料的裂纹损伤与增长行为研究[J]. 工程力学, 2002, 19(5): 118-122.

YAO Xue-feng, LIN Bi-sen, ZHANG Zhi-yong. Crack damage and growth behavior of braided composite[J]. Engineering Mechanics, 2002, 19(5): 118-122.

[12] 张 钧, 徐永东, 张立同, 成来飞, 董 宁. 3D-C/SIC复合材料基体裂纹间距分布规律[J]. 航空材料学报, 2003, 23(3): 11-14.

ZHANG Jun, XU Yong-dong, ZHANG Li-tong, CHENG Lai-fei, DONG Ning. The matrix crack spacing distribution of 3D-C/SIC composites[J]. Journal of Aeronautical Materials, 2003, 23(3): 11-14.

[13] 张 青, 成来飞, 张立同, 徐永东. 界面相对3D-C/SiC复合材料热膨胀性能的影响[J]. 航空学报, 2004, 25(5): 508-512.

ZHANG Qing, CHENG Lai-fei, ZHANG Li-tong, XU Yong-dong. Effects of interphases on thermal expansion of 3D-C/SiC composites[J]. Acta Aeronautica Et Astronautica Sinica, 2004, 25(5): 508-512.

[14] 刘玫潭, 蔡旭升, 李国强. 高性能SiC增强Al基复合材料的显微组织和热性能[J]. 中国有色金属学报, 2013, 23(4): 1040-1046.

LIU Mei-tan, CAI Xu-sheng, LI Guo-qiang. Microstructure and thermal properties of high-performance SiC reinforced Al matrix composite[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 1040-1046.

[15] 王 旭. 合金元素Cf/Al复合材料微观组织及性能影响[D]. 哈尔滨: 哈尔滨工业大学, 2010.

WANG Xu. The effect of alloying elements on the microstructure and properties of Cf/Al composite[D]. Harbin: Harbin Institute of Technology, 2010.

Effect of fiber preheating temperature on microstructure and mechanical properties of 3D-Cf/Al composites

NIE Ming-ming, XU Zhi-feng, XU Peng, YU Huan, WANG Zhen-jun

(National Defence Key Discipline Laboratory of Light Alloy Processing Science and Technology,

Nanchang Hangkong University, Nanchang 330063, China)

Abstract: The vacuum gas pressure infiltration was performed to prepare the 3D-Cf/Al composite reinforced 3D five-directional braided performs woven by M40 graphite fiber with the fiber volume fraction of 51%. The effects of preheating temperature on the microstructure and tensile strength of 3D-Cf/Al composites were studied, and the difference between 3D-Cf/Al composites and continuous Cf/Al composites were compared. The results show that the density of composite increases with the fiber preheat temperature increasing, the increase of the fiber preheat temperature can effectively reduce the infiltration defects, such as internal holes and partial fiber reunited. The tensile strength reduces significantly with the fiber preform preheating temperature increasing. Moreover, the density, tensile strength and elasticity modulus of the 3D-Cf/Al composites are 97.3%, 777.8 MPa and 186.1 GPa, respectively, when the preheating temperature, infiltration temperature, impregnation pressure and dwell time of the fiber are 500 ℃, 720 ℃, 7 MPa and 20 min.

Key words: 3D-woven; Cf/Al composite; fiber preheating temperature; mechanical property; microstructure

Foundation item: Project (51365043) supported by National Natural Science Foundation of China; Project (20151BAB206039) supported by Jiangxi Province Natural Science Foundation, China; Project (GF201101004) supported by National Defence Key Discipline Laboratory of Light Alloy Processing Science and Technology Aviation Technology Key Laboratory of Aerospace Materials Hot Working Processing Technology Jointly Funded Projects

Received date: 2015-07-22; Accepted date: 2016-01-12

Corresponding author: XU Zhi-feng; Tel: +86-791-86453167; E-mail: xu_zhf@163.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51365043);江西省自然科学基金资助项目(20151BAB206039);轻合金加工科学与技术国防重点学科实验室和航空材料热加工技术航空科技重点实验室联合资助项目(GF201101004)

收稿日期:2015-07-22;修订日期:2016-01-12

通信作者:徐志锋,教授;电话:0791-86453167;E-mail:xu_zhf@163.com