DOI: 10.11817/j.ysxb.1004.0609.2020-35904

叠层穿刺结构Cf/Al复合材料的弯曲性能及失效分析

冯景鹏,余 欢,徐志锋,蔡长春,王振军,帅 亮,单嘉立

(南昌航空大学 轻合金加工科学与技术国防重点学科实验室,南昌 330063)

摘 要:采用真空压力浸渗法制备纤维体积分数为47.5%的叠层穿刺结构Cf/Al复合材料,主要研究复合材料的显微组织以及弯曲性能,并进一步分析复合材料的弯曲失效机理。结果表明:复合材料的致密度为95.0%,经、纬向显微组织均存在少量微孔缺陷,且纬向显微组织的微孔缺陷较经向显微组织要多。叠层穿刺结构Cf/Al复合材料的弯曲强度和模量分别为327 MPa和114 GPa,内侧面受压处,基体出现团簇,经向纤维束由于屈曲变形程度大导致被压断,纬向纤维束发生相应地挤压变形,而在外侧面受拉处复合材料被拉伸破坏,造成基体开裂。

关键词:叠层穿刺结构;Cf/Al复合材料;显微组织;弯曲性能;失效机理

文章编号:1004-0609(2020)-11-2597-08 中图分类号:TB331 文献标志码:A

三维编织Cf/Al复合材料除了具有高比强度、高比模量、良好的耐腐蚀性等优异性能外,最为重要的特征是其质轻、密度低,且由于其各方向力学性能具有可设计性,并能编织复杂异形件,是航空航天、武器装备等领域理想的结构材料[1-7]。但目前三维编织Cf/Al复合材料相较于三维编织树脂基和陶瓷基复合材料在实际工程方面的应用还是相对较少,制约其广泛工程应用的最重要因素之一是缺少对三维编织Cf/Al复合材料力学性能的研究。

针对三维编织Cf/Al复合材料的研究,本工作在前期对其成型工艺进行了深入研究的基础上[8-9],进而对不同的预制体结构如2.5D角联锁、三维五向以及三维正交结构Cf/Al复合材料室温、高温力学性能展开了深入研究。对比发现,2.5D角联锁结构Cf/Al复合材料整体力学性能不高;三维五向Cf/Al复合材料压缩性能较低,且复合材料从高温制备到室温冷却过程中复合材料会收缩变形;而三维正交Cf/Al复合材料剪切强度低。因此,制备一种具有良好综合力学性能的复合材料就变得十分有意义,而叠层穿刺结构Cf/Al复合材料无疑是理想之选。王杰等[10]研究了叠层穿刺结构C/C复合材料螺栓件的拉伸性能和剪切性能;吴纯治[11]研究了不同区域密度变化及纤维体积分数与穿刺密度对叠层穿刺工艺SiO(2f)/SiO2复合材料力学性能的影响。而目前有关叠层穿刺结构金属基复合材料力学性能的研究鲜有报道,尤其是弯曲性能作为复合材料实际工程应用中必检的一项重要的性能指标,研究叠层穿刺结构Cf/Al复合材料的弯曲性能进而对推动三维编织Cf/Al复合材料更广泛的工程应用具有十分重要意义。

本文采用真空压力浸渗法制备纤维体积分数为47.5%的叠层穿刺结构Cf/Al复合材料,主要研究了复合材料的显微组织以及弯曲性能,并进一步分析了复合材料弯曲失效机理。本研究丰富了三维编织Cf/Al复合材料力学性能数据,为叠层穿刺结构Cf/Al复合材料在实际工程中的应用提供理论支持。

1 实验

1.1 实验材料

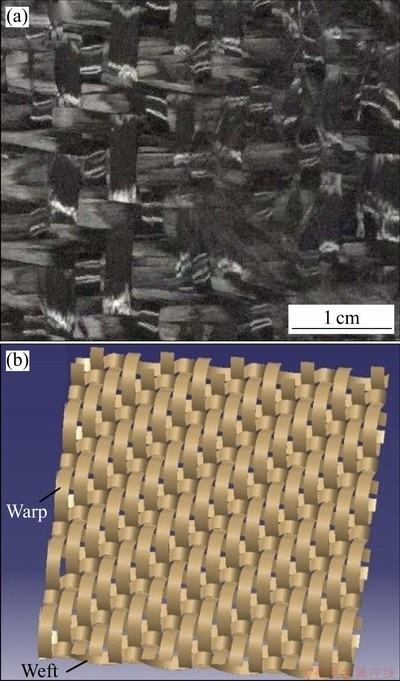

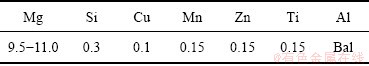

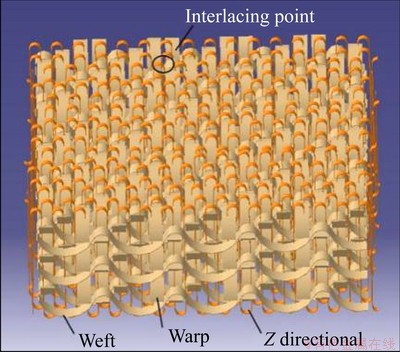

实验选用M40J纤维采用三上一下工艺编织成斜纹结构机织布,将二维斜纹机织布一层层加压密实至设计高度后用Z向穿刺纤维束穿刺密实后的斜纹机织布,得到叠层穿刺结构预制体。其中,Z向穿刺纤维束沿着纬向进行穿刺,且为单股穿刺,三上一下斜纹机织布中经纱密度为6根/cm,纬纱密度为2根/cm,预制体尺寸为230 mm×230 mm×5 mm。M40J纤维性能见表1,三上一下斜纹组织见图1,叠层穿刺结构预制体细观结构见图2。预制体的结构特点为经向、纬向纤维束均呈现“波浪形”,Z向穿刺纤维束与经向、纬向纤维束间的交织点较多。基体合金ZL301的化学成分见表2,ZL301合金中Mg元素含量为9.5%~11.0%,一定含量的Mg元素能改善铝液与碳纤维之间的润湿性并抑制有害界面相生成,同时能够降低铝液的表面能和界面能。

图1 三上一下斜纹组织

Fig. 1 Practical diagram(a) and schematic diagram(b) of three ups and down twill weave

表1 M40J纤维性能

Table 1 Property of M40J fiber

表2 ZL301合金化学成分

Table 2 Chemical composition of ZL301 alloy (mass fraction, %)

图2 叠层穿刺结构预制体细观结构

Fig. 2 Meso structure of preform with laminated puncture structure

1.2 实验方法

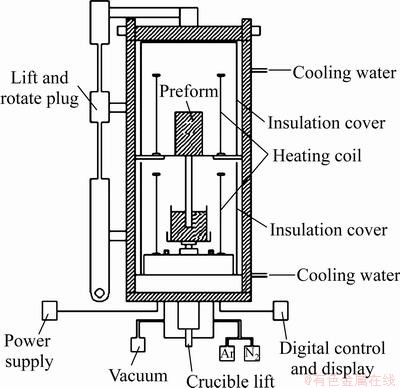

采用真空压力浸渗法制备叠层穿刺结构Cf/Al复合材料,其工艺装置原理如图3所示[12],将尺寸为230 mm×230 mm×5 mm的叠层穿刺结构预制体用石墨板固定后拿不锈钢模具进行封装。铝合金熔炼温度为690 ℃,待铝合金熔炼完成对熔融铝液除气、除杂后进行浸渗实验。设备最高工作温度为1000 ℃,控温精度为±5 ℃,浸渗实验过程中氩气作为保护气体,充入8 MPa压力的氮气作为增压气体。

图3 真空压力浸渗工艺原理示意图

Fig. 3 Schematic diagram of vacuum pressure infiltration process

1.3 测试表征

弯曲试验采用国标GB/T 1449—2005[13]《纤维增强塑料弯曲性能试验方法》进行试验,弯曲试样尺寸为150 mm×10 mm×5 mm,如图4所示。弯曲试样中心贴上横纵应变片,实验过程中同步记录载荷与位移值,直至试样破坏。采用INSPEKT100电子万能材料试验机对复合材料进行弯曲力学性能测试,设备量程为100 kN,载荷测试精度为示值的±1%以内。

图4 叠层穿刺结构Cf/Al复合材料弯曲试样

Fig. 4 Bending specimen of laminated puncture structural Cf/Al composites

从叠层穿刺结构Cf/Al复合材料板上取5处尺寸为10 mm×10 mm×5 mm的试样,采用STP JA1003电子天平分别测得试样在空气和蒸馏水中的质量,设备称量范围为0~100 g,可读性为1 mg,根据阿基米德排水法原理测得复合材料的致密度,采用Quanta2000型扫描电子显微镜(SEM)对复合材料经向、纬向显微组织进行观察,采用型号为Dino-Lite Premier Digital Microscope AM4113ZT(R4)放大倍数为50至250倍的显微镜对复合材料弯曲破损处断口进行观察。

2 结果与讨论

2.1 叠层穿刺结构Cf/Al复合材料的致密度与显微 组织

图5所示为叠层穿刺结构Cf/Al复合材料的致密度,致密度的平均值为95.0%,复合材料致密度较高,说明复合材料浸渗效果较好。

图5 叠层穿刺结构Cf/Al复合材料的致密度

Fig. 5 Density of laminated puncture structural Cf/Al composites

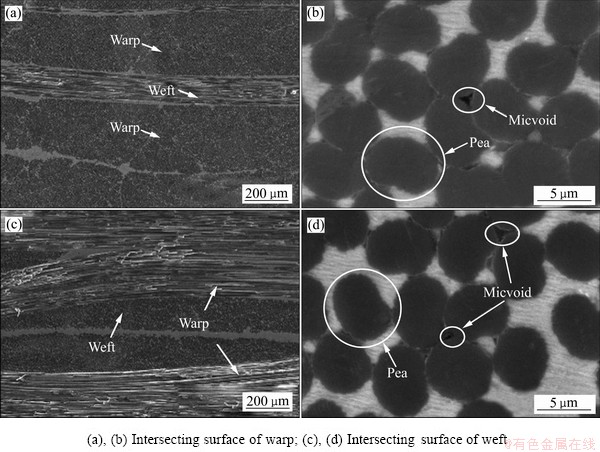

图6 叠层穿刺结构Cf/Al复合材料的显微组织

Fig. 6 Microstructures of laminated puncture structural Cf/Al composites

图6所示为叠层穿刺结构Cf/Al复合材料的显微组织,可以发现,熔融铝液能完整填充纤维束。其中,复合材料经向、纬向显微组织中均出现了在纤维丝团聚区域存在少量微米级微孔缺陷,且复合材料纬向显微组织中纤维丝团聚区域的微孔缺陷较经向显微组织要多。此外,复合材料经向、纬向显微组织中纤维丝的形貌呈现“豌豆状”,如图6(a)~(d)所示。这是由于,叠层穿刺结构预制体中的Z向穿刺纤维束沿着纬向纤维束进行穿刺的,穿刺留下的针孔为熔融铝液提供良好的浸渗通道,使得熔融铝液能较好浸渗预制体。一方面,由于熔融铝液在约8 MPa氮气作用下快速浸渗预制体,使得熔融铝液具有较大的冲击力,较大冲击力的熔融铝液在浸渗预制体过程中会对经向、纬向纤维束束内的纤维丝产生一定程度地团聚现象。而由于熔融铝液的浸渗方向是平行于预制体的经向纤维束,而垂直于纬向纤维束,较大冲击力的熔融铝液对纬向纤维束的冲击作用较经向纤维束而言影响更大,从而使得纬向纤维束束内纤维丝团聚现象较经向纤维束而言要严重。而在纤维丝团聚区域,由于团聚区域的空隙小,根据Yong-Kelvin方程[14](如式(1)所示),纤维丝团聚区域空隙小处即相应的等效毛细半径小,熔融铝液浸渗过程中所引起临界附加压差就越大。在浸渗工艺相同的情况下,铝液进入空隙小的区域需克服的附加阻力就越大[15],使得这些区域不能充分浸渗完全,易形成微孔缺陷。由于纬向纤维束束内纤维丝团聚现象较经向纤维束而言要严重,从而使得复合材料纬向显微组织中纤维丝团聚区域的微孔缺陷较经向显微组织要多。另一方面,由于碳纤维与基体合金的热膨胀系数不一致,基体合金表现为热胀冷缩,而碳纤维表现为冷胀热缩,在复合材料从高温制备到室温冷却过程中会产生较大的残余应力[16]。由于基体相承受拉应力,而增强相承受压应力[17],残余应力使得复合材料经向、纬向显微组织中纤维丝的形貌呈现“豌豆状”,纤维丝形貌呈现“豌豆状”在三维五向结构Cf/Al复合材料显微组织中也有所出现[18]。

(1)

(1)

式中:pc为毛细压力,N;σ1g为气-液界面上的表面张力,N/m;θ为液体在固体表面的浸润角;req为等效毛细管半径,m。

2.2 叠层穿刺结构Cf/Al复合材料的弯曲性能

表3所列为叠层穿刺结构Cf/Al复合材料的经向弯曲性能,可以发现,复合材料的弯曲强度和弯曲模量的平均值分别为327 MPa和114 GPa。

表3 叠层穿刺结构Cf/Al复合材料经向弯曲性能

Table 3 Warp bending properties of laminated puncture structural Cf/Al composites

图7所示为叠层穿刺结构Cf/Al复合材料经向弯曲载荷-位移曲线图,可以看出,初始阶段,1#、2#和3#试样弯曲载荷-位移曲线均呈现出线弹性特征,载荷增量大位移增量小,且2#和3#试样线弹性特征较1#试样更明显。当位移增量约为1 mm时,2#试样的曲线呈现短暂的波动后继续呈现线弹性特征,造成曲线波动的原因与复合材料内部存在少量微孔缺陷有关,微孔会影响碳纤维和基体界面载荷的传递,且微孔在受力条件下易成为裂纹源并进行扩展。随着弯曲位移的增加,复合材料内部损伤进一步积累,当达到复合材料弯曲极限后,曲线呈现缓慢卸载现象;而1#试样的曲线在位移增量约为1 mm后出现轻微卸载后继续呈现线弹性特征,而轻微卸载也是由于微孔的存在影响界面载荷的传递,直至达到复合材料弯曲极限后卸载失效。而3#试样的曲线在位移增量约为1 mm后出现轻微卸载并维持较长位移增量后卸载失效。3个试样弯曲试验后均未断裂,但此时试样均已失效。3个试样的曲线表现出了韧性断裂特征,但通过测得1#、2#和3#试样的室温拉伸伸长率分别为1.2%、0.8%和1.2%,3个拉伸试样伸长率较小,说明复合材料为脆性失效,体现了叠层穿刺结构Cf/Al复合材料弯曲破坏呈现出了“假塑性效应”特征,即曲线形式颇似塑性材料,存在二次承载面[19]。

图7 叠层穿刺结构Cf/Al复合材料经向弯曲载荷-位移曲线

Fig. 7 Warp bending load-displacement curves of laminated puncture structural Cf/Al composites

2.3 叠层穿刺结构Cf/Al复合材料弯曲性能失效机理

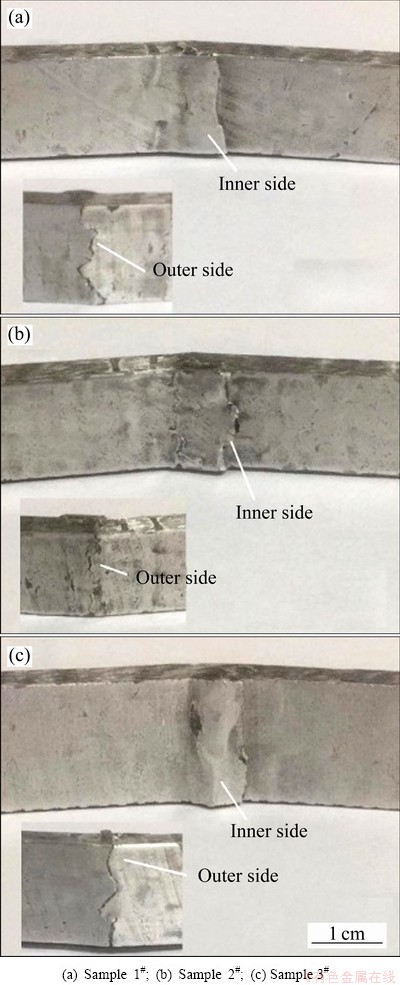

图8所示为叠层穿刺结构Cf/Al复合材料弯曲试验后试样图,可以发现,复合材料内侧(受压面)和外侧(受拉面)均出现不同程度的破损,其中,内侧受压面破损形式主要表现为基体合金的团簇,而外侧受拉面破损形式主要表现为基体的开裂。比较而言,2#试样破损程度相较于1#和3#试样的而言要低一些。如图8(a)~(c)所示。图9所示为叠层穿刺结构Cf/Al复合材料弯曲破损处断口图。由图9可以看出,复合材料在靠近内侧面受压处的基体合金在压应力不断作用下团簇在一起,经向纤维束由于屈曲变形程度大导致被压断,纬向纤维束则发生相应地挤压变形,而外侧面受拉处复合材料被拉伸破坏,造成基体开裂,见图9(a)~ (f)。这是由于在复合材料内侧面受压处由于压应力不断作用下导致经向纤维束屈曲变形程度越来越严重,一方面,经向纤维束屈曲变形程度越来越严重会导致经向纤维束承载性能降低;另一方面,基体合金在压头应力集中处会产生损伤,裂纹扩展至经向纤维束,屈曲的经向纤维束在压应力作用下易被压断,而纬向纤维束在压应力、经向纤维束屈曲变形以及基体团簇过程中产生的挤压力共同作用下则导致发生相应地挤压变形。而在外侧受拉处复合材料被拉伸破坏,造成基体开裂。图10所示为纤维失效行为示意图,由于压应力的施加方向是垂直于经向纤维束和纬向纤维束,平行于Z向穿刺纤维束,经向纤维束是主要载荷承担者(Ⅰ阶段),在压应力作用下,经向纤维束屈曲变形,纬向纤维束则发生挤压变形(Ⅱ阶段),随着弯曲载荷不断作用,经向纤维束屈曲变形以及纬向纤维束挤压变形程度越来越严重(Ⅲ阶段),随着弯曲载荷进一步作用,经向纤维束被压断,纬向纤维束则由于本身承受一部分弯曲载荷以及经向纤维束屈曲变形和基体团簇过程中产生的挤压力共同作用下导致发生相应地挤压变形程度严重;而Z向穿刺纤维束的主要作用是使预制体形成三维不分层整体结构,加之平行于压应力方向,所受的载荷较小。但由于经向纤维束屈曲变形和基体团簇过程中产生的挤压力会造成Z向穿刺纤维束偏转角度越来越大,直至最终失效断裂(Ⅳ阶段)。

图8 叠层穿刺结构Cf/Al复合材料弯曲试验后试样

Fig. 8 Specimen of laminated puncture structural Cf/Al composites after bending test

图9 叠层穿刺结构Cf/Al复合材料弯曲破损处断口的SEM像

Fig. 9 Bending fracture SEM images of laminated puncture structural Cf/Al composites

图10 纤维失效行为示意图

Fig. 10 Schematic diagram of fiber failure behavior

3 结论

1) 叠层穿刺结构Cf/Al复合材料致密度为95.0%,经、纬向显微组织中均存在少量微孔缺陷,且纬向显微组织的微孔缺陷较经向显微组织要多。

2) 叠层穿刺结构Cf/Al复合材料的弯曲强度和模量分别为327 MPa和114 GPa。

3) 内侧面受压处,基体出现团簇,经向纤维束由于屈曲变形程度大导致被压断,纬向纤维束发生相应地挤压变形。而在外侧面受拉处复合材料被拉伸破坏,造成基体开裂。

REFERENCES

[1] 王振军, 朱世学, 余 欢, 徐志锋, 陈新文. 预热温度对Cf/Al复合材料微观组织及室温与高温力学性能的影响[J]. 稀有金属材料与工程, 2018, 47(3): 982-989.

WANG Zhen-jun, ZHU Shi-xue, YU Huan, XU Zhi-feng, CHEN Xin-wen. Effect of fabrication temperature on microstructure and mechanical properties of Cf/Al composites at room and elevated temperature[J]. Rare Metal Materials and Engineering, 2018, 47(3): 982-989.

[2] 刘 兵, 彭超群, 王日初, 王小锋, 李婷婷. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(9): 1705-1715.

LIU Bing, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LI Ting-ting. Recent development and prospects for giant plane aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1705-1715.

[3] 崔 岩, 倪浩晨, 曹雷刚, 杨 越,王一鸣. SiC颗粒整形对高体分铝基复合材料力学性能的影响及有限元模拟[J].材料导报, 2019, 33(24): 4126-4130.

CUI Yan, NI Hao-chen, CAO Lei-gang, YANG Yue, WANG Yi-ming. Effect of SiC particle shaping on mechanical property of aluminum matrix composite with high volume fraction reinforcement and finite element analysis[J]. Materials Reports, 2019, 33(24): 4126-4130.

[4] 胡银生, 余 欢, 王振军, 徐志锋, 董敬涛. 织物结构对2.5D-Cf/Al复合材料微观组织与力学性能的影响[J]. 中国有色金属学报, 2018, 28(12): 2512-2522.

HU Yin-sheng, YU Huan, WANG Zhen-jun, XU Zhi-feng, DONG Jing-tao. Effect of woven fabric structure on microstructure and mechanical properties of 2.5D-Cf/Al composites[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(12): 2512-2522.

[5] PULKIT G, ANBESH J, DEVENDRA K, KISHOR K S, CHAUDHERY M H, PALLAV G. Advance research progresses in aluminium matrix composites: manufacturing & applications[J]. Journal of Materials Research and Technology, 2019, 8(5): 4924-4939.

[6] ZHANG Yun-he, YAN Li-li, MIAO Meng-he, WANG Qing-wen, WU Gao-hui. Microstructure and mechanical properties of z-pinned carbon fiber reinforced aluminum alloy composites[J]. Materials & Design, 2015, 86(5): 872-877.

[7] 徐 鹏, 徐志锋, 余 欢, 王振军, 姚 菁, 聂明明. 3D-Cf/Al复合材料真空气压浸渗工艺研究[J]. 特种铸造及有色合金, 2015, 35(7): 749-753.

XU Peng, XU Zhi-feng, YU Huan, WANG Zhen-jun, YAO Jing, NIE Ming-ming. Preparation of 3D-Cf/Al composites by vacuum pressure infiltration[J]. Special Casting & Nonferrous Alloys, 2015, 35(7): 749-753.

[8] 袁秀妹. 基于真空气压浸渗的2.5D-Cf/Al复合材料微观组织及力学性能研究[D]. 南昌: 南昌航空大学, 2016.

YUAN Xiu-mei. On Microstructure and mechanical properties of 2.5D-Cf/Al composites fabricated by vacuum pressure infiltration[D]. Nanchang: Nanchang Hangkong University, 2016.

[9] 周珍珍. 基于真空气压浸渗的3D-Cf/Al复合材料微观组织及力学性能研究[D]. 南昌: 南昌航空大学, 2015.

ZHOU Zhen-zhen. Research on microstructure and mechanical properties of 3D-Cf/Al composites manufactured by vacuum pressure infiltration[D]. Nanchang: Nanchang Hangkong University, 2015.

[10] 王 杰, 李克智, 郭领军, 李贺军, 李 伟, 高全明, 李照谦. 炭布叠层穿刺C/C复合材料螺栓连接件微观组织和力学性能[J]. 固体火箭技术, 2012, 35(2): 248-252.

WANG Jie, LI Ke-zhi, GUO Ling-jun, LI He-jun, LI Wei, GAO Quan-ming, LI Zhao-qian. Microstructure and mechanical properties of C/C composite bolts[J]. Journal of Solid Rocket Technology, 2012, 35(2): 248-252.

[11] 吴纯治. SiO(2f)/SiO2复合材料的叠层穿刺制备工艺及性能研究[D]. 长沙: 国防科学技术大学, 2015.

WU Chun-zhi. Properties and preparation research of the SiO2f/SiO2 composites with stitched fiber cloth reinforcement[D]. Changsha: National University of Defense Technology, 2015.

[12] 聂明明, 徐志锋, 余 欢, 王振军, 姚 菁. 基体合金对连续M40石墨纤维/Al复合材料纤维损伤及断裂机制的影响[J]. 复合材料学报, 2016, 33(12): 2797-2806.

NIE Ming-ming, XU Zhi-feng,YU Huan,WANG Zhen-jun,YAO Jing. Effects of matrix alloy on fiber damage and fracture mechanism of continuous M40 graphite fiber/Al composites[J]. Acta Materiae Compositae Sinica, 2016, 33(12): 2797-2806.

[13] ZHANG Guo-li, WANG Fu-you, LI Jia-lu, CHEN Guang-wei, CHEN Li. Study on the mechanical performance of glass fiber 2D woven fabric laminated composites with different splicing shape and interval length[J]. Applied Mechanics and Materials, 2010, 34/35(10): 1845-1849.

[14] 胡银生, 余 欢, 徐志锋, 聂明明, 徐燕杰, 姚 菁. 增强纤维对连续纤维增强铝基复合材料界面和力学性能的影响[J]. 中国有色金属学报, 2019, 29(10): 2245-2254.

HU Yin-sheng, YU Huan, XU Zhi-feng, NIE Ming-ming, XU Yan-jie, YAO Jing. Effect of reinforcing fiber on interface and mechanical properties of fiber reinforced aluminum matrix composites[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(10): 2245-2254.

[15] PEI Ri-sheng, CHEN Guo-qin, WANG Ya-ping, ZHAO Ming, WU Gao-hui. Effect of interfacial microstructure on the thermal-mechanical properties of mesophase pitch-based carbon fiber reinforced aluminum composites[J]. Journal of Alloys and Compounds, 2018, 756(4): 8-18.

[16] TROJANOVA Z, LUKA P, RIEHEMANN W, MORDIKE B. Study of relaxation of residual internal stress in Mg composites by internal friction[J]. Materials Science & Engineering A, 2002, 324(1/2): 122-126.

[17] 姜小坤, 余 欢, 徐志锋, 刘 剑, 蔡长春. 深冷处理时间对3D-Cf/Al复合材料残余应力与力学性能的影响[J]. 材料热处理学报, 2018, 39(10): 1-7.

JIANG Xiao-kun, YU Huan, XU Zhi-feng, LIU Jian, CAI Chang-chun. Effect of cryogenic treatment time on residual stress and mechanical properties of 3D-Cf/Al composites[J]. Transactions of Materials and Heat Treatment, 2018, 39(10): 1-7.

[18] 周珍珍, 徐志锋, 余 欢, 王振军. 编织结构对3D-Cf/Al复合材料显微组织与力学性能的影响[J]. 中国有色金属学报, 2016, 26(4): 773-781.

ZHOU Zhen-zhen, XU Zhi-feng, YU Huan, WANG Zhen-jun. Effects of braiding structures on microstructure and mechanical properties of 3D-Cf/Al composites[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(4): 773-781.

[19] 廖晓玲, 李贺军, 李新涛, 候党社. 3DC/C复合材料的弯曲行为[J]. 材料工程, 2006(6): 54-57.

LIAO Xiao-ling, LI He-jun, LI Xin-tao, HOU Dang-she. Flexural behavior of 3DC/C composites[J]. Journal of Materials Engineering, 2006(6): 54-57.

Bending properties and failure analysis of laminated puncture structural Cf/Al composites

FENG Jing-peng, YU Huan, XU Zhi-feng, CAI Chang-chun, WANG Zhen-jun, SHUAI Liang, SHAN Jia-li

(National Defence Key Discipline Laboratory of Light Alloy Processing Science and Technology, Nanchang Hangkong University, Nanchang 330063, China)

Abstract: Laminated puncture structural Cf/Al composites with 47.5% fiber volume fraction were fabricated by vacuum pressure infiltration. The microstructure and bending properties of the composites were studied, and the bending failure mechanism of the composites was further analyzed. The results indicate that the density of the composites is 95.0%, and there are a few micvoids defects in the warp and weft microstructure, and the micvoids defects in the weft microstructure are more than those in the warp microstructure. The bending strength and modulus of laminated puncture structural Cf/Al composites are 327 MPa and 114 GPa, respectively. In the compression area of the inner side, the matrix appears clusters, the warp fiber bundles are compressed fracture due to the large degree of buckling deformation, and the weft fiber bundles are corresponding extrusion deformation. While the composites of the outer side are damaged by tensile, which results in the matrix cracking.

Key word: laminated puncture structural; Cf/Al composites; microstructure; bending property; failure mechanism

Foundation item: Projects(51765045, AA201301219) supported by the National Natural Science Foundation of China; Project(20151BAB206004) supported by the Natural Science Foundation of Jiangxi Province, China

Received date: 2019-12-22; Accepted date: 2020-05-15

Corresponding author: YU Huan; Tel: +86-791-86453167; E-mail: yuhwan@163.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51765045,AA201301219);江西省自然科学基金资助项目(20151BAB206004)

收稿日期:2019-12-22;修订日期:2020-05-15

通信作者:余 欢,教授,博士;电话:0791-86453167;E-mail:yuhwan@163.com