基于BLADED软件的大型风力机叶片气动分析

周鹏展1, 2, 3,曾竟成1,肖加余1,杨军2

(1. 国防科技大学 航天与材料工程学院,湖南 长沙,410073;

2. 株洲时代新材料科技股份有限公司,湖南 株洲,412007;

3. 长沙理工大学 能源与动力工程学院,湖南 长沙,410076)

摘 要:基于BLADED软件,根据德国GL2003国际标准,对应用于GL3A风场的某款1.50 MW大型风力机叶片的气动额定功率、风能利用系数、疲劳载荷、极限载荷等进行分析。研究结果表明:在与某款1.65 MW风力发电机组匹配时,该叶片在风速为11.0 m/s时的额定功率能达到1.65 MW;在叶尖速比为7.8~11.4时,其风能利用系数均在0.460以上,在叶尖速比为9.5时,其最大风能利用系数可达0.486,表明该叶片具有较好的气动性能和较宽的风速适应范围;其叶根等效疲劳载荷为2.107 7 MN?m,叶根极限挥舞载荷为4.614 6 MN?m,均比该叶片载荷的原设计值小,说明其应用是安全的。

关键词:大型风力机叶片;气动分析;动量-叶素理论;BLADED软件

中图分类号:TK8 文献标志码:A 文章编号:1672-7207(2010)05-2022-06

Aerodynamic analysis of a large-scale wind turbine blade

based on BLADED software

ZHOU Peng-zhan1, 2, 3, ZENG Jing-cheng1, XIAO Jia-yu1, YANG Jun2

(1. College of Aerospace and Material Engineering, National University of Defense Technology,

Changsha 410073, China;

2. Zhuzhou Times New Material Technology Co. Ltd., Zhuzhou 412007, China;

3. College of Energy and Power Engineering, Changsha University of Science and Technology, Changsha 410076, China)

Abstract: Based on BLADED software, according to the GL2003 international standard, the aerodynamic rated power, power coefficient, fatigue load and extreme load of a kind of 1.50 MW large-scale wind turbine blade applied in the GL3A wind field were analyzed. The results show that the blade can reach 1.65 MW when it is applied in the wind turbine at the rated power of 1.65 MW at the wind speed of 11.0 m/s. The blade’s power coefficient is above 0.46 when its tip speed ratio is between 7.8 and 11.4. The blade’s maximum power coefficient is 0.486 when its tip speed ratio is 9.5. It is indicated that the blade has good aerodynamic performance and wide scope of wind speed adaptive capacity. The blade root’s equivalent fatigue load is 2.107 7 MN?m, and its extreme flapwise load is 4.614 6 MN?m. The loads are both less than the original designed loads, so the blade’s application is safe.

Key words: large-scale wind turbine blade; aerodynamic analysis; blade element-momentum theory; BLADED software

风力机叶片是风力发电机组的关键部件之一,其制造成本占风力发电机组总成本的20%~30%,其气动性能在很大程度上决定了风力发电机组的可靠性和风能利用的经济性[1-6]。近几年来,随着世界范围内化石能源的逐渐枯竭以及国际社会对于碳排量减排的要求,我国风电作为一种可商业化大规模应用的清洁可再生能源,其装机容量以连年翻番的趋势快速增长,并向单机大型化、大功率方向发展,也带动了兆瓦级大型风力机叶片气动分析工作的发展[1, 3, 7]。风力机叶片的气动性能不仅与其自身翼型结构和风场环境有关,而且与风力发电机组的结构形式和控制方式等因素有关[8-15]。目前,国内外就如何应用国际标准对风力机叶片气动性能进行系统评估的报道较少,因此,如何应用国际标准对风力机叶片在特定应用环境下的气动性能进行分析,并保证风力机叶片能够高效、可靠地运行,是当前风力机叶片工程应用研究急需解决的难题之一。在此,本文作者基于大型通用风力发电机组设计与分析软件BLADED[13],根据德国GL2003国际标准[14],针对应用于GL3A风场的某款1.50 MW大型风力机叶片与某款1.65 MW风力发电机组匹配时的气动性能进行分析。

1 理论基础

目前,用于大型风力机叶片气动分析的理论有贝兹理论、动量理论、叶素理论、动量-叶素理论 等[2, 10-11],其中动量-叶素理论给出了求解轴向诱导因子和周向诱导因子的方法,并通过普朗特修正、Wilson修正、Glauert修正等方法对叶片模型进行修正,是目前最常用、最成熟的叶片设计方法[8-15],其基本公式推导如下。

根据动量理论,有

(1)

(1)

根据叶素理论,有

(2)

(2)

根据叶素理论,速度矢量可表示为:

(3)

(3)

令式(1)和式(2)中的dT与dM相等,由式(1)~(3)可得:

(4)

(4)

式中:v0为相对来流速度;v1为来流风速;a为轴向诱导因子;b为周向诱导因子;ρ为空气密度;c为叶素剖面弦长;B为叶片数;Cn为法向力系数;Ct为切向力系数;Cd为阻力系数; 为入流角;F为修正 系数。

为入流角;F为修正 系数。

(5)

(5)

式中:Cl为升力系数。

若考虑普朗特叶尖损失修正因子:

(6)

(6)

则控制方程可修正为:

(7)

(7)

当风轮叶片部分进入涡环状态时,动量方程不再适用,可用下面的经验公式对动量-叶素理论进行 修正。

(1) 当a>0.38时,采用Wilson修正方法。

将 替代为

替代为

(8)

(8)

(2) 当a>0.2时,采用Glauert修正方法。

将 替代为

替代为

(9)

(9)

式中: ;

; 。

。

(3) 考虑风轮锥角的修正。在上述轴向诱导因子a和周向诱导因子b的计算中,都假设风轮的锥角 为0?。当风轮的锥角不为0?时,将

为0?。当风轮的锥角不为0?时,将 替代为:

替代为:

(10)

(10)

式中: 为风轮锥角。

为风轮锥角。

上述动量-叶素理论是进行风力机叶片气动分析与外形结构设计的理论基础,但同时考虑到大型风力机叶片的气动性能不仅与其自身翼型结构和风场有关,而且与风力发电机组的结构形式和控制方式有关,考虑求取以上因素的理论分析方程解析解非常困难,本文采用基于动量-叶素理论的Bladed软件[8]进行数值求解与气动分析。

2 气动分析模型

2.1 Bladed叶片模型

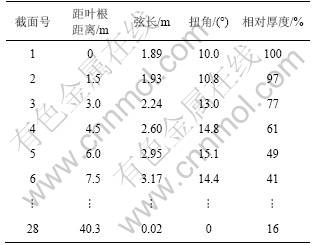

本文采用的应用于GL3A风场的1.50 MW某款大型风力机叶片属于变桨控制型叶片,其安装方式是在每个风轮上安装3个叶片,其设计长度约为40.3 m,设计额定功率为1.50 MW,其基本参数如表1所示。

表1 风力机叶片基本参数

Table 1 Basic parameters of wind turbine blade

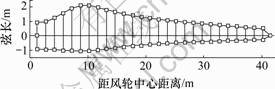

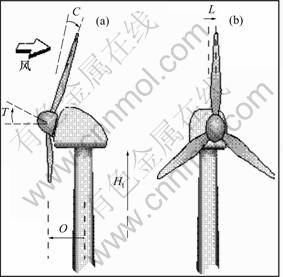

该风力机叶片在应用于1.65 MW风力发电机组时,其实际运行的额定功率要求达到1.65 MW。实际额定功率增大后,对安全问题需要进行客观分析与准确判断。本文采用BLADED软件对其气动性能进行分析,根据表1所示数据,在Bladed软件中建立风力机叶片模型,如图1所示。

图1 基于BLADED的叶片模型

Fig.1 Wind turbine blade model based on BLADED software

2.2 Bladed风轮模型

同一款风力机叶片在应用于不同的风力发电机组时,其气动性能也会产生差异,所以,在对具体的某一款风力机叶片进行气动分析时,需要把叶片与整机联系起来考虑。在分析所述风力机叶片的气动性能时,选配的应用机型是某1.65 MW风力发电机组,其基本参数如表2所示。

表2 风力发电机组基本参数

Table 2 Basic parameters of wind turbine

根据表2所示风力发电机组基本参数,在Bladed软件中建立风轮模型,如图2所示。图2中:T为风轮仰角;C为风轮锥角;Ht为轮毂高度;L为叶片横向偏移;O为风轮悬挂距离。

3 计算结果与分析

3.1 安装角选择

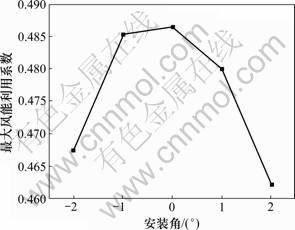

安装角在-2°~2°之间变化时,会引起风力机叶片最大风能利用系数发生变化,如图3所示。从图3可见:当安装角从-2°逐渐向2°变化时,风力机叶片的最大风能利用系数呈现了先增大后下降的变化特征,并且在安装角为0°时最大风能利用系数最高,达到0.486。安装角的正偏或负偏都会引起风力机叶片最大风能利用系数下降,为了使风力机叶片尽可能多发电,选择本款风力机叶片安装角为0°进行分析。

(a) 侧视图;(b) 正视图

图2 基于BLADED的风轮模型

Fig.2 Rotor model based on BLADED

图3 安装角对最大风能利用系数的影响

Fig.3 Effect of set angle on the maximum power coefficient

3.2 气动功率

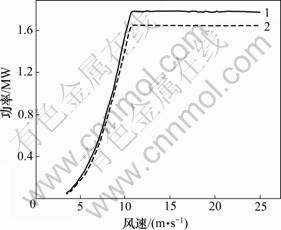

风力机叶片在上述应用条件下的气动功率计算结果如图4所示,图中实线表示风轮输入的轴功率,虚线表示风力发电机组输出的电功率。风力发电机组在满功率时的功率传递效率取93%。从图4可见:当该款风力机叶片在风速为11.0 m/s时,可达到风力发电机组气动额定功率1.65 MW,满足设计要求。

3.3 风能利用系数

由该款风力机叶片计算得到的风能利用系数与叶尖速比的关系曲线如图5所示。从图5可见:该款叶片在叶尖速比为9.5时,其最大风能利用系数可达0.486;而且该款叶片在叶尖速比为7.8~11.4之间变化时,都能保证其最大风能利用系数大于0.46,这说明该款叶片的气动设计比较好,适用风速范围较宽,气动效率较高。

1—轴功率;2—电功率

图4 风力机叶片功率曲线

Fig.4 Powers curves of wind turbine blade

图5 风能利用系数与叶尖速比关系

Fig.5 Relationship between power coefficient and tip speed ratio

3.4 叶根疲劳载荷

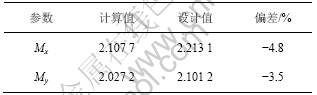

该款风力机叶片在GL3A风场下,按使用寿命为 20 a、循环数为107次计算,根据德国GL2003国际标准[9],用BLADED软件计算得到的叶根等效疲劳载荷的计算值与原有设计值的对比结果如表3所示。表3中,m为叶根等效疲劳载荷对应的材料系数,对于复合材料风力机叶片,取m=10。

表3 叶根等效疲劳载荷对比

Table 3 Comparison of blade root’s equivalent fatigue loads MN?m

由于x方向与叶片的挥舞方向一致,y方向与叶片的摆振方向一致,而叶片挥舞方向的强度和刚度都要弱于摆振方向的强度和刚度,所以,叶根等效疲劳载荷主要参考x方向的疲劳载荷。从表3可见:该1.50 MW风力机叶片在应用于1.65 MW风力发电机组时,计算得到的x方向的叶根等效疲劳载荷Mx为2.107 7 MN?m,比原设计值小4.8%,而y方向的叶根等效疲劳载荷My为2.027 2 MN?m,比原设计值小3.5%。由此可见:该叶片在应用于1.65 MW风力发电机组时,由叶片等效疲劳载荷来判断,其应用是安全的。

3.5 叶根极限载荷

该款风力机叶片在应用于GL3A风场时,根据德国GL2003国际标准[9],在考虑安全系数时,按极限风况计算得到的叶根极限载荷的计算值与原有设计值的对比结果如表4所示。

表4 叶根极限载荷对比

Table 4 Comparison of blade root’s extreme loads MN?m

由于叶片挥舞方向的强度和刚度都比摆振方向的弱,而且叶根处的极限载荷最大,所以,叶片极限载荷也主要参考叶根极限挥舞载荷。从表4可见:该风力机叶片应用于该款1.65 MW风力发电机组时,其叶根极限挥舞载荷为4.614 6 MN?m,比原设计值小1.6%;其叶根极限摆振载荷为2.369 8 MN?m,比原设计值小0.6%。由此可见:该叶片应用于1.65 MW风力发电机组时,由叶根极限载荷来判断,其应用也是安全的。

4 结论

(1) 本款1.50 MW大型风力机叶片在与目标机型匹配时,当安装角为0°时具有最大风能利用系数,并且该叶片在风速为11.0 m/s时的额定功率能达到1.65 MW;在叶尖速比为7.8~11.4时,其风能利用系数均在0.460以上,而且在叶尖速比为9.5时,其最大风能利用系数可达0.486,显示该叶片具有较好的气动性能和较宽的风速适应范围,可以满足该风力发电机组气动功率和效率的使用要求。

(2) 该风力机叶片在应用于1.65 MW风力发电机组时,计算得到的x方向的叶根等效疲劳载荷Mx为2.107 7 MN?m,比原设计值小4.8%,而y方向的叶根等效疲劳载荷My为2.027 2 MN?m,比原设计值小3.5%,由叶片等效疲劳载荷来判断,其应用是安全的。

(3) 该风力机叶片应用于1.65 MW风力发电机组时,其极限挥舞载荷为4.614 6 MN?m,比原设计值小1.6%;其极限摆振载荷为2.369 8 MN?m,比原设计值小0.6%,由叶根极限载荷来判断,其应用也是安全的。

参考文献:

[1] Herbert G M J, Iniyan S, Sreevalsan E, et al. A review of wind energy technologies[J]. Renewable & Sustainable Energy Reviews, 2007, 11(6): 1117-1145.

[2] LU Lin, YANG Hong-xing, Burnett J. Investigation on wind power potential on Hong Kong islands: An analysis of wind power and wind turbine characteristics[J]. Renewable Energy, 2002, 27(1): 1-12.

[3] Hansen M O L, Sorensen J N, Voutsinas S, et al. State of the art in wind turbine aerodynamics and aeroelasticity[J]. Progress in Aerospace Sciences, 2006, 42(4): 285-330.

[4] 戴春晖, 刘钧, 曾竟成, 等. 复合材料风电叶片的发展现状及若干问题的对策[J]. 玻璃钢/复合材料, 2008(1): 53-56.

DAI Chun-hui, LIU Jun, ZENG Jing-cheng, et al. Current development of composite wind turbine blades and proposals to several problems[J]. Fiber Reinforced Plastics/Composites, 2008(1): 53-56.

[5] 张晓明. 风力发电复合材料叶片的现状与未来[J]. 纤维复合材料, 2006(2): 60-63.

ZHANG Xiao-ming. The future and present of wind turbine composite blade[J]. Fiber Composites, 2006(2): 60-63.

[6] 陈宗来, 陈余岳. 大型风力机复合材料叶片技术及进展[J]. 玻璃钢/复合材料, 2005(3): 53-56.

CHEN Zong-lai, CHEN Yu-yue. Large compo-site blades for wind turbines[J]. Fiber Reinforced Plastics/Composites, 2005(3): 53-56.

[7] 施鹏飞. 全球风力发电现况及发展趋势[J]. 电网与清洁能源, 2008, 24(1): 3-5.

SHI Peng-fei. Present situations and development trends of global wind power[J]. Power System and Clean Energy, 2008, 24(1): 3-5.

[8] 刘雄, 陈严, 叶枝全. 水平轴风力机气动性能计算模型[J]. 太阳能学报, 2005, 26(6): 792-800.

LIU Xiong, CHEN Yan, YE Zhi-quan. Research on the aerodynamic performance prediction model for horizontal axis wind turbine[J]. Acta Energy & Solaris Sinica, 2005, 26(6): 792-800.

[9] Bak C, Fuglsang P, Sorensen N N, et al. Airfoil characteristics for wind turbines[EB/OL]. [2009-10-02]. http://130.226.56.153/ rispubl/VEA/veapdf/ris-r-1065.pdf.

[10] Noda M, Flay R G J. A simulation model for wind turbine blade fatigue loads[J]. Journal of Wind Engineering and Industrial Aerodynamics, 1999, 83(1/3): 527-540.

[11] Maalawi K Y, Badawy M T S. A direct method for evaluating performance of horizontal axis wind turbines[J]. Renewable & Sustainable Energy Reviews, 2001, 5(2): 175-190.

[12] Kishinami K, Taniguchi H, Suzuki J, et al. Theoretical and experimental study on the aerodynamic characteristics of a horizontal axis wind turbine[J]. Energy, 2005, 30(11/12): 2089-2100.

[13] Bossanyi E A. GH bladed theory manual[M]. Issue 17. England: Garrad Hassan and Partners Limited, 2007: 1-110.

[14] GL Wind 2003. Guideline for the certification of wind turbines[S].

[15] Grant I. Wind turbine blade analysis using the blade element momentum method[EB/OL]. [2009-10-02]. http://www.dur.ac.uk/ g.l.ingram/download/wind_turbine_design.pdf.

(编辑 陈灿华)

收稿日期:2009-10-12;修回日期:2010-01-25

基金项目:国家高技术研究发展计划项目(2007AA03Z563);中国博士后基金资助项目(20070420832);湖南省科技攻关项目(2008RS4033)

通信作者:周鹏展(1973-),男,湖南沅江人,博士,从事风力机叶片气动分析及结构设计研究;电话:15973362878;E-mail: zpz0731@163.com