文章编号:1004-0609(2008)11-2008-06

制备工艺对C/C-SiC复合材料滑动摩擦特性的影响

葛毅成,易茂中,彭 可,杨芸芸

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:分别采用熔渗硅(MSI)、前驱体裂解(PIP)技术制备4种C/C-SiC复合材料。在M2000型实验机上测试材料的摩擦磨损特性。结果表明:采用MSI制备的2种C/C-SiC摩擦因数高、不稳定,摩擦因数在0.404~0.906之间波动;随载荷增加,MSI-SiC质量分数为40.9%的材料B的摩擦因数变化幅度低于SiC质量分数18.9%的材料A的摩擦因数,但其随时间延长的波动幅度大;随时间延长和载荷增加,采用PIP制备的2种C/C-SiC材料的摩擦因数变化小,在0.08~0.14之间波动;其中,随载荷增加,PIP-SiC质量分数为18.0%的材料C的摩擦因数波动幅度稍大于SiC质量分数为6.0%的材料D的。EDAX分析表明:材料A的部分磨损表面未发现碳元素;而材料C磨损表面的碳硅摩尔比大于1,使其有足够的炭形成自润滑膜,从而降低材料的摩擦因数。SEM形貌表明:MSI技术制备的材料摩擦表面粗糙,未形成完整的摩擦膜,而采用PIP技术制备的材料摩擦表面较完整且致密。

关键词:C/C-SiC复合材料;制备工艺;滑动摩擦;摩擦特性

中图分类号:TB332;TH145.1 文献标识码:A

Influence of fabrication of SiC on tribological behavior of C/C-SiC composite against 40Cr steel

GE Yi-cheng, YI Mao-zhong, PENG Ke, YANG Yun-yun

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Four C/C-SiC composites were prepared using molten-Si infiltration-reaction(MSI) or precursor- pyrolysis(PIP), respectively. The sliding tribological behaviors of these four composites and one C/C composite were tested by M2000 wear tester. The results show that the coefficients of friction (COF) of the two kinds of MSI-composites are high under the applied loads and time, which fluctuate in 0.404?0.906. With increasing loads the COF of composite B with 40.9% (mass fraction) MSI-SiC has lower fluctuation than those of composite A with 18.9% MSI-SiC. But with prolonging time, the COF of composites A has larger changing extent than those of composite B except that under 150N. For the two PIP-composites, the COF are low and stable, which fluctuate in 0.08?0.144. But with increasing load, composite C with 18.0% PIP-SiC has a little larger changing extent than composite D with 6.0% PIP-SiC. The EDAX results show that the carbon element has not been found on part of the worn surface of composite B. The molar ratio of carbon to silicon on the worn surface of composite C is higher than 1, which indicates that carbon friction film can easily form with good lubrication to decrease the COF. SEM images of the MSI-composites have very rough friction films while the PIP-composites have smooth and integrated ones.

Key words: C/C-SiC composites; fabrication process; sliding friction; tribological behavior

炭纤维增强炭基体复合材料(C/C)具有密度低、比强度和比模量高、热导率高、热容大,优异的摩擦特性以及可设计性好等特点,已经在航空航天领域,尤其是高能摩擦领域得到广泛的应用[1?4]。目前,为拓展C/C复合材料的应用领域,克服其易氧化的技术缺陷,在其内添加基体改性剂已成为新的热点。如用SiC改性的C/C-SiC复合材料已被广泛用在F1方程式赛车、高性能飞机以及重载车辆的摩擦副上[5?9]。

目前,制备C/C-SiC复合材料的主要技术手段是模压、熔渗以及前驱体浸渍裂解技术(PIP)等[10?13]。其中采用炭纤维、石墨粉、Si粉以及树脂模压炭化技术制备的C/C-SiC材料强度低[10],难以满足现代高能摩擦领域的应用需求。采用熔渗Si技术制备的C/C-SiC增密速度快,但易形成大块未反应的Si,影响材料的性能[11?12];而采用PIP技术制备的C/C-SiC的原料昂贵、增密速度慢也限制其应用[13]。因此,针对特定的应用需求,在上述3种技术中选用合理的方法,制备相应的C/C-SiC将是此类材料发展的关键。

相对炭材料,SiC硬度高,无自润滑能力,在C/C-SiC的摩擦过程中易形成硬质相颗粒,影响材料磨损表面的稳定性。因此,SiC在C/C-SiC材料的存在形式、质量分数是影响其性能、尤其是摩擦特性的关键因素,必须加以研究。本文作者研究不同技术制备的SiC对C/C-SiC材料摩擦特性的影响及机理。

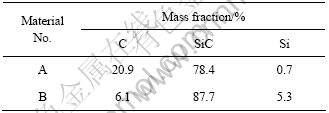

1 实验

采用聚丙烯腈炭纤维无纬布/炭毡混合叠层针刺毡坯体作为增强相,采用化学气相渗透技术(CVI)制备C/C复合坯体。之后分别采用前驱体浸渍裂解反应技术(PIP),熔渗硅反应技术(MSI)在C/C坯体中制备SiC,并最终制备出4种C/C-SiC复合材料。为进行对比研究,选用一种基体炭为光滑层热解炭+树脂炭的C/C复合材料进行摩擦实验。5种材料的性能参数列于表1。材料A和B的XRD半定量分析结果见表2。由表可见,由于半定量检测的技术缺陷,材料A和B的成分分布与表1有较大出入,但总体上材料B内的SiC和单质Si质量分数均高于材料A。材料C和D中的采用PIP技术制备的为β-SiC[14]。

表1 C/C-SiC和C/C复合材料部分性能参数

Table 1 Properties of C/C-SiC and C/C composites

表2 材料A和B的XRD半定量分析结果

Table 2 XRD results of compounds A and B

将材料加工成20 mm×12 mm×6 mm的块状试样,用金相砂纸研磨、清洗后备用,材料表面粗糙度为0.8 ?m。在M2000型摩擦实验机上测试其环?块滑动摩擦行为。对偶为40Cr钢,其尺寸为d1 40 mm×d2 16 mm×10 mm。载荷分别为60、80、100、120和150 N。每次摩擦时间为5 h,干态、室温。配副间线速度为0.42 m/s。每组实验重复3次,取其摩擦因数平均值。

采用SEM观察磨损表面形貌、EDAX分析磨损表面成分变化。

2 实验结果

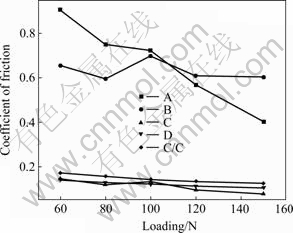

图1所示为实验5 h后4种C/C-SiC复合材料摩擦因数与C/C复合材料的对比。由图1可见,随载荷增加,除材料B的摩擦因数有所波动外,其余材料的基本为下降趋势。其中材料C、D和C/C复合材料的摩擦因数均比材料A和B低且稳定。

图1 C/C-SiC和C/C复合材料摩擦因数随载荷增加的变化

Fig.1 Changes of coefficient of friction for C/C-SiC and C/C composites with load

图2所示为5种材料摩擦因数随时间的变化。由图2(a)可见,随时间延长,在材料A中,其摩擦因数在60、80和100 N载荷为缓慢上升趋势,而在150 N时波动较大。由图2(b)可见,材料B的摩擦因数在所有载荷下的波动较低,未见其趋于稳定的倾向。与材料A、B对比,材料C、D和C/C的摩擦因数十分稳定,未见较大波动,结合图1中数据可知,PIP-SiC对材料在与40Cr钢配副、长时间滑动摩擦时的摩擦行为影响较低。

图2 不同载荷下材料A、B、C、D和C/C材料的摩擦因数随时间的变化

Fig.2 Changes of coefficient of friction for composite A(a), B(b), C(c), D(d) and C/C(e) with time at different loads

3 材料的显微组织

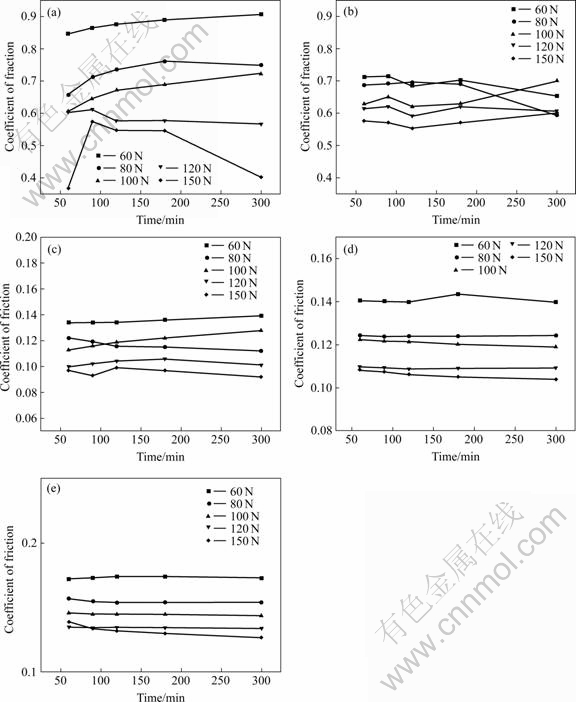

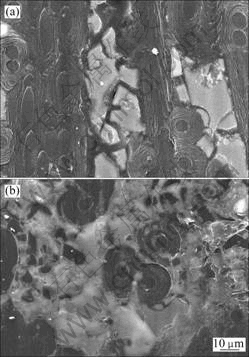

图3所示为材料A分别在载荷60和150 N时实验5 h后的磨损表面形貌。由图3(a)和(c)可见,不同载荷下,材料A均存在大块磨屑膜剥落形貌,摩擦表面不完整。由图3(b)可见,摩擦表面有大量的纤维剪切磨损形貌。由图3(b)和(d)可见,随着载荷增加,磨损表面磨屑显著增多,且磨屑更加细小。这一方面说明,MSI-SiC对材料磨损表面的破坏大;另一方面也表明,高载荷下,MSI-SiC也易形成细小的颗粒,减少对材料表面的磨损,可适当改变材料的摩擦行为。同时,不同载荷下磨损形貌表明,材料的磨损机制主要为磨粒磨损形式。其中,60 N时摩擦膜的剥落形貌是国MSI-SiC磨屑粒度大,在低载荷下被压紧程度低,磨屑结合差,在受到摩擦力作用时易形成较多的裂纹,并逐渐导致摩擦膜的整体剥落。

图3 材料A实验5 h后磨损表面形貌

Fig.3 SEM morphologies of composites A after test at 60 N(a, b) and 150(c, d) for 5 h

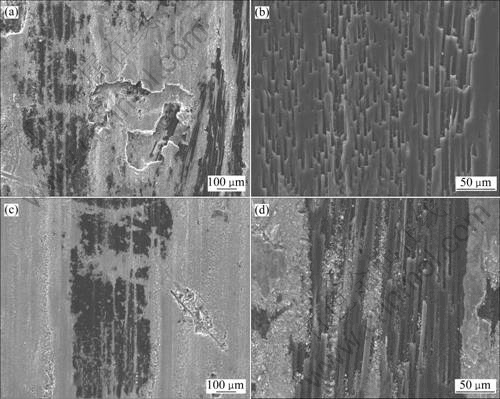

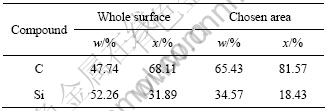

图4(a)和(b)所示分别为材料C在载荷60和150 N下实验5 h后的磨损形貌。由图可见,采用PIP技术制备的SiC呈现出碎块状,集中在纤维取向混乱的炭毡的孔隙中。由图4(a)可见,在60 N时,试样磨损表面的PIP-SiC仍保持块状形貌,不同颗粒间的界限分明,其磨损表面的环状热解炭清晰可辨。由图4(b)可见,在150 N实验后,磨损表面的PIP-SiC颗粒之间的界限不明显。

图4 不同载荷下材料实验5 h后磨损表面形貌

Fig.4 SEM morphologies of composite C after test at 60 N(a) and 150 N(b) for 5 h

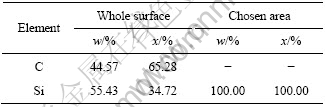

表3和图5所示分别为材料B在150 N实验5 h后,在纤维取向混乱的炭毡处磨损表面形貌及EDAX分析结果。由表3可见,在图5的整个磨损表面,有C和Si元素的存在。但在图5中白色方框内的EDAX分析结果中,仅有Si元素存在,这应是材料内剩余的Si的磨损表面。这表明在摩擦过程中材料A中残留炭未能完全覆盖其磨损表面,不能在整个磨损表面形成炭的摩擦膜。

图5 150 N实验5 h后材料B的磨损表面

Fig.5 morphology for composite B after test at 150 N for 5 h

表3 150 N实验5 h后材料B磨损表面的EDAX分析结果

Table 3 EDAX results for composite B after test at 150 N for 5 h

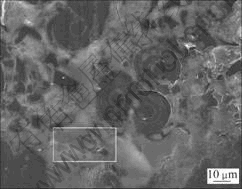

表4和图6所示分别为材料C磨损表面形貌及EDAX分析结果。由图6、表4可见,采用PIP技术制备的C/C-SiC在整个或白色方框内的磨损表面上均含C和Si元素,且C与Si的摩尔比均大于1,从而能在整个磨损表面形成含自由碳的摩擦膜,提高材料的自润滑能力[8]。

图6 150 N实验5 h后材料C的磨损表面

Fig.6 SEM morphology for composite C after test at 150 N for 5 h

表4 150 N实验5 h后材料C磨损表面EDAX的分析结果

Table 4 EDAX results of different areas of composite C after test at 150 N for 5 h

虽然材料A和B采用相同的工艺制备,但材料B的C/C坯体密度低,孔隙率高、孔隙分布连续性好、尺寸大,熔渗后易在坯体内形成大块、连续性较好的SiC并残留较多的Si单质,材料的硬度高[15?16],材料的抗磨损能力高,能承受本实验中的钢对偶以及多种硬质磨粒的磨损,故其摩擦因数随载荷增加的波动幅度小。但随着时间的延长,因受残留炭含量少,自润滑性能差等因素的影响,其摩擦因数随时间延长波动幅度较大。对于材料A,因其C/C坯体密度高,材料内的SiC、残留Si少,受载荷增加的影响大,其摩擦因数下降幅度高;也因其残留炭含量高,在高硬度的对偶、磨粒的作用下形成细小的炭磨屑,能包覆在硬质磨粒表面,降低磨粒对摩擦表面的破坏[5],故材料A 的摩擦因数随时间延长能逐渐趋于平稳。不过在高载荷下,材料A表层被压溃,导致其摩擦因数呈现较大波动。相对于C/C复合材料而言,材料A和B均难以形成完整、致密、自润滑性能良好的摩擦膜,故同等条件下材料A和B的摩擦因数显著高于C/C的。

材料C和D采用PIP技术制备的SiC颗粒细小而松散,在实验中对摩擦膜的磨损小,对材料摩擦行为的影响低,故二者摩擦因数稳定性好。此外,材料内的PIP-SiC硬度高,能适当减少配副间的真实接触面积,降低摩擦阻力,故类似条件下二者的摩擦因数稍低于C/C的。其中,材料C中PIP-SiC的质量分数高于材料D的,影响程度较大,故材料C的摩擦因数随载荷增加的波动幅度略大于材料D的。二者的摩擦磨损机制也以磨粒磨损为主。

4 结论

1) 采用熔渗技术制备的C/C-SiC复合材料的摩擦因数高而不稳定。随载荷增加MSI-SiC质量分数40.9%的材料A摩擦因数比SiC质量分数18.9%的材料B的稳定;随时间延长,除载荷150 N外,材料A摩擦因数的波动幅度高于材料B的波动幅度。

2) 采用PIP技术制备的C/C-SiC复合材料摩擦因数随时间、载荷的变化基本稳定。随载荷增加,PIP-SiC质量分数18.0%的材料C的摩擦因数波动幅度稍大于6.0%的材料D。

3) EDAX分析表明,采用熔渗技术制备、SiC质量分数40.9%的材料部分磨损表面未检测到碳元素存在,故其不能形成完整的含碳的摩擦膜,材料摩擦表面十分粗糙;而采用PIP技术制备,SiC质量分数18.0%的磨损表面的碳硅比大于1,有利于形成含碳的、具有自润滑性能的摩擦膜。

REFERENCES

[1] LEE K J, CHENG H Z, CHEN J S. Effect of densification cycles on continuous friction behavior of carbon–carbon composites[J]. Wear, 2006, 260(1/2): 99?108.

[2] GONG Qian-ming, LI Zhi, ZHANG Zheng-yi, WU Bing, ZHOU Xiang-wen, HUANG Qi-zhong, LIANG Ji. Tribological properties of carbon nanotube-doped carbon/carbon composites[J]. Tribology International, 2006, 39(9): 937?944.

[3] 葛毅成, 易茂中. 载荷、时间、速度对C/C复合材料摩擦磨损行为的影响[J]. 中国有色金属学报, 2006, 16(2): 241?246.

GE Yi-cheng, YI Mao-zhong.  Influence of load, time, speed on sliding tribology behavior of C/C composites[J]. Chinese Journal of Nonferrous Metals, 2006, 16(2): 241?246.

Influence of load, time, speed on sliding tribology behavior of C/C composites[J]. Chinese Journal of Nonferrous Metals, 2006, 16(2): 241?246.

[4] ZHANG, FU qing, HUANG Qi-zhong, HUANG Bai-yun. Characterization of graphitization degree of C/C composites by laser Raman microspectroscopy[J]. Journal of Inorganic Materials, 2003, 18(2): 361?366.

[5] STADLER Z, KRNEL K, KOSMAC T. Friction behavior of sintered metallic brake pads on a C/C-SiC composite brake disc[J]. Journal of the European Ceramic Society, 2007, 27(6): 1411?1417.

[6] KRENKEL W, BERNDT F. C/C-SiC composites for space applications and advanced friction systems[J]. Mater Sci Eng A, 2005(412): 177?181.

[7] KRENKEL W, HERIDENREICH B, RENZ R. C/C-SiC composites for advanced friction systems[J]. Advanced Engineering Materials, 2002, 7(4): 427?436.

[8] MENTZ J, MULLER M, BUCHKREMER H P, STOVER D. Carbon-fibre-reinforced carbon composite filled with SiC particles forming a porous matrix[J]. Mater Sci Eng A, 2006, 425(1/2): 64?69.

[9] RAETHER F, MEINHARDT J, KIENZLE A. Oxidation behaviour of carbon short fibre reinforced C/SiC composites[J]. Journal of the European Ceramic Society, 2007, 27(5): 1217?1221.

[10] 梁锦华, 黄启忠, 苏哲安, 谢志勇. 短纤维C/C-SiC复合材料的组织结构与断裂机制[J]. 中南大学学报: 自然科学版, 2005, 36(6): 924?928.

LIANG Jin-hua, HUANG Qi-zhong, SU Zhe-an, XIE Zhi-yong. Structure and fracturemechanism of short fibre reinforced C/C-SiC composites[J]. J Cent South University: Science and Technology, 2005, 36(6): 924?928.

[11] 肖 鹏, 熊 翔, 张红波, 黄伯云. C/C-SiC陶瓷制动材料的研究现状与应用[J]. 中国有色金属学报, 2005, 15(5): 667?674.

XIAO Peng, XIONG Xiang, ZHANG Hong-bo, HUANG Bai-yun. Progress and application of C/C-SiC ceramic braking material[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 667?674.

[12] 冉丽萍, 易茂中, 王朝胜, 彭 可, 黄伯云. 添加Al对MSI制备C/C-SiC复合材料组织和力学性能的影响[J]. 复合材料学报, 2006, 23(5): 34?38.

RAN Li-ping, YI Mao-zhong, WANG Chao-sheng, PENG Ke, HUANG Bo-yun. Influence of adding Al on the microstructure and mechanical properties of C/C-SiC composites fabricated by MSI[J]. Acta Materiae Compositae Sinica, 2006, 23(5): 34?38.

[13] 邹世钦, 张长瑞, 周新贵, 曹英斌. PIP工艺制备的C/SiC复合材料的氧化行为[J]. 国防科技大学学报, 2005, 27(5): 107?112.

ZOU Shi-qin, ZHANG Chang-rui, ZHOU Xin-gui, CAO Yin-bin. The oxidation behaviors of C/SiC composites prepared by precursor infiltration pyrolysis process[J]. Journal of National University of Defense Technology, 2005, 27(5): 107?112.

[14] PENG Ke, YI Mao-zhong, RAN Li-ping, GE Yi-cheng. Reactive hot pressing of SiC/MoSi2 nanocomposites[J]. Journal of American Ceramic Society, 2007, 90(11): 3708?3711.

[15] XU Yong-dong, ZHANG Ya-ni, CHENG Lai-fei, ZHANG Li-tong, LOU Jian-jun, ZHANG Jun-zhan. Preparation and friction behavior of carbon fiber reinforced silicon carbide matrix composites[J]. Ceramics International, 2007, 33(3): 439?445.

[16] 杨 阳, 熊 翔, 肖 鹏, 旷文敏, 姜四洲. 短炭纤维增强C/C-SiC制动材料的摩擦磨损性能[J]. 中国有色金属学报, 2007, 17(8): 1260?1265.

YANG Yang, XIONG Xiang, XIAO Peng, KUANG Wen-min, JANG Si-zhou. Friction and wear properties of short carbon fiber reinforced C/C-SiC braking materials[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(8): 1260?1265.

基金项目:国家重大基础研究发展计划资助项目(2006CB600906)

收稿日期:2008-03-11;修订日期:2008-07-18

通讯作者:易茂中,教授,博士;电话:0731-8830894;E-mail: yimaozhong@126.com

(编辑 龙怀中)