氧化锌涂覆硼酸镁晶须增强6061铝基复合材料的拉伸性能和热挤压行为

来源期刊:中国有色金属学报(英文版)2015年第2期

论文作者:陈逢源 唐彬彬 金培鹏 张 磊 费维栋

文章页码:412 - 419

Key words:aluminum matrix composites; Mg2B2O5 whisker; coating; extrusion; mechanical properties

摘 要:用挤压铸造法制备不同ZnO包覆量的硼酸镁晶须增强的6061铝基复合材料,并对其进行热挤压处理。对复合材料的显微组织及其力学性能进行研究。结果表明:随着ZnO包覆量的增大,铸态复合材料的弹性模量直线增加。铸态复合材料的极限抗拉强度和屈服强度随ZnO包覆量的增大先增大后减小。然而, 铸态复合材料的伸长率基本一致。经挤压后,复合材料的伸长率大幅增加;无涂层复合材料的极限抗拉强度最大,且其弹性模量有所提高。涂覆ZnO涂层的复合材料中晶须发生明显的折断现象。但是,随着ZnO包覆量的增大,晶须的破坏程度有限。

Abstract: The 6061 aluminum matrix composites reinforced with ZnO-coated Mg2B2O5w were fabricated by squeeze casting method and followed by extruded under a technical equivalent condition. The mechanical properties and microstructures of the composites were investigated. The results showed that the elastic modulus of the as-cast composites increased straightly with increasing ZnO coating content. The ultimate tensile strength and yield strength of the as-cast composites rapidly increased initially and then declined with increasing ZnO coating content. However, the elongations of all the as-cast composites had similar values. The elongations of the composites were highly enhanced and the ultimate tensile strength of the composite without ZnO coating was the largest after extrusion. A number of whiskers in the composites with ZnO coating were fractured during the extrusion process, but the whiskers’ breakage extent was limited with the increase of coating content.

Trans. Nonferrous Met. Soc. China 25(2015) 412-419

Feng-yuan CHEN1, Bin-bin TANG1, Pei-peng JIN1, Lei ZHANG2, Wei-dong FEI1,2

1. School of Mechanical Engineering, Qinghai University, Xining 810016, China;

2. School of Materials and Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 17 March 2014; accepted 20 July 2014

Abstract: The 6061 aluminum matrix composites reinforced with ZnO-coated Mg2B2O5w were fabricated by squeeze casting method and followed by extruded under a technical equivalent condition. The mechanical properties and microstructures of the composites were investigated. The results showed that the elastic modulus of the as-cast composites increased straightly with increasing ZnO coating content. The ultimate tensile strength and yield strength of the as-cast composites rapidly increased initially and then declined with increasing ZnO coating content. However, the elongations of all the as-cast composites had similar values. The elongations of the composites were highly enhanced and the ultimate tensile strength of the composite without ZnO coating was the largest after extrusion. A number of whiskers in the composites with ZnO coating were fractured during the extrusion process, but the whiskers’ breakage extent was limited with the increase of coating content.

Key words: aluminum matrix composites; Mg2B2O5 whisker; coating; extrusion; mechanical properties

1 Introduction

Over the past two decades, metal matrix composites (MMCs) reinforced with a range of reinforcements were employed as structural materials in many fields such as ground transportation, thermal management industry, aerospace, recreation and infrastructure as a consequence of elevated specific modulus and strength as well as their superior wear and thermal resistance [1,2]. Especially, the light metal matrix composites (LMMCs) reinforced with SiC, Si3N4, Al18B4O33, and K4O4Ti whiskers and SiC particles were spurred by efforts in discontinuously reinforced LMMCs, which greatly expanded the scope of MMC systems [3-6].

It is well known that the wettability of whiskers by molten aluminum plays a particularly significant role in determining the mechanical properties of composites. Unfortunately, the wettability is generally poor in many cases. A great number of methods have been proposed to improve the wettability, for instance, the addition of alloying elements to the matrix alloy, coating of the ceramic reinforcements and treatment of ceramic reinforcements [7]. Our previous researches [8,9] indicated that ZnO coating on the surface of whiskers provided effective and feasible means to improve the wettability owing to an interfacial reaction which introduced a strong interface in the composites. However, the hot forming ability of the composites which have a strong interface is unclear.

In addition, magnesium borate whisker (Mg2B2O5 whisker, denoted as MBOw) reinforced magnesium matrix composites have been extensively investigated on account of their absolutely excellent mechanical properties and fairly low cost [10-12]. The production cost of MBOw is much lower since it can be synthesized from the byproducts of seawater desalting or the compounds containing Mg and B originating from saline [13]. Thus, MBOw will have an enormous potential to expand the applications of MMCs in the future. But little work had been done on the Mg2B2O5w/Al composites over the past years.

Furthermore, secondary processing of the discontinuously reinforced composites can lead to the break-up of whiskers (or particles) agglomerates, the reduction or elimination of porosity, and the improved bonding, all of which contribute to improving the mechanical properties of MMCs [14]. Among various classical metal forming procedures, extrusion has been used as the most common secondary processing operation because of its preferential axial alignment of discontinuous whiskers as well as its large compressive hydrostatic stress state [15,16]. However, few studies have been done in relation to the hot extrusion behavior and the tensile properties of the Mg2B2O5w/Al composites with coating.

In the present study, ZnO was coated on the surface of MBOw in order to improve the interface wettability. Subsequently, the composites reinforced with MBOw were extruded. The mechanical properties, fracture mechanism and microstructure characteristics of the as-cast and extruded composites were investigated.

2 Experimental

ZnO was coated on the surface of MBOw with a diameter of 0.5-2 mm and a length of 10-50 mm using chemical precipitation method. At first, zinc nitrate hexahydrate and MBOw were dissolved in distilled water by an ultrasonic vibration technique to prevent whiskers from agglomeration. The solution was then vigorously stirred to form a stable sol. Secondly, dilute NH3·H2O solution was dribbled into the MBOw solution and the compound solution was continuously stirred. Zn(OH)2 began to precipitate on the MBOw surface with the addition of NH3·H2O. The precipitation reaction is

Zn2++2OH-=Zn(OH)2 (1)

It was considered that all of Zn(OH)2 precipitated when the pH value was 7. The MBOw solution was then poured into a preform mold and the whisker preform with Zn(OH)2 could be obtained. Thirdly, the whisker preforms were dried at room temperature for 48 h and sintered at 80 °C and 150 °C for 24 h, respectively. When the preforms were sintered at 150 °C, the following reaction occurred:

Zn(OH)2=ZnO+H2O (2)

At last, the whisker preforms were sintered at 900 °C for 2 h to obtain higher compression strength.

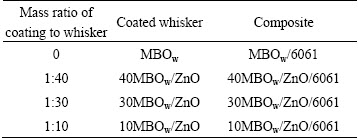

The mass ratios of ZnO to MBOw were selected as 0, 1:40, 1:30 and 1:10 respectively for investigating the effect of coating content on the extrusion behavior of the composites. The 6061 aluminum alloy was employed as the matrix and the MBOw with different ZnO coating contents was used as the reinforcement. The composites were fabricated by squeeze casting method with the molten aluminum of 800 °C and die temperature of 550 °C, and the volume fraction of MBOw in the composites was 25%. The corresponding abbreviations for coated whiskers and composites are listed in Table 1.

Table 1 Corresponding abbreviations for coated whiskers and composites

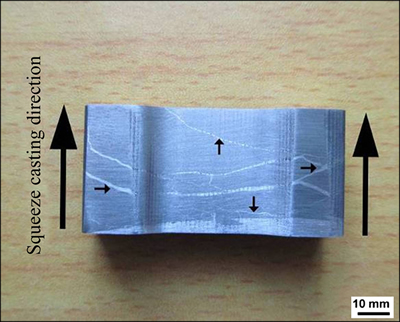

The as-cast composite billets with a diameter of 39 mm and a length of 35 mm were extruded by forward extrusion method at 450 °C with an extrusion ratio of 10:1 and a die angle of 45°. The mixture of graphite powders and high-temperature oil was used as a lubricant. The extruded composites were cooled down in air.

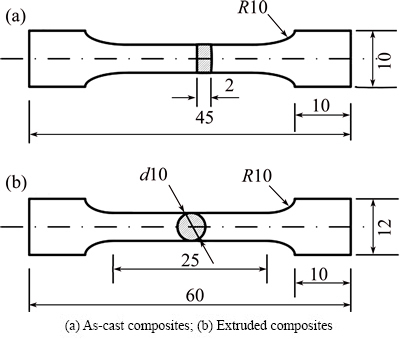

The tensile test was carried out on an Instron-5569 tension machine at room temperature. The dimensions of tensile specimens are shown in Fig. 1. The tensile fractures were observed using a JSM6610LV scanning electron microscope (SEM) and the microstructures of the composites were observed by an LEICA DMI3000M optical microscope (OM).

Fig. 1 Schematic diagrams of tensile specimens (unit: mm)

3 Results and discussion

3.1 Characterization of coated MBOw

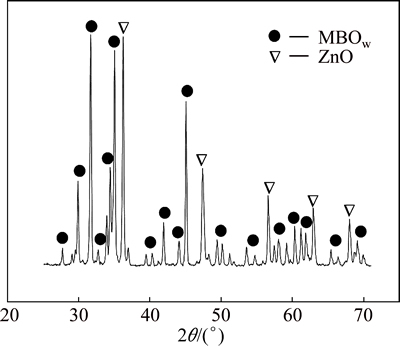

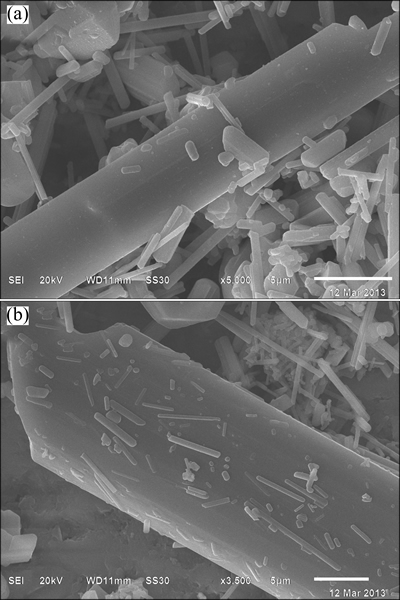

Figure 2 shows the XRD pattern of 10MBOw/ZnO sintered at 900 °C, indicating that no additional diffraction peaks can be found besides those of ZnO and MBOw. Figure 3 shows the SEM images of MBOw and 10MBOw/ZnO sintered at 900 °C. The surface of MBOw is relatively smooth and clear (Fig. 3(a)) and a lot of spherical ZnO particles are uniformly distributed on the surface of the whiskers after coating (Fig. 3(b)).

3.2 Microstructures and mechanical properties of as-cast composites

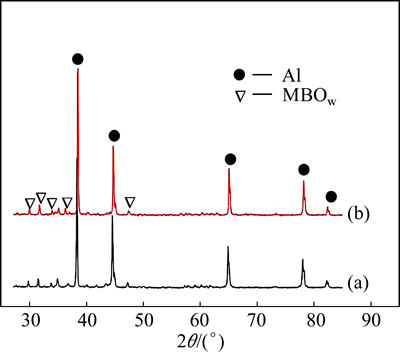

Figure 4 shows the XRD patterns of MBOw/6061 and 10MBOw/ZnO/6061 composites. Only Al and MBOw diffraction peaks can be found in the 10MBOw/ZnO/ 6061 composite, which reveals that ZnO is completely consumed during the squeeze cast route.

Fig. 2 XRD pattern of 10MBOw/ZnO composite sintered at 900 °C

Fig. 3 SEM images of MBOw (a) and 10MBOw/ZnO (b) sintered at 900 °C

Fig. 4 XRD patterns of MBOw/6061 (a) and 10MBOw/ZnO/ 6061 (b) composites

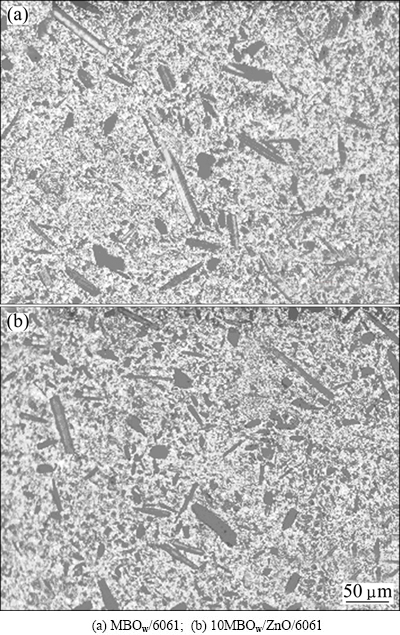

To investigate the distribution of whiskers in the as-cast composites, the microstructures that are parallel to the squeeze casting direction of MBOw/6061 and 10MBOw/ZnO/6061 composites were observed using an optical microscope (Fig. 5). The micrographs for MBOw/ 6061 and 10MBOw/ZnO/6061 composites exhibit a relatively homogeneous whisker distribution with a random orientation.

Fig. 5 OM micrographs of as-cast composites

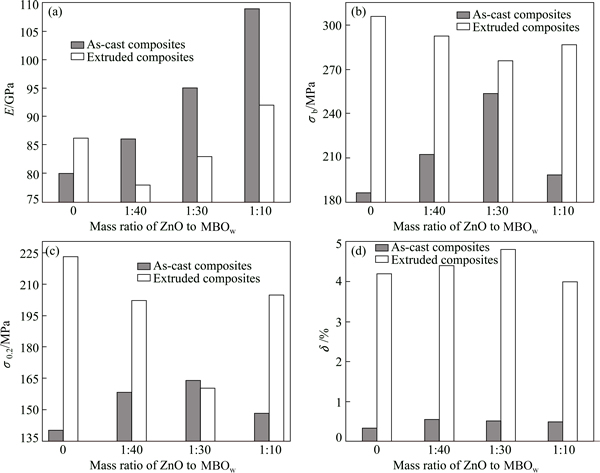

Figure 6 shows the elastic modulus (E), ultimate tensile strength (σb), yield strength (s0.2), and elongation (d) of the as-cast and extruded composites. In the as-cast composites, the elastic modulus increased straightly with increasing ZnO coating content. It was also apparent that the σb and s0.2 increased when the mass ratios of ZnO to MBOw were from 0 to 1:30. Eventually, the σb and s0.2 declined with the increase of the coating content. This implies that an optimal ZnO coating content exists in the as-cast composites. However, the elongation has no obvious improvement after coating.

Fig. 6 Tensile properties of as-cast and extruded composites

The mechanical properties of the as-cast composites were heightened with increasing coating content as the interface of the composites was strengthened. It is well known that there is no reaction between MBOw and aluminum. However, the ZnO coated on the surface of whiskers can react with the molten aluminum during the squeeze casting process [8]. The reaction formula is

3ZnO+2Al=Al2O3+3Zn (3)

Obviously, more Al2O3 was generated at the interface of composites with the increase of coating content and the interfacial bonding was strong. Besides, the strength of the matrix was likewise enhanced with increasing coating content due to the solid solution of Zn. Thus, the elastic modulus increased with increasing coating content. At the beginning, the higher the ZnO coating content is, the stronger the interfacial bonding is, the more load was transferred to the whiskers. Therefore, the sb and s0.2 increased when the mass ratios of ZnO to MBOw were from 0 to 1:30. However, the sb and s0.2 decreased when the coating content increased further (1:10). This was because a lot of alumina inclusions (as shown by arrows in Fig. 7) were generated in the 10MBOw/ZnO/6061 composite during the squeeze casting process. The alumina inclusions were whisker free weak areas in the composites. The cracks could be easily initiated from these areas, and earlier fracture would occur, thus resulting in a lower tensile strength.

Fig. 7 Alumina inclusion on surface of 10MBOw/ZnO/6061 composite

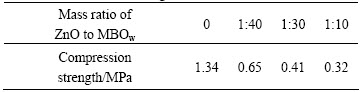

It is known that the contact surface between whiskers in whisker preforms becomes smaller and smaller with increasing coating content. As a result, it was hard for whiskers to bond together when the preforms were sintered at high temperature. Thus, the compression strength of whisker preform, decreased with the increase of coating content (Table 2). The whisker preforms were then easily fractured during the squeeze casting route, and a lot of alumina inclusions were generated in the 10MBOw/ZnO/6061 composite. At the same time, the fractured whisker preforms easily led to the incomplete infiltration of the melt, which contributed to a coarse interface in the 10MBOw/ZnO/6061 composite. Accordingly, the sb and s0.2 decreased when the mass ratio of ZnO to MBOw was 1:10.

Table 2 Compression strength of whisker preforms (MBOw) with increase of ZnO coating content

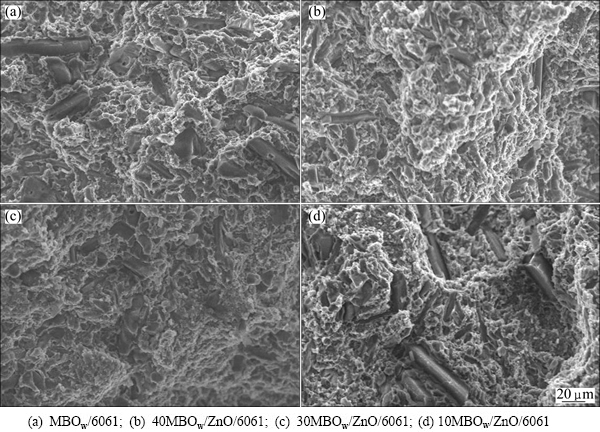

The elongations of as-cast composites were low owing to the high volume fraction of ceramic reinforcement. Figure 8 shows the fracture mechanism of the as-cast composites. The evident interfacial debond was found in the MBOw/6061 and 10MBOw/ZnO/6061 composites (Figs. 8(a) and (d)). In the MBOw/6061 composite, this was because the wettability of whiskers by molten aluminum was poor. The low compression strength of whisker preforms resulted in incomplete infiltration of aluminum melt in the 10MBOw/ZnO/6061 composite, which was a main reason for a coarse interface. The coarse interface debonded when the imposed load was employed. However, the interfacial debond phenomena reduced in the 40MBOw/ZnO/6061 composite as the ZnO coated on the surface of whiskers enhanced bond strength of the interface. Few interfacial debond can be found in the 30MBOw/ZnO/6061 composite, which showed that the interfacial bond strength was particularly high. The indication accounted again for the highest tensile strength of the 30MBOw/ ZnO/6061 composite.

3.3 Mechanical properties and microstructures of extruded composites

The elastic modulus, ultimate tensile strength, yield strength and elongation of the extruded composites were compared with those of the as-cast composites. Only the elastic modulus of the MBOw/6061 composite could be enhanced after extrusion. The sb and s0.2 of extruded composites were improved except for the s0.2 of the 30MBOw/ZnO composite. However, the sb and s0.2 of the extruded composites had a marked decline at the beginning and then rose with the increase of ZnO coating content. The elongation of extruded composites was highly improved compared with that of the as-cast composites. The elongation of the 30MBOw/ZnO composite can reach 4.8% after the extrusion.

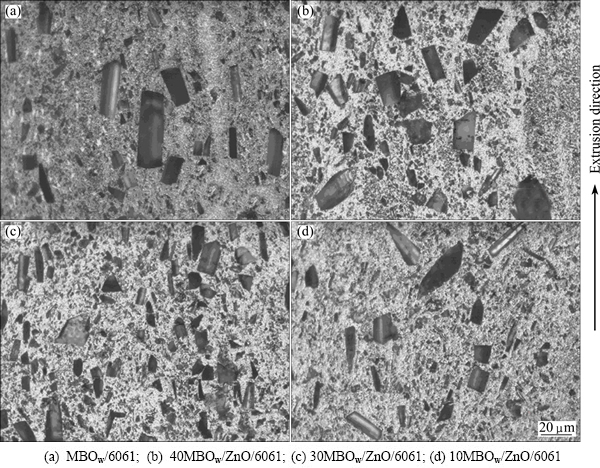

The improvement of different extents of mechanical properties of the extruded composites was attributed to the decreased porosity level and the improved microstructures. The pores and defects formed during the casting process as the poor wettability was improved during the extrusion process. The porosity level of the composites was eventually reduced after the extrusion. Besides, it was caused by the work-hardening of the matrix due to the high density of dislocations generated by the extrusion deformation. Moreover, this was further caused by the directional alignment of the longer whiskers. Figure 9 shows the whiskers’ arrangement of the extruded composites, which displayed the longer whiskers aligning along the extrusion direction.

Fig. 8 Tensile fractographs of different as-cast composites

Fig. 9 OM micrographs of different extruded composites in longitudinal direction

Therefore, more whiskers bear the load in the longitudinal direction. Figure 9 also revealed that the whiskers that had a regular shape were more seriously fractured than the whiskers that had an irregular shape in the extrusion process. Additionally, a small amount of whiskers that have a large aspect ratio and irregular shape did not align along the extrusion direction as the whiskers hardly rotated during the plastic deformation process (Figs. 9(b) and (d)). The elastic modulus of the composites with ZnO coating decreased after the extrusion because the strong interface was broken and the whiskers were seriously fractured during the extrusion process. Whiskers breakage behavior was more and more serious with increasing the ZnO coating content (Figs. 9(a)-(c)). Especially, almost all the whiskers were fractured in the 30MBOw/ZnO/6061 composite (Fig. 9(c)). However, the whisker breakage extent in the 10MBOw/ZnO/6061 composite was lower than that in the 30MBOw/ZnO composite, which revealed that the whisker breakage was limited with the increase of the coating content during the extrusion process. As a result, the sb and s0.2 of the extruded composites had a marked decline at the beginning and then rose with the increase of ZnO coating content. Besides, almost all the whiskers were fractured in the 30MBOw/ZnO/6061 composite and the matrix was then easily yielded, which gave rise to the fact that the s0.2 of the extruded 30MBOw/ZnO/6061 composite was lower than that of the as-cast composite. The sb of the extruded MBOw/6061 composite was the highest as the whiskers maintained a larger aspect ratio than those of composites with ZnO coating.

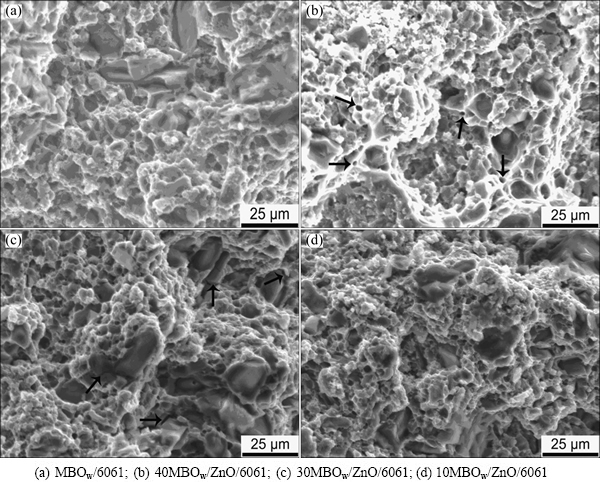

The increased elongation of the composites after the extrusion was attributed to the increase of plastic deformation capacity of the composites compared with the as-cast composites. Figure 10 illustrates the fracture mechanism of the extruded composites, which shows that every tensile fracture surface has obvious characteristics of fracture toughness. Many holes generated by the pulling out of whiskers during the tensile test process could be found in the 40MBOw/ZnO/6061 composite (as shown by arrows in Fig. 10(b)). It was quite difficult to see the fracture and the pulling out of whiskers in the MBOw/6061 composite. There were numerous microcracks in the matrix of 30MBOw/ZnO/6061 composite (as shown by arrows in Fig. 10(c)). This is maybe caused by thermal mismatch stress between the whiskers and the matrix. No obvious characteristics can be found in the 10MBOw/ZnO/6061 composite. The elongation of the 30MBOw/ZnO/6061 composite was the highest as the optimal interfacial bonding was damaged and the plastic of the matrix played an absolutely crucial role in the fracture of the composite. Reference [17] revealed that the coarse MgAl2O4 with a high brittleness at the interface was easy to fracture, decreasing the mechanical properties of Al18B4O33w/6061Al composite considerably. In the present study, the coarse Al2O3 with a high brittleness at the interface was easy to fracture with the increase of ZnO coating content. Accordingly, the elongation decreased when the mass ratio of ZnO to whisker was 1:10.

Fig. 10 Tensile fractographs of different extruded composites

4 Conclusions

1) The ZnO coating content obviously affects the mechanical properties of the as-cast MBOw/ZnO/6061 composites. The elastic modulus increased straightly with increasing ZnO coating content. The sb, s0.2 and elongation of the as-cast composites initially increased and then declined with increasing ZnO coating content.

2) After the extrusion, the sb of the MBOw/6061 composite and the elongation of the 30MBOw/ZnO/6061 composite were the highest.

3) The whisker breakage is limited with the increase of ZnO coating content during the extrusion process.

References

[1] MIRACLE D B. Metal matrix composites—From science to technological significance [J]. Composites Science and Technology, 2005, 65: 2526-2540.

[2] ZHANG Gui-feng, SU Wei, ZHANG Jian-xun, SUZUMURA A. Development of Al-12Si-xTi system active ternary filler metals for Al metal matrix composites [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 596-603.

[3] GENG L, WU K, YAO G K. SiC-Al Interface crystallographic orientation relationship in a squeeze-cast SiCw/Al composite [J]. Materials Characterization, 1995, 34: 227-229.

[4] NING X G, PAN J, LI J H, HU K Y, YE H Q, FUKUNAGA H. The whisker-matrix interfacial reactions in SiC, Si3N4 and Al18B4O33 whisker-reinforced aluminum-matrix composites [J]. Journal of Materials Science Letters, 1993, 12: 1644-1647.

[5] SUGANUMA K, FUJITA T, SUZUKI N, NIIHARA K. Aluminum composites reinforced with a new aluminum borate whisker [J]. Journal of Materials Science Letters, 1990, 9: 633-635.

[6] PERIYASAMY P, MOHAN B, BALASUBRAMANIAN V, RAJAKUMAR S, VENUGOPAL S. Multi-objective optimization of friction stir welding parameters using desirability approach to join Al/SiCp metal matrix composites [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 942-955.

[7] HASHIM J, LOONEY L, HASHMI M S J, MATER J. The wettability of SiC particles by molten aluminum [J]. Journal of Materials Processing Technology, 2001, 119: 324-328.

[8] YUE H Y, FEI W D, LI Z J, WANG L D. Effects of ZnO coating on the wettability and tensile properties of aluminum borate whisker reinforced aluminum composite [J]. Materials Science and Engineering A, 2006, 441: 197-201.

[9] JIN Pei-peng, HAN Li, CHEN Shan-hua, WANG Jin-hui, ZHU Yun-peng. Microstructure and tensile properties of ZnO-coated magnesium borate whisker reinforced AZ31B composite [J]. Materials Science and Engineering A, 2012, 554: 48-52.

[10] LI Jian-guo, XIA Cun-juan, ZHANG Yi-jie, WANG Ming-liang, WANG Hao-wei. Effects of TiO2 coating on microstructure and mechanical properties of magnesium matrix composite reinforced with Mg2B2O5w [J]. Materials and Design, 2012, 39: 334-337.

[11] CHEN S H, JIN P P, SCHUMACHER G, WANDERKA N. Microstructure and interface characterization of a cast Mg2B2O5 whisker reinforced AZ91D magnesium alloy composite [J]. Composites Science and Technology, 2010, 70: 123-129.

[12] LI Jian-guo, WANG Fei-fei, WENG Wei, ZHANG Yi-jie, WANG Ming-liang, WANG Hao-wei. Characteristic and mechanical properties of magnesium matrix composites reinforced with Mg2B2O5w and B4Cp [J]. Materials and Design, 2012, 37: 533-536.

[13] ZHU Dong-hai, NAI Xue-ying, ZHU Cheng-cai, GUO Feng-qin, BIAN Shao-ju, LI Wu. Synthesis of Mg2B2O5 whiskers via coprecipitation and sintering process [J]. International Journal of Minerals, Metallurgy and Materials, 2012, 19 (10): 969-972.

[14] KANG C G, KIM N H, KIM B M. The effect of die shape on the hot extrudability and mechanical properties of 6061 Al/Al2O3 composites [J]. Journal of Materials Processing Technology, 2000, 100: 53-62.

[15] STANFORD-BEALE C A, CLYNE T W. Extrusion and high-temperature deformation of fibre-reinforced aluminium [J]. Composites Science and Technology, 1989, 35: 121-157.

[16] WANG Xiao-jun, HU Xiao-shi, NIE Kai-bo, WU Kun, ZHENG Ming-yi. Hot extrusion of SiCp/AZ91 Mg matrix composites [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1912-1917.

[17] GAO H Q, WANG L D, FEI W D. Interfacial reaction and tensile strength of copper-coated Al18B4O33 whisker reinforced 6061 Al composite [J]. Materials Science and Engineering A, 2008, 479: 261-268.

陈逢源1,唐彬彬1,金培鹏1,张 磊2,费维栋1, 2

1. 青海大学 机械工程学院,西宁 810016;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001

摘 要:用挤压铸造法制备不同ZnO包覆量的硼酸镁晶须增强的6061铝基复合材料,并对其进行热挤压处理。对复合材料的显微组织及其力学性能进行研究。结果表明:随着ZnO包覆量的增大,铸态复合材料的弹性模量直线增加。铸态复合材料的极限抗拉强度和屈服强度随ZnO包覆量的增大先增大后减小。然而, 铸态复合材料的伸长率基本一致。经挤压后,复合材料的伸长率大幅增加;无涂层复合材料的极限抗拉强度最大,且其弹性模量有所提高。涂覆ZnO涂层的复合材料中晶须发生明显的折断现象。但是,随着ZnO包覆量的增大,晶须的破坏程度有限。

关键词:铝基复合材料;Mg2B2O5晶须;涂层;挤压;力学性能

(Edited by Wei-ping CHEN)

Foundation item: Project (2011CB612200) supported by the National Basic Research Program of China

Corresponding author: Pei-peng JIN; Tel: +86-971-5363028; E-mail: jinpeipeng@hotmail.com

DOI: 10.1016/S1003-6326(15)63618-4