文章编号:1004-0609(2013)07-1826-07

挤压比对粉末热挤压制备铝基复合材料组织和力学性能的影响

马国俊1, 2,丁雨田1,金培鹏2,刘国龙1

(1. 兰州理工大学 有色金属新材料国家重点实验室,兰州 730050;

2. 青海大学 金属材料研究所,西宁 810016)

摘 要:采用粉末热挤压法制备硼酸镁晶须增强铝基复合材料,研究不同挤压比对挤压态复合材料微观组织和性能的影响。结果表明:随着挤压比的增加,硼酸镁晶须的排布取向逐渐趋向于材料的热挤压方向,晶须长径比有所减小,挤压比为25:1时,材料力学性能达到最佳值,屈服强度、极限拉伸强度及伸长率分别为113.5 MPa、230 MPa和7.0%;拉伸强度(UTS)相比挤压态的6061铝合金和挤压比为9:1的复合材料分别提高了37%和25%;拉伸断口分析表明,材料的失效形式以6061Al基体的韧性断裂、晶须与基体间的脱粘以及晶须团聚体的脆性开裂3种形式为主。

关键词:铝基复合材料;硼酸镁晶须;热挤压;断口

中图分类号:TB331 文献标志码:A

Influence of extrusion ratio on microstructure and mechanical properties of Al matrix composites by hot extrusion of powders

MA Guo-jun1, 2, DING Yu-tian1, JIN Pei-peng2, LIU Guo-long1

(1.State Key Laboratory of Gansu Advanced Non-ferrous Metal Materials, Lanzhou University of Technology, Lanzhou 730050, China;

2.Institute of Metal Materials, Qinghai University, Xining 810016, China)

Abstract: The Mg2B2O5 whisker reinforced Al matrix composites were fabricated using powder metallurgy routes. The effects of different extrusion ratios on the microstructure and tensile strength of composites were investigated. The results show that the alignment of Mg2B2O5 whisker along the extrusion direction is improved and the aspect ratio decreases with increasing extrusion ratio, meanwhile, the composites exhibit the best mechanical properties at the extrusion ratio of 25:1. Respectively, the yield strength, the tensile strength and the elongation of the extruded composites is 113.5 MPa, 230 MPa and 7.0%. The tensile strength increases by 37% and 25%, in comparison with the aluminum and composites. According to the analysis of fracture, the ductile failure of 6061Al matrix, the reinforcement fracture and the whisker-matrix interface debonding act as the main mechanism of fracture nucleation.

Key words: Al matrix composites; Mg2B2O5 whisker; hot extrusion; fracture

非连续陶瓷相增强铝基复合材料以高比强度、比模量、良好的尺寸稳定性和耐磨性等一系列优异的综合性能在军事、航空航天、汽车、机械等领域得到广泛的应用[1-3]。硼酸镁(Mg2B2O5)晶须是海水淡化副产品和盐湖资源的开发产物,它作为铝基复合材料的增强体,具有接近于碳化硅晶须的性能,但价格仅为碳化硅晶须的1/20~1/30,是一种性价比非常高的增强 相[4-5],从而展示出非常诱人的应用前景。

目前,晶须增强铝基复合材料的制备工艺包括挤压铸造[6-7]和粉末冶金等方法[8-9]。挤压铸造法对界面润湿性的考虑要小,在制备复合材料的过程中,简化了涂层工艺,通过控制挤压温度、预热温度、挤压压力等参数,能获得增强体随机取向并均匀分布的铝基复合材料,但这种方法缺点在于显微组织中容易出现增强体的偏聚重融、夹杂、显微缩孔及裂纹等缺陷,此外,由于挤压铸造压力大,如何保证增强体预制件的质量,降低孔隙度也是困扰这种方法的关键所在[10];采用传统的粉末冶金法制备铝基复合材料时,存在工艺流程长、工序复杂、生产成本高等一系列问题[11-12]。在本实验中,采用了将粉末冶金与后续致密化处理(挤压)结合起来的粉末成形工艺,这种工艺使粉末能够在短时高温、高压作用下发生塑性变形, 进而实现粉末颗粒间的结合,此外,这种方法无需烧结,制备工序少,成本低。

影响复合材料强度和塑性的因素主要包括制备方法、微观组织以及具体工艺参数的选择等。对于制备硼酸镁晶须增强铝基复合材料的粉末热挤压方法而言,控制微观组织结构、优化制备工艺是获得优异综合性能的关键。许多文献[13-17]报道了铝基复合材料各种制备工艺参数和微观组织对强度的影响,但使用粉末热挤压工艺制备晶须增强铝基复合材料的相关报道较少。因此,本文作者以研制具有高性价比,高强度和相对较高塑性的复合材料结构件为背景,采用粉末热挤压工艺制备体积分数10%Mg2B2O5w/6061铝基复合材料,测定材料在挤压态下的拉伸性能,分析复合材料的微观组织结构,论述晶须增强铝基复合材料制备工艺的改进和复合材料的断裂形式,为实际复合材料结构件制备工艺路线的设计和工艺参数的优化提供实验依据。

1 实验

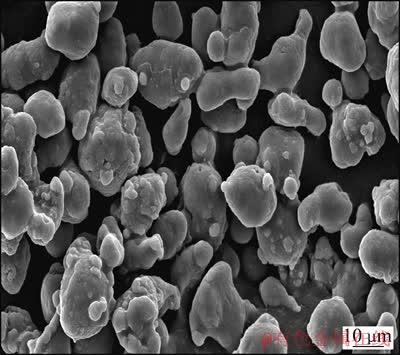

实验选用6061铝合金作为基体合金,这种铝合金具有较高的强度、良好的耐腐蚀性能以及优异的成型性能[18],基本成分如表1所列。通过激光粒度仪对6061铝粉颗粒尺寸进行测定,其平均粒径尺寸为22.7 μm。

图1和2所示分别为6061铝粉及硼酸镁晶须的微观组织形貌。由图1可以看出,铝颗粒近似球状,且颗粒尺寸相对均匀;由图2可以看出,硼酸镁(Mg2B2O5)晶须呈短纤维状且表面相对光滑,晶须直径范围为0.5~1.5 μm,长度在10~80 μm左右,长径比为5~20左右不等。

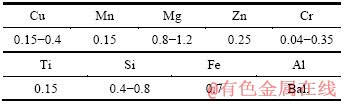

表1 6061铝合金粉末的基本成分

Table 1 Nominal composition of the 6061 matrix alloy (mass fraction, %)

图1 6061铝粉的SEM像

Fig. 1 SEM image of 6061Al powders

图2 硼酸镁晶须的SEM像

Fig. 2 SEM image of Mg2B2O5 whisker

实验过程中,将10%Mg2B2O5晶须与铝合金粉末混合均匀后,在行星式球磨机中进行球磨,磨球选用Al2O3陶瓷,球料比10:1,球磨时间12 h,再将粉末预压成坯,坯件直径60 mm,随后热挤压成型制备出铝基复合材料。

图3所示为Mg2B2O5晶须与铝合金粉末的混粉球磨12 h后的微观形貌。由图3可以看出,球磨后的6061铝粉颗粒形状不规则,表面有不同程度的点蚀和剥落,晶须有一定程度的折断且均匀分布在铝合金粉末周围。

图3 球磨12 h后的Mg2B2O5w/6061Al复合粉末形貌

Fig. 3 SEM image of Mg2B2O5w/6061Al mixture powder after 12 h milling

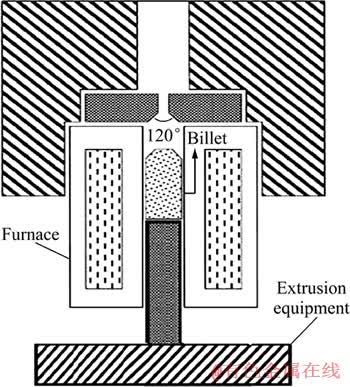

挤压装置示意图如图4所示,挤压锥角60o,挤压比分别为9:1、16:1、25:1和36:1,挤压后所得的棒材直径分别为33、19、12和8 mm。挤压温度为530 ℃,挤压前对挤压模具壁均匀涂覆定量的润滑剂。

图4 粉末热挤压装置示意图

Fig. 4 Schematic diagram of extrusion press for powder blend compact

图5所示为挤压比25:1、热挤压温度530 ℃时,不同挤压速度下复合材料的表面形貌。通过调整挤压压力将挤压模头速度控制在2~3 mm/min时,得到棒材直径12 mm、表面连续光滑的试样,如图5(a)所示;若挤压速度过快,挤压棒材表面呈现鱼鳞状,如图5(b)和(c)所示。

轴向拉伸试样按GB7963—87加工成d5 mm×25 mm的标准试样,在Instron1195电子拉伸机上测定其室温力学性能,拉伸速度为2 mm/min;复合材料的微观组织及拉伸断口在JSM-6700F场扫描电镜上进行观察分析。

图5 挤压比为25:1时不同挤压速度下的挤压态复合材料的表面形貌

Fig. 5 Surface morphologies of extruded composite samples (25:1) at various velocities

2 实验结果

2.1 复合材料的热挤压态组织

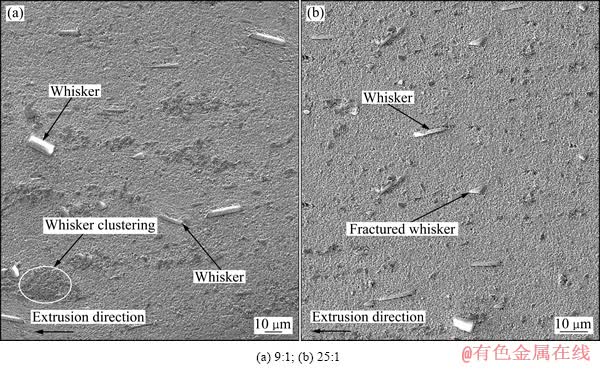

图6(a)和(b)所示分别为不同热挤压比(9:1、25:1)铝基复合材料的纵向显微组织。由图6(a)可见,当挤压比为9:1时,晶须发生不同程度的折断,相比球磨前的晶须,长径比有所减小,此外,部分位置存在晶须的团簇;当挤压比为25:1时,晶须的折断现象更加明显,但相比挤压比为9:1的材料,晶须的分散更加均匀,团簇现象明显减少,如图6(b)所示。

2.2 挤压态复合材料晶须的取向分布

VIPIN等[19]在研究磁控溅射纳米TiN薄膜的结构特征时,通过采用织构因子对沉积不同时间后TiN薄膜的结构取向进行分析,有效地反映出材料择优取向的变化,其所谓的织构因子(T)即XRD衍射三强峰中某一峰值的相对强度与三强峰相对强度之和的比值,即:

T=I(hikili)/[I(h1k1l1+h2k2l2+h3k3l3)] (i=1,2,3)

在本实验中,对4种挤压比下的挤压件进行了XRD衍射,并对4种状态下Mg2B2O5晶须的织构因子变化进行了分析,图7所示为不同挤压比复合材料的XRD谱及织构因子变化。

由于晶须的部分衍射峰与铝合金基体重合,因此我们在实验过程中选取了晶须较明显的3个峰进行分析,如图7(a)所示。通过实验发现,材料经过热挤压后,晶须的分布沿(100)晶面存在择优取向,且随着挤压比的增加这种趋势愈发明显,但当挤压比超过25:1后,由于晶须折断率较高,一定程度上减少了晶须沿(100)面的定向排布,如图7(b)所示。

图6 不同挤压比Mg2B2O5w/6061铝基复合材料纵向显微组织

Fig. 6 SEM micrographs of Mg2B2O5w/6061Al composites at different extrusion ratios

图7 不同挤压比复合材料的XRD谱及织构因子变化

Fig. 7 XRD patterns (a) and texture coefficients (b) of composites at different extrusion ratios

2.3 室温拉伸性能及断口形貌

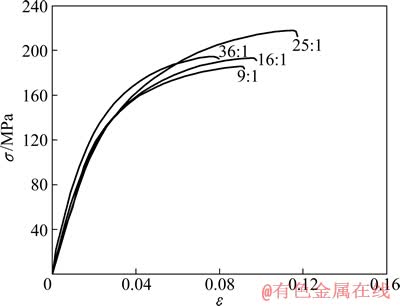

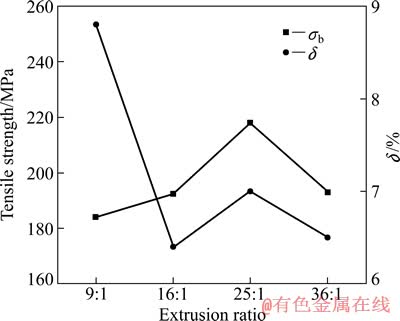

图8所示为不同挤压比晶须增强铝基复合材料的应力—应变曲线,图9所示为复合材料力学性能随挤压比的变化曲线。结合图8和9可知,随着挤压比的增加,复合材料的抗拉强度逐渐增大,挤压比为25:1时材料拉伸强度达到最佳,伸长率随挤压比的增加总体呈下降趋势;热挤压态Al合金及复合材料的力学性能及所测密度如表2所列。与同种工艺制备的挤压态6061铝合金和挤压比为9:1的复合材料相比,挤压比为25:1的复合材料的拉伸强度(UTS)分别提高了37%和25%;与基体相比,复合材料的伸长率明显降低,说明复合材料强度的增加是以牺牲塑性为代价的,尽管如此,7%的伸长率也体现出材料一定程度的塑性;此外,由表2可见,随着挤压比的增加,复合材料的实测密度也有所增加。

图8 不同挤压比热挤压态Mg2B2O5w/6061铝基复合材料应力—应变曲线

Fig. 8 Tensile stress—strain curves of as-hot extruded Mg2B2O5w/6061 composites at different extrusion ratios

图9 挤压比对Mg2B2O5w/6061铝基复合材料力学性能的影响

Fig. 9 Effect of extrusion ratio on mechanical properties of Mg2B2O5w/6061Al composites

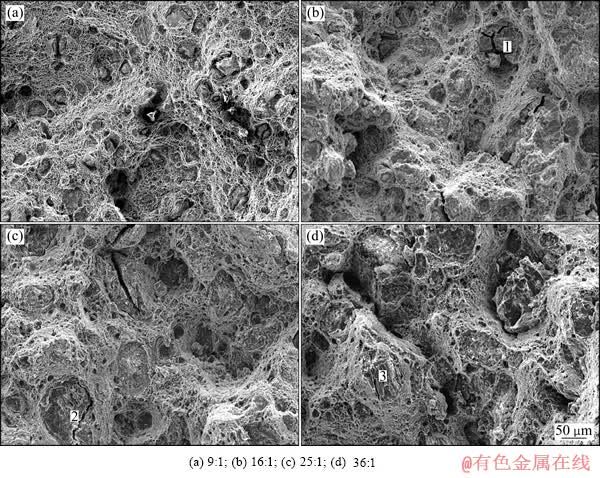

图10所示为不同挤压比的热挤压态复合材料室温拉伸断口形貌。复合材料在拉伸时没有明显的颈缩现象,塑性也很低,宏观上表现为脆性断裂,但不同挤压比的断口都呈现出代表塑性断口特征的韧窝形貌。

表2 热挤压态6061Al合金及其复合材料的性能及密度

Table 2 Tensile properties and densities of hot-extruded 6061Al and composites

3 讨论

3.1 断口分析

由图9所示,复合材料在挤压比为9:1时伸长率相对较高,拉伸强度相对较低,这与图10(a)所示断口上表现出的韧窝数量多、断裂的晶须数量少以及断口起伏较大等微观组织特征相一致;随着挤压比的增大,在微观组织形貌上可以看到韧窝的平均尺寸逐渐减小,且代表脆性断口特征的平面逐渐增加。图10(b)~(d)的位置1、2和3处有较大的裂纹,能谱分析表明均为Mg2B2O5晶须,表面干净且没有基体合金组织,但主要以团聚体的形式存在。当复合材料受力时,外力就会由基体通过结合良好的界面传递给晶须,结果导致晶须增强体的开裂;基体则后于团聚体发生韧性断裂,形成众多小韧窝;对于分散较好的晶须,因其自身没有缺陷,在高挤压比下与基体结合良好,对强度的贡献较大。但是由于增强体晶须和基体合金在各方面性能上存在明显的不同,如弹性模量等,这将使得材料在随着施加应力的增加后,界面处的剪切应力提高,剪切应力值一旦超过晶须与基体的界面结合强度的极限,将出现界面脱粘现象。拉伸断口的形貌表明复合材料的断裂机制主要为基体的韧性断裂、晶须与基体间的脱粘以及晶须团聚体的脆性开裂3种形式。

图10 Mg2B2O5w/6061铝基复合材料断口形貌

Fig. 10 Fracture surface morphologies of Mg2B2O5w/6061Al composites at different extrusion ratios

3.2 力学性能分析

大挤压比有利于提高复合材料的强度,其原因主要在于热挤压过程中材料的大塑性变形有利于进一步改善增强体的分布和增强体与铝合金基体之间的界面结合[20],这使得铝基复合材料在受力时,增强体晶须与基体在界面处能够更加有效的进行载荷传递,从而使材料的力学性能得到提高。由图9可见,随着挤压比的增加,抗拉强度逐渐增大,当挤压比为25:1的复合材料与同种工艺制备的挤压态的6061铝合金和挤压比为9:1的复合材料相比时,其拉伸强度(UTS)分别提高了37%和25%;尽管如此,由实测的Mg2B2O5w/ 6061铝基复合材料纵向拉伸强度随挤压比的变化情况可知,复合材料的强度并不随挤压比的增加而单调增加,在挤压比为36:1时,其拉伸强度有所降低。

这是由于挤压过程中还存在着决定强度大小的其他两个因素,即晶须的折断率和晶须的定向排列程度。在热挤压过程中,复合材料受到三维压应力作用后,作为塑性流动性较好的铝合金产生两边压缩而一方向延伸的塑性流动,基体沿热挤压方向延展;Mg2B2O5晶须作为“刚体”,硬度高,塑性差,很难发生塑性变形,而是随着基体的流动作相应的转动,并在晶须与铝合金基体界面处的切应力作用下调整方向,整体上造成晶须的方向沿着材料的热挤压方向排布;此外,随着热挤压比的增加,在热挤压过程中Mg2B2O5晶须发生不同程度的折断。这两种因素以相反的方式影响着复合材料的拉伸强度,晶须的排布越趋于热挤压方向,材料的拉伸强度越高,而其长径比越小,即折断率越高拉伸强度就越低[21]。由图6和7可知,当热挤压比为25:1时,晶须的分布相对均匀,且保留了一定的长径比,此外晶须定向排列程度在此挤压比下达到最佳,因而具有良好的增强效果,证实了在力学性能中的测试结果。

4 结论

1) 随着挤压比的增加,Mg2B2O5晶须的分散更加均匀化,但晶须的折断程度呈递增趋势变化;此外热挤压过程促进了晶须的定向排布。

2) 随着挤压比的增加,复合材料的拉伸强度在挤压比为25:1时达到最高值,随后呈下降趋势;其伸长率随着挤压比的增加有所降低。

3) 复合材料的断裂机制主要为基体的韧性断裂、晶须与基体间的脱粘以及晶须团聚体的脆性开裂3种形式。

REFERENCES

[1] MIRACLE D B. Metal matrix composites—From science to technological significance[J]. Composites Science and Technology, 2005, 65(15/16): 2526-2540.

[2] ORTEGA-CELAYA F, PECH-CANUL M I,  J C, PECH-CANUL M A. Microstructure and impact behavior of Al/SiCp composites fabricated by pressureless infiltration with different types of SiCp Original Research Article[J]. Journal of Materials Processing Technology, 2007, 183(2/3): 368-373.

J C, PECH-CANUL M A. Microstructure and impact behavior of Al/SiCp composites fabricated by pressureless infiltration with different types of SiCp Original Research Article[J]. Journal of Materials Processing Technology, 2007, 183(2/3): 368-373.

[3]  ZrC particle reinforced Al-4wt.%Cu alloy composites fabricated by mechanical alloying and vacuum hot pressing: Microstructural evaluation and mechanical properties[J]. Materials Science and Engineering A, 2010, 527(21/22): 5930-5938.

ZrC particle reinforced Al-4wt.%Cu alloy composites fabricated by mechanical alloying and vacuum hot pressing: Microstructural evaluation and mechanical properties[J]. Materials Science and Engineering A, 2010, 527(21/22): 5930-5938.

[4] 金培鹏, 丁雨田, 刘孝根, 王金辉, 王 府. 硼酸镁晶须增强镁基复合材料的摩擦性能及磨损行为[J]. 中国有色金属学报, 2009, 19(3): 452-458.

JIN Pei-peng, DING Yu-tian, LIU Xiao-gen, WANG Jin-hui, WANG Fu. Tribological properties and wear behavior of Mg2B2O5w/AZ91D magnesium alloy matrix composites[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(3): 452-458.

[5] 马正先, 王万起, 刘 豹, 马志军. 硼酸镁晶须应用研究进展[J]. 矿产综合利用, 2008(6): 37-39.

MA Zheng-xian, WANG Wan-qi, LIU Bao, MA Zhi-jun. Progress in applied research of magnesium borate whisker[J]. Multipurpose Utilization of Mineral Resources, 2008(6): 37-39.

[6] YUE H Y, WANG L D, FEI W D. Effect of ZnO coating of whiskers on thermal expansion properties of aluminum borate whisker reinforced aluminum composites[J]. Materials Science and Technology, 2009, 25(8): 1035-1038.

[7] 俞泽民, 吴叶伟, 岳红彦, 费维栋. ZnAl2O4 涂覆Al18B4O33(w)增强6061Al复合材料界面结构与拉伸性能[J]. 复合材料学报, 2008, 25(3): 132-137.

YU Ze-min, WU Ye-wei, YUE Hong-yan, FEI Wei-dong. Interfacial microstructure and tensile properties of 6061Al matrix composite reinforced with ZnAl2O4-coated Al18B4O33 whiskers[J]. Acta Materiae Compositae Sinica, 2008, 25(3): 132-137.

[8] RODRIGO P, POZA P, UTRILLA V,  A. Effect of reinforcement geometry on precipitation kinetics of powder metallurgy AA2009/SiC composites[J]. Journal of Alloys and Compounds, 2009, 479(1/2): 451-456.

A. Effect of reinforcement geometry on precipitation kinetics of powder metallurgy AA2009/SiC composites[J]. Journal of Alloys and Compounds, 2009, 479(1/2): 451-456.

[9] CORROCHANO J, CERECEDO C,  Whiskers of Al2O3 as reinforcement of a powder metallurgical 6061 aluminium matrix composite[J]. Materials Letters, 2008, 62(1): 103-105.

Whiskers of Al2O3 as reinforcement of a powder metallurgical 6061 aluminium matrix composite[J]. Materials Letters, 2008, 62(1): 103-105.

[10] 李正佳, 李贺军, 齐乐华, 欧阳海波, 魏 剑. 液态浸渗挤压制备(AlBO)w/Al复合材料缺陷分析[J]. 稀有金属材料与工程, 2007, 36(12): 2144-2147.

LI Zheng-jia, LI He-jun, QI Le-hua, OUYANG Hai-bo, Wei Jian. Defects analysis of (AlBO)w/Al composites[J]. Rare Metal Materials and Engineering, 2007, 36(12): 2144-2147.

[11] 祖丽君, 罗守靖, 张洪彦. 半固态挤压SiCp/2024 复合材料的组织性能研究及缺陷分析[J]. 哈尔滨工业大学学报, 2000, 32(5): 69-72.

ZU Li-jun, LUO Shou-jing, ZHANG Hong-yan. Microstructure, properties and defect of SiCp/2024 composites fabricated by semi-solid extrusion[J]. Journal of Harbin Institute of Technology, 2000, 32(5): 69-72.

[12] 肖伯律, 马宗义, 王全兆, 倪丁瑞, 毕 敬. 高性能铝基复合材料的设计与加工技术[J]. 中国材料进展, 2010, 29(4): 29-35.

XIAO Bo-lü, MA Zong-yi, WANG Quan-zhao, NI Ding-rui, BI Jing. An overview of high performance aluminum matrix composites design and processing technologies[J]. Materials China, 2010, 29(4): 29-35.

[13] 孙旭炜, 曾苏民, 陈志谦, 程南璞, 甘秉太. 制备工艺对铝基复合材料增强体颗粒分布均匀性的影响[J]. 材料工程, 2006(9): 27-30.

SUN Xu-wei, ZENG Su-min, CHEN Zhi-qian, CHENG Nan-pu, GAN Bing-tai. Effect of fabricating parameters on spatial distribution of reinforcements in aluminum matrix composites[J]. Journal of Materials Engineering, 2006(9): 27-30.

[14] SHOWAITER N, YOUSEFFI M. Compaction, sintering and mechanical properties of elemental 6061 Al powder with and without sintering aids[J]. Materials and Design, 2008, 29(4): 752-762.

[15] ZHAO P T, WANG L D, DUA Z M, Xu S C, JIN P P, FEI W D. Low temperature extrusion of 6061 aluminum matrix composite reinforced with SnO2-coated Al18B4O33 whisker[J]. Composites: Part A, 2012, 43(1): 183-188.

[16] PEDRO F, RICARDO F, GASPAR G D, GIOVANNI B. Correlation between matrix residual stress and composite yield strength in PM 6061Al-15vol%SiCw[J]. Scripta Materialia, 2005, 52(8): 793-797.

[17] CORROCHANO J, LIEBLICH M,  J. The effect of ball milling on the microstructure of powder metallurgy aluminum matrix composites reinforced with MoSi2 intermetallic particles[J]. Composites Part A: Applied Science and Manufacturing, 2011, 42(9): 1093-1099.

J. The effect of ball milling on the microstructure of powder metallurgy aluminum matrix composites reinforced with MoSi2 intermetallic particles[J]. Composites Part A: Applied Science and Manufacturing, 2011, 42(9): 1093-1099.

[18] 朱 浩, 吕 丹, 朱 亮, 陈剑虹, 陈德利. 6061铝合金断裂机理的原位拉伸研究[J]. 机械工程学报, 2009, 45(2): 94-99.

ZHU Hao,  Dan, ZHU Liang, CHEN Jian-hong, CHEN De-li. Investigation of fracture mechanism of 6061 aluminum alloy by means of in-situ observation[J]. Journal of Mechanical Engineering, 2009, 45(2): 94-99.

Dan, ZHU Liang, CHEN Jian-hong, CHEN De-li. Investigation of fracture mechanism of 6061 aluminum alloy by means of in-situ observation[J]. Journal of Mechanical Engineering, 2009, 45(2): 94-99.

[19] VIPIN C, JAYAGANTHAN R, RAMESH C. Structural characterizations of magnetron sputtered nanocrystalline TiN thin films[J]. Materials Characterization, 2008, 59(8): 1015-1020.

[20] 苏 海, 高文理, 毛 成, 张 辉, 刘洪波, 卢 健, 陆 政. 搅拌铸造SiCp/2024铝基复合材料的显微组织与力学性能[J]. 中国有色金属学报, 2010, 20(2): 217-225.

SU Hai, GAO Wen-li, MAO Cheng, ZHANG Hui, LIU Hong-bo, LU Jian, LU Zheng. Microstructures and mechanical properties of SiCp/2024 aluminum matrix composite synthesized by stir casting[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(2): 217-225.

[21] HONG S H, CHUNG K H, LEE C H. Effects of hot extrusion parameters on the tensile properties and microstructures of SiCw-2124Al composites[J]. Materials Science and Engineering A, 1996, 206(2): 183-188.

(编辑 何学锋)

基金项目:国家重点基础研究发展计划资助项目(2011CB612200);青海省科技厅资助项目(2010-H-803)

收稿日期:2012-10-08;修订日期:2013-04-26

通信作者:丁雨田,教授,博士;电话:13893243521;E-mail:dingyutian@126.com