DOI:10.19476/j.ysxb.1004.0609.2017.08.18

Ti-Al和Ti-Al-Ce复合改性剂对高硼铁基耐磨合金组织和性能的影响

钱旭东1, 2,李 德1, 2,许秉坤1, 2,陆 周1, 2,叶旭初1, 2

(1. 南京工业大学 材料科学与工程学院,南京 210009;

2. 南京工业大学 材料化学工程国家重点实验室,南京 210009)

摘 要:研究Ti-Al和Ti-Al-Ce两种复合改性剂对高硼铁基耐磨合金组织和性能的影响。采用X射线衍射仪(XRD)、金相显微镜(OM)、扫描电子显微镜(SEM)、硬度测试仪和摩擦磨损试验机等分析合金的组织结构和性能,结果表明:Ti-Al和Ti-Al-Ce的添加都能很好地破坏共晶硼化物的连续网状结构,改善硼化物的形貌、尺寸和分布情况,其中Ce添加后改善效果更加明显。热处理后合金硬度出现小幅度的减小,但硬度都在60HRC以上,改性处理显著提高高硼铁基耐磨合金的冲击韧性和耐磨性能,冲击韧性最高可达15.2 J/cm2,并表现出很好的耐磨性能。

关键词:高硼铁基耐磨合金;Fe-B合金;改性处理;冲击韧性;耐磨性

文章编号:1004-0609(2017)-08-1687-06 中图分类号:TG146.2 文献标志码:A

传统的铁基耐磨材料主要包括高锰钢、镍硬铸铁和高铬铸铁,但由于合金元素含量高,导致价格高。目前,一种新型的耐磨材料高硼铁基耐磨合金(Fe-B合金)受到广泛关注,它以共晶硼化物M2B为耐磨骨架[1-2],表现出优异的耐磨性能,打破了以碳化物为硬质相的传统格局。与碳化物相比,硼化物具有更高的硬度和热稳定性[3-4]。除了优异的耐磨性外,它还具有低合金消耗、铸造工艺简单以及生产成本低等优点。虽然硼化物硬度很高,但其本身脆性高,由于这种硬而脆且连续的硼化物的存在,破坏了基体的连续性,降低了材料的韧性,在高冲击环境中会出现断裂的情况,因此,Fe-B合金的应用受到限制。

研究表明,稀土和铝都能有效改善初级奥氏体。铝能够阻碍碳化物在晶界处形成,能够提高合金的硬度和热硬性,从而有利于提高合金的高温耐磨性[5],同时铝能够与氧反应生成Al2O3,从而提高合金的高温抗腐蚀性。稀土极活泼,能与合金中的氧和硫反应生成氧硫化物,能作为异质核心,从而细化奥氏体晶粒[6]。钛是一种比铁更加活泼的硼化物形成元素,能与硼反应生成稳定的TiB2[7-8],TiB2具有高硬度、高熔点、好的抗腐蚀性和热导率,且TiB2在液态铁中是稳定的,TiB2的形成能消耗一些硼,从而减少沿晶界生长的连续Fe2B网状结构。目前,国内外的研究主要集中在单一的稀土、Al或Ti对Fe-B合金的影响,本文作者以Fe-B合金为研究对象,旨在考察Ti-Al和Ti-Al-Ce复合改性剂对Fe-B合金微观组织结构和性能的影响。

1 实验

1.1 材料制备

实验合金(质量分数)采用Fe(99.95%)、Mn(99.5%)、Cr(99.9)、Si(99.999%)、Ni(99.9%)、Ti(99.995%)、Al(99.99%)、稀土硅铁以及硼铁为原料,按照表1所示化学组成,首先将原料在高真空、氩气氛保护下采用真空非自耗电弧炉熔炼3遍,然后将熔炼出的圆锭线切割成所需尺寸。切割好的试样在HY-1600 ℃箱式电阻炉中进行热处理,其工艺如下:(1050 ℃, 1 h, WC)水淬+(250 ℃, 4 h, AC),热处理后的试样经打磨去除表面氧化层。

1.2 实验方法

将尺寸为5 mm×5 mm×5 mm的试样,经过镶嵌、打磨并抛光后,用4%硝酸酒精溶液腐蚀,采用4XC型金相显微镜(OM)和扫描电子显微镜(SEM)观察其显微结构及表面形貌;采用X射线衍射仪(XRD)及能谱仪(EDX)分析相组成;采用HR-150DT型洛氏硬度测试仪测试材料的洛氏硬度,每个试样测量5个点取平均值;将尺寸为d 30 mm×4 mm的试样在MMG-10型万能摩擦磨损试验机上进行摩擦磨损实验,采用2520不锈钢作为止推圈摩擦副,摩擦形式为止推圈摩擦,实验载荷为50 N,转速为50 r/min,时间为30 min,止推圈的规格为外径22 mm,内径16 mm,实验前后将试样放入丙酮溶液中用LT-05型超声波清洗器清洗15 min,洗干净后用酒精擦洗,然后用电吹风机吹干,采用精度为0.1 mg 的BSA224S 电子分析称重天平称量;在摆锤冲击试验机上进行冲击实验,冲击韧性值取3根冲击试样的平均值,试样尺寸为10 mm×10 mm×55 mm。

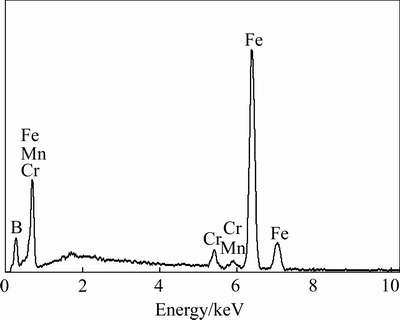

表1 Fe-B合金的化学成分

Table 1 Chemical compositions of Fe-B alloys

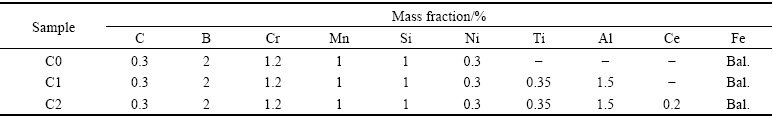

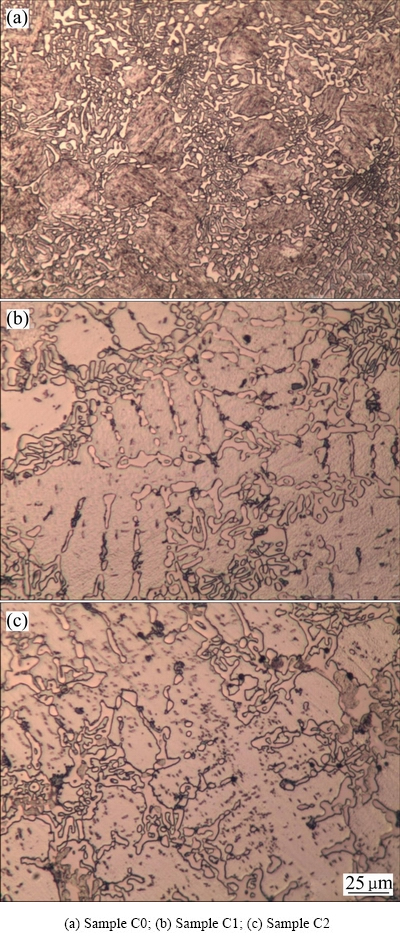

图1 Fe-B合金的铸态微观组织结构

Fig. 1 Microstructures of as-cast Fe-B alloys

2 结果与讨论

2.1 改性处理对Fe-B合金铸态组织的影响

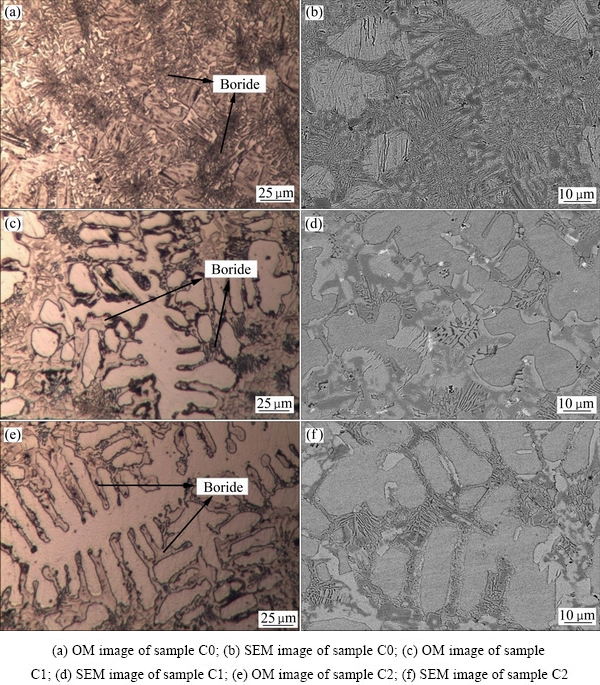

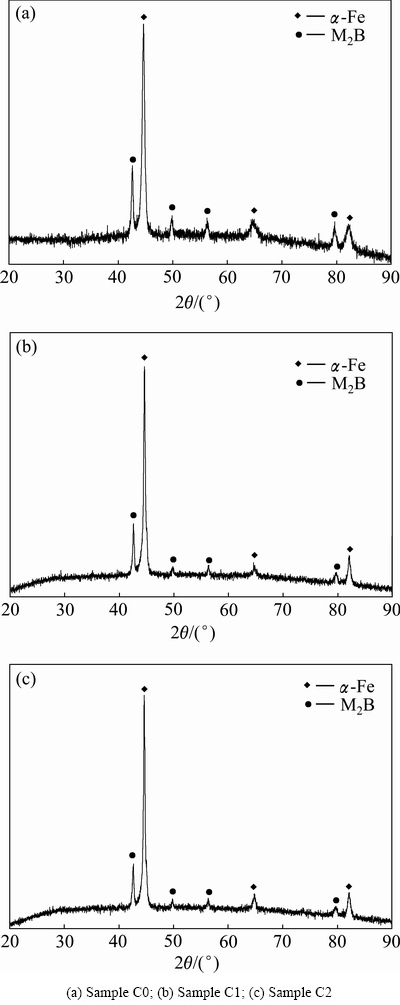

Fe-B合金的铸态微观组织结构如图1(a)和(b)所示,合金组织由树枝状基体和粗大、连续网状结构的共晶体组成,粗大的硼化物虽然能提高合金硬度,但容易产生微裂纹,导致冲击韧性下降。根据XRD谱(见图2)和EDX能谱(见图3)可以确定共晶硼化物是M2B(M代表Fe、Cr或Mn)。Fe-B合金中硼化物的形貌和高铬铸铁中碳化物的形貌是很相似的。硼在铁中的溶解度很低,在1149 ℃的奥氏体中溶解度为0.0218%[9],而在910 ℃的铁素体中溶解度不到0.0021%,铁合金中硼的加入量超过它的溶解度就会形成硼化物。Fe-B合金的冷却凝固过程如下[10]:L→ γ-Fe;初生晶体γ相从液态合金中分离,由于铬、锰和硼等元素在γ相的分配系数小于1,在γ相生长过程中这些元素会跑到溶液中,当液态金属中硼含量达到3.8%时,L→γ相+硼化物的共晶反应就会在剩余的溶液中发生,所以,硼的加入促进了共晶硼化物的形成。相比于Fe-C合金中,只有液态合金中碳含量达到4.3%时,L→γ相+Fe3C的共晶反应才会发生,硼化物的形成更加容易。随着温度进一步降低,硼元素和碳元素会从基体中溶解到奥氏体中[9],最后凝固组织主要由铁素体、珠光体、少量马氏体和共晶硼化物组成。

图2 铸态Fe-B合金的XRD谱

Fig. 2 XRD patterns of as-cast Fe-B alloys

图3 试样C0中硼化物的EDX能谱

Fig. 3 EDX spectrum of boride in sample C0

通过图1(a)和(c)的对比发现,没有改性剂加入的Fe-B合金晶界存在着粗糙连续的网状M2B,掺入钛和铝改性剂后,基体中的共晶硼化物出现了紧缩和网状结构破裂现象,而且马氏体相和珠光体相消失,主要含有铁素体和M2B,这可能是由于钛的加入细化了奥氏体晶粒和共晶结构,钛是一种很活泼的碳化物形成元素[11-12],加入的钛在高温下会形成一定量的TiC颗粒和TiB2,在凝固过程中,TiC会成为第一沉淀相,TiC和奥氏体都具有面心立方结构,晶胞参数分别为:aTiC=0.433nm,aγ=0.357,两者的晶格常数很接近并且晶格配位数很小,能作为γ-Fe的异质晶核成核并生长,从而细化初级奥氏体和硼化物,而TiB2的形成也消耗了部分硼。同时铝是非碳化物形成元素[5],主要固溶于基体中,能够有效地提高铁素体的相转变温度,使得连续冷却转变曲线向左移,这些都导致铁素体的形成[13]。

相比于图1(a)和(c),从图1(e)中可以发现硼化物断网现象更加明显,且分布更加均匀。这可能是由于铈元素熔点低,原子尺寸大,rCe = 0.182 nm,是Fe-B合金凝固过程中的强连续过冷元素,其平衡常数远小于1,在凝固过程中容易发生严重偏析,通过溶质的重新分配,铈富集在初级奥氏体树突生长边界,阻碍了奥氏体的生长,造成较大的成分过冷,有利于奥氏体枝晶的多次分枝以及枝晶间距的减小[14],从而细化奥氏体枝晶。初级奥氏体细化强化了共晶反应过程中剩余液态金属分离的趋势,在共晶生长过程中,共晶奥氏体会优先结晶与初级奥氏体分离,这就促进了共晶硼化物的细化,从而出现网状结构的紧缩或破损。另外,铈元素能作为合金中的脱氧剂,形成高熔点的Ce2O3,根据错配理论,Ce2O3与γ-Fe相之间的错配度为5.4%<6%[15],它能够作为有效的奥氏体异质核心,使晶粒细化。同时,稀土作为表面活性元素,能有效降低形成临界尺寸晶核所需要的功,有利于异质成核,促进奥氏体组织细化。

2.2 改性处理对热处理后Fe-B合金组织的影响

图4所示为Fe-B合金经过(1050 ℃, 1 h, WC)+ (250 ℃, 4 h, AC)热处理后的金相组织。由图4可知,经热处理后合金组织仍由树枝状基体和网状结构的M2B组成,但金属基体转变成了马氏体,同时热处理后连续的硼化物结构出现了不同程度的断网现象。从图4(a)可以看到,未经改性的Fe-B合金中硼化物仍粗大,经热处理后,局部出现断网现象,说明热处理对改善网状结构有一定的作用,但这种断网效果并不明显。相比于图4(a),图4(b)和(c)中共晶硼化物都得到很好的细化,网状结构断裂更加明显,甚至出现了球状和短杆状的硼化物结构,这表明在热处理中Ti-Al和Ti-Al-Ce的加入对共晶硼化物断裂具有很好的效果。

Fe-B合金中网状共晶硼化物的断裂机理与M2钢中共晶碳化物是相似的。根据热力学原理[16],当硼化物沿晶界形成连续网状结构时,共晶硼化物与晶体之间的接触面积和界面能都要大于球状硼化物形成时的情况,所以共晶硼化物的断裂或者球状和短杆状硼化物的形成降低了硼化物与晶体接触的表面能[17]。另外,在高温下硼化物的溶解和原子的扩散会使得硼化物分解,在拐角和比较细的连接点硼化物更容易溶解,所以热处理后硼化物会出现局部断网现象,而改性处理后硼化物得到细化,经热处理后断网更加明显。

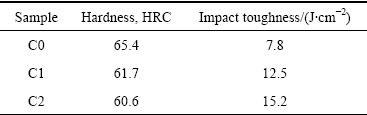

2.3 改性处理对热处理后Fe-B合金性能的影响

表2所列为Fe-B合金经过(1050 ℃, 1 h, WC)+(250 ℃, 4 h, AC)热处理后的硬度和冲击韧性。从表2可知,未经改性的Fe-B合金由于存在粗大、连续、硬而脆的共晶M2B,硬度很高,而改性后的合金硬度出现小幅度的减小,这可能是由网状硼化物的断裂引起,但仍能达到60HRC以上,说明改性处理对合金硬度的影响不明显。改性处理后Fe-B合金的冲击韧性明显提高,其中加入Ti-Al-Ce复合改性剂后,合金(试样C2)的冲击韧性达到15.2 J/cm2。

图4 Fe-B合金经热处理后的微观组织结构

Fig. 4 Microstructures of Fe-B alloys after heat treatment

根据断裂力学理论,脆性断裂是由裂纹的萌生和和扩展引起的[18],这往往由硼化物的数量、形貌和尺寸决定。在未改性处理的Fe-B合金的晶界处存在粗大的连续网状的硼化物,其切断了基体之间的连接,使得晶粒间的结合强度大幅度减小。同时,在冲击载荷下,微裂纹很容易在粗大的硼化物与晶体的接触面产生,伴随着裂纹在晶粒中传播导致晶粒劈裂,当裂纹扩展到粗糙的硼化物时,将沿着晶界扩展,从而加速裂纹的扩展,所以试样C0的冲击韧性较低。

加入改性剂后,Fe-B合金中粗糙连续的硼化物得到细化,尺寸变小,并且出现明显的断裂,甚至出现了球状和短杆状的硼化物,这就强化了基体之间的联系,微裂纹不容易沿着晶界萌生[19],并且改性后硼化物呈弥散分布,能够有效地阻碍裂纹的扩展,所以合金冲击韧性得到较大的提高。试样C2的冲击韧性的提高更加明显,这是由于铈的加入能够进一步细化晶粒。

表2 热处理后Fe-B合金的性能

Table 2 Properties of Fe-B alloys after heat treatment

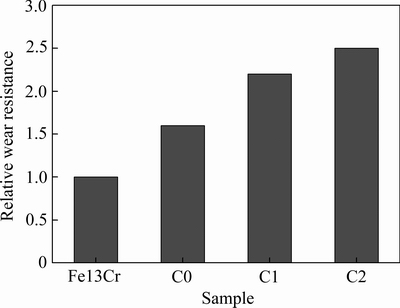

图5所示为热处理后Fe-B合金的耐磨性能。摩擦磨损试验中采用高铬铸铁(Fe13Cr)作对比实验,用相对耐磨性来表征其耐磨性能的差异(相对耐磨性=高铬铸铁磨损量/试样磨损量)。每个试样重复3次测试后,称量并计算每次的质量损失,取平均值。从图5中可以看出,Fe-B合金的耐磨性要优于高铬铸铁,改性处理后耐磨性能提高。这可能是因为改性后的Fe-B合金具有高的硬度、强度和好的韧性,减少了裂纹的产生和传播[11]。

图5 热处理后Fe-B合金的耐磨性能

Fig. 5 Wear resistance of Fe-B alloys after heat treatment

3 结论

1) 通过Ti-Al和Ti-Al-Ce复合改性剂的改性,Fe-B合金中奥氏体晶粒得到细化,连续网状的共晶硼化物得到破坏,改善了硼化物的形貌、尺寸和分布状况。

2) 热处理之后,硼化物的网状结构得到一定程度的破坏,改性处理后的合金,其硼化物网状结构的破坏程度更大,甚至出现了球状和短杆状的硼化物。由于铈的存在,Ti-Al-Ce复合改性剂要比Ti-Al复合改性剂的改性效果更好。

3) 改性处理后Fe-B合金硬度出现小幅度的减小,但宏观硬度都在60HRC以上,尤其是冲击韧性和耐磨性能都得到大幅度提高,冲击韧性值ak由7.8 J/cm2增大到15.2 J/cm2,Fe-B合金的耐磨性能要好于高铬铸铁(Fe13Cr)。

REFERENCES

[1] 符寒光, 胡开华. 高硼铸造耐磨合金研究的进展[J]. 现代铸铁, 2005(3): 32-37.

FU Han-guang, HU Kai-hua. Progress of research on high boron wear resistant cast alloys[J]. Modern Cast Iron, 2005(3): 32-37.

[2] 张艳玲. 耐磨高硼低碳铸造合金的研究[J]. 铸造, 2014, 63(12): 1273-1276.

ZHANG Yan-ling. Study of wear resistance of high boron low carbon cast alloy[J]. Foundry, 2014, 63(12): 1273-1276.

[3] GUO Chang-qing, WANG Cai-dong, LIU Xiao-ping, KELLY P M. Effect of variable heat treatment modes on microstructures of Fe-Cr-B cast iron alloy[J]. China Foundry, 2008, 5(1): 28-31.

[4] LIU Zhong-li, LI Yan-xiang, CHEN Xiang, HU Kai-hua. Microstructure and mechanical properties of high boron white cast iron[J]. Materials Science & Engineering A, 2008, 486(1/2): 112-116.

[5] YU Zhen, FU Han-guang, JIANG Ye-hua, CEN Qi-hong, LEI Yong-ping, ZHOU Rong, GUO Hong-xing. Effect of aluminum content on solidification microstructure and properties of Fe-Cr-B-Al alloys[J]. Materialwissenschaft und Werkstofftechnik, 2012, 43(12): 1080-1085.

[6] 郭长庆, 王彩东, 程 军, 高明星. 铈变质处理Fe-Cr-B合金组织和机械性能研究[J]. 稀土, 2009, 30(4): 95-97.

GUO Chang-qing, WANG Cai-dong, CHENG Jun, GAO Ming-xing. Investigation of microstructure and mechanical properties of Fe-Cr-B alloys modified with cerium[J]. Chinese Rare Earth, 2009, 30(4): 95-97.

[7] HE Lin, LIU Ying, LI Jun, LI Bing-hong. Effects of hot rolling and titanium content on the microstructure and mechanical properties of high boron Fe-B alloys[J]. Materials & Design, 2012, 36: 88-93.

[8] LIU Ying, LI Bing-hong, LI Jun, HE Lin, GAO Sheng-ji, NIEH T G. Effect of titanium on the ductilization of Fe-B alloys with high boron content[J]. Materials Letters, 2010, 64(11): 1299-1301.

[9] SANG Pei, FU Han-guang, QU Yin-hu, WANG Chang-an, LEI Yong-ping. Effect of boron concentration on solidification structure and hardness of Fe-B-C wear-resistant alloy[J]. Materialwissenschaft und Werkstofftechnik, 2015, 46(9): 962-969.

[10] YI Da-wei, XING Jian-dong, FU Han-guang, MA Sheng-qiang. Effects of RE-Al additions and austenitising time on structural variations of medium carbon Fe–B cast alloy[J]. Materials Science and Technology, 2010, 26(7): 849-857.

[11] LI Xue-yi, HOU Jian, QU Yin-hu, FU Han-guang. A study of casting high-boron high-speed steel roll materials[J]. Materialwissenschaft und Werkstofftechnik, 2015, 46(10): 1029-1038.

[12] 陈 祥, 胡 潇, 李言祥. 等温淬火含硼高硅铁基合金的韧化研究[J]. 铸造, 2014, 63(2): 105-109.

CHEN Xiang, HU Xiao, LI Yan-xiang. Toughness improvement of austempered boron alloyed high silicon ferrous alloy[J]. Foundry, 2014, 63(2): 105-109.

[13]  Zheng, FU Han-guang, XING Jian-dong, MA Sheng-Qiang, HU Ying. Microstructure and crystallography of borides and mechanical properties of Fe-B-C-Cr-Al alloys[J]. Journal of Alloys & Compounds, 2015, 662: 54-62.

Zheng, FU Han-guang, XING Jian-dong, MA Sheng-Qiang, HU Ying. Microstructure and crystallography of borides and mechanical properties of Fe-B-C-Cr-Al alloys[J]. Journal of Alloys & Compounds, 2015, 662: 54-62.

[14] FU Han-guang, XIAO Qiang, LI Yan-xiang. A study of the microstructures and properties of Fe-V-W-Mo alloy modified by rare earth[J]. Materials Science & Engineering A, 2005, 395(1/2): 281-287.

[15] YI Da-wei, ZHANG Zhi-yun, FU Han-guang, YANG Cheng-yan, MA Sheng-qiang, LI Ye-fei. A study on the microstructures and toughness of Fe-B cast alloy containing rare earth[J]. Journal of Materials Engineering & Performance, 2014, 24(2): 626-634.

[16] LI Yan-jun, JIANG Qi-chuan, ZHAO Yu-guan, HE Zhen-ming, ZHONG Xue-you. A dynamic study on the spheroidizing of eutectic carbide in the modified M2 steel[J]. Acta Metallrugica Sinica, 1999, 35: 207-210.

[17] YI Da-wei, ZHANG Zhi-yun, FU Han-guang, YANG Cheng-yan. Investigations on microstructures and toughness of Fe-B cast alloy containing titanium and nitrogen[J]. Journal of Materials Engineering & Performance, 2014, 23(23): 673-678.

[18] FU Han-guang, XIAO Qiang, KUANG Jia-cai, JIANG Zhi-qiang, XING Jian-dong. Effect of rare earth and titanium additions on the microstructures and properties of low carbon Fe-B cast steel[J]. Materials Science & Engineering A, 2007, 466(1/2): 160-165.

[19] 吴中佳, 陈志国, 向 勇, 魏 祥, 张纪帅. 少量铈对高硼高速钢微观组织与力学性能的影响[J]. 中国有色金属学报, 2013, 23(5): 1289-1294.

WU Zhong-jia, CHEN Zhi-guo, XIANG Yong, WEI Xiang, ZHANG Ji-shuai. Effect of small amount of Ce addition on microstructure and mechanical properties of high-boron high speed steel[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1289-1294.

Effects of Ti-Al and Ti-Al-Ce additions on microstructures and properties of high boron iron-based wear-resistant alloys

QIAN Xu-dong1, 2, LI De1, 2, XU Bing-kun1, 2, LU Zhou1, 2, YE Xu-chu1, 2

(1. School of Materials Science and Engineering, Nanjing Technology University, Nanjing 210009, China;

2. State Key Laboratory of Materials-Oriented Chemical Engineering, Nanjing Technology University, Nanjing 210009, China)

Abstract: The effects of Ti-Al and Ti-Al-Ce additions on the microstructures and properties of high boron iron-based wear-resistant alloys were studied. The microstructure and properties of these alloys were analyzed with X-ray diffractometry (XRD), optical microscopy (OM), scanning electron microscopy (SEM), hardness testing machine and friction-abrasion testing machine. The results show that the interconnected boride network is destroyed with Ti-Al and Ti-Al-Ce additions, the morphology and distribution of modified as-cast eutectic borides are refined. With the Ce addition, it shows more effective modification. After heat treatment, the hardness of alloys decreases slightly but over 60HRC. The impact toughness and the wear resistance of high boron iron-based wear-resistant alloys are increased by modification treatment, the impact toughness is up to 15.2 J/cm2 and it shows excellent wear resistance.

Key words: high boron iron-based wear-resistant alloy; Fe-B alloy; modification treatment; impact toughness; wear resistance

Foundation item: Project(IRT1146) supported by the Program for Changjiang Scholars and Innovative Research Team in University(PCSIRT), Ministry of Education, China

Received date: 2016-05-17; Accepted date: 2016-10-17

Corresponding author: YE Xu-chu; Tel: +86-25-83172122; E-mail: yexuchu@njtech.edu.cn

(编辑 何学锋)

基金项目:教育部长江学者和创新团队发展计划资助项目(IRT1146)

收稿日期:2016-05-17;修订日期:2016-10-17

通信作者:叶旭初,教授,博导;电话:025-83172122;E-mail: yexuchu@njtech.edu.cn