文章编号:1004-0609(2014)08-1960-08

复合能场铸轧对AZ61镁板组织及性能的影响

张欢欢1,黄元春1, 2, 4,刘胜胆1,刘 宇3,肖政兵2, 3,杜志勇4

(1. 中南大学 高性能复杂制造国家重点实验室,长沙 410083;

2. 中南大学 材料科学与工程学院,长沙 410083;

3. 中南大学 机电工程学院,长沙 410083;

4. 中南大学 轻合金研究院,长沙 410083)

摘 要:采用金相显微镜、扫描电镜、拉伸及弯曲性能测试等分析手段,研究复合能场(超声波和电磁场)铸轧工艺对AZ61镁合金板微观组织、力学性能和加工性能的影响。结果表明:与常规铸轧镁合金板带相比,复合能场可有效减小晶粒尺寸,并使析出相均匀弥散分布;施加复合能场之后,铸轧板抗拉强度、屈服强度及伸长率较常规铸轧板分别提高10.58%、12.84%和52.17%,而终轧成品板分别提高10.45%、20.56%和65.25%,且板材轧制后具有裂纹倾向小、抗弯强度及最大挠度大、弯曲抗力小等性质,可有效减少加工过程中材料及工具磨损,获得较好的综合性能。

关键词: AZ61镁合金;复合能场;铸轧;力学性能;加工性能

中图分类号:TG146.2 文献标志码:A

Effect of compound energy field cast-rolling on microstructure and properties of AZ61 magnesium alloy plate

ZHANG Huan-huan1, HUANG Yuan-chun1, 2, 4, LIU Sheng-dan1, LIU Yu3, XIAO Zheng-bing2, 3, DU Zhi-yong4

(1. State Key Laboratory of High Performance and Complex Manufacturing, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

3. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China;

4. Light Alloy Research Institute, Central South University, Changsha 410083, China)

Abstract: The influence of compound energy field (ultrasonic and electromagnetic field) cast-rolling process on the microstructure, mechanical and processing properties of AZ61 magnesium alloy plate was investigated by metallurgical microscopy, scanning electron microscopy, tensile and bending tests. The results show that the compound energy field effectively decreases the grain size and the precipitates distribute homogeneously compared with the conventional cast-rolling magnesium alloy strip. After adding the compound energy field, the tensile strength, the yield strength and elongation of the alloy plate increase by 10.58%, 12.84% and 52.17%, respectively, accompanied with the final rolling plate increasing by 10.45%, 20.56% and 65.25%. Furthermore, after cast-rolling, the alloy plate shows the characteristics of a weaker crack tendency, higher tensile strength and the maximum deflection, a lower bending resistance, etc, which reduces the abrasion between the material and tool during processing, and is also good to omnibus properties.

Key words: AZ61 magnesium alloy; compound energy field; cast-rolling; mechanical property; processing property

镁合金密度低,具有环保、抗电磁干扰和价格优势,另外其减震性及电磁屏蔽性能良好,能够极好地满足当今社会对于轻量化及节能环保问题的需求,被广泛应用于交通、电子、航空航天和国防军工等重要领域,是21世纪极具发展前景的绿色结构材料[1-2]。但镁合金属于密排六方晶体结构,滑移系少,塑性不及面心立方结构金属的塑性,不易加工,阻碍了镁合金的应用,国内外众多学者虽不断探索适当的手段来获取高品质的镁合金,在一定程度上改善了其塑性差、不易成型等问题,但仍有许多问题亟待解决[3-4]。

研究表明,当晶粒小于一定尺寸后,脆塑性转变温度降低,材料以塑性变形为主。通过微合金化细化晶粒、改变组织结构从而提升镁合金性能的工艺已日趋成熟,近年来又开发出了累积叠轧、等径角挤压、异步轧制等大塑性变形方法来获取细小晶粒,并取得了较满意的效果,但这类工艺工序繁杂、能耗大且细晶强化和织构软化作用共存,因而材料强度提高幅度有限[5-11]。连续铸轧工艺生产金属板材流程短、效率高、可降低成本,但铸轧后镁合金板带晶粒组织不均匀,力学性能较差,因此研究者在铸轧过程中通过添加外场以改善其性能[12-13]。施加电磁场,电磁搅拌使液相区温度趋于均匀,表面质量提升,Mg17Al12相的分布更细小、均匀,延展性有所提高,而超声波在细化凝固组织、减轻中心偏析、去除气体及夹杂等方面具有显著作用,但单独使用一种外场不能同时改变凝固前沿流动场和温度场,作用效果有限[14-16],谭湘夫等[13]通过实验发现,施加电磁超声复合能场,使两种能量得以相互叠加,并协调作用在熔体中,从而导致晶粒细化的程度和力学性能的提高均比单一能场更显著。以上研究极少涉及镁合金加工性能的探索,而关于镁合金铸轧过程中施加复合能场的工艺也鲜见报道。

本文作者拟通过在AZ61镁合金双辊连续铸轧过程中施加电磁超声复合能场,制备出镁合金铸轧板带,并与在相同变形温度、变形速度及后续轧制工艺条件下生产出的常规板带相比较,旨在验证复合能场对于镁合金微观组织和力学性能的改善效果,并探索其对于镁合金深加工整个过程的影响,以便为制定出合理、高效的AZ61镁合金板带生产工艺提供指导,使之综合性能提升且易加工,为该合金寻求更广阔的应用空间。

1 实验

1.1 实验设备与材料

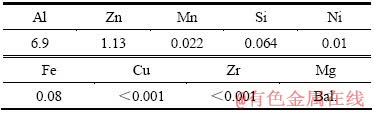

实验经规格为d 400 mm×500 mm的水平式双辊铸轧机分别在常规(不添加能场)和添加复合能场两种情况下采用连续铸轧技术生产出宽250 mm、厚5.2 mm的AZ61镁合金板。在复合能场的施加过程中,将电磁场导入铸嘴区,并将一超声波变幅杆垂直插入前箱中,再在轧辊和铸嘴相接触处,呈45°方向插入另一变幅杆,从而使镁溶液先经过一级超声波处理,再通过铸嘴进入具有超声波和电磁场共存的辊缝中,进行复合能场铸轧。两级超声波功率均为100 W,频率(20±0.1) kHz;电磁场为三相电流,电流大小10 A,换向周期是一完整波形,中心频率(13±1) Hz。实验合金的化学成分如表1所列。

表1 AZ61镁合金的化学成分

Table 1 Chemical compositions of AZ61 magnesium alloy (mass fraction, %)

1.2 实验方法

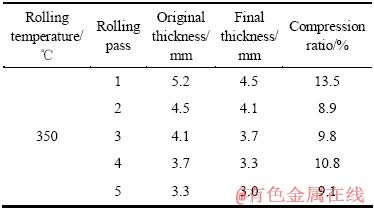

先按照名义化学成分要求配置AZ61镁合金材料,置于封闭电阻熔化炉内加热融化,并撒上覆盖剂随炉升温,熔炼至500 ℃通入氩气,阻隔镁溶液与空气,防止两者发生反应。随后继续升温至715 ℃,添加精炼剂进行精炼、除渣,静置20 min后进行铸轧,即将镁溶体引入两个旋转并具有冷却作用的轧辊,使其在结晶凝固过程中承受压力及塑性变形,短时间内获得铸轧板带的过程。由于AZ61镁合金板常用于飞机和汽车结构件中,厚度多为3 mm左右,因此,为了更好地研究AZ61镁合金在实际生产与应用中的各项性能,将两类成型铸轧板再进行5个道次的轧制,使最终板厚为3 mm。不同道次间,将镁合金板置于电阻加热炉内加热至350 ℃,保温1 h,表2所列为各道次轧制工艺参数。本实验中将常规方式和复合能场方式下生产的镁合金铸轧板分别定义为A板和B板。

将轧制前和五道次轧制后的A板和B板进行250 ℃、2 h的退火处理后,沿不同方向截取试样,经镶样、粗磨、精磨、抛光和腐蚀(腐蚀液为苦味酸4.2 g、乙酸10 mL、乙醇70 mL、水 10 mL的混合液,腐蚀时间为5~15 s),在Leica DMI 5000M光学显微镜下观察显微组织,并经专用金相分析软件OLYCZA DSX测量晶粒平均尺寸;采用JSM-6490LV型扫描电镜(SEM)观察A、B初始板和终轧板中析出相分布;分别沿与轧制方向成0°、45°和90°方向取样,进行室温拉伸试验,试样标距尺寸为40 mm×8 mm,拉伸速度恒为1 mm/min,并测得各拉伸样的抗拉强度、屈服强度和伸长率;通过跨距为20 mm的三点弯曲试验,测量A、B初始板和终轧板的弯曲性能。

表2 铸轧镁合金板带的轧制工艺参数

Table 2 Rolling process parameters of cast-rolling magnesium alloy plate

2 实验结果

2.1 金相显微组织观察

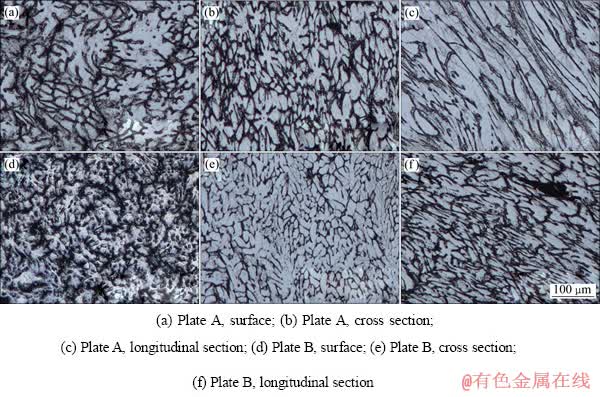

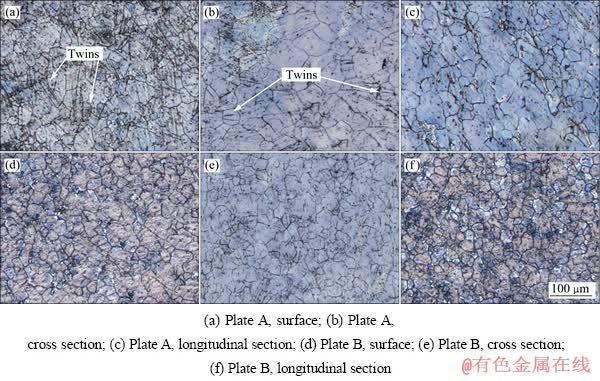

AZ61镁合金A、B初始铸轧板不同截面金相组织对比见图1。图2~4所示分别为第一、三、五道次两类板材的金相组织。

如图1所示,A铸轧板中具有大量尺寸不均匀、呈菊花状的粗大枝晶网胞,平均晶粒尺寸为90~105 μm,部分达到125 μm以上;受轧制力作用,部分晶粒横向受压缩径向被拉长,呈现出一定的方向性,但对其尺寸影响较小,而纵截面的影响更为明显,晶粒呈纤维状。而B铸轧板微观组织显著细化,粗大枝晶破碎且无明显枝晶网胞存在,晶粒平均尺寸仅60~70 μm,在局部区域出现破碎后的细小晶粒,3个方向上晶粒形貌也出现沿轧制方向的变形趋势,但形貌差异较小。

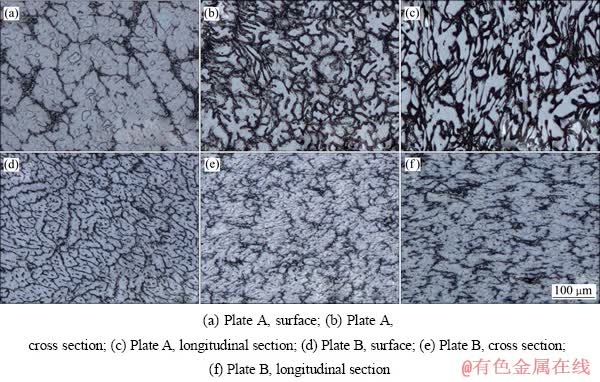

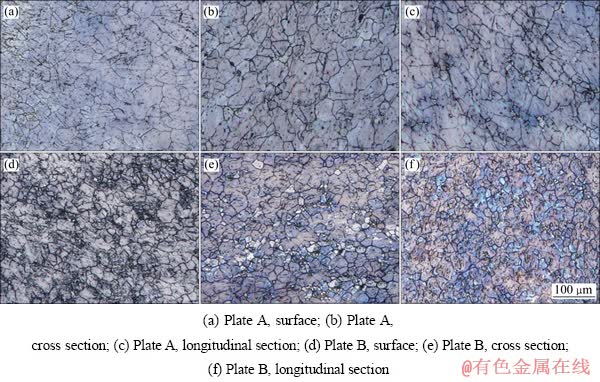

由图2~4可见,轧制一道次后,两类板材均呈现铸态组织,但晶粒较初始状态有所细化,A、B板晶粒平均尺寸分别为75~85 μm和55~60 μm。经三道次轧制后,枝晶演变成圆滑的等轴晶,晶粒大幅细化,两类板材平均尺寸分别为60~70 μm和 25~30 μm,其中A板中晶粒发生明显再结晶,大晶粒周围有细小晶粒围绕,但组织以粗大晶粒为主,因粗晶内部位错滑移程长,晶界处应力集中严重,出现部分孪晶现象,而B板再结晶充分,形核率提高,细化效果明显且组织分布较均匀,未发现孪晶。轧制五道次后,微观组织进一步细化,形核率提高,晶粒大小分别为40~50 μm和15~20 μm,A板中孪晶基本消失,但仍处于大小晶粒共存的状态,B板再结晶完全,金相组织处于退火态,圆滑且均匀细小。

观察整个组织演变过程可知,B板组织均匀性明显改善,且细化效果较明显,晶粒尺寸减小约75%;而A板晶粒尺寸仅减小50%左右,晶粒较粗大,形状不规则。A板变形过程中发现孪晶,孪晶界对位错运动起到一定的阻碍作用,且根据Basinski机制可知,孪晶可提高材料加工硬化率,降低其整体变形协调性[17-19]。A板和B板最终均发生再结晶,但B板再结晶充分,再结晶是镁合金变形时的主要软化机制之一,其程度大小可以决定微观性能的好坏,晶粒细小圆滑,晶界易发生滑动和转动,使组织形貌不易产生方向性和组织缺陷,应力分布更均匀,也可进一步为力学性能及加工性能的改善创造条件[20-21]。

图1 A、B初始铸轧板各方向的金相组织

Fig. 1 Metallographs of A and B initial cast-rolling plates in different directions

图2 A板和B板第一道次轧制后各方向的金相组织

Fig. 2 Metallographs of A and B cast-rolling plates in different directions after first-pass rolling

图3 A板和B板第三道次轧制后各方向的金相组织

Fig. 3 Metallographs of A and B cast-rolling plates in different directions after third-pass rolling

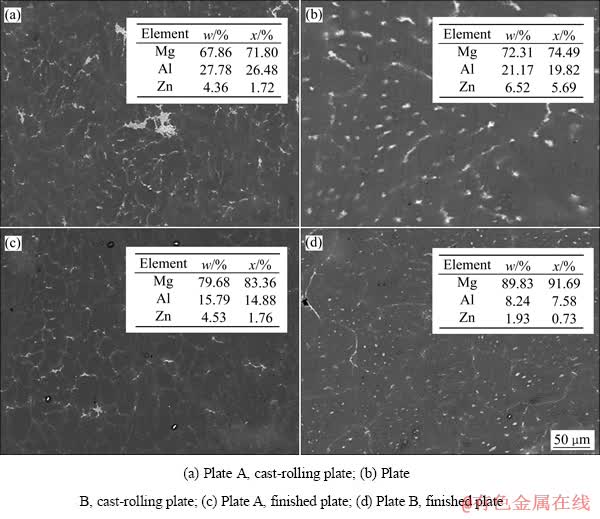

2.2 析出相观察

镁合金铸轧及终轧板析出相扫描显微电镜分析照片及成分分析结果见图5。如图5所示,A板中析出相分布不均匀,且大量聚集在晶界处,而B板中析出相减少且不易聚集,分布弥散、均匀,多以钉扎的形式出现在晶界及晶粒内部。由箭头所指区域析出相成分分析结果可知,同种情况下,B板中Al和Zn的成分比例明显减少,Mg元素含量增大,更接近于基体成分,固溶度较大。

2.3 力学性能及加工性能分析

图4 A板和B板第五道次轧制后各方向的金相组织

Fig. 4 Metallographs of A and B cast-rolling plates in different directions after fifth-pass rolling

图5 A板和B板析出相分布的SEM像及EDS分析结果

Fig. 5 SEM images showing distribution of precipitates in A and B plates and EDS results

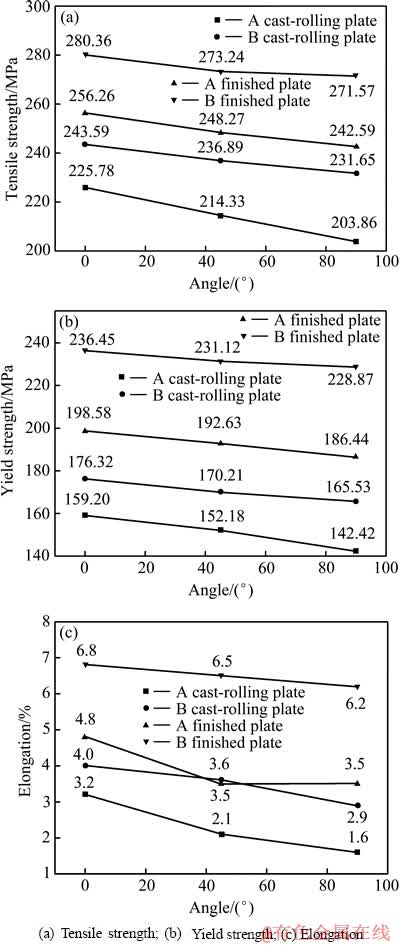

常规及复合能场镁合金板带轧制前后抗拉强度、屈服强度和伸长率分别在与轧制方向成0°、45°及90°方向上的变化见图6。由图6可知,初始状态下复合能场铸轧板3个方向上的平均抗拉强度、屈服强度以及伸长率分别比常规铸轧板的提高10.58%、12.84%和52.17%,而终轧成品板的抗拉强度、屈服强度及伸长率分别比常规铸轧板的提高了10.45%、20.56%和65.25%。

图6 分别与轧制方向成0°、45°及90°时A、B板材的力学性能

Fig. 6 Mechanical properties of A and B plate at angles with rolling direction of 0°, 45° and 90°

经五个道次轧制后,可明显观察到A板颜色暗淡、无金属光泽且边缘出现少许开裂,而B板颜色较亮、开裂现象明显减轻(形貌见图7)。另外,与初始板对比,采用相同轧制工艺经五道次轧制后,A、B终轧板的平均抗拉强度、屈服强度及伸长率分别提高了16.02%、24.19%、71.01%和15.87%、36.01%、85.71%,除抗拉强度的改善较小之外,B板其他性能的提高效果均优于A板的。

图7 A和B终轧板边部裂纹图

Fig. 7 Edge crack photos of finished plate

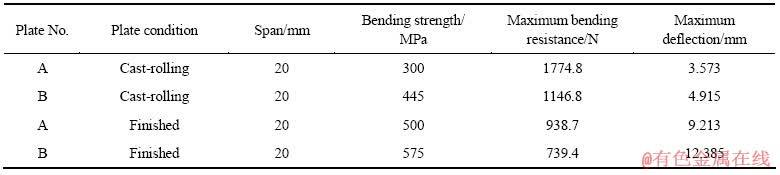

镁合金板材在三点弯曲试验机上进行弯曲试验,测试结果如表3所列。由表3可知,在铸轧和终轧两种状态下,B板抗弯强度及最大挠度均较大,而最大弯曲抗力均较小。变形抗力小使板材易于加工,且可减少加工工具磨损;而当抗弯强度和最大挠度大地,板材弯曲性能好,开裂倾向显著减小,从而降低加工成本。

3 分析与讨论

3.1 复合能场对镁合金微观组织的影响

表3 A板和B板拉伸性能测试结果

Table 3 Tensile test results of A and B plate

镁熔体在电磁场搅拌过程中,受径向挤压及切向变形作用,各部位产生小位移震荡,粗大枝晶在不断震荡与相互挤擦中被剪断并破碎,抑制了枝晶臂的进一步生长。提高形核率,运动状态由简单变为复杂且无规律,这种运动状态使镁溶液在型壁处冷却,从而使凝固持续进行。另外,热金属自溶体中心区域被带回,结晶前沿重新融化,从而使整体温度分布均匀,促进微观组织均匀分布。电磁搅拌力作用范围广,搅拌可使能场的作用传递到整个区域。引入超声波后,一方面,熔体在震动过程中产生大量微小空化泡,其在超声波传递过程中承受压力并破裂,粗大晶粒在冲击波中破碎,晶核大量增殖,未破碎部分经塑性变形后,枝晶网胞大幅度退化;另一方面,位于结晶壁处的晶核受震动作用脱离结晶壁,并均匀分布在熔体内部,成为新的形核质点,细化晶粒。超声波作用过程中,不断生成的能量可以补充重新形核产生新界面时的能量损失,提高形核率。在复合能场的共同作用下,两类能场相互叠加、协调产生作用,使震动及搅拌效果得以加强,在电磁震荡中,镁溶液中粗大晶粒被不断破碎,形核率大幅提高的同时,超声波不断补给形核时的能量损失,并使温度场分布均匀,晶核数增加,再结晶充分进行,晶粒显著细化且均匀分布。

若析出相分布过于集中,基体相的连续性遭到破坏,容易造成应力集中,影响合金的塑性,而弥散分布的析出相可使合金承受较大的变形,塑性提高,并强化合金,因此,在镁合金板材的生产中应尽可能使析出相细化且弥散分布。添加电磁超声复合能场后,在搅拌及震动作用下,析出相弥散分布,很好地满足了此要求。

3.2 复合能场对镁合金力学性能及加工性能的影响

相同条件下,由于镁溶液始终处于复合能场的搅拌与震动中,凝固前沿的温度场和流动场受到影响,且粗大晶粒被破碎,团聚形式变为均匀分布,形核率提高。析出相减少且弥散分布在基体相中,起到钉扎作用,强化镁合金,并可保持基体相的完整性和连续性不被破坏,不易形成应力集中。综上所述可知,通过改善镁合金板材的微观组织可提高力学性能,一方面,圆滑、细小晶粒的晶界易发生滑动、转动及移动,参与塑性变形;另一方面,屈服强度随晶粒尺寸减小而增大,其关系可用Hall-Petch公式表示:

(1)

(1)

式中: 为材料屈服强度;d为晶粒平均直径;

为材料屈服强度;d为晶粒平均直径; 为晶格摩擦力;K为Petch斜率;

为晶格摩擦力;K为Petch斜率; 和K均为与材料相关的常数[10]。此外,晶粒越细小、晶界越曲折,可阻碍裂纹沿晶界的传播。在相同加工条件下,降低弯曲变形抗力,提高抗弯强度及最大挠度,减轻板材裂纹倾向,从而减少材料及工具损耗,提高成品率,克服镁合金难加工及成本高的缺陷,使其加工和应用空间更加广泛。

和K均为与材料相关的常数[10]。此外,晶粒越细小、晶界越曲折,可阻碍裂纹沿晶界的传播。在相同加工条件下,降低弯曲变形抗力,提高抗弯强度及最大挠度,减轻板材裂纹倾向,从而减少材料及工具损耗,提高成品率,克服镁合金难加工及成本高的缺陷,使其加工和应用空间更加广泛。

4 结论

1) 电磁超声复合能场可有效细化晶粒,使之均匀分布,并在镁合金板带铸轧及整个深加工过程中晶粒细化效果更加显著。常规铸轧板及经一、三、五道次轧制后的板材晶粒尺寸分别为90~105 μm、75~85 μm、60~70 μm、40~50 μm;而在相同条件下,添加复合能场轧制后,其晶粒尺寸分别为60~70 μm、55~60 μm、25~30 μm、15~20 μm,观察整个组织演变过程,复合能场板带晶粒尺寸减小约75%,而常规板带仅细化50%左右。

2) 复合能场使析出相弥散、均匀分布在晶界及晶粒内部,而常规镁合金板材析出相多以团聚形式聚集在晶界处。

3) 复合能场可大幅提高AZ61镁合金板带力学性能。相对常规铸轧板而言,复合能场铸轧板的抗拉强度、屈服强度及伸长率分别提高了10.58%、12.84%和52.17%,而终轧成品板的分别提高了 10.45%、20.56%和65.25%,除抗拉强度外,加工完成的复合能场板带屈服强度及伸长率的提升率均大于常规板带的。

4) 复合能场可改善AZ61镁合金板材弯曲加工性能。与常规铸轧相比,复合能场铸轧板轧制后裂纹倾向小,且抗弯强度、最大挠度较大,弯曲抗力较小,可减少加工过程中材料及工具磨损。

REFERENCES

[1] 李天生, 徐 慧. 镁合金成形技术的研究和发展现状[J]. 材料研究与应用, 2007, 1(2): 91-94.

LI Tian-sheng, XU Hui. Research and development status of the forming technology of magnesium alloys[J]. Materials Research and Application, 2007, 1(2): 91-94.

[2] MIN Dong, SHEN Jun, LAI Shi-qiang, CHEN Jie. Effect of heat input on the microstructure and mechanical properties of tungsten inert gas arc butt-welded AZ61 magnesium alloy plates[J]. Materials Characterization, 2009, 60(12): 1583-1590.

[3] PEREZ-PRADO M T, RUANO O A. Texture evolution during annealing of magnesium AZ31 alloy[J]. Scripta Materialia, 2002, 46(2): 149-155.

[4] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Research and development and application of wrought magnesiumalloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[5] KIM W J, HONG S I, KIM Y S. Texture development and its effect on mechanical properties of an AZ61 Mg alloy fabricated by equal channel angular pressing[J]. Acta Materialia, 2003, 51(11): 3293-3307.

[6] AGNEW S R, HORTON J A, LILLO T M, BROWN D W. Enhanced ductility in strongly textured magnesium produced by equal channel angular processing[J]. Scripta Materialia, 2004, 50(3): 377-381.

[7] PEREZ-PRADO M T, VALLE D, RUANO O A. Grain refinement of Mg-Al-Zn alloys via accumulative roll bonding[J]. Scripta Materialia, 2004, 51(11): 1093-1097.

[8] SAITO Y, UTSUNOMIYA H, SUZUKI H, SAKAI T. Improvement in the r-value of aluminum strip by a continuous shear deformation process[J]. Scripta Materialia, 2000, 42(12): 1139-1144.

[9] UTSUNOMIYA H, HATSUDA K, SAKAI T, SAITO Y. Continuous grain refinement of aluminum strip by conshearing[J]. Materials Science and Engineering A, 2004, 372(1/2): 199-206.

[10] 杜文博, 秦亚灵, 严振杰, 左铁镛. 大塑性变形对镁合金微观组织与性能的影响[J]. 稀有金属材料与工程, 2009, 38(10): 1870-1875.

DU Wen-bo, QIN Ya-ling, YAN Zhen-jie, ZUO Tie-yong. Influence of severe plastic deformation on microstructure and properties of magnesium alloy[J]. Rare Metal Materials and Engineering, 2009, 38(10): 1870-1875.

[11] 夏伟军, 蔡建国, 陈振华, 陈 刚, 蒋俊峰. 异步轧制AZ31镁合金的微观组织与室温成形性能[J]. 中国有色金属学报, 2010, 20(7): 1247-1253.

XIA Wei-jun, CAI Jian-guo, CHEN Zhen-hua, CHEN Gang, JIANG Jun-feng. Microstructure and room temperature formability of AZ31 magnesium alloy produced by differential speed rolling[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7): 1247-1253.

[12] 仲增墉. 中国薄板坯连铸连轧技术的现状和发展[J]. 钢铁, 2003, 38(7): 4-27.

ZHONG Zeng-yong. Thin slab casting and rolling in China[J]. Iron and Steel, 2003, 38(7): 4-27.

[13] 谭湘夫, 毛大恒, 蔡安辉, 安伟科,张晓红. 镁合金板带双辊连续铸轧试验研究[J]. 机械工程学报, 2012, 48(16): 30-35.

TAN Xiang-fu, MAO Da-heng, CAI An-hui, AN Wei-ke, ZHANG Xiao-hong. Experimental study on twin-roll casting magnesium alloy strip[J]. Journal of Mechanical Engineering, 2012, 48(16): 30-35.

[14] 冯海阔, 于思荣. 超声波在冶金及金属基复合材料制备过程中的应用[J]. 特种铸造及有色合金, 2006, 26(1): 31-33.

FENG Hai-kuo, YU Si-rong. Application of ultrasonic in metallurgy and metal based composite material preparation process[J]. Special Casting and Nonferrous Alloys, 2006, 26(1): 31-33.

[15] 房灿峰, 张兴国, 季首华, 于延浩, 金俊泽. AZ61镁合金软接触电磁连铸的研究[J]. 稀有金属材料与工程, 2006, 35(8): 1319-1322.

FANG Can-feng, ZHANG Xing-guo, JI Shou-hua, YU Yan-hao, JIN Jun-ze. Study of soft contact electromagnetic continuous casting of AZ61 magnesium alloy[J]. Rare Metal Materials and Engineering, 2006, 35(8): 1319-1322.

[16] 张小立, 凌向军, 李廷举, 谢水生,金云学. 电磁搅拌过程中镁合金半固态浆料初生相颗粒的团簇行为[J]. 中国有色金属学报, 2012, 22(9): 2448-2453.

ZHANG Xiao-li, LING Xiang-jun, LI Ting-ju, XIE Shui-sheng, JIN Yun-xue. Agglomerating behavior of primary solid particles in magnesium alloy semisolid slurry during electromagnetic stirring[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2448-2453.

[17] 刘俊伟, 陈振华, 陈 鼎. 镁合金轧制板材低温变形行为与微观机制[J]. 中国有色金属学报, 2008, 18(9): 1577-1583.

LIU Jun-wei, CHEN Zhen-hua, CHEN Ding. Microstructure evolution and deformation behavior of hot-rolled Mg alloy at low temperatures[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(9): 1577-1583.

[18] 胡水平, 王 哲. 织构和晶粒尺寸对AZ31镁合金薄板成形性能的影响[J]. 中国有色金属学报, 2012, 22(9): 2424-2429.

HU Shui-ping, WANG Zhe. Effects of texture and grain size on press formability of AZ31 magnesium alloy sheets[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2424-2429.

[19] JIANG L, JONAS J J, LUO A A, SACHDEV A K,GODET S. Twinning-induced softening in polycrystalline AM30 Mg alloy at moderate temperatures[J]. Scripta Materialia, 2006, 54(5): 771-775.

[20] MOHRI T, MABUCHI M, NAKAMURA M, ASAHINA T, IWASAKI H, AIZAWA T, HIGASHI K. Microstructural evolution and superplasticity of rolled Mg-9Al-1Zn[J]. Materials Science and Engineering A, 2000, 290(1/2): 139-144.

[21] BARNETT M R. Influence of deformation conditions and texture on the high temperature flow stress of magnesium AZ31[J]. Journal of Light Metals, 2001, 1(3): 167-177.

(编辑 龙怀中)

基金项目:高性能复杂制造国家重点实验室(中南大学)自主研究课题(zzyjkt2013-07B)

收稿日期:2013-11-21;修订日期:2014-05-26

通信作者:黄元春,教授,博士;电话:0731-88877315;E-mail: 123111088@csu.edu.cn