文章编号:1004-0609(2010)02-0182-07

电磁场和钙微合金化对变形镁合金AZ61

组织和力学性能的影响

任 政,张兴国,邱 月,隋 里,张 涛,金俊泽

(大连理工大学 材料科学与工程学院,铸造工程研究中心,大连 116024)

摘 要:研究电磁场和钙微合金化对连铸造过程中变形镁合金微观组织和力学性能的影响。利用金相显微镜(MEF-4A)、X射线衍射仪(XRD-6000)、扫描电镜(JSM-5600LV)和电子探针(EPMA-1600)对制备的连铸造锭微观组织、相组成和元素分布进行分析,并利用MTS NFW-810型试验机对连铸造锭的力学性能进行考察。结果表明:电磁场和钙微合金化复合作用能连续铸造出表面光滑、无氧化夹杂和偏析瘤的高质量铸锭,合金的微观组织得到改善,施加电磁场和钙微合金化后变形镁合金AZ61连铸锭具有晶粒细小、析出相弥散分布的均匀组织;电磁场和钙微合金化均能提高变形镁合金AZ61的抗拉强度,合金的最大抗拉强度值达到259.4MPa,较直冷连铸AZ61镁合金的提高24.2%;但钙微合金化不利于提高AZ61镁合金的伸长率。

关键词:AZ61镁合金;电磁场;微合金化;Ca

中图分类号:TG146.2 文献标识码: A

Effects of electromagnetic field and microalloying of Ca on

microstructure and mechanical properties of

wrought AZ61 magnesium alloy

REN Zheng, ZHANG Xing-guo, QUE Yue, SUI Li, ZHANG Tao, JIN Jun-ze

(School of Materials Science and Engineering, Foundry Research Center,

Dalian University of Technology, Dalian 116024, China)

Abstract: The continuous cast of wrought magnesium alloy AZ61 with or without electromagnetic field and microalloying of Ca was investigated. The microstructures and mechanical properties of the billets were analyzed by MEF-4A metallographic microscopy, XRD-6000 diffractometry, JSM-5600LV scanning electron microscopy, EPMA-1600 electron probe microanalyser and MTS NEW-810. The results show that the billets prepared by electromagnetic cast (EMC) and microalloying of Ca have smooth surface, and the defects, such as segregation and trapped oxide, on the billet surface can be eliminated. The microstructure is improved through applying electromagnetic cast (EMC) and microalloying of Ca,the refined grains and β-Mg17Al12 phases with small size are observed. The electromagnetic field and microalloying of Ca can improve the tensile strength, and the yield strength of AZ61 billet is 259.4MPa, increased by 24.2% compared with that of AZ61 billet by direct cold casting (DCC), but microalloying of Ca is disadvantageous to increasing the elongation of AZ61 magnesium alloy.

Key words: AZ61 magnesium alloy; electromagnetic field; microalloying; Ca

镁及其合金是目前最轻的金属结构材料,与其他结构材料相比,镁及其合金具有比强度和比刚度高,减振性、电磁屏蔽和抗辐射能力强,易切削加工和易回收等一系列优点[1]。基于镁合金的优越性能和人们利用轻质材料缓解环境压力的综合需要,镁及其合金的研究和发展在过去的几十年得到较快的发展。镁及其合金在汽车、航空航天和电子产品的生产中越来越扮演着重要角色[2]。与铸造镁合金相比,变形镁合金的强度指标明显高于铸造镁合金的[3?4]。因此,开发和研究高性能变形镁合金成为世界镁工业的一个重要课题。

电磁连铸是在普通连铸结晶器壁上沿铸造方向开设窄缝,并在金属弯月面部位结晶器外围设置感应线圈,当线圈内通入交变电流时,可以使液态金属受到的电磁压力与金属静压力及表面张力引起的附加压力达到平衡,实现软接触连铸[5]。电磁连铸过程中产生的电磁力对熔体产生强烈的搅拌作用,强化铸坯液相中金属液的运动,从而影响金属液凝固过程中的动量传输、热量传输和质量传输过程,达到减少偏析、细化合金铸态组织和改善合金表面质量的目的[6?7]。电磁连铸技术已经已成功地应用于钢铁、铝合金和铜合金等领域[8?10]。近年来,随着镁工业的推进和发展,电磁连铸技术在镁合金中也得到了发展和应用,并取得较好的效果[11?13]。但由于电磁连铸过程中的电磁力强烈搅拌作用增大了金属液面的不稳定性,也就增大了镁合金液面氧化的可能性。大量研究表明[14?17],钙合金化能提高镁合金的燃点,提高镁合金的纯净度,而且少量的钙还能够细化铸造组织,提高合金的力学性能。钙、镁和铝能形成热稳定性很高的第二相,显著改善镁合金的高温蠕变性能。此外,钙还具有价格低廉、密度小和熔点低等一系列优点。本文作者采用变形镁合金AZ61添加少量的钙进行微合金化,并利用电磁连铸技术对铸造工艺进行改善,探讨电磁场和钙微合金化对变形镁合金AZ61组织、相组成和性能的影响。

1 实验

镁合金的化学成分如表1所列。本试验配制合金所用原料为纯镁锭(纯度约为99.7%)、铝锭(纯度约为99.99%)、锌锭(纯度约为99.9%)、纯钙(纯度约为99.9%)和Al-10%Mn中间合金。采用自制电阻炉进行合金熔炼,炉内温度由可控硅温度控制仪来控制。先将坩埚预热至700 ℃,在坩埚底部均匀地撒上一层粉状RJ-2熔剂(其成分(质量分数)为NaCl 36%~38%,CaF2 15%~20%,MgCl2 44%~47%),然后加入镁锭和铝锭并在400 ℃预热2 h,并在炉料上撒一层RJ-2熔剂,熔剂用量约占炉料质量的1%~2%。待镁锭和铝锭熔化后,加入预热的金属锌及Al-10%Mn中间合金,然后升温熔炼,待合金完全熔化后对熔体轻轻搅拌,静置15 min后撇渣,最后待金属熔体降低到720 ℃后开始浇铸。对于AZC6101合金,待AZ61合金完全熔化后,将金属液降到690 ℃,加入金属Ca,然后升温到720~730 ℃,待熔体温度稳定后对熔体轻轻搅拌,静置15 min后撇渣,最后待金属熔体降低到720 ℃后开始浇铸。为了减少熔体在浇铸过程中的氧化,提高铸锭质量,熔体浇铸的过程在Ar/SF6混合气体保护下进行。

表1 变形镁合金的化学成分

Table 1 Chemical composition of wrought magnesium alloy (mass fraction, %)

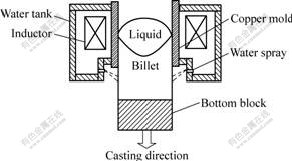

对变形镁合金AZ61和AZC6101采用直冷连铸(DCC)和电磁连铸(EMC)进行试验,制备出d 120的镁合金连铸毛坯。试验过程中冷却水流量为1.2 t/h,拉坯速度为1.5 mm/s。对电磁连铸过程中,施加频率2.5 kHz、功率10 kW的交变磁场,试验装置示意图如图1所示。

图1 电磁连铸试验装置示意图

Fig.1 Schematic diagram of electromagnetic cast

根据荧光光谱(XRF-1800)的分析结果,对变形镁合金AZ61和AZC6101的成分在浇铸前进行调整。合金铸态金相试样分别从铸锭横截面边部和中心处截取,并加工成尺寸为d 15 mm×20 mm的圆柱体,然后用200#、400#、600#、800#、1 000#和1 200#砂纸打磨后抛光,抛光后用4%的硝酸酒精进行浸蚀,浸蚀后在MEF-4A 金相显微镜进行金相观察,并用XRD—6000型X射线衍射仪对合金的相组成进行表征,采用JSM?5600LV型扫描电镜对合金析出相的形貌和分布进行进一步分析,并对电磁连铸AZC6101镁合金中钙元素分布进行面扫描分析(EPMA-1600)。不同条件下制备的合金铸锭按照国标GB/T 16865—1997分别加工3个半径为R3的标准拉伸试样,拉伸性能测试在MTS NEW?810型试验机上进行,拉伸速率控制为10?2 s?1,测量后求平均值。

2 结果和讨论

2.1 变形镁合金连铸锭的表面形貌

变形镁合金AZ61直冷连铸和AZC6101电磁连铸锭照片如图2所示。从图2(a)可以看出,变形镁合金AZ61直冷连铸锭的表面有大量的氧化夹杂和偏析瘤。从整个铸锭来看,沿铸锭开始端到铸造末端氧化夹杂越来越多,在铸锭末端聚集了大量的氧化残留物。但当变形镁合金AZ61添加微量的钙和施加10kW的中频交变磁场后,氧化夹杂和偏析瘤则完全消失,得到具有美观金属光泽和光滑表面的高质量铸锭(见图2(b))。由此可见,变形镁合金施加中频电磁场和钙微合金化有利于改善连铸锭的表面质量。

图2 AZ61 (DCC)和AZC6101 (EMC)连铸锭的表面形貌

Fig.2 Appearance photos of AZ61 (DCC) (a) and AZC6101 (EMC) billets (b)

在变形镁合金AZ61的直冷连铸过程中,当镁合金液接触到结晶器壁时,在结晶器壁的冷却作用下,镁液在结晶器内表面形成一层凝固壳。由于镁液的凝固收缩,使凝固壳脱离结晶器壁,导致凝固壳与器壁间形成一气隙,由于空气几乎不导热,因此,凝固壳在液穴内镁液的作用下产生温度回升,使凝固壳枝晶间的低熔点化合物重新熔化,这些低熔点化合物在液穴内镁液静压力作用下,通过枝晶间隙被挤出铸锭表面而形成偏析瘤。而在中频电磁场(频率2.5 kHz,功率10 kW)的作用下,电磁力抵消了液体金属的静压力,减少了金属与结晶器壁之间的接触压力和摩擦阻力[5];电磁搅拌还使液相区的金属液温度趋于一致,使初生凝固壳变薄,减少一冷区的高度[6];电磁感应加热则减小了凝固壳的温降,减少了一冷区的热扩散,降低了初期凝固壳的位置[6]。中频电磁场对熔体这些综合作用都有利于改善合金的表面质量。

镁合金与铝合金不同,其氧化膜结构的α值较低,在高温下不足以阻止氧对合金液体的进一步氧化。在变形镁合金AZ61的直冷连铸过程中,从熔化炉中进入的高温液体就更容易破坏本不牢固的保护壳层。YOU等[18]通过研究钙对高温镁氧化的影响中发现,含钙镁合金在熔体表面形成的热稳相和CaO/MgO复合氧化壳层能够有效的阻止镁合金的连续氧化。所以,在变形镁合金AZC6101的电磁连铸过程中,合金中的Ca和Mg与O2形成致密的CaO/MgO复合保护壳层,从而有效地抑制铸锭中氧化夹杂的产生,合金铸锭的质量得到大大提高。由此可见,通过对变形镁合金AZ61 施加中频电磁场和钙微合金化有助于改善镁合金的表面质量,得到表面光滑、无氧化夹杂和偏析瘤的高质量变形镁合金铸锭。

2.2 变形镁合金铸态微观组织

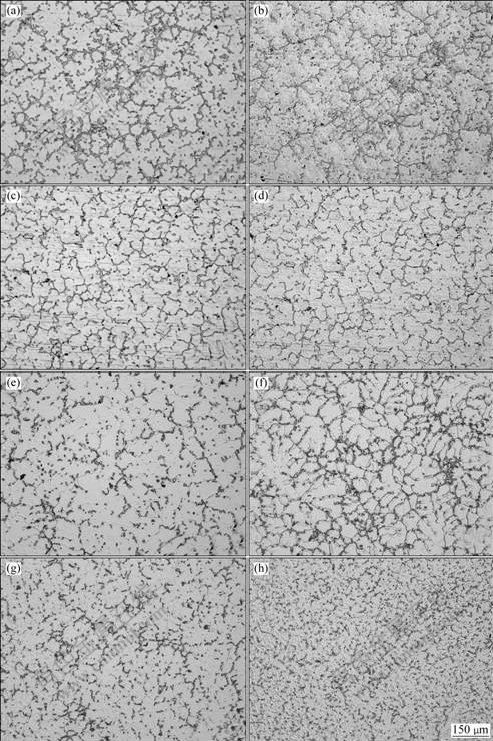

在不同条件下得到的变形镁合金连铸锭的微观组织如图3所示。从图3(a)和(b)可以看出,变形镁合金AZ61在直冷连铸条件下连铸锭的铸态微观组织较为粗大,析出相呈连续状分布在晶界。当施加中频磁场化,但析出相仍曾连续状分布。当AZC6101镁合金施后,晶粒在铸锭的边沿和中心处都得到不同程度的细化,且铸锭内外晶粒大小趋于一致,析出相变薄,在晶界处呈断续状分布(见图3(c)和(d))。钙微合金化后变形镁合金AZ61的直冷连铸锭的组织较AZ61略有细加中频磁场后,铸锭的微观组织得到明显的细化,析出相连续分布的状况得到有效改善,在局部呈现了点状弥散分布(见图3(e)、(f)、(g)和(h))。

图3 变形镁合金的铸态微观组织

Fig.3 As-cast microstructures of wrought magnesium alloys: (a) AZ61, DCC, at billet border; (b) AZ61, DCC, at billet center; (c) AZ61, EMC, at billet border; (d) AZ61, EMC, at billet center; (e) AZC6101, DCC, at billet border; (f) AZC6101, DCC, at billet center; (g) AZC6101, EMC, at billet border; (h) AZC6101, EMC, at billet center

在变形镁合金的电磁连铸过程中,电磁搅拌可通过流动的母液对树枝晶的动力折断作用和熔蚀作用而形成大量晶枝碎片,成为晶核;强烈的流动可大大加速液体的传热而使过热度迅速消失、两相区迅速扩大;

同时,强力流动将加速传质,使凝固前沿扩散层减薄,溶质浓度梯度增大,从而使两相区内成分过冷[19]。最终铸锭从边缘到中心形成分布均匀的细小晶粒,而析出的二次相也趋于弥散分布。Ca和Mg的最外层均为两个电子,为表面活性元素,所以钙微合金化后变形镁合金AZ61中的Ca在凝固的过程中偏聚在α-Mg晶粒的相界面上,Ca在界面的聚集增加了成分起伏,提高了过冷度,增加了形核率,减小了枝晶间距,起到阻止α晶粒长大的作用。其次钙的生长抑制因子高达11.94[15],在所有的溶质元素中,Ca元素的GRF值仅次于Fe和Zr,能明显抑制晶粒的生长,从而细化晶粒。所以,在电磁场和钙微合金化的复合作用下,变形镁合金AZ61得到晶粒细小、析出相弥散的均匀组织。

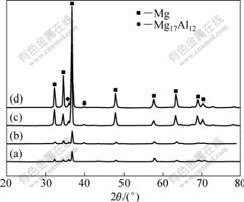

不同铸造条件下合金铸锭的XRD谱如图4所示。从图4可以看出,合金的析出相主要有α-Mg和β相Mg17Al12组成。对比图4中曲线(a)和(b)可以看出,电磁场并没有改变变形镁合金AZ61凝固中相的生成。从图4中曲线(c)和(d)可以看出,变形镁合金AZC6101中各相的峰值比AZ61有所增强,但合金中并没有出现(Mg, Al)2Ca 相,这可能主要与合金中的钙含量较少有关[20]。

图4 变形镁合金的XRD谱

Fig.4 XRD patterns of wrought magnesium alloys: (a) AZ61, DCC; (b) AZ61, EMC; (c) AZC6101, DCC; (d) AZC6101, ECC

2.2 变形镁合金的铸态力学性能

变形镁合金不同铸造条件下的力学性能如图5所示。从图5可以看出,施加中频磁场和钙微合金化后,合金的抗拉强度达到最大值259.4MPa,比直冷连铸镁合金AZ61铸锭抗拉强度提高了约24.2%。从图5中合金伸长率的对比研究发现,变形镁合金AZ61电磁连铸锭的伸长率达到最大为14.8%,比直冷连铸镁合金AZ61铸锭的提高了32.1%。当对镁合金AZ61钙微合金化后,在直冷连铸条件下,合金AZ61和AZC6101伸长率基本相当,但施加同等条件电磁后,变形镁合金AZC6101的伸长率较AZ61的有所下降。

图5 在不同条件下变形镁合金的力学性能

Fig.5 Mechanical properties of wrought magnesium alloys under different conditions

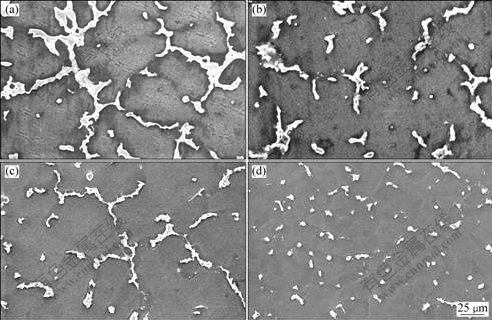

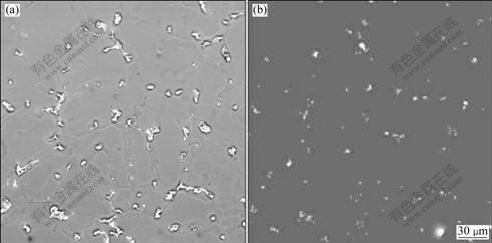

不同条件下连铸合金析出相的SEM像如图6所示。从图6可以看出,合金施加中频电磁场后,合金在直冷连铸过程中形成的在晶界析出的连续状析出相均得到改善,得到断续的弥散析出相(见图6(c)和(d))。结合合金的的力学性能,这种断续的弥散分布的析出相有利于改善合金的力学性能。此外,合金连铸过程中施加电磁场使晶粒变得更加细小(见图3),晶粒越细小,同样体积材料内晶界面积越大,合金的拉伸性能越好。施加电磁后,镁合金AZ61和AZC6101的抗拉强度和伸长率较直冷连铸锭的均有所提高。对比图6(a)、(b)和(c)、(d)可以看出,对镁合金AZ61钙微合金化后,合金的析出相变细,并且有短棒状和球状析出。从合金的XRD谱图4得知,合金钙微合金化后并没有生成含钙的合金相(可能与含量较少有关),但从电磁连铸AZC6101镁合金钙元素的面扫描分析可知,Ca除了一部分熔入基体外,另一部分Ca连同β相一并析出(见图7)。这和一些学者得出的Ca对Mg-Al合金系合金化过程中部分Ca溶解在Mg17Al12相中的结论是一致的[14, 16],本文作者在对AZ31钙微合金化的研究中也发现了类似的情况。结合合金的力学性能可以发现,钙微合金化不利于提高变形镁合金AZ61的伸长率,这可能是由于钙在晶界的析出导致镁合金在变形时晶粒的相互协调性有所降低。另一种可能的原因是形成的微量Al2Ca相与晶界β-Mg17Al12相的晶格结构不同(Al2Ca相为面心立方结构,而β-Mg17Al12为体心立方结构),导致晶界的聚合力降低。所以,钙微合金化导致合金的伸长率有所下降。

图6 不同条件下连铸镁合金析出相的SEM像

Fig.6 SEM images of extraction phase in magnesium alloys under different conditions: (a) AZ61, DCC; (b) AZ61, EMC; (c) AZC6101, DCC; (d) AZC6101, EMC

图7 电磁连铸AZC6101中 Ca 元素的分布

Fig.7 EPMA image of Ca and corresponding map scanning of Ca element in AZC6101 alloy (EMC)

3 结论

1) 变形镁合金AZ61通过施加中频磁场和钙微合金化可以制备出表面光滑、无氧化夹杂和偏析瘤的高质量铸锭。

2) 在电磁场和钙微合金化的复合作用下,变形镁合金AZ61连铸锭得到晶粒细小,析出相弥散的均匀组织。

3) 电磁场和钙微合金化均能提高变形镁合金AZ61的抗拉强度,但钙微合金化不利于提高AZ61镁合金的伸长率。

REFERENCES

[1] 陈振华. 镁合金[M]. 北京: 化学工业出版社, 2004.

CHEN Zhen-hua. Magnesium alloys[M]. Beijing: Chemical Industry Press, 2004.

[2] YANG Z, LI J P, ZHANG J X, LORIMER G W, ROBSON J. Review on research and development of magnesium alloys[J]. Acta Metallurgica Sinica, 2008, 21(5): 313?328.

[3] KAINER K U. Magnesium alloys and technologies[M]. New York: Jon Wiley & Sons Ltd, 2003.

[4] 潘复生, 韩恩厚. 高性能变形镁合金及加工技术[M]. 北京: 科学出版社, 2007.

PAN Fu-sheng, HAN En-hou. High performance magnesium alloys and processing technology[M]. Beijing: Science Press, 2007.

[5] 贾 非. 电磁连续铸造过程工艺优化及组织性能研究[D]. 大连: 大连理工大学, 2002.

JIA Fei. Study of technique optimization and structure property of electromagnetic continuous casting[D]. Dalian: Dalian University of Technology, 2002.

[6] 任忠鸣, 董华锋, 邓 康, 蒋国昌. 软接触结晶器电磁连铸中初始凝固的基础研究[J]. 金属学报, 1999, 35(8): 851?855.

REN Zhong-ming, DONG Hua-feng, DENG Kang, JIANG Guo-chang. Study of initial solidification in soft contact electromagnetic continuous casting[J]. Acta Metallurgica Sinica, 1999, 35(8): 851?855.

[7] LI Ting-ju, NAGAYA S, SASSA K, ASAI S. Study of meniscus behavior and surface properties during casting in a high-frequency magnetic field[J]. Metall Mater Trans B, 1995, 26: 353?359.

[8] HAO Hai, ZHANG Xing-guo, YAO Shan, JIN Jun-ze. Improvement of casting speed and billet quality of direct chill cast aluminum wrought alloy with combination of slit mold and electromagnetic coil[J]. Mater Trans, 2007, 48: 2194?2201.

[9] LI Jian-chao, WANG Bao-feng, MA Yong-li. Effect of complex electromagnetic stirring on inner quality of high carbon steel bloom[J]. Mater Sci Eng A, 2006, 425: 201?204.

[10] LI Xin-tao, GUO Zhao-xiang, ZHAO Xiang-wei. Continuous casting of copper tube billets under rotating electromagnetic field[J]. Mater Sci Eng A, 2007, 460/461: 648?651.

[11] 马晓东, 张兴国, 任 政, 房灿峰, 郝 海, 金俊泽. 电磁连铸过程中电磁场对变形镁合金凝固组织的影响[J]. 铸造, 2007, 56(9): 914?917.

MA Xiao-dong, ZHANG Xing-guo, REN Zheng, FANG Can-feng, HAO Hai, JIN Jun-ze. The effects of electromagnetic field on the solidification structure of magnesium alloys in EMC process[J]. Foundry, 2007, 56(9): 914?917.

[12] 房灿峰, 张兴国, 季首华, 于延浩, 金俊泽. AZ61镁合金软接触电磁连铸的研究[J]. 稀有金属材料与工程, 2006, 35(8): 1319?1322.

FANG Can-feng, ZHANG Xing-guo, JI Shou-hua, YU Yuan-hao, JIN Jun-ze. Research on soft contact electromagnetic continuous casting of AZ61 magnesium alloy[J]. Rare Metals and Materials Engineering, 2006, 35(8): 1319?1322.

[13] 于延浩, 房灿峰, 张兴国, 郝 海, 金俊泽. AZ61镁合金电磁连铸工艺与性能研究[J]. 铸造, 2006, 55(3): 276?280.

YU Yan-hao, FANG Can-feng, ZHANG Xing-guo, HAO Hai, JIN Jun-ze. Study on technology parameter and properties of AZ61 magnesium alloy under soft-contact EMC[J]. Foundry, 2006, 55(3): 276?280.

[14] CAO G, KOU S. Hot tearing of ternary Mg-Al-Ca alloy castings[J]. Metals Mater Trans A, 2006, 37: 3647?3663.

[15] LEE Y C, DAHLE A K, STJOHN D H. The role of solute in grain refinement of magnesium[J]. Mater Trans A, 2000, 31: 2895.

[16] LI Pei-jie, TANG Bin, KANDALOVA E G. Microstructure and properties of AZ91D alloy with Ca additions[J]. Mater Lett, 2005, 59: 671?675.

[17] HIRAI K, SOMEKAWA H, TAKIGAW Y, HIGASHI K. Effects of Ca and Sr addition on mechanical properties of a cast AZ91 magnesium alloy at room and elevated temperature[J]. Mater Sci Eng A, 2005, 403: 276?280.

[18] YOU B S, PARK W W, CHUNG I S. The effect of calcium addition to magnesium on the microstructure and compositional changes of oxide film formed at high temperature[J]. Mater Trans A, 2001, 42(6): 1139?1141.

[19] 周尧和, 胡壮麒, 介万奇. 凝固技术[M]. 北京: 机械工业出版社, 1998.

ZHOU Yao-he, HU Zhuang-qi, JIE Wan-qi. Solidification technology[M]. Beijing: China Machine Press, 1998.

[20] YUSUKE N, AKIRA W, OHORI K. Effects of Ca, Sr addition on properties of Mg-Al based alloys[J]. Mater Trans A, 2006, 47(4): 1031?1039.

基金项目:国家自然科学基金资助项目(50475157,50234022);教育部重点资助项目(105052)

收稿日期:2009-00-00;修订日期:2009-07-16

通信作者:张兴国,教授,博士;电话:0411-84706183;E-mail:zxgwj@dlut.edu.cn

(编辑 龙怀中)