AZ91D镁合金化学复合镀Ni-P-ZrO2的工艺与性能

宋影伟, 单大勇, 陈荣石, 韩恩厚

(中国科学院 金属研究所 材料环境腐蚀试验研究中心, 沈阳 110015)

摘 要: 对镁合金传统化学镀工艺进行了改进, 避免了使用氢氟酸和六价铬等有毒物质。 采用化学镀与化学复合镀相结合方法, 在AZ91D镁合金上获得了Ni-P-ZrO2 纳米化学复合镀层, 并研究了新工艺化学镀前处理和镍沉积机理及复合镀层的结构和性能。 结果表明: 新工艺方法获得的Ni-P镀层更均匀、 致密, 耐蚀性优于传统工艺化学镀层; Ni-P-ZrO2 复合镀层与AZ91D合金基体在3.5%NaCl 溶液中的动电位极化曲线对比表明, 该复合镀层对镁合金可以起到明显的保护作用; 从磨损实验结果可见, Ni-P镀层的磨损质量损失率几乎为Ni-P-ZrO2 镀层的3倍, 说明ZrO2 纳米粉的加入能改善镀层的耐磨性。

关键词: A291D镁合金; Ni-P-ZrO2镀层; 化学复合镀; 耐蚀性; 耐磨性 中图分类号: TG174.4

文献标识码: A

Processes and properties of electroless Ni-P-ZrO2 composite coating on AZ91D magnesium alloy

SONG Ying-wei, SHAN Da-yong, CHEN Rong-shi, HAN En-hou

(EnvirProcesses and properties of electroless Ni-P-ZrO2 composite coating on AZ91D magnesium alloy onmental Corrosion Center, Institute of Metals Research,Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: Traditional process of electroless Ni-P plating on AZ91D magnesium alloy was improved, and the poisonous substances of hydrofluoric acid and Cr6+ were not used. The mechanism of pretreatment and nickel initial deposition for new process was investigated. Meantime, the process of Ni-P-ZrO2 composite plating was developed, and the microstructure and properties of the composite coating were studied. The results show that the Ni-P coating prepared with new process is more compact and uniform, and the corrosion resistance is superior to that of traditional process Ni-P coating. The potentiodynamic polarization curves in 3.5%NaCl solution indicate that the Ni-P-ZrO2 composite coating could provide adequate protection to magnesium alloy substrate. The wear mass loss of Ni-P coating is nearly twice more than that of Ni-P-ZrO2 coating, implying that the wear resistance of the composite coating is improved due to the co-deposition of ZrO2 nanometer particles.

Key words: AZ91D magnesium alloy; Ni-P-ZrO2 coating; electroless composite plating; corrosion resistance; wear resistance

镁合金是密度最小的工业用金属, 具有许多优异的物理和力学性能[1], 在航空、 航天、 汽车、 电子、 通讯等领域获得了广泛的应用。 但是, 耐蚀性差是镁合金进一步应用的障碍之一[2]。 为了提高镁合金的耐蚀性能, 一般采用化学转化、 阳极氧化、 电镀、 化学镀等表面防护技术[3-5]。 比较而言, 镁合金上化学镀镍磷层厚度均匀、 硬度高、 耐磨性和耐蚀性好, 而且有很好的传导性和电磁屏蔽性, 在某些领域是一种不可替代的表面处理方法。 镁合金化学镀研究开始于20世纪四五十年代, 首先由Dow公司设计了浸锌工艺[6, 7], 但是此法有许多的缺点。 近年来镁合金上直接化学镀日益受到重视。 Sharma等[8]采用直接化学镀镍工艺获得的Ni-P镀层经过钝化及热处理后完全满足航天器部件的严苛要求。 Ambat等[9]深入研究了镁合金上直接化学镀的各项工艺参数, 确定了最佳配方。 霍宏伟等[10, 11]在镁合金化学转化膜上沉积Ni-P, 发现耐蚀性得到进一步改善。 然而, 这些直接化学镀工艺不但使用了六价铬和氢氟酸等有危害的物质, 而且镀层容易有孔隙存在。 为此, 本文作者对镁合金前处理工艺进行了改进, 避免使用六价铬和氢氟酸等有毒物质, 提高了镀层的耐蚀性, 而且在化学镀液中加入了纳米粉ZrO2, 制备出了Ni-P-ZrO2纳米复合镀层, 使镀层的耐蚀性和耐磨性都有明显的改善。

1 实验

1.1 样品制备

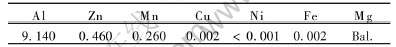

实验材料为AZ91D铸造镁合金, 其化学成分列于表1。

表1 AZ91D镁合金的化学成分

Table 1 Chemical composition of AZ91D alloy (mass fraction, %)

样品尺寸为25mm×20mm×2mm, 用SiC水磨砂纸由粗到细(1000#)打磨, 使所有实验用材料表面呈相同的粗糙度。

化学镀工艺流程为: 预磨试样→碱浸→水洗→活化→水洗→化学镀30min→复合镀→水洗→吹干。 为了提高基体和镀层之间的结合力, 前处理后先化学镀30min, 使基体被Ni-P镀层完全包裹, 然后再进行复合镀。 实验中先将ZrO2 纳米粉(20nm)制备成浓缩浆的形式加入到化学镀液中。 改进后的碱浸溶液以焦磷酸钠为主要成分, pH值大于12, 目的是为了去除样品上的油污, 并增加表面粗糙度。 活化过程采用氟化氢氨取代了对人体极为有害的氢氟酸。 化学镀液成分及操作条件如下: 碱式碳酸镍8~12g/L, 次亚磷酸钠20~25g/L, 柠檬酸钠10~15g/L, 氟化钾5~10g/L, 缓冲剂10~15g/L, pH 5.5~6.5, 温度 80℃。 化学复合镀是在化学镀工艺的基础上加入2~6g/L ZrO2, 1~5mg/L稳定剂, 复合镀过程中采用超声波间歇式搅拌。

1.2 镀层结构和性能测试

复合镀层用X射线衍射进行相成分分析, 表面形貌用扫描电镜观察。

镀层的耐蚀性测试包括3.5%NaCl溶液浸泡实验和动电位极化曲线实验。 其中极化曲线测试使用的是EG&G273系统, 采用标准的三电极体系, 样品为工作电极, 饱和甘汞电极为参比电极, 铂电极为辅助电极。

镀层的耐磨性测试使用的是JM-IV型磨损仪, 对磨副是硬度为HRC62、 d50mm×12mm的钢环, 载荷1.0kg, 转速70r/min。

2 结果与讨论

2.1 AZ91D合金的显微组织

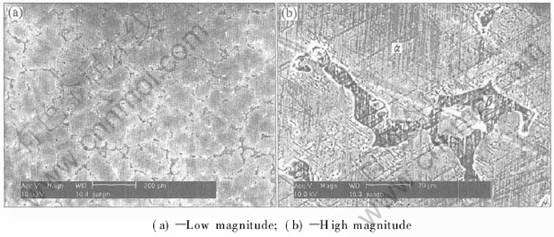

图1所示为AZ91D铸造镁合金的显微组织。 主体为α相, 金属间化合物β相(Mg17Al12)沿晶界呈网状分布。 EDX分析表明, α相的铝含量要远低于β相。 两者的自腐蚀电位也明显不同, 分别为-1.73V和-1.0V[12], 将在合金内部形成腐蚀微电池, 导致该合金的耐蚀性更差。 因此, 镁合金在使用前必须加以防护。

图1 AZ91D镁合金的显微组织

Fig.1 Microstructure of AZ91D alloy

2.2 新工艺化学镀前处理

图2所示为碱浸后AZ91D镁合金的形貌。 β相清晰可见, 表面仍然呈网格结构, 与碱浸前有些类似。 碱浸的目的是为了去除表面的油污和杂质, 增加基体的粗糙度, 提高镀层的结合力。

活化后AZ91D镁合金的形貌如图3所示。 表面变得比较均匀, 隐约可见β相分布所形成的网格结构。 活化的作用是: 一方面可以进一步去除碱浸时留下的残余物质; 另一方面可以生成均匀的MgF2膜[13], 减小β相和α相的差别, 利于化学镀时镍的均匀形核。

图2 AZ91D镁合金碱浸后的表面形貌

Fig.2 Surface morphologies of AZ91D alloy after alkaline cleaning

图3 AZ91D镁合金活化后的表面形貌

Fig.3 Surface morphologies of AZ91D alloy after activating

2.3 化学镀镍沉积过程

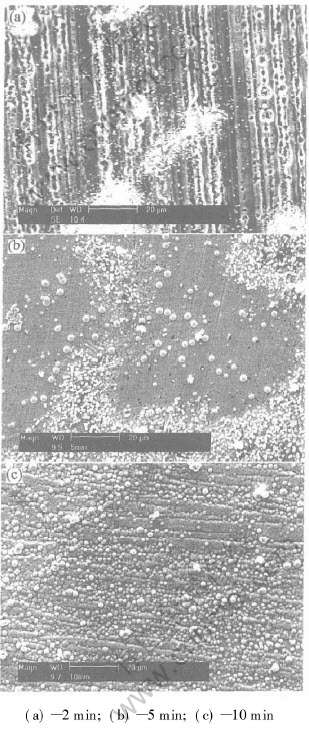

化学镀2min时(图4(a)), 表面各处零星地分布着镍颗粒, 大部分镁基体仍裸露着, 没有镍颗粒沉积在上面。 在化学镀5min后(图4(b)), 基体已经完全被镍层所包裹, 但此时的镀层不是很致密, 有些镍颗粒之间可见孔隙存在。 在10min后(图4(c)), 镀层进一步长大, 镁基体已经完全被覆盖, 该镀层很均匀、 致密, 基本无孔隙存在。

根据上述镀层的生长过程可推测其形核机理如下:

首先, 活化后生成的MgF2膜并不是十分连续的, 某些部位仍然有MgO或Mg存在[14], 浸入到化学镀溶液中后, MgO溶解生成了Mg, 这些有金属镁存在的位置与镀液中的Ni2+发生置换反应, Mg +Ni2+ → Mg2+ +Ni, 生成了金属镍。

其次, 由于镍具有自催化作用, 之后就靠这些初始沉积的镍的自催化作用, 镍核在横向和纵向两个方向同时生长, 最后所有的镍核相连, 把镁基体完全覆盖。

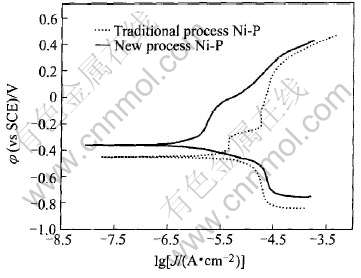

对传统工艺镍的沉积过程的研究表明[15, 16], 镍优先在β相处的氟化物膜下面形核, 施镀过程中氟化物膜不会消失, 而是夹杂在镀层中, 同时镀层中也夹杂有镀液成分, 该混杂层为镀层与基体结合的最薄弱部位, 降低了镀层的结合力。 本文研究的新工艺中β相和α相上的镍形核过程相同, 镀层在各处都是均匀、 致密的。 3.5%NaCl溶液中动电位极化曲线测试证明了新工艺镀层的耐蚀性比传统工艺的更优异。 由图5可见, 新工艺和传统工艺镀层的自腐蚀电位分别为-0.37V和-0.45V, 自腐蚀电流分别为1.5×10-7~7A/cm2和1.3×10-6~6A/cm2。 可见, 新工艺的自腐蚀电位更正, 而自腐蚀电流比传统工艺的要低一个数量级, 这就表明新工艺镀层有更优异的耐蚀性。

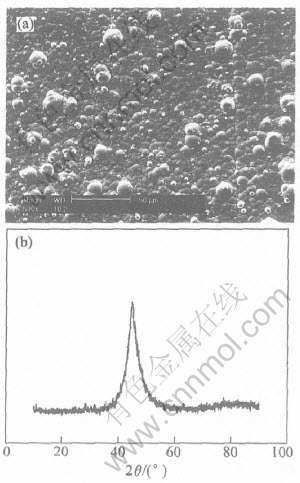

2.4 复合镀层形貌和结构

化学镀30min后再复合镀, 获得的Ni-P-ZrO2镀层的表面形貌和结构如图6所示。 表面布满许多胞状物, 这些胞状物大小十分不均匀, 一些半径很大, 约有十几微米, 而有一些很小只有几十纳米。 纳米粉ZrO2大部分包裹在这些胞状物中, 那些半径很小的胞状物是ZrO2粘附在镀层上后表面仅有少量的镍包裹。 还有一小部分ZrO2没有被镍磷完全覆盖, 部分露在外面。 由X射线衍射谱可见, 在衍射角为45°处出现漫散射馒头峰, 表明该复合镀层为非晶态结构。

图4 化学镀镍不同时间后合金的表面形貌

Fig.4 Surface morphologies of alloy after electroless nickel plated for different time

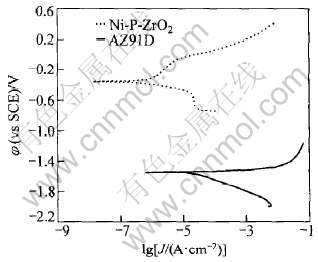

2.5 耐蚀性

图7所示为AZ91D镁合金基体与Ni-P-ZrO2纳米复合镀层在3.5%NaCl溶液中的动电位极化曲线对比。 自腐蚀电位分别为-1.55V和-0.40V左右, 复合镀层的自腐蚀电流远小于AZ91D基体的自腐蚀电流, 表明该复合镀层对镁合金有明显的保护作用。

图5 传统与新工艺镍磷镀层

在3.5%NaCl溶液中极化曲线的对比

Fig.5 Comparison of polarization curves for two kinds of coatings in 3.5%NaCl solution

图6 Ni-P-ZrO2纳米复合镀层的表面形貌和X射线衍射谱

Fig.6 Surface morphology(a) and XRD pattern for Ni-P-ZrO2 coating(b)

图7 AZ91D合金与Ni-P-ZrO2纳米复合镀层在3.5%NaCl溶液中的动电位极化曲线的对比

Fig.7 Comparison of polarization curves for AZ91D and Ni-P-ZrO2 coating in 3.5%NaCl solution

对厚度为20μm左右的Ni-P-ZrO2和Ni-P镀层的耐蚀性通过3.5%NaCl溶液浸泡实验进行了对比。 以浸泡开始到镀层上出现一个肉眼可见的腐蚀坑所经历的时间作为评价耐蚀性好坏的标准, 时间越长说明耐蚀性越好。 每组实验以3个样品的平均值作为最终的实验结果。 Ni-P-ZrO2镀层浸泡可达到482h, 而Ni-P镀层仅为210h。 从浸泡实验结果可见, Ni-P-ZrO2镀层的耐蚀性要明显优于Ni-P镀层, 这主要由于纳米粉ZrO2的加入改善了镀层的耐蚀性。

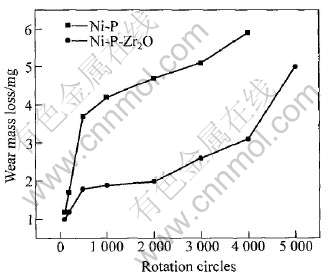

2.6 耐磨性

纳米粉ZrO2加入以后能够起到提高镀层耐磨性的作用, 如图8所示。 随着磨损转数的增加, 两镀层的质量损失都在增加, 但Ni-P镀层的质量损失率几乎为Ni-P-ZrO2纳米复合镀层的3倍。 这主要是由于纳米粉ZrO2是很硬的粒子, 一方面可以起到支撑载荷的作用, 另一方面由于纳米粉ZrO2共沉积于镍磷中增加镀层的均匀性和致密性, 都有助于提高镀层的耐磨性。

3 结论

1) 新工艺化学镀获得的Ni-P镀层的耐蚀性要优于传统的Ni-P镀层。

2) Ni-P-ZrO2纳米复合镀层表面由许多大小不均的胞状物组成, 为非晶态结构。

3) 3.5%NaCl溶液中极化测试表明, Ni-P- ZrO2纳米复合镀层对基体AZ91D可以起到明显的保护作用, 浸泡实验证明Ni-P-ZrO2镀层的耐蚀性比Ni-P镀层更优异。

图8 镀态Ni-P和Ni-P-ZrO2镀层磨损质量损失的对比

Fig.8 Comparison of abrasion mass loss of two kinds of coating with different rotation circles

4) Ni-P镀层的磨损质量损失率几乎为Ni-P-ZrO2纳米复合镀层的3倍, 说明ZrO2纳米粉的加入可以改善镀层的耐磨性。

REFERENCES

[1]Gray J E, Luan B. Protective coatings on magnesium and it alloys—a critical review[J]. Journal of Alloys and Compounds, 2002, 336: 88-113.

[2]Makar G L, Kruger J. Corrosion of magnesium[J]. International Materials Reviews, 1993, 38(3): 138-153.

[3]Zhou W Q, Shan D Y, Han E H, et al. Phosphate conversion coating on die-cast AZ91D and its corrosion resistance[J]. Materials Science Forum, 2004, 488-489: 819-822.

[4]Zhang R F, Shan D Y, Han E H, et al. Two step anodization of AZ91D magnesium alloy[J]. Materials Science Forum, 2004, 488-489: 653-656.

[5]单大勇, 周婉秋, 韩恩厚, 等. 镁合金化学镀层的性能研究[J]. 材料保护, 2004, 37(4): 1-2.

SHAN Da-yong, ZHOU Wan-qiu, HAN En-hou, et al. Properties study on the electroless plating on magnesium alloy[J]. Materials Protection, 2004, 37(4): 1-2.

[6]Delong H K. Method of Producing a Metallic Coating on Magnesium and its Alloys[P]. US 2526544, 1950-10-06.

[7]Delong H K. Electrodeposition of Metal from Alkaline Cyanide Bath[P]. US 2654702, 1948-09-03.

[8]Sharma A K, Suresh M R, Narayanamurthy H, et al. Electroless nickel plating on magnesium alloy[J]. Metal Finishing, 1998(3): 10-18.

[9]Ambat R, Zhou W. Electroless nickel-plating on AZ91D magnesium alloy: effect of substrate microstructure and plating parameters[J]. Surface and Coatings Technology, 2004, 179: 124-134.

[10]霍宏伟, 李瑛, 王福会. 化学转化膜上沉积镍对镁合金耐蚀性能的影响[J]. 中国有色金属学报, 2004, 14(2): 267-272.

HUO Hong-wei, LI Ying, WANG Fu-hui. Effect of chemical conversion film plus electroless nickel plating on corrosion resistance of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(2): 267-272.

[11]Huo H W, Li Y, Wang F H. Corrosion of AZ91D magnesium alloy with a chemical conversion coating and electroless nickel layer[J]. Corrosion Science, 2004, 46: 1467-1477. [12]Lunder O, Lein J E, Aune T K, et al. The role of Mg17Al12 phase in the corrosion of Mg alloy AZ91[J]. Corrosion, 1989, 45(9): 741-748.

[13]Fairweather W A. Electroless nickel plating of magnesium[J]. Trans IMF, 1997, 75(3): 113-117.

[14]Xiang Y H, Hu W B, Liu X K, et al. A study on surface state during the pretreatment of electroless nickel plating on magnesium alloy[J]. Trans IMF, 2001, 79(1): 27-29.

[15]Xiang Y H, Hu W B, Liu X K, et al. Initial deposition mechanism of electroless nickel plating on magnesium alloy[J]. Trans IMF, 2001, 79(1): 30-32.

[16]刘新宽, 向阳辉, 胡文彬, 等. 镁合金化学镀镍层的结合机理[J]. 中国腐蚀与防护学报, 2002, 22(4): 233-236.

LIU Xin-kuan, XIANG Yang-hui, HU Wen-bin, et al. Adhesion mechanism of direct electroless nickel coating on magnesium alloys[J]. Journal of Chinese Society for Corrosion and Protection, 2002, 22(4): 233-236.

(编辑陈爱华)

基金项目: 国家自然科学基金资助项目(50574086)

收稿日期: 2005-08-09; 修订日期: 2005-12-09

通讯作者: 韩恩厚, 研究员; 电话: 024-23893841; E-mail: ehhan@imr.ac.cn