文章编号:1004-0609(2014)05-1285-08

镁合金表面氟化镁钠膜形成机制及其生物腐蚀性能

方信贤1,章晓波1,王 强2,巴志新1,王章忠1

(1. 南京工程学院 材料工程学院,南京211167;

2. 江苏康尚医疗器械有限公司,丹阳,212300)

摘要:采用浸泡法在Mg-Nd-Zn-Zr镁合金表面制备氟化镁钠膜,采用点滴法、电化学法和浸泡法评定镁合金基体和氟化镁钠膜的耐蚀性,采用扫描电镜(SEM)和能谱仪(EDS)分析氟化镁钠膜试样腐蚀前后的形貌及成分。结果表明,提高转化处理温度可显著减小氟化镁钠颗粒尺寸,而转化处理时间对颗粒尺寸影响较小;氟化镁钠颗粒通过二维形核后的台阶生长机制和螺旋生长机制长大;氟化镁钠膜可显著降低Mg-Nd-Zn-Zr镁合金在模拟体液中的平均析氢速率,在模拟体液中,氟化镁钠膜逐渐转变为氟化物和磷酸盐混合膜层,新膜层继续起到保护镁合金基体的作用。

关键词:镁合金;NaMgF3膜;模拟体液;析氢速率;腐蚀机制

中图分类号:TG146;R318.08 文献标志码:A

Formation mechanism and bio-corrosion properties of NaMgF3 film on surface of magnesium alloy

FANG Xin-xian1, ZHANG Xiao-bo1, WANG Qiang2, BA Zhi-xin1, WANG Zhang-zhong

(1. School of Material Engineering, Nanjing Institute of Technology, Nanjing 211167, China;

2. Jiangsu Konsung Equipment Co., Ltd., Danyang 212300, China)

Abstract: The NaMgF3 films on the surface of Mg-Nd-Zn-Zr magnesium alloy were fabricated by immersion method. Their corrosion properties were valuated by dripping test, electrochemical test and immersion method, respectively. The microstructures of the original and corrosive samples were observed by SEM and their chemical compositions were analyzed by EDS. The results show that the size of NaMgF3 particle is obviously reduced with the increase of conversion treatment temperature; however, it is little affected by the conversion treatment time. The NaMgF3 particles grow by two-dimensional nucleation, step growth mechanism and screw growth mechanism. The average hydrogen evolution rate of Mg-Nd-Zn-Zr magnesium alloy in simulated body fluid (SBF) solution can be significantly decreased by NaMgF3 film. The NaMgF3 films gradually transform into a new film consisting of fluoride and phosphate in the SBF solution, which will continue to protect the magnesium alloy from the corrosion.

Key words: NaMgF3 film; SBF; magnesium alloy; hydrogen evolution rate; corrosion mechanism

生物镁合金具有可降解、密度与人体骨的接近、弹性模量和屈服强度接近人体骨、可有效降低“应力遮挡效应”等特点[1],而且降解形成的镁离子是人体必需常量元素之一[2],在人工关节、骨修复材料、人工牙齿、心脏起搏器、人工内耳电极、心血管支架等[1-4]医用器件领域存在巨大的应用前景。

镁合金在体内降解速度快,常导致实际服役寿命与期望寿命不匹配,制约了其在医用领域的应用。整体合金化[5]和表面改性[6-15]是提高镁合金耐蚀性的两个重要途径。研究表明,在镁合金表面制备阳极氧化镁膜[6]、磷酸盐膜[7]、钙磷涂层[8-9]、PLGA高分子膜[10]、氟化镁及其复合膜 [11-15]等进行表面改性,均可明显降低镁合金的生物降解速度。

王宪涛等[14]的研究表明,氟化镁膜不仅具有降低镁合金生物降解速度的作用,而且氟化镁膜中的氟还有促进植入材料周围骨生成的作用。传统方法制备氟化镁膜均采用高浓度的氢氟酸溶液进行转化处理,为获得较厚的氟化镁转化膜,其工艺时间非常长,如李绮等[11]和王宪涛等[14]制备氟化镁膜的转化处理工艺时间分别达到48和72 h。由于钠、镁是人体必需常量元素[2],氟具有促进骨生成作用[14],为此,本课题组研究者提出用转化处理时间较短的一种新型氟化镁钠转化膜来改善镁合金生物降解性能的构想,与传统氟化镁转化膜制备工艺相比,该转化膜的处理时间仅为0.5 h左右。由于这种新型氟化镁钠转化膜的制备方法、耐蚀性及生物降解行为等未见文献报道,因此,本文作者对氟化镁钠膜制备工艺、形成机制、耐蚀性表征方法及在模拟体液中的降解行为等进行研究。

1 实验

1.1 转化膜的制备

采用线切割将直径为20 mm的Mg-Nd-Zn-Zr挤压棒切割成厚度为4 mm的圆片,为便于实验时试样吊挂,用台钻在试样边缘钻直径为2 mm的圆孔,然后用砂纸打磨、抛光,得到原始镁合金基体试样。

将镁合金基体试样碱性除油和水洗后,分别放入温度为80和90 ℃的转化处理液1(40 g/L NaF+50 mL/L HF)中分别转化处理10、20、30和60 min,以及90 ℃的转化处理液2(40 g/L NaF+300 mL/L HF)中转化处理30 min,转化处理结束后将试样取出,先后用水和酒精清洗,吊挂凉干,得到表面覆盖氟化镁钠转化膜的镁合金试样。

1.2 转化膜的耐蚀性实验

分别采用点滴法测定变色时间、电化学法测量腐蚀电位和腐蚀电流密度,浸泡法(析氢腐蚀)测量平均析氢速率来评定镁合金基体和氟化镁钠转化膜的耐蚀性。

点滴法参照QJ/Z134-85标准进行,点滴液由30 mL的65%HNO3、0.5 g KMnO4和950 mL的去离子水配制而成,变色时间越长,试样的耐蚀性越好。

用PARSTAT2273电化学工作站测量镁合金基体和氟化镁钠膜试样的动电位极化曲线。采用标准三电极系统,参比电极为饱和甘汞电极,辅助电极为铂电极,工作电极为样品。用试样做工作电极时,留出的工作面尺寸为10 mm×10 mm,试样的其他表面用环氧树脂固封。

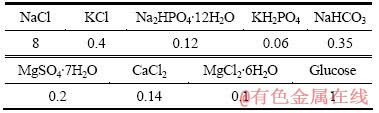

电化学测量所用介质为模拟体液(SBF),其成分如表1所列,温度为(37±1) ℃,用HH-S水浴锅加热保温。

表1 模拟体液(SBF)的成分

Table 1 Composition of SBF solution (g/L)

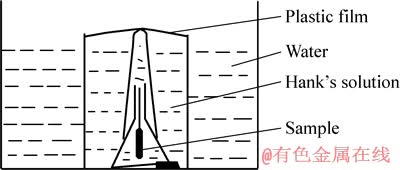

浸泡法测量析氢量的实验装置原理如图1所示。模拟体液体积与试样表面积之比为30 mL/cm2,每浸泡24 h更换一次模拟体液,并记录析出氢气体积,浸泡5 d后取出试样,分别用去离子水和酒精清洗后晾干。浸泡腐蚀实验中平均析氢速率v的计算公式为

v=V/(St)

式中:V为总析氢体积,mL;S为试样表面积,cm2;t为浸泡时间,d。

图1 析氢量测试原理图

Fig. 1 Principle diagram of hydrogen evaluation test

图2 不同转化工艺制备的NaMgF3转化膜的SEM像及其XRD谱

Fig. 2 SEM images ((a), (b), (c), (d)) of NaMgF3 films and XRD pattern (e) under different conversion treatment conditions

1.3 转化膜的组织及成分分析

用JSM-6360LV型扫描电子显微镜(SEM)对浸泡腐蚀前后试样表面组织形貌进行观察,用GENESLS2000XMS60能谱仪(EDS)分析试样表面成分,由于NaMgF3转化膜的导电性较差,部分转化处理试样在高倍观察前进行表面喷金处理。用UltmaⅣ型X射线衍射仪(XRD)和薄膜XRD测试技术对转化膜进行物相分析。

2 结果与分析

2.1 转化处理工艺对NaMgF3转化膜组织的影响

当转化处理液1的温度为80 ℃时,分别转化处理10、20和30 min得到的转化膜均由边长约为2 μm的等轴状立方体颗粒组成(见图2(a)~(c)),随着转化处理时间延长,转化膜中的黑色孔隙(见图2(a)箭头A)尺寸变小,数量减少,转化膜变得更加均匀致密。

当转化处理液1的温度为90 ℃时,转化处理30 min得到的转化膜虽也由等轴状立方体颗粒组成,但立方体颗粒尺寸显著细化,其边长约为0.5 μm(见图2(d)),且颗粒间的界面也变得比较模糊,与80 ℃转化处理30 min的转化膜相比,转化膜的致密度明显提高。XRD分析表明,80 ℃转化处理试样的转化膜为氟化镁钠(NaMgF3)转化膜(见图2(e))。能谱分析表明,80和90 ℃转化处理30 min制备的转化膜均由F、Mg和Na元素组成,但80 ℃转化处理试样中F、Na和Mg元素的摩尔分数分别为32.66%、11.68%和56.66%,而90 ℃转化处理试样中F、Na和Mg元素的摩尔分数则分别为5.75%、1.51%和92.74%。由于能谱分析时电子束穿透转化膜,90 ℃转化处理膜较薄,因此,包含更多基体信息,即含更多Mg。

能谱分析结果中Mg的含量可见,90 ℃转化处理试样的能谱分析结果中包含更多来自基体的信息。

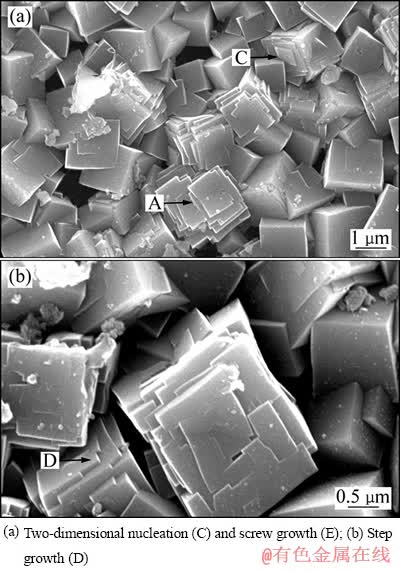

2.2 NaMgF3转化膜的形成机制

镁合金表面NaMgF3转化膜形成过程大致可分成以下几个阶段:1) 当镁合金试样放入转化液时,试样表面的氧化膜首先与转化液中的H+发生下述反应溶解:MgO+2H+→Mg2++H2O,氧化镁膜溶解后,裸露出的镁合金基体将与转化液直接接触,此时,电位较负的镁将与转化液中的H+在界面上发生下述反应:Mg+2H+→Mg2++H2↑,这与转化处理时观察到氢气沿试样表面缓慢逸出的实验结果一致;2) 在界面区内,上述反应产生的Mg2+与界面区内的F-和Na+发生下述反应:Na++Mg2++3F-→NaMgF3↓,反应形成的NaMgF3沉积在试样表面,形成NaMgF3核心,界面区内Mg2+浓度越高,NaMgF3形核率越大;3) 在镁合金表面形成NaMgF3核心后,随着转化处理时间延长,NaMgF3核心将不断长大。对NaMgF3转化膜组织高倍观察表明,在NaMgF3颗粒表面存在二维形核机制(见图3(a)箭头C)、二维形核后的台阶生长机制(见图3(b) 中箭头D)和螺旋生长机制(见图3(a)中箭头E)。由于NaMgF3核心形核时间及生长环境差异,NaMgF3颗粒尺寸也有所不同,如尺寸较大的NaMgF3颗粒孔隙中常可见到尺寸明显较小的NaMgF3颗粒(见图2(a)箭头B);4) 随着转化处理时间延长,一方面,已形成的NaMgF3颗粒将不断长大;另一方面,在NaMgF3颗粒孔隙中还伴随着新的NaMgF3核心的形成及长大,当NaMgF3颗粒生长到相碰时,即在镁合金试样表面形成一层多孔的NaMgF3转化膜;5) NaMgF3转化膜的致密度随着转化处理时间的延长不断增大(见图2(a)~(c)),而随着NaMgF3转化膜致密度增大,转化液与镁合金基体表面间的接触面积越来越小,NaMgF3晶体形核和生长所需的Mg2+供给速率变得越来越小,因此,当转化处理时间达到某一值后,进一步延长转化处理时间,转化膜致密度和转化膜厚度的增大速率将逐步下降。

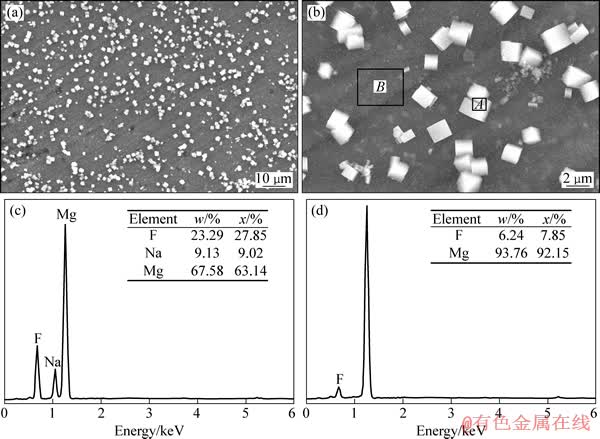

图3 NaMgF3转化膜的高倍SEM像

Fig. 3 High magnification SEM images of NaMgF3 films

NaMgF3转化膜能谱分析结果中的Na和F全部来自转化膜,一部分Mg来自转化膜,一部分则来自基体,根据Na与F摩尔比为1:1和剩余F与Mg的摩尔比为2:1,扣除基体镁信息后的计算表明,镁合金在80 ℃的转化处理液1中转化处理30 min后,得到的NaMgF3转化膜中Mg和Na的摩尔比为0.89:1,而在90 ℃的转化处理液1中转化处理30 min后,得到的NaMgF3转化膜中Mg和Na的摩尔比则为1.40:1,表明转化处理形成的膜层中Na、Mg的摩尔比与其形核和生长过程中界面区内Mg2+供给速率有关。根据化学反应动力学理论,化学反应Mg+2H+→Mg2++H2↑的反应速率随着反应温度的升高按指数规律增大,即在90 ℃转化处理液1的界面区内Mg2+供给速率显著大于80 ℃转化处理液1的界面区内的Mg2+供给速率,导致90 ℃转化处理得到的NaMgF3晶体中Mg和Na的摩尔比增大。当界面区内Mg2+供给速率进一步增大时,NaMgF3转化膜将向氟化镁转化膜转变。为求证上述分析,将镁合金试样放入90 ℃的转化处理液2中转化处理30 min后,对转化膜的组织观察表明,转化膜由灰色膜层上较均匀分布的白色立方体颗粒组成(见图4(a)~(b)),能谱分析表明,白色颗粒由Na、Mg、F元素组成,即白色颗粒为NaMgF3晶体,NaMgF3晶体中Mg和Na的摩尔比为1.04:1,灰色膜层中不含Na,因此,灰色膜为MgF2连续膜(见图4(c)~(d)),该实验结果与上述分析结果一致。

根据NaMgF3转化膜形成机制,转化处理液固定时,转化膜中NaMgF3颗粒的平均尺寸主要取决于转化处理温度,提高转化处理温度使NaMgF3颗粒平均尺寸减小,因为提高转化处理温度不仅使界面区内Mg2+浓度增大,而且还加速化学反应Na++Mg2++3F-→ NaMgF3↓的进行,NaMgF3形核率增大使晶核横向生长空间减小,导致NaMgF3颗粒平均尺寸减小。转化处理时间对NaMgF3颗粒尺寸影响较小,因为转化液和转化处理温度一定时,NaMgF3形核率和晶核横向生长空间一定。延长转化处理时间可明显提高转化膜致密度,因为已形成的NaMgF3颗粒会不断长大,另外在孔隙中还会形成新的NaMgF3颗粒并长大。上述分析与图2的实验结果一致。

根据NaMgF3转化膜形成机制,镁合金表面NaMgF3转化膜厚度与转化处理温度和转化处理液中的HF浓度有关。一方面,转化处理温度和HF浓度越高,界面区内Mg2+浓度越大,NaMgF3形核率越大,核心间距越小,NaMgF3核心生长到相碰所需时间越短;另一方面,转化处理温度和界面区内Mg2+浓度越高,Na++Mg2++3F-→NaMgF3↓反应速度越快,NaMgF3核心生长速率越快,而一旦NaMgF3颗粒生长到相碰时,其对镁合金基体和转化处理液间的隔离作用导致NaMgF3膜纵向生长所需Mg2+供给受到限制,因而过高的转化处理温度和HF浓度不利于获得较厚的NaMgF3转化膜,转化处理液和转化处理时间相同时,90 ℃转化处理试样表面转化膜的厚度低于80 ℃转化处理试样的。上述分析与镁合金试样在90 ℃的转化处理液1和2中转化处理30 min后的能谱分析结果,即镁含量高于在80 ℃的转化处理液1中转化处理30 min的结果一致,因为转化膜能被电子束穿透时,膜越薄基体信息越多,镁含量越高。

2.3 转化处理工艺对耐蚀性的影响

图4 NaMgF3转化膜形貌及EDS能谱图

Fig. 4 SEM images of NaMgF3 conversion films ((a), (b)) and EDS patterns of white particle A (c) and dark zone B (d) shown in Fig. 4(b)

图5所示为不同转化处理温度时转化处理时间对变色时间的影响。由图5可见,转化处理温度一定时,变色时间随着转化处理时间延长而增大;转化处理温度对变色时间也有影响,当转化处理时间较短时,90 ℃转化处理的转化膜变色时间大于80 ℃转化处理时的,但当转化处理时间大于某一值后,80 ℃转化处理转化膜的变色时间反而大于90 ℃转化处理时的。

图5 不同转化处理温度时转化处理时间对变色时间的影响

Fig. 5 Effect of conversion time on color change time at different conversion temperatures

当滴定液滴在试样表面时,一方面,滴定液可直接从转化膜中孔隙渗入而与基体接触,高锰酸钾与基体镁发生氧化还原反应使滴定液变色,因此,转化膜致密度越低,变色时间越短;另一方面,转化膜在稀硝酸溶液中是不稳定的,转化膜越薄,转化膜溶解所需时间越短,变色时间也越短,因此,变色时间是转化膜致密度和厚度的综合反映。当转化处理时间较短时,由于90 ℃转化处理形核率高及生长速率快,其致密度较80 ℃转化处理时的高,因而其变色时间较80 ℃转化处理的长;而当转化处理时间较长时,转化膜的致密度均较高,此时转化膜厚度是决定变色时间的控制因素,由于80 ℃转化处理的转化膜较90 ℃转化处理时的厚,因而其变色时间要比90 ℃转化处理时的长。

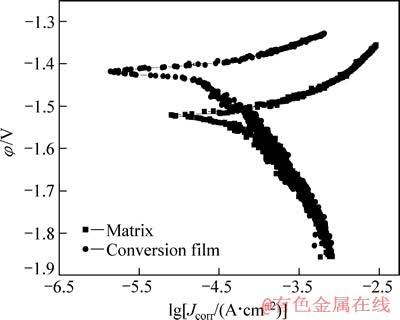

图6所示为镁合金基体和在80 ℃的转化处理液1中转化处理30 min镁合金试样的动态极化曲线,转化处理试样的自腐蚀电位约为-1.42 V,比镁合金基体的自腐蚀电位-1.53 V正移了110 mV左右;转化处理试样的自腐蚀电流密度为3.504×10-5 A/cm2,仅为镁合金基体自腐蚀电流密度7.518×10-5 A/cm2的46.6%,可见,转化处理可明显改善镁合金的耐蚀性。

2.4 SBF液中析氢速率及腐蚀机制

图7所示为镁合金基体和转化处理试样在SBF中的平均析氢速率与浸泡时间的关系曲线。由图7可见,镁合金基体和转化处理试样的平均析氢速率随着浸泡时间延长表现出不同的变化趋势,对于未转化处理的镁合金基体试样,随着浸泡时间的延长,平均析氢速率呈现单调下降并逐渐趋于稳定;与此相比,转化处理试样在浸泡初期随着浸泡时间延长,平均析氢速率逐渐下降,但在浸泡大约3 d后,进一步延长浸泡时间,平均析氢速率开始逐渐增大。由图还可见,转化处理试样的平均析氢速率与转化处理工艺有关,转化处理时间一定时,80 ℃转化处理试样的平均析氢速率明显低于90 ℃转化处理试样的;转化处理温度一定时,延长转化处理时间可降低平均析氢速率。

图6 镁合金和转化膜的动电位极化曲线

Fig. 6 Potentiodynamic polarization curves of magnesium alloy and conversion film

图7 镁合金及其转化膜在SBF中浸泡析氢曲线

Fig. 7 Hydrogen evolution curves of magnesium alloy and conversion film soaked in SBF

对SBF中浸泡试样表面形貌观察表明,未转化处理镁合金试样低倍下表面形貌由凹陷的平坦区和凸起的粗糙区两部分组成(见图8(a)中箭头F和G所指),高倍进一步观察可见,平坦区和粗糙区均呈现干枯河床的“干泥巴”块状组织特征,“干泥巴”块的尺寸和“干泥巴”块之间的缝隙较宽(见图8(b)和(c)),在3个“干泥巴”块交界处常可见到尺寸较大的孔洞存在(见图8中箭头H和I所示),粗糙区腐蚀产物层厚度较平坦区大。与此相比,转化处理试样低倍下表面比较平坦(见图8(d)),高倍下其表面形貌虽也具有“干泥巴”块状组织特征,但“干泥巴”块的尺寸仅为未转化处理镁合金试样的四分之一左右,且“干泥巴”块之间的缝隙宽度也明显小于未转化处理试样的(见图8(e)和(f)),在3个“干泥巴”块交界处也未看到像未转化处理镁合金试样表面的那种孔洞。不同温度转化处理的镁合金试样,当转化处理时间均为30 min时,80 ℃转化处理试样的“干泥巴”块尺寸及“干泥巴”块之间的缝隙宽度略小于90 ℃转化处理镁合金试样的。对浸泡试样表面(见图8(e)和(f))进行能谱分析,转化处理镁合金试样“干泥巴”块状组织中含有F元素(见图8(g)和(h)),表明浸泡腐蚀5 d后,在“干泥巴”块状组织中依然存在较多的难溶氟化物。

浸泡试样表面形貌观察和能谱分析表明,浸泡腐蚀过程大致可分成以下4个阶段:1) 浸泡初期,对于未转化处理试样,当试样表面不稳定的薄氧化镁膜在SBF中溶解后,SBF液将与镁合金基体直接接触,裸露出的新鲜Mg具有较高的化学活性,在界面上将直接发生Mg+2H2O→H2↑+Mg(OH)2反应,由于SBF与镁合金的直接接触面积大,因而平均析氢速率较大;与此相比,对于转化处理试样,由于SBF与镁合金基体被难溶的NaMgF3转化膜隔离,SBF与镁合金基体间的上述反应只能在转化膜中的孔隙界面上进行,由于直接接触面积较小,因而平均析氢速率较小,这与图7所示的平均析氢速率的测量结果一致;2) 随着试样在SBF中浸泡时间的延长,未转化处理试样表面逐渐变黑,根据图8所示的能谱分析结果,在试样表面形成了由钙镁磷酸盐组成的腐蚀产物膜,钙镁磷酸盐膜的存在降低了SBF与镁合金试样表面间的离子扩散速率,导致平均析氢速率逐渐下降。对于转化处理试样,一方面,由于在转化膜孔隙界面上腐蚀形成的钙镁磷酸盐对孔隙的堵塞,导致SBF与镁合金基体间直接接触面接进一步减小;另一方面,NaMgF3转化膜部分溶解产生的F-与腐蚀产生的Mg2+ 或SBF中的Ca2+反应形成的氟化物对转化膜的修复作用,导致其平均析氢速率进一步降低;3) 试样浸泡3 d左右后,对于未转化处理试样,其表面基本形成了一定厚度的稳定腐蚀产物层,因而进一步延长浸泡时间,其平均析氢速率基本趋于稳定(见图7)。对于转化处理试样,随着NaMgF3转化膜的不断溶解,NaMgF3转化膜逐渐被腐蚀形成的钙镁磷酸盐、未溶NaMgF3及新形成的氟化物混合物膜层所取代,混合膜层的保护效果不如NaMgF3转化膜,导致其平均析氢速率逐渐增大;4) 浸泡5 d后,未转化处理试样由于表面腐蚀形成的半固态腐蚀产物层含水率高,因而晾干后形成的“干泥巴”块尺寸较大;根据图8(g)和(h)所示的能谱分析结果,转化处理试样腐蚀膜层由钙镁磷酸盐和氟化物组成,该膜层由于含水率低,因而晾干后形成的“干泥巴”块尺寸较小。

图8 浸泡(5 d)腐蚀试样表面SEM像及其EDS谱

Fig. 8 SEM images ((a)-(f)) and EDS patterns ((g), (h)) of samples after dipping corrosion for 5 d

3 结论

1) 延长转化处理时间可提高NaMgF3转化膜的致密度,但对NaMgF3颗粒尺寸影响较小;提高转化处理温度可使NaMgF3颗粒尺寸减小。NaMgF3颗粒生长机制主要有二维形核、台阶生长机制和螺旋生长机制两种。

2) 转化处理使Mg-Nd-Zn-Zr镁合金的变色时间延长、平均析氢速率下降、自腐蚀电流密度降低、腐蚀电位正移。

3) 随着浸泡时间的延长,未转化处理Mg-Nd-Zn-Zr镁合金平均析氢速率单调减小后趋于稳定,而转化处理试样平均析氢速率则表现为由大变小、而后逐渐增大的趋势。

4) 转化处理Mg-Nd-Zn-Zr镁合金浸泡腐蚀形成的“干泥巴”块状组织尺寸和“干泥巴”块间缝隙宽度均小于未转化处理试样的。

REFERENCES

[1] 张 佳, 宗 阳, 袁广银, 常建卫, 付鹏怀, 丁文江. 新型医用Mg-Nd-Zn-Zr镁合金在模拟体液中的降解行为[J]. 中国有色金属学报, 2010, 20(10): 1989-1997.

ZHANG Jia, ZONG Yang, YUAN Guang-yin, CHANG Jian-wei, FU Peng-huai, DING Wen-jiang. Degradable behavior of new-type medical Mg-Nd-Zn-Zr magnesium alloy in simulated body fluid[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 1989-1997.

[2] 黄晶晶, 任伊宾, 张炳春, 杨 柯. 镁及镁合金的生物相容性研究[J]. 稀有金属材料与工程, 2007, 36(6): 1102-1105.

HUANG Jing-jing, REN Yi-bin, ZHANG Bing-chun, YANG Ke. Study on biocompatility of magnesium and its alloys[J]. Rare Metal Materials and Engineering, 2007, 36(6): 1102-1105.

[3] YANG J X, CUI F Z, LEE I S. Surface modification of magnesium alloys for biomedical applications[J]. Annals of Biomedical Engineering, 2011, 39(7): 1857-1871.

[4] 许鑫华, 程 静, 张春怀, 闫学良, 朱天兵, 姚康德, 曹 路, 刘 寅. 医用镁合金的生物腐蚀及高分子涂层处理[J]. 稀有金属材料与工程, 2008, 37(7): 1225-1228.

XU Xin-hua, CHENG Jing, ZHANG Chun-huai, YAN Xue-liang, ZHU Tian-bing, YAO Kang-de, CAO Lu, LIU Yin. Bio-corrosion and polymer coating modification of magnesium alloys for medicine[J]. Rare Metal Materials and Engineering, 2008, 37(7): 1225-1228.

[5] 章晓波, 袁广银, 王章忠. 铸造镁合金Mg-Nd-Zn-Zr的生物腐蚀性能[J]. 中国有色金属学报, 2013, 23(4): 905-911.

ZHANG Xiao-bo, YUAN Guang-yin, WANG Zhang-zhong. Biocorrosion properties of as-cast Mg-Nd-Zn-Zr magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 905-911.

[6] 郭 磊, 刘 魁, 张世亮, 黄晶晶, 谭丽丽, 杨 柯. 氧化镁膜AZ31B镁合金材料的细胞毒性研究[J]. 稀有金属材料与工程, 2008, 37(6): 1027-1031.

GUO Lei, LIU Kui, ZHANG Shi-liang, HUANG Jing-jing, TAN Li-li, YANG Ke. Cytotoxicity of AZ31B magnesium alloy covering with magnesium oxide[J]. Rare Metal Materials and Engineering, 2008, 37(6): 1027-1031.

[7] YE Cheng-hong, XI Ting-fei, ZHENG Yu-feng, WANG Shu-qin, LI Yang-de. In vitro corrosion and biocompatibility of phosphating modified WE43 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 996-1001.

[8] XU Li-ping, ZHANG Er-lin, YANG Ke. Biocorrosion property and cytocompatibility of calcium phosphate coated Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 23(8): 2014-2020.

[9] MAREIKE LALK, JANIN REIFENRATH, NINA ANGRISANI, ALEXANDR BONDARENKO, JAN-MARTEN SEITZ, PETER P MUELLER, ANDREA MEYER-LINDENBERG. Fluoride and calcium-phosphate coated sponges of the magnesium alloy AX30 as bone grafts: A comparative study in rabbits[J]. Journal of Materials Science: Materials in Medicine, 2013, 24(2): 417-436.

[10] LI J N, CAO P, ZHANG X N, ZHANG S X, HE Y H. In vitro degradation and cell attachment of a PLGA coated biodegradable Mg-6Zn based alloy[J]. Journal of Materials Science, 2010, 45(22): 6038-6045.

[11] 李 绮, 刘新杰, 颜廷亭, 谭丽丽, 张炳春, 杨 柯. 氟处理对AZ31B镁合金生物耐蚀降解行为的影响[J]. 稀有金属材料与工程, 2011, 40(10): 1859-1863.

LI Qi, LIU Xin-jie, YAN Ting-ting, TAN Li-li, ZHANG Bing-chun, YANG Ke. Effect of fluoride conversion treatment on bio-corrosion behavior of AZ31B magnesium alloy[J]. Rare Metal Materials And Engineering, 2011, 40(10): 1859-1863.

[12] YAN Ting-ting, TAN Li-li, XIONG Dang-sheng, LIU Xin-jie, ZHANG Bing-chun, YANG Ke. Fluoride treatment and in vitro corrosion behavior of an AZ31B Mg alloy[J]. Materials Science and Engineering A, 2010, 30(5): 740-748.

[13] WITTE F, FISCHER J, NELLESEN J, VOGT C, VOGT J, DONATH T, BECKMANN F. In vivo corrosion and corrosion protection of Mg alloy LAE442[J]. Acta Biomaterialia, 2010, 6(5): 1792-1799.

[14] 王宪涛, 郭 磊, 柴宏伟, 付玉平, 管俊林. 氟化镁涂层AZ31B镁合金体内成骨作用的研究[J]. 中国医科大学学报, 2011, 40(10): 870-873.

WANG Xian-tao, GUO Lei, CHAI Hong-wei, FU Yu-ping, GUAN Jun-lin. In vivo evaluation of osteogenesis of fluoride treated AZ31B[J]. Journal of China Medical University, 2011, 40(10): 870-873.

[15] BAKHSHESHI-RAD H R, IDRIS M H, ABDUL-KADIR M R. Synthesis and in vitro degradation evaluation of the nano-HA/MgF2 and DCPD/MgF2 composite coating on biodegradable Mg-Ca-Zn alloy[J]. Surface and Coatings Technology, 2013, 222(15): 79-89.

(编辑 龙怀中)

基金项目:南京工程学院创新基金重大项目(CKJA201202);江苏省高校自然科学研究课题(12KJB430007)

收稿日期:2013-09-05;修订日期:2014-01-14

通信作者:方信贤,副教授,博士;电话:025-86118276;E-mail:fangxinxian@njit.edu.cn