航空铝合金厚板残余应力数值模拟研究现状

来源期刊:中国有色金属学报2020年第5期

论文作者:祝楷 熊柏青 闫宏伟 张永安 李志辉 李锡武 温凯 刘红伟 闫丽珍

文章页码:961 - 974

关键词:航空铝合金厚板;固溶淬火;预拉伸;残余应力;有限元模拟

Key words:aviation aluminum alloy thick plate; solution and quenching; pre-stretching; residual stress; FEM

摘 要:为获得理想性能,航空铝合金厚板在生产过程中需经历轧制、固溶淬火、预拉伸和时效强化等工艺过程。其中,厚板在进行固溶淬火处理时整体温度变化异常剧烈,内部产生较高残余应力。近年来,借助数值模拟的手段分析铝合金厚板内部固溶淬火残余应力分布状态并对其进行消减处理是研究关注的热点。介绍基于有限元方法的7xxx系航空铝合金厚板固溶淬火及预拉伸处理过程中板材内部残余应力演化规律研究现状,对固溶淬火和预拉伸仿真计算过程中所用方法及模型参数进行归纳,展望该领域未来的重点研究内容和发展方向。

Abstract: In order to obtain desired mechanical properties, rolling, solution, quenching, pre-stretching and age-hardening treatments were applied to produce aluminum alloy thick plates. Among the aforementioned processes, the temperature in the whole thick plate will be severely changed during the quenching process. Simultaneously, high residual stress also can be formed in the plate. In recent years, numerical simulation has been treated as an effectively method to study and predict the development, distribution and evolvement behavior of residual stress in the thick plate during quenching and pre-stretching processes. The research situation on the evolvement of residual stress in the thick aluminum plate during quenching and pre-stretching processes based on the FEM simulation method was reviewed. The usage of relative skills and parameters for the models were also concluded. Moreover, the key research content and develop orientations in this filed were prospected at the summary chapter of this article.

DOI: 10.11817/j.ysxb.1004.0609.2020-39557

祝 楷1, 2, 3,熊柏青1, 3,闫宏伟1, 2, 3,张永安1, 2, 3,李志辉1, 3,李锡武1, 2, 3,温 凯1, 2, 3,刘红伟1, 2, 3,闫丽珍1, 2, 3

(1. 有研科技集团有限公司有色金属材料制备加工国家重点实验室,北京100088;

2. 有研工程技术研究院有限公司,北京101407;

3. 北京有色金属研究总院,北京100088)

摘 要:为获得理想性能,航空铝合金厚板在生产过程中需经历轧制、固溶淬火、预拉伸和时效强化等工艺过程。其中,厚板在进行固溶淬火处理时整体温度变化异常剧烈,内部产生较高残余应力。近年来,借助数值模拟的手段分析铝合金厚板内部固溶淬火残余应力分布状态并对其进行消减处理是研究关注的热点。介绍基于有限元方法的7xxx系航空铝合金厚板固溶淬火及预拉伸处理过程中板材内部残余应力演化规律研究现状,对固溶淬火和预拉伸仿真计算过程中所用方法及模型参数进行归纳,展望该领域未来的重点研究内容和发展方向。

关键词:航空铝合金厚板;固溶淬火;预拉伸;残余应力;有限元模拟

文章编号:1004-0609(2020)-05-0961-13 中图分类号:TG146.2 文献标志码:A

自1912年以来,高性能铝合金在航空工业材料家族中长期占据主导地位,例如2xxx系硬铝合金、7xxx系超高硬铝合金、部分6xxx系铝合金和Al-Li合金等[1-11]。但是,近年来随着高性能复合材料地快速发展[12-15],使得铝合金在航空工业中的应用前景受到了前所未有的挑战。以商业大飞机为例,波音787客机机身材料中铝合金的质量分数仅为20%;空客公司多种型号客机机身材料中铝合金的占比也呈下降趋 势[16]。然而,通过对机身材料构成深入分析可以看出作为机身主承重件的壁板、承力框形件、侧翼、尾翼及翼身对接接头等选材仍以铝合金为主[7, 16],足见铝合金在现代飞机设计中依然扮演十分重要的角色,并且由铝合金厚板或超厚板(主要为7xxx系)加工而成的整体结构件在近年来飞机大型结构件设计中占据主要位置。例如由厚板加工而成的空客A330/A340机身铝合金结构件约占铝合金总使用量的50%[17-18]。其中,7xxx系高性能铝合金在强度、韧性等方面都展现出比较优势,约占航空铝合金总使用量的90%[19],可以说优良的服役性能奠定了7xxx系铝合金市场地位。以美铝公司(ALCOA)开发的7055-T77(于1993年申请专利)铝合金厚板为例,已应用于BOEING 777和空客A380等现役最先进大型民用客机的上翼和长桁等机身整体结构件的加工制造[11]。

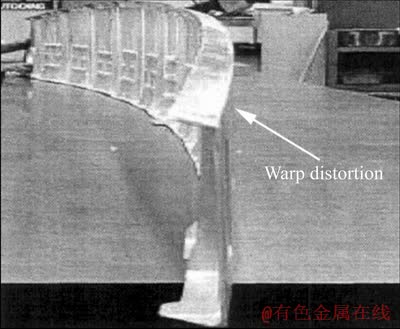

众所周知,7xxx系铝合金为典型时效强化型合金,其强化过程依赖固溶淬火阶段得到过饱和固溶体,这是由于淬火处理可以确保合金在急速的冷却条件下最大限度地避免过饱和固溶体发生脱溶析出[20-22],进而为后续的时效处理奠定基础。目前,工厂在7xxx系铝合金厚板生产过程中广泛采用辊底式高压喷淋淬火工艺以确保能够达到理想的冷却效果[16, 21]。需要强调,急速淬火冷却尽管可以保证厚板的性能,但同时也导致板内特别是沿板厚方向形成较大温度梯度,产生较高残余应力,诱发整体结构件在后续加工及服役过程中产生翘曲、扭曲变形[23](如图1所示),严重者可导致零件直接报废。此外,残余拉应力的存在还增加了7xxx系铝合金整体结构件应力腐蚀开裂的敏感性,导致其过早发生疲劳失效,危及飞机的运行安全。已有研究表明造成整体结构件发生形变的影响因素中,板内初始残余应力占比高达90%[24]。

因此,在满足7xxx系厚板使用性能的前提下削弱板内残余应力水平、改善板内残余应力分布状态受到了学者的广泛关注,并分别以预防和消减为切入点开展了大量的工作:1) 调整合金元素Zn/Mg比例[25]、向合金中添加微量元素(如Zr元素可以改善7xxx铝合金的淬火特性)[26]和调整淬火介质[27-28]等方面入手,削弱7xxx铝合金的淬火敏感性,提高板材的淬透深度,缩小由于板厚因素所造成的沿厚度方向所形成的温差,从而实现板内残余应力分布状态的改善。2) 采用后处理手段消减板材内部原始残余应力。后处理消减手段主要包括热消除法(退火、恒温时效、深冷处理等)和机械消除法(拉伸、模压、振动处理等)两类。相关研究指出,恒温时效法的应力消除率约为10%~35%,深冷处理法约为25%~83%,振动消除法约为20%~70%,机械拉伸法约为90%[29]。

图1 飞机整体框架翘曲变形[23]

Fig. 1 Warp distortion of aircraft frame after machining[23]

综上,掌握航空铝合金厚板内部残余应力演变规律及分布状态并对其加以控制将有助于整体结构件机加工工艺的优化,进而改善其装配性能和服役性能。厚板在固溶淬火过程中内部温度和残余应力变化剧烈、过程短暂,借助传统实测手段难以获取有效信息且成本较高。近年来,高速发展的有限元方法和计算机技术为航空铝合金厚板内部残余应力的研究开辟了一条新的途径。与实测相比,有限元仿真计算可以实现温度场、应力场和应变场等多场的耦合计算并实时给出任意位置、任意时刻的温度、应力、应变状态。因此,本文通过调研国内外相关领域研究文献,以固溶淬火和预拉伸过程中7xxx系铝合金厚板内部残余应力数值模拟研究为主要关注对象进行了重点分析介绍。

1 铝合金厚板固溶淬火残余应力有限元仿真计算研究现状

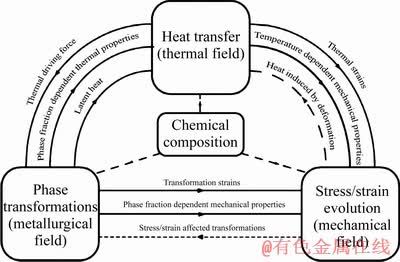

金属材料在制坯、热处理和后续加工过程中,由于温度变化导致其内部微观结构产生非协调变形或非协调变形的趋势等原因都会或多或少的产生残余应力。目前,残余应力按尺度主要分为宏观、介观和微观3类[30]。同时,由于温度变化所引起的残余应力又可分为热残余应力和相变残余应力2类,划分标准即为温度变化(热处理)过程中材料内部是否发生固态相变。SIMSIR等[31]描述了金属材料热处理过程中材料内部化学成分、微观组织、温度场和应力场等多物理场之间的耦合作用关系,如图2所示。由图2中可以看出,温度驱动相变、潜热、应力、应变、热量传输等过程贯穿于整个热处理过程,因此在进行模拟计算时应综合考虑多物理场之间的相互关系对材料内部残余应力分布的影响。

图2 热处理过程中所涉及的多物理场及耦合作用关系[31]

Fig. 2 Physical fields and coupling reactions during heat treatments[31]

事实上,关于固溶淬火过程中金属材料组织和性能转变的研究最早可追溯至20世纪30年代,国外学者通过对钢冷却过程的研究相继提出了等温转变曲线(TTT曲线)和连续冷却曲线(CCT)曲线[32],而借助数值模拟手段研究材料的固溶淬火过程则兴起于20世纪70~80年代并于1984年在瑞典召开了第一届国际热处理过程内应力计算学术研讨会,美国金属学会(ASM international)于2000年提出对于制造业而言数值模拟是代表先进热处理工艺的一项关键技术,由此可见包括固溶淬火数值模拟在内的热处理仿真技术的重要地位[33-34]。国内关于金属材料固溶淬火过程的数值模拟研究起源于20世纪80年代,上海交通大学潘健生院士[35-36]、清华大学刘庄教授[37]、山东大学赵国群教授[38-39]等高校科研团队相继开展了大量的研究工作,在钢的淬火过程数值模拟领域取得了丰硕的成果。同时期,国外学者率先借助数值模拟的手段针对7xxx系铝合金厚板内部残余应力状态的进行了研究。国内,浙江大学[40-41]、北京航空航天大学[42-43]、中南大学[44-47]、山东大学[48]及北京有色金属研究总院[49-51]等高校院所近年来也借助数值模拟手段对铝合金厚板生产制造过程中的残余应力分布及切削加工变形规律开展了相关研究工作。

1.1 厚板固溶淬火有限元模拟方法、导热方程和边界条件

1.1.1 有限元模拟方法

目前,借助有限元软件实现铝合金厚板淬火过程中热、力耦合状态的仿真计算主要采用顺序耦合(Sequentially coupled thermal stress analysis,又称准耦合)和全耦合(Fully coupled thermal stress analysis)两种方法。

1) 顺序耦合(Sequentially coupled thermal stress analysis)

若待分析问题中温度场与应力场、位移场为正向相关,即应力场、位移场的发展、演变受控于温度场的发展、演变,而应力场、位移场对模型内部温度场的影响可忽略不计时,则可选用顺序耦合方式对该工程问题进行描述和计算。借助顺序耦合方式求解问题需首先进行温度场求解,随后将温度场求解结果作为先决条件导入模型中并设为预定义场继而进行应力场、位移场求解。因此,顺序耦合方式适用于塑性变形量较小工程问题,目前使用较为广泛。

2) 全耦合(Fully coupled thermal stress analysis)

全耦合方法是指在计算过程中同时进行温度场和应力场、位移场的求解。若待分析问题中温度场和应力场、位移场彼此之间的发展、演变相互作用明显,这时宜采用全耦合方式进行对该工程问题进行描述和计算。

对比上述两种计算方法,可以看出顺序耦合方法是分别计算温度场和应力场、位移场;而全耦合方法则是同时计算温度场和应力场、位移场,驱动变量同时为位移自由度和温度自由度,且两变量在计算过程中同时发挥作用。因此,与全耦合方法相比,当模型较大、单元量较多时顺序耦合方法具有更高的计算效率。

1.1.2 导热方程

铝合金厚板固溶淬火热传导过程为典型的带第三类边界条件的非稳态导热过程。其中,厚板内部导热方式主要为热传导,控制方程为瞬态热传导方程:

(1)

(1)

式中: 为密度;c为定压比热容;

为密度;c为定压比热容; 为热传导系数;T为温度;t为时间;Q为相变潜热;由式(1)可以看出温度T为时间t和空间(x,y,z)的函数;c、Q、

为热传导系数;T为温度;t为时间;Q为相变潜热;由式(1)可以看出温度T为时间t和空间(x,y,z)的函数;c、Q、 为温度T的函数;需要指出,铝合金固溶淬火处理的目的是尽可能限制η相(MgZn2)的析出量。因此,尽管实际生产中合金内部仍存在η相析出,但总量较少。所以在铝合金厚板固溶淬火过程的数值模拟中往往不考虑相变过程对温度变化的影响,即上式中Q=0。

为温度T的函数;需要指出,铝合金固溶淬火处理的目的是尽可能限制η相(MgZn2)的析出量。因此,尽管实际生产中合金内部仍存在η相析出,但总量较少。所以在铝合金厚板固溶淬火过程的数值模拟中往往不考虑相变过程对温度变化的影响,即上式中Q=0。

1.1.3 边界条件

固溶淬火过程中,厚板表面与淬火介质之间导热方式主要为辐射和对流两类,其中对流传热占据主导地位。因此,固溶淬火时厚板表面传热边界条件简化为板材与介质之间的对流换热边界条件:

(2)

(2)

式中:q为通过换热边界的热流密度;h为板材表面与淬火介质之间的界面换热系数;Ts为板材表面温度,是时间的函数;T0为介质温度,通常设为一个定值。

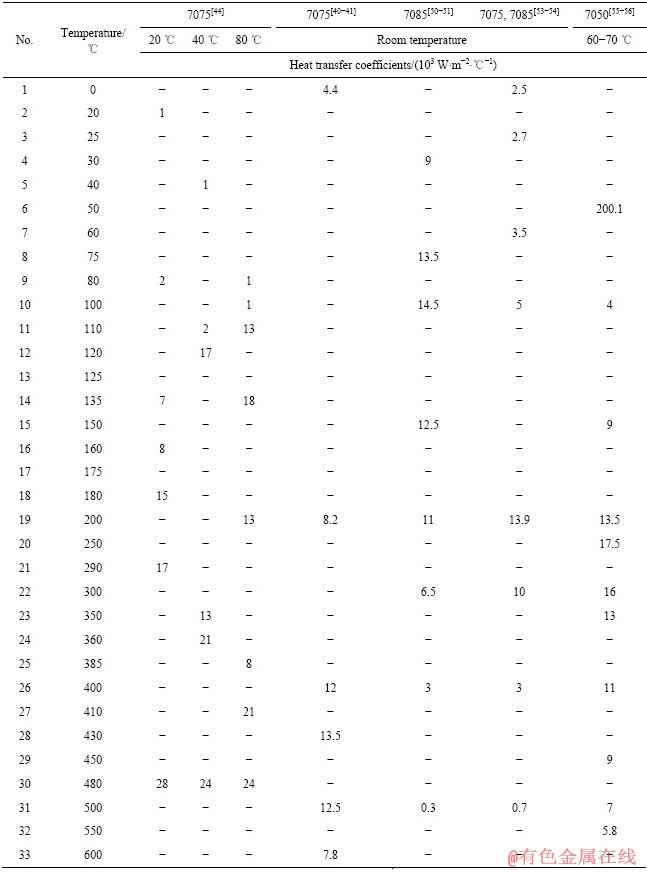

式(2)中,界面换热系数h描述了厚板表面与周围冷却介质之间的热交换能力,它是一个随周围环境变化的变量,可反映厚板在固溶淬火过程中一段时间内的热能输出能力。在有限元计算过程中,界面换热系数作为关键的初始边界条件对于厚板内部温度场的发展、演变过程预测至关重要。需要指出,目前界面换热系数的获取方式主要有反算法和迭代法两类。针对一维非稳态导热问题,可以采用反算法获取试样淬火过程中的界面换热系数;针对多维非稳态导热问题,可以先对试样内部某一特定点温度曲线进行测量,然后对模型施加不同的换热系数以校核该点冷却曲线,直至模拟结果于实测结果吻合为止。本节对所调研部分文献中仿真计算所用界面换热系数进行了简要归纳,如表1所列。

1.2 厚板固溶淬火残余应力模拟计算过程中的几类影响因素

1.2.1 界面换热边界条件

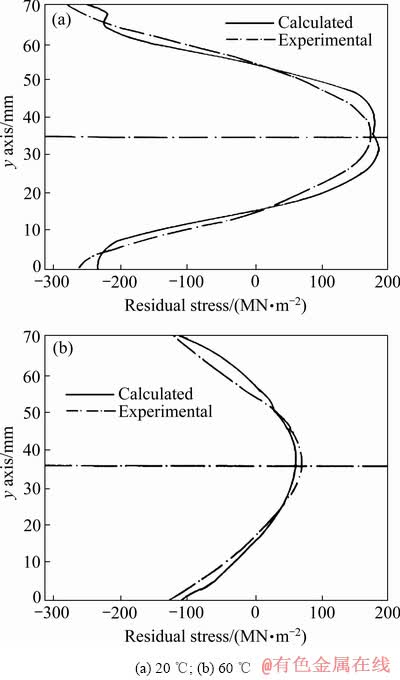

针对7xxx系铝合金厚板,法国学者JEANMART等[52]率先运用MARC软件以顺序耦合方法对7075铝合金厚板固溶淬火残余应力场进行了仿真模拟,温度场计算时假设厚板为无限大板且边界条件为与厚板表面温度相关的函数,并重点考虑了淬入温度对板内残余应力水平的影响。计算结果表明随淬入温度上升,板内残余应力水平明显下降,且模拟结果与层剥法实测结果吻合度较好,具体如图3所示。

胡少虬等[44]根据实测界面换热系数,通过建立2D模型以顺序耦合的方法对不同淬入温度(20 ℃、40 ℃、80 ℃)条件下7075铝合金厚板中瞬态温度场和应力场进行了模拟计算,结果表明当淬火时间为1 s、淬火水温为40 ℃铝合金厚板芯表温差和热应力差均最小。

表1 部分文献中铝合金厚板残余应力数值模拟所用换热系数

Table 1 Heat transfer coefficients used for modeling residual stresses in various thick aluminum plates extracted from some selected research papers

图3 铝合金厚板淬火(20 ℃、60 ℃,水)残余应力分布[52]

Fig. 3 Residual stress in thick aluminum plate after quenched in cold and hot water[52]

姚灿阳[57]运用MSC.Marc软件研究了7050铝合金厚板固溶淬火过程,结果表明界面换热系数对厚板表面冷却速率影响程度远大于对芯部冷却速率的影响。以120 mm厚板为例,当界面换热系数由10000 W/(m2·℃)增大至15000 W/(m2·℃)时,厚板芯部冷却速率相差不到2%,但是板内残余应力水平确大幅提升。

GONG等[58]采用全耦合的方法对7050铝合金厚板固溶淬火残余应力场研究结果同样表明冷却速率对厚板内部残余应力场分布影响显著,例如当板材表面传热系数由8000 W/(m2·℃)增加至14000 W/(m2·℃)时,厚板表面残余应力值增加约67%。

YAZDI等[59]对7075和7175铝合金淬火残余应力场进行了模拟研究,对比了界面换热系数和板材表面温度2类边界条件对温度场计算结果的影响,YAZDI等[59]认为直接采用板材表面温度作为边界条件可以提高温度场计算计算精度,并将应力场模拟结果进一步与中子衍射及改进型钻孔法残余应力试验表征结果进行了对比分析,证明了上述边界条件的可靠性。

1.2.2 轧制等关联过程

赵丽丽等[42]对7075铝合金厚板生产过程中轧制→升温→保温→淬火等阶段的残余应力演变过程进行了全流程仿真计算并重点研究了轧制、升温、保温等阶段对厚板内部最终残余应力的影响。结果表明在轧制、升温、保温各阶段中厚板内部应力均有明显变化,但历经升温、保温等后工序过程后板内所形成的热应力基本已将前期的轧制应力覆盖,最终残余应力表现为淬火应力。

LI等[43]通过模拟了轧制阶段和固溶淬火阶段之间的相互作用关系对7075铝合金厚板内部残余应力分布状态的影响,结果表明轧制压下量对厚板内部初始应力分布状态具有显著影响,且按照<1%、1%~10%、>10%的压下量范围可大致划分为3种空间分布形式。同时,耦合轧制和固溶淬火计算结果发现当轧制应力较小时板材内部残余应力主要来源于淬火阶段;随轧制应力的增加,上述两者之间的相互作用关系对板内残余应力分布状态的影响越来越明显。与前述研究相比,LI等[43]并未考虑升温、保温过程对厚板内部应力状态演变的影响。

1.2.3 板材厚度

关于板材厚度铝合金厚板内部固溶淬火残余应力水平及分布状态的影响,许晓静等[53]以7085铝合金厚板为研究对象进行了仿真计算。结果表明当板材厚度为20 mm、40 mm、80 mm时,板内残余应力水平随板厚的增加而提升;当板材厚度为200 mm、300 mm、400 mm时,随着板材厚度的增加板内残余应力水平变化不明显。

张志伟等[60]运用ABAQUS/Standard计算模块研究了不同厚度的2A12铝合金厚板固溶淬火过程。结果表明板材厚度为20 mm、30 mm时,板内残余应力水平随板厚的增加而提升;当板材厚度为40 mm、50 mm、60 mm时,随着板材厚度的增加板内残余应力水平变化不明显;当板材厚度为60 mm、70 mm时,板内残余应力出现一定的下降。

1.2.4 不同软件平台

王金亮等[55]、刘嘉辰等[56]采用Simufact软件对7050铝合金厚板固溶淬火过程进行了模拟计算,并将计算结果同ABAQUS软件计算结果进行了对比。Simufact软件和ABAQUS软件计算结果均表明厚板淬火过程中各部分温度下降速率不断变化尤以表层温降速率变化最为明显,厚板芯部冷却速率相比较为缓慢,板内残余应力场由淬火初期的外拉内压转变为后期的外压内拉型空间分布。进一步将计算值与试验值对比可见,Simufact软件对厚板残余应力的仿真结果精度较高。

此外,CHOBAUT等[61-62]还提出在热力耦合模拟预测铝合金厚板残余应力分布状态的基础上充分考虑沉淀相对厚板内部淬火残余应力分布的影响。对于厚度相对较小的板材,淬火过程中表面和芯部冷速差距较小,表面和芯部沉淀相比率较为一致,因此,在仿真过程中可不考虑沉淀相对板材性能的影响;但当板材厚度较大时,淬火过程中表面和芯部冷速差距较大,板内不同位置沉淀相的析出比率差距增大,这时在进行厚板残余应力模拟计算时应充分考虑沉淀相析出强化作用对计算结果的影响,以提高模拟计算的精确度。

通过上述调研分析可以看出,影响铝合金厚板固溶淬火残余应力有限元仿真计算结果的因素主要包括模型界面换热边界条件、尺寸因素(板厚)及轧制、升温、保温等关联过程,且界面换热边界条件尤为关键。因此,获取准确的界面换热边界条件,有助于仿真计算结果精度的改善。此外,针对不同软件之间的横向比较也可看出,采用不同的软件平台对仿真结果的精度会产生一定的影响,但对板内残余应力分布规律的预测结果较为一致。本节对所调研部分文献中所涉及的合金类型、模型尺度、厚板淬火起始温度、淬火介质类型及所用软件平台等进行了简要归纳,如表2所列。

表2 部分文献中铝合金厚板残余应力数值模拟所用参数

Table 2 Parameters used for modeling residual stresses in thick aluminum plates extracted from some selected papers

2 预拉伸消减铝合金厚板残余应力有限元仿真计算研究现状

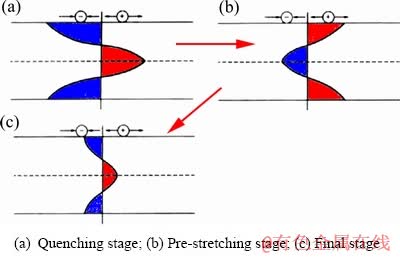

与深冷处理、模压和机械振动等手段相比,预拉伸法是消除或降低形状结构较为简单的铝合金厚板内部残余应力的有效途径,拉伸过程中板内固溶淬火残余应力在厚板产生塑性屈服后得到消减,具体演变过程如图4所示。

图4 固溶淬火铝合金厚板预拉伸过程残余应力重新分布示意图[41]

Fig. 4 Residual stress redistribution behavior in quenched thick aluminum plate during pre-stretching process[41]

2.1 预拉伸量对厚板残余应力的影响

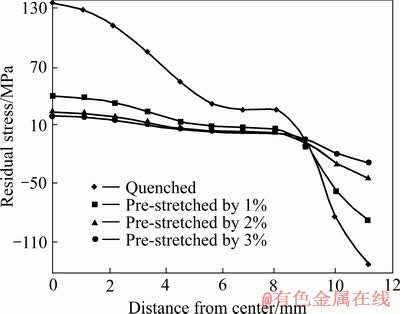

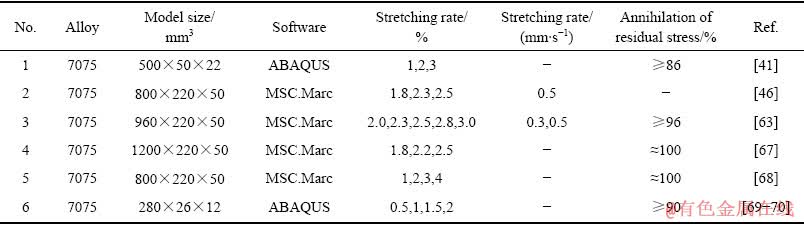

铝合金厚板预拉伸过程中,预拉伸量反映了厚板塑性变形程度的大小,直接影响厚板内部残余应力状态的改变程度。柯映林等[41]针对含有淬火残余应力场的7075铝合金毛坯进行了不同拉伸量的残余应力消除过程数值模拟,结果表明当预拉伸量为3%时铝合金毛坯将产生2.1%~2.6%的塑性形变,残余应力消除率约为86%,具体如图5所示。

图5 不同预拉伸量对铝合金厚板内残余应力水平的影响[41]

Fig. 5 Effect of different pre-stretched rates on quenching-induced residual stresses in thick aluminum plate[41]

张园园等[66]通过建立含有淬火残余应力场的7075铝合金厚板预拉伸有限元模型,模拟了不同预拉伸量(2.0%、2.3%、2.5%、2.8%、3.0%)条件下板内残余应力的分布状态和消减程度。结果表明当厚板预拉伸量为3%时,板内残余应力消除量约为96%,且只在钳口夹持区附近存在局部应力过渡。

LIAO等[46]和龚海等[67]对7075铝合金厚板预拉伸过程进行了模拟计算,并采用序列层剥法和裂纹柔度法对计算结果进行了对比研究。结果表明经过预拉伸处理后厚板内部残余应力水平大幅下降,且当预拉伸量介于2.0%~2.5%之间时既能有效消减厚板内部残余应力,又可确保厚板的最终力学性能满足使用要求。

2.2 钳口夹持对厚板残余应力的影响

钳口夹持对预拉伸厚板端部应力分布具有显著的影响。对此,袁望姣等[68]借助“生死单元”技术模拟了7075铝合金厚板预拉伸过程中钳口的加载和卸载过程。结果表明预拉伸过程中厚板表面的应力状态由压应力逐渐转变为拉应力,厚板芯部持续受到拉应力且在夹具卸载后出现明显的应变松弛,板内残余应力水平大大下降。

朱才朝等[69-70]通过对7075铝合金厚板预拉伸过程的模拟研究发现,由于拉伸机钳口的制约因素使得厚板在预拉伸完成后沿长度方向形成夹持区、过渡区和均匀区等3个区域。以厚度12 mm的7075铝合金厚板为例,其过渡区长度约为8 mm。

GONG等[58]研究了钳口虚夹状态下厚板内部残余应力状态及影响区域,模型中单侧各设置13副夹钳。结果表明,当单侧靠边缘位置3副钳口虚夹时,影响区域较大;当单侧靠边缘位置2副钳口虚夹时,影响区域明显缩小;当两侧靠中心堆成位置处3副钳口虚夹时,影响区域明显最小。

2.3 厚度方向力学性能的不均匀性对厚板残余应力的影响

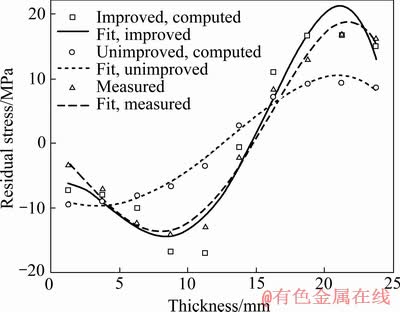

由于铝合金厚板固溶淬火后沿厚度方向力学性能具有明显的不均匀性,ZHANG等[71]提出了一种基于分层法的7075铝合金厚板预拉伸过程残余应力场预测数学模型,模型中将铝合金厚板视为多层薄板贴合的层合板结构,由于时效强化作用沿板厚方向排列的薄板由于具备不同的初始状态,因此在预拉伸过程中相邻的薄板由于具备不同屈服强度而渐次抵达拉伸关键点,以此为基础建立了厚板整体的应力演化模型。研究结果表明,由于厚板芯部在固溶淬火阶段形成残余应力状态为拉应力状态且屈服强度较低,因此,在预拉伸过程中厚板芯部位置率先发生到达材料屈服点并发生塑性形变,导致厚板整体产生不均匀塑性变形,而板内由于固溶淬火所产生的残余应力在芯部与表面之间塑性变形程度的差异。

LIN等[72]在ZHANG等[71]所提出的数学模型基础上将模型进一步改进,考虑了薄板弹性模量和剪切模量对7075铝合金板材预拉伸处理后板材内部残余应力水平的影响。如图6所示结果表明同时考虑屈服强度、弹性模型和剪切模量时模拟结果与实验测试结果的吻合程度较好。ZHANG等[71]和LIN等[72]所提出的数学模型均是建立在厚板固溶淬火时效后的状态,考虑了时效处理对板材预拉伸处理的影响。

图6 铝合金厚板轧制方向内残余应力分布(拉伸量为2.2%)[72]

Fig. 6 Residual stress distribution in thick aluminum plate after pre-stretched (2.2% stretching ratio)[72]

通过上述调研分析可以发现,预拉伸过程可以显著消除铝合金厚板在固溶淬火阶段所形成的残余应力,预拉伸量、拉伸机钳口及工作状态、厚板自身力学性能的不均匀性等都会影响厚板内部最终的残余应力分布状态。预拉伸量决定了厚板内部的残余应力消减程度,钳口及其工作状态决定了厚板端部的应力分布及锯切量大小,而获取厚板准确的力学本构模型有助于改善仿真计算精度。同样地,本节对所调研的部分文献中模拟计算的相关参数进行了简要归纳,如表3所列。由表3中可以看出,仿真计算的预拉伸量一般介于0.5%~3%之间,残余应力消减率≥86%,消减效果十分显著。

3 总结与展望

纵观7xxx系铝合金厚板固溶淬火及预拉伸过程数值模拟发展历程及研究工作可以看出:

1) 厚板内部固溶淬火残余应力水平及分布状态受控于界面换热边界条件、几何尺度及关联生产过程等因素,且界面换热边界条件对其影响作用最为显著。因此,在有限元仿真计算过程中设置更加精确的界面换热边界条件,有助于提高计算结果的准确程度。

2) 预拉伸过程可以有效消减厚板内部固溶淬火残余应力,预拉伸量和钳口夹持状态直接影响厚板内部最终残余应力水平及分布状态。此外,建立能够反映厚板自身力学性能不均匀性的仿真计算模型,有助于揭示预拉伸过程中厚板内部不同区域之间更加细微的应力应变演变过程及相互作用关系。

3) 综上所述,在传统有限元计算的基础上充分考虑差异化的材料微观组织结构与残余应力之间的关系,以微观组织结构为衡量指标,建立其与宏观残余应力之间的量化分析数据库,引入材料各向异性及不均匀分布等因素,将有助于构建更加精确的厚板残余应力数值模拟有限元模型,进而为制订更加科学、合理的铝合金厚板生产加工工艺提供有效的参考和借鉴。

表3 部分文献中铝合金厚板预拉伸过程数值模拟所用参数

Table 3 Parameters used for modeling pre-stretched process in thick aluminum plates extracted from some selected papers

REFERENCES

[1] ZHANG X, CHEN Y, HU J. Recent advances in the development of aerospace materials[J]. Progress in Aerospace Sciences, 2018, 97: 22-34.

[2] DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminium alloys[J]. Materials & Design, 2014, 56: 862-71.

[3] WILLIAMS J C, STARKE E A. Progress in structureal materials for aerospace systems[J]. Acta Materialia, 2003, 51(19): 5775-5799.

[4] HEINZ A, HASZLER A, KEIDEL C, MOLDENHAUER S, BENEDICTUS R, MILLER W S. Recent development in aluminium alloys for aerospace applications[J]. Materials Science and Engineering A, 2000, 280(1): 102-107.

[5] IMMARIGEON J P, HOLT R T, KOUL A K, Zhao L, Wallace W, Beddoes J C. Lightweight materials for aircraft applications[J]. Materials Characterization, 1995, 35(1): 41-67.

[6] 杨守杰, 戴圣龙. 航空铝合金的发展回顾与展望[J]. 材料导报, 2005, 19(2): 76-80.

YANG Shou-jie, DAI Sheng-long. A glimpse at the development and application of aluminum alloys in aviation industry[J]. Materials Review, 2005, 19(2): 76-80.

[7] 熊柏青. 中国新材料产业发展报告第四章[C]// 北京: 中国科技论坛杂志社, 2010: 40-51.

XIONG Bai-qing. The 4th chapter of the Report on the development of advanced materials industries of China[C]// Beijing: Forum on Science and Technology in China, 2010: 40-51

[8] 陈小明, 宋仁国, 李 杰. 7xxx系铝合金的研究现状及发展趋势[J]. 材料导报, 2009, 23(3): 67-70.

CHEN Xiao-ming, SONG Ren-guo, LI Jie. Current research status and development trends of 7xxx series aluminum alloys[J]. Materials Review, 2009, 23(3): 67-70.

[9] 姬 浩. 7000系高强铝合金的发展及其在飞机上的应用[J]. 航空科学技术, 2015, 26(6): 75-78.

JI Hao. Development and application of 7000 high strength aluminum alloys on airplane[J]. Aeronautical Science and Technology, 2015, 26(6): 75-78.

[10] 王祝堂. 铝材在国产大飞机上的应用[J]. 轻合金加工技术, 2016, 44(11): 1-8.

WANG Zhu-tang. Application of aluminum materials on domestic large aircrafts[J]. Light Alloy Fabrication Technology, 2016, 44(11): 1-8.

[11] 刘 兵, 彭超群, 王日初, 王小锋, 李婷婷. 大飞机用铝合金的研究现状及展望[J]. 中国有色金属学报, 2010, 20(9): 1705-1715.

LIU Bing, PENG Chao-qun, WANG Ri-chu, WANG Xiao-feng, LI Ting-ting. Recent development and prospects for giant plane aluminum alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1705-1715.

[12] 张丽华, 范玉青. 复合材料在飞机上的应用评述[J]. 航空制造技术, 2006(3): 64-66.

ZHANG Li-hua, FAN Yu-qing. Applications of composites in airoplanes: A review[J]. Aeronautical Manufacturing Technology, 2006(3): 64-66.

[13] 范玉青, 张丽华. 超大型复合材料机体部件应用技术的新进展 —— 飞机制造技术的新跨越[J]. 航空学报, 2009, 30(3): 534-543.

FAN Yu-qing, ZHANG Li-hua. New development of extra large composite aircraft components application technology— Advance of aircraft manufacture technology[J]. Acta Aeronautica ET Astronautica Sinica, 2009, 30(3): 534-543.

[14] 冯 军. 复合材料技术在当代飞机结构上的应用[J]. 航空制造技术, 2009(22): 40-42.

FENG Jun. Application of composite technology in modern aircraft structure[J]. Aeronautical Manufacturing Technology, 2009(22): 40-42.

[15] 孙振起, 吴安如. 先进复合材料在飞机结构中的应用[J]. 材料导报, 2015, 29(11): 61-64, 69.

SUN Zhen-qi, WU An-ru. Application of advanced composite in aircraft structures[J]. Materials Review, 2015, 29(11): 61-64, 69.

[16] 张新明, 刘胜胆. 航空铝合金及其材料加工[J]. 中国材料进展, 2013, 32(1): 39-55.

ZHANG Xin-ming, LIU Sheng-dan. Aerocraft aluminum alloys and their materials processing[J]. Materials China, 2013, 32(1): 39-55.

[17] 航空航天材料咨询组. 航空航天材料咨询报告[R]. 北京: 国防工业出版社, 1999: 41-42.

Aeronautics and Astronautics Materials Advisory Group. Aeronautical and aerospacematerials consulting report[R]. Beijing: National Defense Industry Press, 1999: 41-42.

[18] 庾莉萍, 阮鹏跃. 高性能铝合金厚板的生产技术及应用[J]. 铝加工, 2010(4): 27-33.

YU Li-ping, RUAN Peng-yue. Fabrication technologies and applications of thick aluminum plates with high performance[J]. Aluminum Fabrication, 2010(4): 27-33.

[19] 曹海龙. 7055铝合金厚板淬火残余应力的测量与数值模拟[D]. 北京: 北京有色金属研究总院, 2016: 43-52.

CAO Hai-long. Measurement and numerical simulation of quenching residual stress in 7055 aluminum alloy thick plate[D]. Beijing: General Research Institute for Nonferrous Metals, 2016: 43-52

[20] 刘晓涛, 崔建忠. Al-Zn-Mg-Cu系超高强铝合金的研究进展[J]. 材料导报, 2005, 19(3): 47-51.

LIU Xiao-tao, CUI Jian-zhong. Progress in research on ultra high strength Al-Zn-Mg-Cu alloy[J]. Materials Review, 2005, 19(3): 47-51.

[21] 熊柏青, 李锡武, 张永安, 李志辉, 王 锋, 刘红伟. 高强韧低淬火敏感性7XXX系铝合金的发展[J]. 中国材料进展, 2014, 33(2): 114-119.

XIONG Bai-qing, LI Xi-wu, ZHANG Yong-an, LI Zhi-hui, WANG Feng, LIU Hong-wei. Development of 7XXX series aluminum alloy with high strength, high toughness and low quench sensitivity[J]. Materials China, 2014, 33(2): 114-119.

[22] ROBINSON J S, REDINGTON W. The influence of alloy composition on residual stresses in heat treated aluminium alloys[J]. Materials Characterization, 2015, 105: 47-55.

[23] 廖 凯. 铝合金厚板淬火-预拉伸内应力形成机理及其测试方法研究[D]. 长沙: 中南大学, 2010: 4.

LIAO Kai. Research on mechanism and measurement method of quenching-prestretching stress in aluminum thick plate[D]. Changsha: Central South University, 2010: 4.

[24] HUANG X, SUN J, LI J. Finite element simulation and experimental investigation on the residual stress-related monolithic component deformation[J]. The International Journal of Advanced Manufacturing Technology, 2014, 77(5/8): 1035-1041.

[25] LIU S, ZHONG Q, ZHANG Y, LIU W, ZHANG X, DENG Y. Investigation of quench sensitivity of high strength Al-Zn-Mg-Cu alloys by time-temperature-properties diagrams[J]. Materials & Design, 2010, 31(6): 3116-3120.

[26] LIU Sheng-dan, ZHANG Xin-ming, CHEN Ming-an, You Jiang-mei, ZHANG Xiao-yan. Effect of Zr content on quench sensitivity of AlZnMgCu alloys[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(4): 787-92.

[27] DOLAN G P, ROBINSON J S. Residual stress reduction in 7175-T73, 6061-T6 and 2017A-T4 aluminium alloys using quench factor analysis[J]. Journal of Materials Processing Technology, 2004, 153/154: 346-51.

[28] LIN Gao-yong, ZHANG Hui, ZHU Wei, PENG Da-shu, LIANG Xuan, ZHOU Hong-zhang. Residual stress in quenched 7075 aluminum alloy thick plates[J]. Transactions of Nonferrous Metals Society of China, 2003, 13(3): 641-644.

[29] 王秋成, 柯映林. 航空高强度铝合金残余应力的抑制与消除[J]. 航空材料学报, 2002, 22(3): 59-62.

WANG Qiu-cheng, KE Yin-lin. Control and relief of residual stresses in high-strength aluminum alloy parts for aerospace industry[J]. Journal of Aeronautical Materials, 2002, 22(3): 59-62.

[30] 张定铨, 何家文. 材料中残余应力的X射线衍射分析和作用[M]. 西安: 西安交通大学出版社, 1999.

ZHANG Ding-quan, HE Jia-wen. Residual stress analysis by X-ray diffraction and its functions[M]. Xi’an: Xi’an Jiaotong University Press, 1999.

[31] SIMSIR C, GüR C H. A FEM based framework for simulation of thermal treatments: Application to steel quenching[J]. Computational Materials Science, 2008, 44(2): 588-600.

[32] 宋维锡. 金属学[M]. 北京: 冶金工业出版社, 2008: 318-329.

SONG Wei-xi. Metallography[M]. Beijing: Metallurgical Industry Press, 2008: 318-329.

[33] INOUE T, FUNATANI K, E.TOTTEN G. Process modeling for heat treatment: Current status and future developments[J]. Journal of Shanghai Jiaotong University, 2000, 5(1): 14-25.

[34] FUNATANI K. The trends and tasks of modeling and simulation for reduction of heat treatment distortion[J]. Journal of Shanghai Jiaotong University, 2000, 5(1): 35-41.

[35] 潘健生, 胡明娟, 田 东, 顾剑锋. 淬火过程计算机模拟研究的若干进展[J]. 金属热处理, 1998, 19(12): 32-35.

PAN Jian-sheng, HU Ming-juan, TIAN Dong, GU Jian-feng. Some development of the researches on computer simulat ion of quenching processes[J]. Heat Treatment of Metals, 1998, 19(12): 32-35.

[36] 陈乃录, 潘健生, 廖 波. 淬火冷却技术的研究进展[J]. 热处理, 2004(3): 17-22.

CHEN Nai-lu, PAN Jian-sheng, LIAO Bo. The progress in the quenching technology[J]. Heat Treatment, 2004(3): 17-22.

[37] 刘 庄. 热处理过程数值模拟[M]. 北京: 科学出版社, 1996: 10.

LIU Zhuang. Numerial simulation on heat treatment process[M]. Beijing: Science Press, 1996: 10.

[38] 李辉平, 赵国群, 栾贻国, 王广春. 淬火过程有限元模拟技术的研究现状及其关键技术[J]. 山东大学学报(工学版), 2004, 34(5): 116-121.

LI Hui-ping, ZHAO Guo-qun, LUAN Yi-guo, WANG Guang-chun. Key technologies and research status of numerical simulation technology in quenching process[J]. Journal of Shandong University(Engineering Science), 2004, 34(5): 116-121.

[39] 李辉平, 赵国群, 牛山廷, 栾贻国. 基于有限元和最优化方法的淬火冷却过程反传热分析[J]. 金属学报, 2005, 41(2): 167-172.

LI Hui-ping, ZHAO Guo-qun, NIU Shan-ting, LUAN Yi-guo. Inverse heat conduction analysis of quenching process based on finite element and optimization method[J]. Acta Metallurgica Sinica, 2005, 41(2): 167-172.

[40] 董辉跃, 柯映林, 孙 杰, 吴 群. 铝合金厚板淬火残余应力的有限元模拟及其对加工变形的影响[J]. 航空学报, 2004, 25(4): 429-432.

DONG Hui-yue, KE Ying-lin, SUN Jie, WU Qun. Finite element method simulation for residual stress in quenched aluminum alloy thick-plate and its effect on machining distortion[J]. Acta Aeronautica ET Astronautica Sinica, 2004, 25(4): 429-432.

[41] 柯映林, 董辉跃. 7075铝合金厚板预拉伸模拟分析及其在淬火残余应力消除中的应用[J]. 中国有色金属学报, 2004, 14(4): 639-645.

KE Ying-lin, DONG Hui-yue. Pre-stretching process and its application in reducing residual stress of quenched 7075 aluminum alloy thick-plates[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(4): 639-645.

[42] 赵丽丽, 张以都. 基于轧制应力分布的铝合金厚板淬火应力仿真[J]. 北京航空航天大学学报, 2006, 32(1): 88-91.

ZHAO Li-li, ZHANG Yi-du. FEM simulation for residual stress in quenched aeronautics aluminum alloy thick-plate based on rolled residual stresses distribution[J]. Journal of Beijing University of Aeronautics and Astronautics, 2006, 32(1): 88-91.

[43] LI H Y, ZHANG Y D, ZHANG H W. Finite element analysis for comprehensive residual stress of 7075 aluminum alloy thick plate[J]. Advanced Materials Research, 2010, 154/155: 1255-1261.

[44] 胡少虬, 张 辉, 杨立斌, 林高用, 张 颖. 7075铝合金厚板淬火温度场及热应力场的数值模拟[J]. 湘潭大学自然科学学报, 2004, 26(2): 66-71.

HU Shao-qiu, ZHANG Hui, YANG Li-bin, LIN Gao-yong, ZHANG Ying. Numerical analysis of temperature and thermal stresses fields in quenching 7075 aluminum alloy thick plates[J]. Natural Science Journal of Xiangtan University, 2004, 26(2): 66-71.

[45] 林高用, 郑小燕, 冯 迪, 杨 伟, 彭大暑. 铝合金厚板淬火残余应力的研究进展[J]. 材料导报, 2008, 22(6): 70-74.

LIN Gao-yong, ZHENG Xiao-yan, FENG Di, YANG Wei, PENG Da-shu. Research development of quenching-induced residual stress of aluminum thick plates[J]. Materials Review, 2008, 22(6): 70-74.

[46] LIAO K, WU Y X, GONG H. Pre-stretching simulation and residual stresses measurement in aluminum alloy thick plates[C]// 2009 International Conference on Measuring Technology and Mechatronics Automation. IEEE, 2009, 2: 287-291.

[47] 李 涛, 吴运新. 7075铝合金厚板淬火残余应力的数值模拟[J]. 科学技术与工程, 2010, 10(27): 6735-6737.

LI Tao, WU Yun-xin. Numerical analysis of residual stress fields in quenching 7075 aluminum alloy thick plates[J]. Science Technology and Engineering, 2010, 10(27): 6735-6737.

[48] TANG Z T, YU T, XU L Q. Study on the deformations caused by the original residual stresses of aluminum alloy[J]. Advanced Materials Research, 2014, 875/877: 1016-1020.

[49] LI Ya-nan, ZHANG Yong-an, LI Xi-wu, LI Zhi-hui, WANG Guo-jun, JIN Long-bing, XIONG Bai-qing. Residual stress analysis in quenched aluminum alloy plate using the contour method[J]. Materials Science Forum, 2016, 850: 167-174.

[50] LI Y N, ZHANG Y A, LI X W, LI Zhi-hui, WANG Guo-jun, JIN Long-bing, HUANG Shu-hui, XIONG Bai-qing.. Quenching residual stress distributions in aluminum alloy plates with different dimensions[J]. Rare Metals, 2019, 38(11): 1051-1061.

[51] CAO H L, LI X W, LI Y N, YAN H W, LI Z H, ZHANG Y A, HUANG S H, XIONG B Q. Numerical simulation of quenching and pre-stretching residual stress in 7085 aluminum alloy plate[J]. Materials Science Forum, 2016, 852: 211-217.

[52] JEANMART P, BOUVAIST J. Finite element calculation and measurement of thermal stresses in quenched plates of high–strength 7075 aluminium alloy[J]. Materials Science and Technology, 1985, 1(10): 765-769.

[53] 许晓静, 韦宝存, 房士义, 程晓农. 铝合金大厚板淬火残余应力数值分析[J]. 江苏大学学报(自然科学版), 2010, 31(3): 296-299.

XU Xiao-jing, WEI Bao-cun, FANG Shi-yi, CHENG Xiao-nong. Numerical analysis of residual stresses in quenching of aluminum alloy thick plate[J]. Journal of Jiangsu University (Natural Science Edition), 2010, 31(3): 296-299.

[54] 李大峰, 丁华锋, 刘立斌, 王 孟, 蔡 奎. 7075铝合金板淬火残余应力模拟及实验研究[J]. 机械研究与应用, 2012, 25(3): 92-95.

LI Da-feng, DING Hua-feng, LIU Li-bin, WANG Meng, CAI Kui. Numerical simulation and experimental study of quenching-induced residual stress in 7075 aluminum alloy plates[J]. Mechanical Research & Application, 2012, 25(3): 92-95.

[55] 王金亮, 刘嘉辰, 陈慧琴. Al-Zn-Mg-Cu系高强铝合金厚板淬火过程数值模拟[J]. 金属热处理, 2014, 39(3): 130-133.

WANG Jin-liang, LIU Jia-chen, CHEN Hui-qin. Numerical simulation of quenching process of Al-Zn-Mg-Cu high strength aluminum alloy thick plate[J]. Heat Treatment of Metals, 2014, 39(3): 130-133.

[56] 刘嘉辰, 王金亮, 陈慧琴. 高强铝合金超厚板淬火残余应力及其冷压缩消除过程分析[J]. 轻合金加工技术, 2014, 42(9): 27-32, 47.

LIU Jia-chen, WANG Jin-liang, CHEN Hui-qin. Analysis of residual stress in quenched high-strength aluminum alloy ultra-thick plates and their reduction through cold compression[J]. Light Alloy Fabrication Technology, 2014, 42(9): 27-32, 47.

[57] 姚灿阳. 7050铝合金厚板淬火温度场及内应力场的数值模拟研究[D]. 长沙: 中南大学, 2007: 6, 37-48.

YAO Can-yang. Numerical simulation research on the quenching-induced temperature and inner stress fields of 7050 aluminum alloy thick plate[D]. Changsha: Central South University, 2007: 6, 37-48.

[58] GONG H, WU Y X, YANG Z P, LIAO K. Analysis of quenching and stretching processes of aluminum alloy thick plates[J]. Advanced Materials Research, 2014, 996: 532-537.

[59] YAZDI S R, RETRAINT D, LU J. Study of through-thickness residual stress by numerical and experimental techniques[J]. Journal of Strain Analysis for Engineering Design, 1998, 33(6): 449-458.

[60] 张志伟, 许 东, 孙清汝. 2A12铝合金厚板淬火残余应力的数值模拟[J]. 金属热处理, 2013, 38(12): 88-93.

ZHANG Zhi-wei, XU Dong, SUN Qing-ru. Numerical simulation on quenching residual stress of 2A12 aluminum alloy thick sheet[J]. Heat Treatment of Metals, 2013, 38(12): 88-93.

[61] CHOBAUT N, CARRON D, ARSENE S, SCHLOTH P, DREZET J M. Quench induced residual stress prediction in heat treatable 7xxx aluminium alloy thick plates using Gleeble interrupted quench tests[J]. Journal of Materials Processing Technology, 2015, 222: 373-380.

[62] DREZET J M, CHOBAUT N, SCHLOTH P, VAN SWYGENBHOVEN H. Internal stress generation during quenching of thick heat treatable aluminium alloys[C]//EPD Congress. John Wiley & Sons, Inc, 2013: 65-72

[63] 张园园. 铝合金厚板淬火过程及预拉伸热-力仿真与实验研究[D]. 长沙: 中南大学, 2008: 3, 37-50.

ZHANG Yuan-yuan. Thermal-mechanical coupled modeling and experimental study on thick aluminum alloy plate during quenching and pre-stretching treatments[D]. Changsha: Central South University, 2008: 3, 37-50.

[64] YUAN W J, WU Y X. Parameter simulation for quenching and pre-stretching about aluminum alloy thick plates based on MARC finite element[J]. Advanced Materials Research, 2010, 152/153: 357-362.

[65] 林高用. 高性能7x75系铝合金厚板加工技术相关基础研究[D]. 长沙: 中南大学, 2006: 125-126.

LIN Gao-yong. Fundamental research related to the fabrication technology for high quality thick plates of 7x75 series aluminum alloys[D]. Changsha: Central South University, 2006: 125-126.

[66] 张园园, 吴运新, 李丽敏, 张明容. 7075铝合金预拉伸板淬火后残余应力的有限元模拟[J]. 热加工工艺, 2008, 37(14): 88-91.

ZHANG Yuan-yuan, WU Yun-xin, LI Li-min, ZHANG Ming-rong. Finite element simulation of residual stress in pre-stretching thick-plates of 7075 aluminum alloy after quenching[J]. Hot Working Technology, 2008, 37(14): 88-91.

[67] 龚 海, 吴运新, 廖 凯. 预拉伸对7075铝合金厚板残余应力分布的影响[J]. 材料热处理学报, 2009, 30(6): 201-205.

GONG Hai, WU Yun-xin, LIAO Kai. Influence of pre-stretching on residual stress distribution in 7075 aluminum alloy thick-plate[J]. Transactions of Materials and Heat Treatment, 2009, 30(6): 201-205.

[68] 袁望姣, 吴运新. 基于预拉伸工艺的铝合金厚板残余应力消除机理[J]. 中南大学学报(自然科学版), 2011, 42(8): 2303-2308.

YUAN Wang-jiao, WU Yun-xin. Coupled thermal- mechanical simulation on quenching of aluminum alloy thick-plate based on ANSYS[J]. Journal of Central South University (Science and Technology), 2011, 42(8): 2303-2308.

[69] 朱才朝, 罗家元, 钟 渝. 考虑夹持影响的铝合金板拉伸模拟及试验[J]. 材料科学与工艺, 2011, 19(6): 16-21.

ZHU Cai-chao, LUO Jia-yuan, ZHONG Yu. Stretching simulation and experiment of aluminum alloy sheet with clamping[J]. Materials Science & Technology, 2011, 19(6): 16-21.

[70] ZHU Cai-chao, LUO Jia-yuan. Stretch rate and deformation for pre-stretching aluminum alloy sheet[J]. Journal of Central South University, 2012, 19(4): 875-881.

[71] ZHANG S, WU Y, GONG H. A modeling of residual stress in stretched aluminum alloy plate[J]. Journal of Materials Processing Technology, 2012, 212(11): 2463-2473.

[72] LIN F, WANG H M, QIN G H, ZUO D W. Investigation on residual stresses in pre-stretching process of aluminum alloy thick plate based on material non-uniformity[J]. Key Engineering Materials, 2016, 693: 821-829.

ZHU Kai1, 2, 3, XIONG Bai-qing1, 3, YAN Hong-wei1, 2, 3, ZHANG Yong-an1, 2, 3, LI Zhi-hui1, 3, LI Xi-wu1, 2, 3,WEN Kai1, 2, 3, LIU Hong-wei1, 2, 3, YAN Li-zhen1, 2, 3

(1. State Key Laboratory of Nonferrous Metals and Processes, GRINM Group Co., LTD., Beijing 100088, China;

2. GRIMAT Engineering Institute Co., Ltd., Beijing 101407, China;

3. General Research Institute for Nonferrous Metals, Beijing 100088, China

Abstract: In order to obtain desired mechanical properties, rolling, solution, quenching, pre-stretching and age-hardening treatments were applied to produce aluminum alloy thick plates. Among the aforementioned processes, the temperature in the whole thick plate will be severely changed during the quenching process. Simultaneously, high residual stress also can be formed in the plate. In recent years, numerical simulation has been treated as an effectively method to study and predict the development, distribution and evolvement behavior of residual stress in the thick plate during quenching and pre-stretching processes. The research situation on the evolvement of residual stress in the thick aluminum plate during quenching and pre-stretching processes based on the FEM simulation method was reviewed. The usage of relative skills and parameters for the models were also concluded. Moreover, the key research content and develop orientations in this filed were prospected at the summary chapter of this article.

Key words: aviation aluminum alloy thick plate; solution and quenching; pre-stretching; residual stress; FEM

Foundation item: Project(2016YFB0300903, 2016YFB0300803) supported by the National Basic Research Development Program of China; Project(2012CB619504) supported by the National Basic Research and Development Program of China

Received date: 2019-05-31; Accepted date: 2019-12-19

Corresponding author: XIONG Bai-qing; Tel:+86-10-82241885; E-mail: xiongbq@grinm.com

(编辑 王 超)

基金项目:国家重点研发计划资助项目(2016YFB0300903,2016YFB0300803);国家重点基础研究发展计划资助项目(2012CB619504)

收稿日期:2019-05-31;修订日期:2019-12-19

通信作者:熊柏青,教授,博士;电话:010-82241885;E-mail:xiongbq@grinm.com