基于预拉伸工艺的铝合金厚板残余应力消除机理

袁望姣,吴运新

(中南大学 机电工程学院,湖南 长沙,410083)

摘要:基于有限元软件MSC.Marc,对7075铝合金厚板淬火过程和预拉伸过程进行参数化模拟。以淬火残余应力作为初始条件读入预拉伸模型,利用生死单元技术,对预拉伸机夹具的夹紧和放松进行模拟,并对拉伸机理进行研究。研究结果表明:在拉伸过程中,表层金属应力由受压逐渐变为拉应力,而内层金属一直受拉应力作用,松开夹具后,铝合金厚板回弹,应变出现松弛,应力大大减小;随着拉伸量的增加,残余应力随之减小;而塑性变形随之增加;当拉伸量相同时,残余应力随铝合金板厚的增加而增加,为达到消除残余应力的最佳效果,预拉伸量需随板厚的增加而增加;在满足应力消除效果的前提下,拉伸量应取较小值。

关键词:铝合金厚板;预拉伸;残余应力;有限元法;参数化数值分析;淬火

中图分类号:TB156.3;TG146.21 文献标志码:A 文章编号:1672-7207(2011)08-2303-06

Mechanics about eliminating residual stress of

aluminum alloy thicken-plates based on pre-stretching technology

YUAN Wang-jiao, WU Yun-xin

(School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: The quenching and pre-stretching process of 7075 aluminum plates were simulated by MSC.Marc FEA program. The quenched residual stress was used as initial condition to apply on the pre-stretch model. The clamp and release of the clamp of pre-stretch machine were simulated using life and death element, and the pre-stretch mechanism was researched. The results show that the stress of the surface metal is changed from compress stress to tensile stress and the center metal stress suffers tensile stress all along in the process of the pre-stretch. When the clamp is released, the aluminum alloy thicken-plate is spring back, the strain is loosen and the stress diminishes greatly. The stress is diminished and the plastic deform is increased along with the increases of stretch value. The residual stress is increased with the increase of thickness of the aluminum alloy plate when the different plates have the same pre-stretching value. In order to diminish efficiently the residual stress, the pre-stretch value should increase with the increase of thickness of the aluminum alloy plate. The pre-stretch value should adopt the small value when the residual stress is diminished.

Ke ywords: aluminum alloy thicken-plate; pre-stretching; residual stress; finite element method; parametric numerical simulation; quenching

新型高强韧型铝合金7075属于Al-Zn-Mg-Cu系,主要应用于航空航天领域,王洪等[1-3]对超高强铝合金的研究进展进行了阐述。高强铝合金预拉伸板代替模锻件,用于航天、航空飞行器受力部件,大大降低了加工成本和制造成本。铝合金预拉伸板虽然具有很多优良性能,但在实际应用中仍然存在较为严重的问题,如:部分板材经机械加工后仍然产生弯曲变形,或者发生非预期的变形,加工精度达不到要求,严重影响了铝合金板材的使用性能。残余应力是存在于预拉伸板中一种无形隐患。拉伸法消除残余应力是指在机件的端面上,仅仅施加均匀的拉应力使之产生塑性变形,并由之而使应力得到松弛的方法。预拉伸工艺对应力的消减效果明显,是目前在生产铝合金预拉伸板时普遍采用的工艺。聂波等[4-7]对热处理工艺、预拉伸工艺、残余应力的消减及其对微观结构和特性的影响进行了研究,Adrien等[8]对铝合金弹塑性行为进行了研究。有限元是研究铝合金板从淬火到预拉伸工艺应力变化的有效手段,国内外有不少学者利用有限元对残余应力进行了研究[9-11]。为消除铝合金厚板淬火后产生的残余应力,本文作者首先利用非线性计算功能强大的有限元软件MSC.Marc对厚板淬火过程进行模拟,然后,采用弹塑性有限元法对含有淬火残余应力的铝合金厚板进行预拉伸数值模拟,了解拉伸应力场和拉伸应变场的分布规律,并对预拉伸消除残余应力的机理进行研究。

1 基本条件

对预拉伸分析模型进行如下基本假设:

(1) 材料为各向同性的连续固体介质,具有等向硬化的弹塑性。

(2) 拉伸时钳口夹持区域为难变形区。

(3) 拉伸均匀,边界条件相同,两端钳口内所有牙板出力均等。

7075铝合金厚板外形尺寸(长×宽×高)为800 mm×220 mm×50 mm,根据模拟对象的几何对称性和边界条件的对称性,取试样的1/8进行模拟。7075铝合金的弹性模量、泊松比、密度等参数见文献[12],基于完全热弹塑性理论进行淬火模拟,基于弹塑性有限元理论进行预拉伸仿真,应力应变曲线通过拉伸实验获得。

2 铝合金厚板残余应力消除有限元模型

建模时,先进行参数定义[13],以便对几何尺寸和网格数进行更改。将过程文件的命令流文件进行修改,并保存。单元形式选用8 节点六面体单元,分析单元类型号选为7;应力-应变关系呈多线性关系,使用等向强化的 Von Mises 屈服准则,7075铝合金材料温度为室温,材料强化准则选用多线性等向强化。选择直接划分网格的方法划分网格,铝合金厚板单元数为4 500个,节点数为5 450个,夹具单元数为240个,节点数为378个。

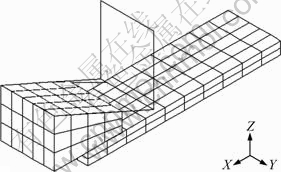

应力场计算的理论基础是弹塑性理论,有限元模型所采用的直角坐标系设为:板的长度方向为X轴,宽度方向为Y轴,厚度方向为Z轴,如图1所示。根据结构的对称性,在模型的3个对称面上沿X,Y和Z 3个方向分别施加对称约束。以淬火残余应力的结果文件*.t16,作为初始条件读入预拉伸模型,将拉伸法消除应力过程按其实际工艺分为加载和缷载2部分进行模拟。在MARC中通过用table的方式定义拉伸力和拉伸速度来实现拉伸过程;缷载过程通过利用生死单元技术,缷载时将夹具各单元变成死单元,以实现夹具的释放。

图1 有限元模型和坐标系

Fig.1 Finite element model and coordinate system

3 铝合金厚板残余应力消除机理

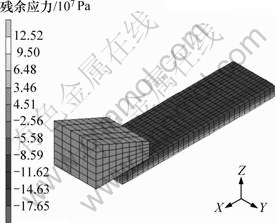

图2所示为铝合金厚板淬火后残余应力作为初始应力的读入预拉伸模型。淬火后,板材残余应力呈现内拉外压的分布规律。对淬火后人工时效之前的航空铝合金板材,分析不同拉伸量时,铝合金板材内部残余应力场的消除规律。

图2 拉伸前残余应力

Fig.2 Residual stress before pre-stretched

图3所示为对预拉伸板进行3%拉伸得到的残余应力分布云图。从图3可以看出:淬火后的铝合金厚板经拉伸后,中间部分应力分布均匀,应力波动不大,而钳口端的拉伸区域出现了很大的应力,钳口端的板材应予以锯切。

图3 拉伸3%后残余应力

Fig.3 Residual stress on pre-stretched by 3%

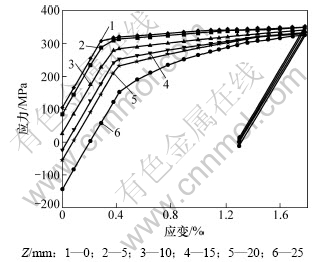

图4所示为拉伸过程中厚度上沿轧制方向上的应力应变变化。拉伸前内层金属受拉应力,表层金属受压应力。在拉伸的起始阶段,表层金属所受压应力逐渐减小,一直到0 MPa后,逐渐增大为拉应力,内层金属是受拉应力逐渐增大。当拉伸量超过一定量时(图中轧制方向总应变为0.22%),内外层金属同时受拉。内层金属一直受拉应力,应力的变化幅度比外层的要小。内层金属先超过弹性极限进入塑性变形。在拉伸过程中,铝合金厚板产生弹塑性变形,当预拉伸一定量后松开夹具,厚板会回弹,从而释放弹性应变,只留下塑性变形,在回弹过程中,应力重新分布。当拉伸量达到3%后继续拉伸,内外层金属的X方向应力基本重合在一条直线上,应力很大,但应力差值很小。松开夹具(卸载)后X方向应力迅速下降,最终接近于0 MPa。这说明当预拉量恰当时能将淬火产生的残余应力降低到接近于零。在消除了残余应力之后,若继续拉伸板材,则会重新引起新的弹塑性变形,产生新的应力分布;若无限制地增大拉伸量,则一方面导致板材最终残余应力不降反而增大,另一方面,可导致板材超过屈服极限而被拉断。

图4 拉伸过程中应力与应变的关系

Fig.4 Relationship between stress and strain on pre-stretching process

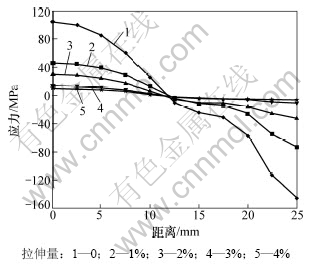

图5所示为拉伸量分别为0,1%,2%,3%和4%时X方向残余应力沿厚度上从中心至表面的应力分布。从图5可见:当拉伸量从1%变化到4%时,随着拉伸量的增加,应力的消减作用增强;当拉伸量达到1%时,卸载后内外层所受应力仍然相差较大,X方向残余应力仍然外层受压而内层受拉,内部拉应力的消减率为55.9%,表面压应力的消减率为49.6%,这说明对于铝合金厚板,1%的拉伸量不足以消除其残余应力;当拉伸量达到3%时,X方向残余应力基本重合在1条直线上,应力差很小,卸载后X方向残余应力接近于0 MPa,内部拉应力的消减率为87.7%,表面压应力的消减率为92.0%。这说明拉伸法可明显消除板材淬火残余应力,应力消除效果随拉伸量的增加而 增强。

图5 拉伸对淬火铝合金残余应力的影响

Fig.5 Effect of pre-stretching on quenched stress

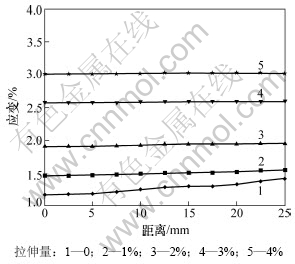

图6所示为拉伸量分别为0,1%,2%,3%和4%时X方向残余应力沿厚度上从中心至表面的塑性应变分布。从图6可见:当拉伸量从1%变化到4%时,随着拉伸量的增加,塑性应变随着增加;当拉伸量为2%时,塑性应变约为1.9%;当拉伸量为3%时,塑性应变约为2.6%;当拉伸量为4%时,塑性应变约为3%。这说明预拉伸板残余应力的消除是以塑性变形增大为代价的。在消除残余应力的同时,板材会产生较大的变形,因此,在具体的工程实际中不能一味地追求残余应力的消除效果,而应充分考虑材料的塑性储备及板材的实际要求,选择恰当的拉伸量。在满足残余应力需要的前提下,应降低预拉伸量。

航空工业所用的铝合金厚板生产工艺规定:拉伸产生2.0%的永久变形,但不能小于1.5%,也不能大于3.0%。因此,对于50 mm厚的铝合金板,拉伸量应控制在2.0%~3.5%。

图6 拉伸对塑性变形的影响

Fig.6 Effect of pre-stretching on plastic deformation

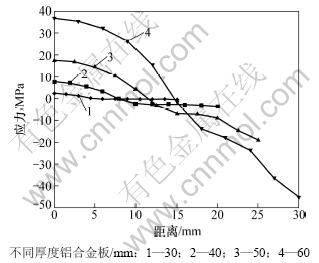

图7所示为厚度分别为30,40,50和60 mm的铝合金板,拉伸量都为2.5%时,X方向残余应力沿中心厚度分布图。由图7可知:当拉伸量相同时,残余应力随板厚的增加而增加。为了有效地降低残余应力,当板厚增加时,需适当增加拉伸量来降低其残余应力。拉伸量是控制拉伸最主要的工艺参数之一,对于不同厚度的预拉伸板材,都应有最适合拉伸量范围。

图7 不同厚度板应力与厚度的关系

Fig.7 Relationship between stress and width at different thick plates

此外,沿X方向所施加的均匀拉力对其余2个方向的残余应力也有影响。比较拉伸之前和拉伸之后的Y方向残余应力σY和Z方向残余应力σZ,应力均明显降低。这说明沿轧制方向所施加的均匀拉伸外力对宽度方向和厚度方向的残余应力都有影响。适当的拉伸量不仅可使轧制方向应力σX大大降低,而且同时会使残余应力σY和σZ明显减小。所以,适当地控制拉伸量可使板材各向残余应力大幅度降低,这也是工程上将机械拉伸法作为消除应力的主要手段之一的重要 原因。

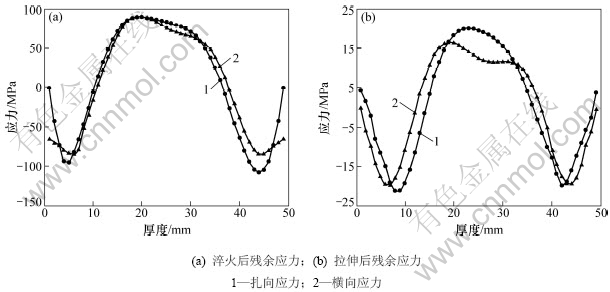

对预拉伸消除铝合金厚板淬火后残余应力的机理进行探讨。淬火时,将固溶后的铝合金厚板快速放入冷水中,由于板材表层金属和内部金属冷却速度不均,使得最后表层金属有残余压应力,内层金属有残余拉应力[9]。对淬火后的板材进行拉伸,无论是受压应力的表层金属,还是受拉应力的内层金属,它们在受到外力的作用后都将发生变形,当给予的拉伸力超过该金属的弹性极限后,就发生塑性变形。由于板材的内层金属原来就具有残余拉应力,所以,它首先超过弹性极限进入塑性变形。这显然会导致内层金属的变形速度比表层金属的变形速度快,但是,由于板材仍然是一个整体,表层金属将牵制内层金属的变形[14]。对淬火后的板材进行预拉伸的实质是使板材内部的残余应力重新分布。图8所示为铝合金板材拉伸时应力分布。由图8(a)可知:表层金属原来具有压应力,随着拉伸的不断进行,逐步转变为拉应力,而内层金属一直受拉应力的作用,当拉伸量达到一定值后,表层金属和内层金属均受拉应力作用,随着拉伸的进行,表层金属和内层金属的应力差不断减小。拉伸后松开夹具,铝合金板会发生弹性回复,只留下塑性变形,在回弹过程中,应力被释放,卸载前后的应力分布如图8(b)所示。从图8(b)可见:卸载后残余应力变得很小,呈现内拉外压的应力分布;当拉伸量选择恰当时,残余应力可接近于0 MPa;在消除残余应力的同时,板材会产生较大的变形,塑性应变随拉伸量的增加而增加,预拉伸消除残余应力是以塑性变形增大为代价的。

用裂纹柔度法对50 mm厚的铝合金板淬火后和预拉伸后的残余应力进行测量[15],采取线切割的方法在试件上引入裂纹,沿切深每增加1 mm记录1次应变。试验采用西南铝业生产的7075轧制铝合金厚板,铝合金厚板的淬火温度为470 ℃,淬火介质为室温自来水。考虑到厚板淬火的边缘效应,应力测试时,从板的中间部位进行测量。使用沈阳四龙机器有限公司生产的500 t液压拉伸机对淬火后的铝合金厚板进行预拉伸,拉伸量为2.5%。图9所示为淬火后和预拉伸后残余应力测量值,实验结果与Marc有限元计算结果比较,应力分布的规律基本相同,其值略小。其原因是:裂纹柔度法求解的是作用在整个裂纹面上的综合应力,测量方法存在固有的计算误差;在实验过程中,存在加工及读数误差;在仿真时,为简化问题进行了一些必要的假设,表面换热系数的测定精度还有待进一步提高。

图8 铝合金板材拉伸时应力分布

Fig.8 Stress distribution on stretching

图9 淬火后和拉伸2.5%后残余应力分布图

Fig.9 Residual stress distribution after quenching and pre-stretching by 2.5%

4 结论

(1) 利用“生死单元技术”,模拟预拉伸过程中拉伸机夹具的夹紧和放松,并对不同拉伸量消除残余应力进行模拟。随着拉伸量的增加,残余应力随之减小。

(2) 对预拉伸消除铝合金厚板淬火后残余应力的机理进行了研究。淬火后残余应力呈现内拉外压的分布规律,随着拉伸的不断进行,表层金属由压应力逐步转变为拉应力,而内层金属一直受拉应力的作用。当拉伸量达到一定值后松开夹具,铝合金板会发生弹性回复,只留下塑性变形,在回弹过程中,应力被释放;当拉伸量选择恰当时,残余应力可接近于0 MPa。

(3) 残余应力随板厚的增加而增加,随着铝板厚度的增加,拉伸量也要适当增加,以便更有效地消除残余应力。

(4) 随预拉伸量的增加,塑性变形随之增加,预拉伸板拉伸消除残余应力是以塑性变形增大为代价的。在消除残余应力时应注意材料的塑性储备,在满足残余应力和矫直需要的前提下,应尽量降低预拉 伸量。

参考文献:

[1] 王洪, 付高峰, 孙继红, 等. 超高强铝合金研究进展[J]. 材料导报, 2006, 20(2): 58-60.

WANG Hong, FU Gao-feng, SUN Ji-hong, et al. Present research and developing trends of ultra high strength aluminum alloys[J]. Materials Review, 2006, 20(2): 58-60.

[2] 刘晓涛, 崔建忠. Al-Zn-Mg-Cu系超高强铝合金的研究进展[J]. 材料导报, 2005, 19(3): 47-51.

LIU Xiao-tao, CUI Jian-zhong. Progress in research on ultra high strength Al-Zn-Mg-Cu alloy[J]. Materials Review, 2005, 19(3): 47-51.

[3] 冯春, 刘志义, 宁爱林,等. 超高强铝合金RRA热处理工艺的研究进展[J]. 材料导报, 2006, 20(4): 98-101.

FENG Chun, LIU Zhi-yi, NING Ai-lin, et al. Research and progress in retrogression and reaging treatment of super-high strength aluminum alloy[J]. Materials Review, 2006, 20(4): 98-101.

[4] 聂波, 王志超, 刘显东,等. 2A70铝合金预拉伸厚板热处理工艺研究[J]. 轻合金加工技术, 2004, 32(7): 41-45.

NIE Bo, WANG Zhi-chao, LIU Xian-dong, et al. Study of heat treatment process of 2A70 aluminum alloy pre-stretching plate[J]. Light Alloy Fabrication Technology, 2004, 32(7): 41-45.

[5] 陆海庆, 张思平. 7050-T7651铝合金预拉伸厚板生产工艺研究[J]. 铝加工, 2004(4): 48-54.

LU Hai-qing, ZHANG Si-ping. Study on process of 7075-T7651 aluminum alloy prestretched plate[J]. Aluminum Fabrication, 2004(4): 48-54.

[6] LI Zhi-hui, XIONG Bai-qing, ZHANG Yong-an. Effects of the two-step ageing treatment on the microstructure and properties of 7B04 alloy pre-stretched thick plates[J]. Rare Metals, 2007, 26(3): 193-199.

[7] Michael B, Michael R. Residual stress, stress relief, and inhomogeneity in aluminum plate[J]. Scripta Materialia, 2002, 46(1): 77-82.

[8] Adrien J, Maire E, Estevez R, et al. Influence of the thermomechanical treatment on the microplastic behaviour of a wrought Al-Zn-Mg-Cu alloy[J]. Acta Materialia, 2004, 52(6): 1653-1661.

[9] 柯映林, 董辉跃. 7075铝合金厚板预拉伸模拟分析及其在淬火残余应力消除中的应用[J].中国有色金属学报, 2004, 14(4): 639-645.

KE Ying-lin, DONG Hui-yue. Pre-stretching process and its application in reducing residual stress of quenched 7075 aluminum alloy thick-plates[J].The Chinese Journal of Nonferrous Metals, 2004, 14(4):639-645.

[10] Muammer K, John C, Taylan A. Prediction of residual stresses in quenched aluminum blocks and their reduction through cold working processes[J]. Journal of Materials Processing Technology, 2006, 174(1): 342-354.

[11] Tanner D A, Robinson J S. Modeling stress reduction techniques of cold compression and stretching in wrought aluminum alloy products[J]. Finite Elements in Analysis and Design, 2003, 39(5): 369-386.

[12] 王祝堂, 田荣璋. 铝合金及加工手册[M].长沙:中南工业大学出版社, 2000: 322-324.

WANG Zhu-tang, TIAN Rong-zhang. Aluminum alloy and hand book of machining[M]. Changsha: Central South University of Technology Press, 2000: 322-324.

[13] 陈火红, 尹伟奇, 薛小香. MSC.Marc二次开发指南[M]. 北京:科学出版社, 2004: 414.

CHEN Huo-hong, YIN Wei-qi, XUE Xiao-xiang. MSC. Marc redevelopment guide[M]. Beijing: Science Press, 2004: 414.

[14] 赵丽丽, 张以都. 预拉伸板轧制-拉伸残余应力的计算机仿真[J]. 北京航空航天大学学报, 2004, 30(7): 606-609.

ZHAO Li-li, ZHANG Yi-du. Computer simulation of residual stress for cold rolling prestretching board[J]. Journal of Beijing University of Aeronautics and Astronautics, 2004, 30(7): 606-609.

[15] GONG Hai, WU Yun-xin, LIAO Kai. Influence of specimen sampling on internal residual stress test[J]. Advanced Materials Research, 2010, 97(3): 2658-2663.

(编辑 陈灿华)

收稿日期:2010-08-10;修回日期:2010-10-28

基金项目:国家重点基础研究发展计划(“973”计划)项目(2005CB623708,2010CB731703)

通信作者:袁望姣(1969-),女,湖南双峰人,博士研究生,副教授,从事机械设计及理论研究;电话:13617315689;E-mail:ywjiao@csu.edu.cn