文章编号:1004-0609(2008)08-1492-06

共沉淀法制备BaHfO3?Ce纳米粉体及发光性能

刘 晶1, 3,马伟民1,闻 雷2,李喜坤3,沈世妃4 郭易芬4

(1. 沈阳化工学院 材料科学与工程学院,沈阳 110142;

2. 中国科学院金属研究所 沈阳材料科学国家(联合)实验室,沈阳 110016;

3. 沈阳理工大学 材料工程学院,沈阳 110168;

4. 沈阳大学 材料科学与工程系,沈阳 110044)

摘 要:研究以草酸和氨水作为沉淀剂制备BaHfO3?Ce纳米粉体的工艺。用XRD、TEM等测试技术,分析不同沉淀剂对粉体合成中的物相变化、形貌及Ce3+掺杂量对粉体激发光谱和发射光谱的影响。结果表明:以氨水做沉淀剂在900 ℃煅烧2 h合成的BaHfO3?Ce粉体形貌近似球形,平均粒径约15 nm。用草酸做沉淀剂、合成温度为1 000 ℃时其粉体形貌呈多边形,粒径约60 nm。微量Ce3+的掺杂不改变BaHfO3的晶体结构。Ce3+掺杂量(摩尔分数)为0.3%的BaHfO3发射光谱相对峰强度最高,当Ce3+掺杂量大于0.3%时出现浓度淬灭现象。粉体的激发和发射光谱均存在较宽的谱带,主要由激活Ce3+的5d→2F5/2和5d→2F7/2宽带能级跃迁产生。

关键词:BaHfO3?Ce粉体;共沉淀法;Ce3+掺杂量;光谱特性

中图分类号:O614.33; TQ 422 文献标识码:A

Preparation and spectrum characteristics of BaHfO3?Ce nano-powder by co-precipitation

LIU Jing1. 3, MA Wei-min1, WEN Lei2, LI Xi-kun3, SHEN Shi-fei4, GUO Yi-fen4

(1. School of Materials Science and Engineering, Shenyang Institute of Chemical Technology, Shenyang 110142, China;

2. Shenyang National Laboratory for Materials Science, Institute of Metal Research, Chinese Academy of Sciences,

Shenyang 110016, China;

3. School of Materials and Engineering, Shenyang Technology University, Shenyang 110168,China;

4. Department of Materials Science and Engineering, Shenyang University, Shenyang 110044, China)

Abstract: The processing technology of Ce doped-BaHfO3 nano-powders that is prepared by co-precipitation (with oxalic acid and ammonia as the precipitant, respectively) was investigated. XRD and TEM were employed to analyze the effects of different precipitates on the phase change, morphologies of powders and influences of Ce3+ dopant content on the excitation and emission spectra of powders. The results show that spherical BaHfO3?Ce nano-powders are synthesized only at 900 ℃ for 2 h and the average diameter is about 15 nm with ammonia as precipitant. But using oxalic acid as precipitant, the powders have polygonal morphology after calcining at 1 000 ℃ for 2 h and the average diameter is about 60 nm. Minor Ce3+ has no effect on the crystal structure. The relative intensity of photoluminescence peak has the maximum value when the Ce3+ dopant content is 0.3% (mole fraction). The concentration quench occurs when the Ce3+ dopant content exceeds 0.3%. The emission character is resulted from 5d→2F5/2 and 5d→2F7/2 transitions of Ce3+ and both the excitation and emission spectra are wide band.

Key words: BaHfO3?Ce powder; co-precipitation; Ce3+ dopant content; spectrum characteristics

随着先进陶瓷材料制备工艺的不断进步与创新,使透明陶瓷应用领域有了较大的进展,为开发闪烁陶瓷材料奠定了一定的理论和实验基础[1?2]。近几年来GE、SIEMENS、HITACHI及众多材料研究机构对闪烁体新材料体系、合成方法、制备技术等进行了深入研究,相继开发出(Y, Gd)3O3?Eu, Pr(YGO),Gd2O2S?Pr, Ce, F(GOS)等氧化物闪烁陶瓷。SIEMENS公司已经成功地将Gd2O2S陶瓷闪烁体应用于医学X-CT[3?6]。文献[7]报道钙钛矿型BaHfO3具有稳定的简单立方结构,光学各向同性,易实现透明,且密度高(8.35 g/cm3),阻止本领强,衰变时间短(30 ns),是适应于快速响应探测器的一种极有前途的陶瓷闪烁体基体材料。Ce3+作为闪烁体激活离子,具有光学电负性小,能实现5d→4f完全跃迁,符合闪烁体发光衰减<100 ns的特征要求[8]。

选择合适的材料体系、合成特性优良的粉体是制备陶瓷闪烁体的重要环节之一。目前TAKUJI等[7]和JI等[9?10]报道了采用固相合成、高温自蔓延制备BaHfO3粉体材料。尽管上述方法反应温度低、时间短、速度快,但都不同程度的出现粉体团聚严重、易形成网络状颗粒等不足。而湿化学共沉淀法具有工艺简单、易精确控制化学计量比、能实现均匀掺杂、适合批量生产等优点。因此,本文作者用共沉淀法研究不同沉淀剂(草酸、氨水)制备BaHfO3?Ce纳米粉体的工艺,对BaHfO3?Ce形貌、结构进行表征,讨论不同Ce3+掺杂浓度对BaHfO3晶体结构和发光特性的影响。

1 实验

1.1 材料制备

实验原料为Ba(NO3)2(99.9%)、Ce(NO3)3(99.99%)、HfO(NO3)2(99.99%)、无水乙醇(分析纯)、草酸(99.5%)、氨水(25%~28%)。分别精确称取Ba(NO3)2、Ce(NO3)3 、HfO(NO3)2并配成阳离子浓度为0.1 mol/L的混合溶液,配置浓度为0.5mol/L的C2H2O4溶液、pH=12.0的NH3?H2O溶液各500 mL作为沉淀剂。将配好沉淀剂滴加到混合溶液中,滴定速度为2 mL/min,反应期间滴定与搅拌同时进行,最终得到白色絮状沉淀物。将先驱沉淀物用去离子水、无水乙醇及丙酮多次清洗,除去杂质离子,将过滤后的沉淀物置于真空干燥箱中70 ℃烘干。烘干后粉体经研钵研磨后,放入刚玉坩埚在箱式电阻炉中不同温度下进行煅烧2 h,分别合成出所需要的BaHfO3?Ce粉体样品。

1.2 分析方法

采用日本理学D/max?2500Pc型X射线衍射仪(XRD)研究不同煅烧温度下的物相组成;用SETSYS evolution热重/差式分析仪(TG-DSC) 在升温速度为10 ℃/min,气氛为氮气保护下分析粉体加热中的物相变化;用JEM?2010型透射电镜(TEM)观察粉体的形貌与晶体结构;用Perkin Elmer LS?55型荧光光度计分析样品的发光特性。

2 结果与讨论

2.1 粉体合成的差热分析

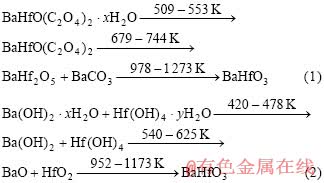

图1(a)和(b)所示分别为以草酸和氨水做沉淀剂制备的先驱沉淀物的TG-DSC曲线。图1(a)中在236 ℃和329 ℃出现的吸热峰对应前驱物失去结晶水,质量损失约2%;在406 ℃的强吸热峰为BaHfO(C2O4)2分解放出CO和CO2,质量损失比较大,约24%;在638℃较为平缓的放热峰为BaHf2O5从四方相转化为立方相,质量损失约4.4%;在714 ℃的吸热峰是BaHf2O5和BaCO3反应造成的,质量损失约5.9%。图1(b)中在205、271和352 ℃分别出现了3个强的放热峰,分别对应Ba(OH)2、Ce(OH)3和Hf(OH)4脱去—OH形成氧化物,质量损失约占3.1%,在679 ℃的吸热峰为氧化物进一步反应形成BaHfO3造成的,质量损失约占9.8%。综上所述,两种方法得到先驱沉淀物的反应式可归纳如下:

图1 先驱沉淀物的TG-DSC曲线

Fig.1 TG-DSC curves of precursor precipitates: (a) Oxalic acid as precipitant; (b) Ammonia as precipitant

2.2 BaHfO3?Ce物相表征及形貌

图2(a)和(b)所示分别为BaHfO3?Ce先驱沉淀物在不同温度下煅烧2 h的XRD谱。如图2(a)所示,先驱沉淀物在500 ℃时主要为非晶态;在700 ℃左右形成晶态BaHf2O5的峰出现,但还有杂峰BaCO3存在;到 1 000 ℃时BaHf2O5和BaCO3已全部转化成BaHfO3。图2(b)与图2(a)比较,先驱沉淀物在500和700 ℃的衍射峰有较大区别,由于沉淀剂不同导致图2(b)中的晶型转变温度较图2(a)中的滞后200 ℃。其原因是在此温度阶段,图2(a)中的先驱沉淀物为草酸复合盐,在高温下容易热分解出CO和CO2后直接转化为BaHfO3,缩短了非晶态转化为晶态的时间;而图2(b)中的先驱沉淀物为氢氧化物,要先经高温煅烧转化为氧化物,继续升温才可进一步合成BaHfO3,故提高了晶态BaHfO3的起始合成温度。图2(b)中900 ℃和1 000 ℃的衍射峰无明显区别,说明氨水做沉淀剂在900 ℃时已能完全合成BaHfO3?Ce。比较图2(a)和(b)中的谱线可以看到,在(110)、(200)、(211)、(220)、(310)和(222)晶面的主晶相所对应的衍射角是一致的,说明两种合成BaHfO3?Ce的工艺只存在合成温度对物相影响的差异,后者比前者的合成温度低100 ℃,但不改变物相的结构。

图2 不同煅烧温度下先驱沉淀物的XRD谱

Fig.2 XRD patterns of precursor precipitates at different calcination temperatures: (a) Oxalic acid as precipitant; (b) Ammonia as precipitant)

图3(a)和(b)所示分别为在1 000 ℃煅烧2 h和在900 ℃煅烧2 h得到的BaHfO3?Ce粉体的TEM形貌。图3(a)中的粉体粒径大约为60 nm,形貌呈多边形。图3(b)中的粉体粒径大约为15 nm,形貌近似球形,且分散性较图3(a)中的粉体的分散性要好。这主要是因为过量的NH4+吸附在晶核表面,当有效控制NH4+浓度、分散速率时能驱动先驱体分子级的形核,有利于近似球形晶核的形成且在一定程度上抑制了核的生 长[11]。通过控制体系中溶质的相对过饱和度来控制形核速率,并使其晶核形成过程与长大过程分开,就可以使得已经形成的晶核同步生长,这样就可以得到尺寸均匀分布的单分散先驱沉淀物[12?13]。从图3(b)可以看出,用氨水做沉淀剂合成BaHfO3?Ce时,合成温度得到降低,同时粉体形貌和粒径的均匀性都优于用草酸做沉淀剂所合成的粉体。

图3 BaHfO3?Ce粉体的TEM形貌

Fig.3 TEM micrographs of nano-particles BaHfO3?Ce: (a) Oxalic acid as precipitant; (b) Ammonia as precipitant

2.3 Ce3+掺杂浓度对晶体结构的影响

在1 000 ℃煅烧2 h后,BaHfO3中Ce3+掺杂浓度为0%~0.5%,所得粉体的XRD谱如图4所示。当Ce3+掺杂浓度在0.5%以下时,所有的衍射峰都同属于单一相BaHfO3,并无新的相及化合物生成,这是由于所掺杂的Ce3+相当微量并不足以影响基质BaHfO3的结晶结构。另一方面,Ce3+与基质中的Ba2+和Hf4+阳离子价数都不同且离子半径相差比例分别约为23.1%和24.1%(Ce3+:0.103 nm;Ba2+:0.134 nm;Hf4+:0.083 nm),可以推测掺杂于BaHfO3中的发光中心Ce3+为取代Ba2+并占据其晶格位置,然而当微量的Ce3+掺杂时,对基质的结晶结构没有影响。图5(a)所示为单颗粒粉体的电子衍射斑点图,图5(b)所示为单晶衍射花样,BaHfO3粉体晶粒属钙钛矿结构,晶格常数为0.417 1 nm[8]。

图4 不同Ce3+掺杂浓度的BaHfO3粉体在1 000 ℃煅烧2 h的XRD谱

Fig.4 XRD patterns of BaHfO3 powders with different Ce3+ dopant contents after calcining at 1 000 ℃ for 2 h

图5 BaHfO3粉体的电子衍射斑点及单晶衍射花样

Fig.5 Electron diffraction pattern of BaHfO3 powders and diffraction pattern of single crystal

2.4 BaHfO3?Ce的发光特性

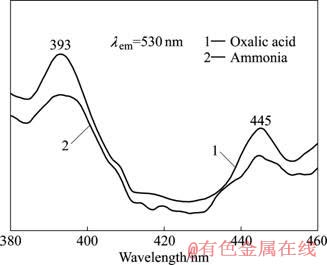

从图6可知,用不同沉淀剂制备的 BaHfO3?Ce纳米粉体存在两个较宽的激发光谱带:380~400 nm和430~460 nm,其峰值分别为393 nm和445 nm,对应于Ce3+4f能级向5d能级的跃迁吸收。由于Ce3+在4f能级只有一个电子,自旋轨道耦合使4f能级分解为两个能级2F5/2和2F7/2,Ce3+进入Ba2+的晶格位置,4f能级由于受到外层5s25p6电子的屏蔽,受晶体场影响较小,仍然保持自由离子时的LS耦合能级的特征。5d能级受晶体场的作用以及在低对称条件下,简并度被完全消除,5d能级被分裂成5个亚能级[14?15]。

图6 BaHfO3?Ce的激发光谱

Fig.6 Excitation spectrums of BaHfO3?Ce

如图7所示,BaHfO3?Ce在393 nm波长激发下的发射光谱。样品在 480~540 nm波段,具有较宽的发光谱带。发射光谱是由两个发光谱带组成,分别在485 nm和530 nm波长处存在最大峰值,对应着掺杂Ce3+的5d→2F5/2和5d→2F7/2发光跃迁[12]。

图7 393 nm激发下BaHfO3?Ce的发射光谱

Fig.7 Emission spectrums of BaHfO3?Ce excited by 393 nm

从图8中可以看出,Ce3+掺杂量为0.3%的BaHfO3在393 nm激发下的发射光谱的峰相对强度最大,而Ce3+掺杂量分别为0.1%、0.5%和1.0%的BaHfO3的发射光谱的峰相对强度依次递减。少量的Ce3+掺杂可以使粉体具有较佳的结晶性,且在掺杂浓度未达到发光浓度淬灭情形前,随着掺杂浓度的增加,有效发光中心数目增加,使得发光强度增强;而当掺杂浓度大于0.3%时,则因Ce3+与Ce3+之间的距离减短,使得更多的激发光能量在Ce3+与Ce3+之间传递而损耗,导致发光浓度淬灭情形发生,并随着掺杂浓度的增加其发光强度骤减[16]。

图8 393 nm激发下不同Ce3+掺杂浓度BaHfO3的发射光谱

Fig.8 Emission spectrums of BaHfO3 with different Ce3+ dopant contents excited by 393 nm

3 结论

1) 用氨水做沉淀剂经900 ℃煅烧2 h可得到的分散良好、尺寸均匀、形貌近球形、粒径约为15 nm 的BaHfO3?Ce粉体。而以草酸做沉淀剂时,所需合成温度为1 000 ℃,煅烧时间为2 h。由于草酸根离子与前者形核机制的差异,所得粉体粒径约为60 nm,形貌为多边形。XRD谱分析表明,两种合成方法在(110)、(200)、(211)、(220)、(310)和(222)晶面的主晶相所对应衍射角是一致的,合成的BaHfO3?Ce只存在温度对物相影响的差异,前者比后者的合成温度低100 ℃,并不改变物相结构。

2) 经电子衍射斑点分析,合成BaHfO3?Ce的晶体为钙钛矿结构,Ce3+的掺杂未使BaHfO3的晶体结构发生变化。当Ce3+掺杂浓度为0.3%时,BaHfO3?Ce受激发的发光峰相对强度最大。当Ce3+掺杂浓度大于0.3%时,会出现浓度淬灭现象。两种纳米粉体的激发和发射光谱均为宽带谱,激发光谱分别在393 nm和445 nm波长处存在最大峰值,形成机制是Ce3+的掺杂受激发时对应5d→2F5/2和5d→2F7/2发光能级带的跃迁。

REFERENCES

[1] 闻 雷, 孙旭东, 其 鲁, 马伟民. 湿化学法合成YAG纳米粉体及透明陶瓷[J]. 中国有色金属学报, 2005, 15(8): 1272?1277.

WEN Lei, SUN Xu-dong, QI Lu, MA Wei-min. Nanocrystalline YAG powders and translucent ceramics by wet-chemical method[J]. The Chinese Journal of Nonferrous Metals,2005, 15(8): 1272?1277.

[2] 闻 雷, 其 鲁, 孙旭东, 徐国祥. 碳酸盐沉淀法制备Y2O3纳米粉及透明陶瓷[J]. 中国有色金属学报, 2006, 16(2): 235?240.

WEN Lei, QI Lu, SUN Xu-dong, XU Guo-xiang. Synthesis of Y2O3 nanopowders and transparent Y2O3 ceramics by carbonate- precipitation process[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(2): 235?240.

[3] KIM Y K, KIM H K, KIM D K. Synthesis of Eu-doped(Gd, Y)2O3 transpatent optical ceramic scintillator[J]. Journal of Materials Research, 2004, 19(2): 413?416.

[4] GRESKOVICH C, DUCLOS S. Ceramic scintillators[J]. Annual Review of Material Science, 1997, 27: 69?88.

[5] SURTI S, KARP J S, FREIFELDER R. Optimizing the performance of a PET detector using discrete GSO crystals on a continuous light-ugide[J]. IEEE Trans Nucl Sci, 2000, 47: 1030?1036.

[6] KADALAMANI V S, LOUREIRO S M. To improve the transparency of the alkaline-earth-doped cerium dioxide hafnium scintillator and manufacturing methods. U S 03110589[P]. 2003?10?29.

[7] MAEKAWA T, KUROSAKI K, YAMANAKA S. Thermal and mechanical properties of perovskite-type barium hafnate[J]. Journal of Alloys and Compounds, 2006, 407: 44.

[8] 孙家跃, 杜海燕. 固体发光材料[M]. 北京: 化学工业出版社, 2004.

SUN Jia-yue, DU Hai-yang. Solid-state luminescence materials [M]. Beijing: Chemical Industry Press, 2004.

[9] JI M Y, JIANG D Y, CHEN J J, QIN L S, XU Y P, FENG T, SHI J L. Preparation, luminescence and sintering properties of Ce-doped BaHfO3 phosphors[J]. Optical Materials, 2006, 28: 436.

[10] JI Y M, JIANG D Y, WU Z H, FENG T, SHI J L. Combustion synthesis and photoluminescence of Ce3+-activated MHfO3 (M = Ba, Sr, or Ca)[J]. Materials Research Bulletin, 2005, 40: 1521?1526.

[11] SUGIMOTO T. Mono dispersed particles[M]. Japan: Tohoku University Press, 2000.

[12] NIELSEN A E. Kinetics of precipitation[M]. New York: The Macmillan Company, 1964.

[13] WALTON A G. The formation and properties of precipitates[M]. New York: Interscience Publishers, 1967.

[14] 黄朝洪, 张庆礼, 周东方, 李运奎, 殷绍唐, 施朝淑. Ce3+?YAG闪烁晶体的真空紫外激发光谱特性[J]. 中国稀土学报, 2002, 20(spec): 36?39.

HUANG Chao-hong, ZHANG Qing-li, ZHOU Dong-fang, LI Yun-kui, YIN Shao-tang, SHI Chao-shu. Luminescence properties of Ce3+?YAG single crystal scintillator under vacuum ultraviolet excitation[J]. Journal of the Chinese Rare Earth Society, 2002, 20(spec): 36?39

[15] 刘 晶, 马伟民, 闻 雷, 李喜坤, 沈世妃, 郭易芬. BaHfO3?Ce纳米材料的制备及光谱特性[J]. 金属学报, 2008, 44(3): 381?384.

LIU Jing, MA Wei-min, WEN Lei, LI Xi-kun, SHEN Shi-fei, GUO Yi-fen. Preparation and optical spectrum characteristics of BaHfO3?Ce nano-powder[J]. Acta Metallurgica Sinica, 2008, 44(3): 381?384.

[16] BLASS G, SCHIPPER W, HAMELINK J J. On the quenching of the luminescence of thetrivalent cerium ion[J]. Inorg Chim Acta, 1991, 189: 77?80.

基金项目:辽宁省科技攻关计划资助项目(2005222009);辽宁省自然科学基金资助项目(20062001)

收稿日期:2007-12-13;修订日期:2008-04-06

通讯作者:马伟民,教授,博士;电话:024-81358863;E-mail: maweimin56@163.com

(编辑 何学锋)