DOI: 10.11817/j.ysxb.1004.0609.2021-37938

T2-Y/Q345B双金属接头微观组织与力学性能研究

张 敏1,杜明科1,张云龙1,张兵宪2,雷龙宇1,史 杰1

(1. 西安理工大学 材料科学与工程学院,西安710048;

2. 中航西安飞机工业集团股份有限公司,西安 710087)

摘 要:为了优化铜/钢复合件的焊接工艺,提高焊接接头的力学性能,采用S201焊丝对T2-Y/Q345B异质材料进行不同工艺窗口下的熔化极气体保护焊(GMAW)试验,并且利用金相、扫描以及拉伸、硬度等试验研究了不同焊接工艺对铜/钢焊接接头组织及性能的影响。结果表明,对T2-Y紫铜母材进行焊前预热处理有利于提高焊缝金属的铺展性,同时不同的保护气体对接头质量的影响也较大。铜侧热影响区(HAZ)主要由孪晶组织组成,均垂直于熔合线方向生长。另外,在电弧力及浓度梯度的作用下焊缝中元素进行了充分的扩散,其中Fe元素对焊缝具有第二相强化作用,从而导致焊缝硬度高于铜侧母材。接头抗拉强度最高达224.1 MPa,达到铜侧母材强度的90%以上。铜侧热影响区晶粒粗化,成为焊接接头的薄弱环节。

关键词:异质接头,预热处理,微观组织,力学性能

文章编号:1004-0609(2021)-xx-- 中图分类号:TG407 文献标志码:A

引文格式:张 敏, 杜明科, 张云龙, 等. T2-Y/Q345B双金属接头微观组织与力学性能研究[J]. 中国有色金属学报, 2021, 31(x): xxxx-xxxx. DOI: 10.11817/j.ysxb.1004.0609.2021-37938

ZHANG Min, DU Ming-ke, ZHANG Yun-long, et al. Study on microstructure and mechanical properties of T2-Y/Q345B bimetallic joints[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(x): xxxx-xxxx. DOI: 10.11817/j.ysxb.1004.0609.2021-37938

随着现代工业的迅猛发展,任何单一的材料已经无法满足尖端领域的应用需求,材料发展逐步转向多功能化,因此对焊接结构件的制造提出了更为严格的要求[1-4]。金属铜因为具有良好的导电性、导热性和逆磁性等特点,被广泛应用于航空、航天、石油化工以及变压器制造等领域。但由于有色金属价格昂贵,对企业制造成本控制方面造成了极大的不利,因此需要优化设备结构,降低贵金属材料的使用量[5-7]。同时,钢作为现代工业中用量最大的一种金属,具有强度高、韧性好且成本低等优势[8-9]。故而使用铜/钢异种金属的复合结构件代替单一结构件,不仅使每种材料的性能得以充分发挥,而且也大大降低了工业制造成本,使其复合结构在大型变压器箱体制造等领域得到广泛应用[10-13]。

目前,国内外诸多学者对铜钢复合结构件的连接进行了研究,并取得了很多成果[14-15]。北京科技大学程志等[16]对采用MIG-TIG双面弧焊获得的铜/钢异种金属焊接接头进行了研究,发现接头铜侧热影响区出现了明显的软化现象,并且推断出降低焊接热输入可以提高焊接接头的抗软化能力;陈高 澎[17]学者对铜/钢复合板电子束焊接接头的组织与性能进行了研究,结果表明:选用合理的焊接工艺及焊接方向,可以得到组织、性能优异的焊接接头,接头强度可以达到482 MPa;GANDHAM等[18]研究了CO2激光焊接铜/钢异质接头的组织与性能,发现钢侧组织向焊缝中心生长,铜侧组织对界面生长有一定的阻碍作用,同时在铜侧界面发现了明显的泛铁现象。然而,大多数研究都是以复合焊、激光焊、电子束焊接为基本连接手段,难以实现大规模生产,对企业的成本控制产生了极为不利的影响。

因此,本文将以工程应用背景为出发点,采用熔化极气体保护焊实现铜/钢异质材料的连接,研究其焊接工艺对铜/钢复合焊接接头组织和性能的影响机理,建立组织与性能之间的依存关系,为大型变压器储油箱的制造提供一定的理论支撑,从而降低企业的生产制造成本。

1 试验材料和方法

1.1 试验材料

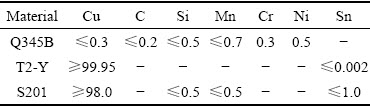

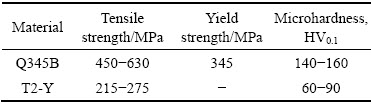

试验所采用的母材为Q345B钢和T2-Y紫铜,规格均为300 mm×150 mm×5 mm,接头填充材料为1.2 mm的S201纯铜焊丝。母材和填充材料的化学成分如表1所示,力学性能如表2所示。

1.2 试验方法

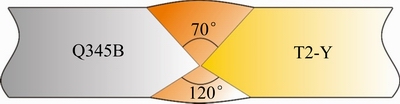

本次试验焊接设备采用松下MIG/MAG气保焊机,焊机型号YD-500GL。由于焊接过程中采用的热输入较小,因此为了防止出现未焊透等缺陷,以及便于进行焊道的清根处理,需要将两种母材采用线切割的方式加工X型坡口,其坡口示意图如图1所示。

表1 试验材料化学成分

Table 1 Chemical composition of test materials (mass fraction, %)

表2 试验材料力学性能

Table 2 Mechanical Properties of test materials

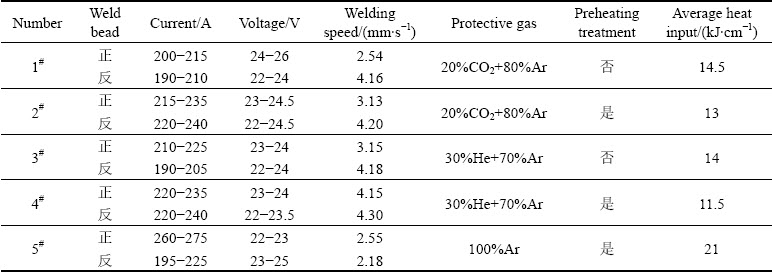

焊接工艺的合理控制是获得高质量焊接接头的关键,因此本试验将从母材预热、控制焊接热输入以及控制保护气体方面着手,通过对比分析,得出最优的铜/钢异质接头的连接工艺。采用型号为STM-36-14的恒温箱式电阻炉对T2-Y母材进行预热处理(400 ℃),保温时间15 min。焊接参数的选择与焊丝直径、试板规格等有关。通过查询相关文献,确定参数范围。并采用试焊的方法,选择成形质量最优的焊缝所对应的参数为试验施焊参数,最终确定具体的焊接工艺窗口如表3所示。其中,5组试验的保护气体流量均为15 L/min。

图1 焊接接头坡口示意图

Fig. 1 Schematic diagram of welding joint groove

表3 焊接工艺参数

Table 3 Welding parameters

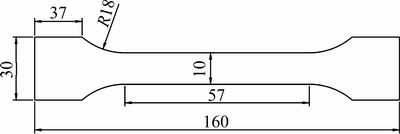

利用超声波检测焊缝内部质量,经检测合格后,采用线切割制备金相试样。试样经过研磨、抛光之后,利用FeCl3+HCl水溶液腐蚀铜侧,4%的HNO3+C2H5OH溶液腐蚀钢侧,采用OLYMPUS- GX71型光学显微镜观察焊接接头组织形貌,然后使用SM-6700F扫描电镜和EDS能谱仪进行显微组织结构、线扫描及断口形貌观察;为了表征焊接件的力学性能,在HT-2402电脑控制材料试验机上进行焊接试样的拉伸试验,试验速度2 mm/min,试样尺寸如图2所示。同时,使用MHV1000Z型数显维氏硬度计测量焊接接头的显微硬度,试验载荷为0.98 N,保荷时间为15 s,打点间隔0.2 mm。

图2 拉伸试样尺寸

Fig. 2 Dimensional tensile specimen size (Unit: mm)

2 结果与讨论

2.1 焊接接头宏观形貌分析

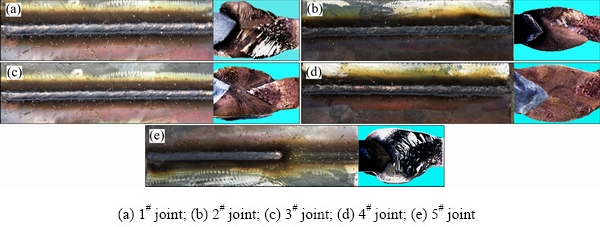

按照既定工艺进行焊接试验,所得5组试板的宏观形貌如图3所示。通过对比图3(a)与(b)、(c)与(d)可以发现,由于预热处理后采用较小的焊接热输入,使得焊缝表面飞溅明显减少,但焊缝宽度并无明显差异。从焊缝的表面铺展情况来看,经过预热处理的试板焊缝铺展性较好。从图3(b),(d),(e)可以发现,5#试件虽然焊缝表面保护较好,但是焊接难度较大,施焊过程中易出现断弧、飞溅大、焊后试板变形严重等问题,说明保护气体的种类对焊接件的质量影响较大。另外,图3(a),(b),(c),(e)中的接头晶粒都表现出明显的外延生长现象,且都为粗大的柱状晶粒,各个晶粒取向明显,这是由熔池的冷却结晶过程所决定的。熔池结晶时,晶粒倾向于沿着温度梯度大的方向生长,由于垂直于熔合线方向散热最快,为柱状晶的形成和生长提供了有利条件。

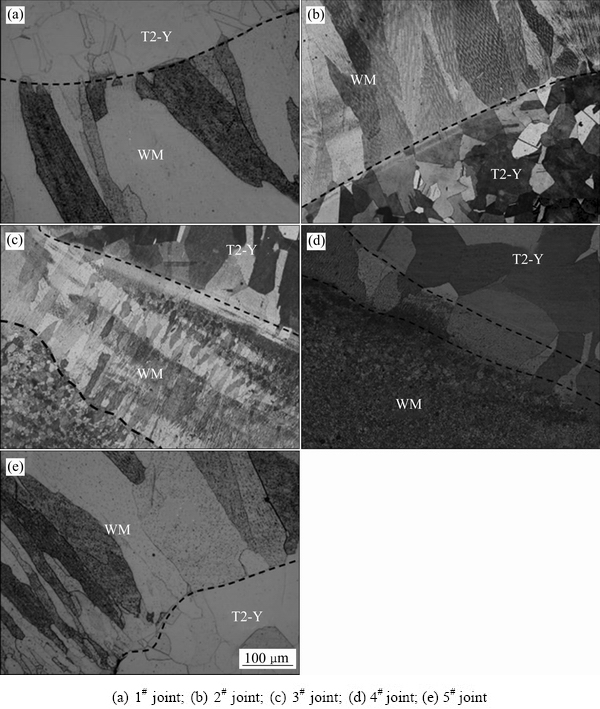

2.2 焊接接头微观组织分析

焊缝及热影响区是整个焊接接头的重要区域,直接影响焊接件的质量和性能,因此本文着重研究了焊缝和热影响区的组织形貌和演化机理。图4所示为5组焊接接头的铜侧熔合区显微组织形貌。由于焊接过程中使用的焊材为纯铜焊丝,与母材成分基本相似,所以熔池结晶过程中液态金属可以发生充分混合,界面结合良好,并未发现明显的焊接缺陷。同时,在5组焊接工艺下,铜侧热影响区均存在典型的孪晶组织,且都垂直于熔合线方向生长。这是由于熔池凝固过程中,垂直于熔合线方向温度梯度较大,因此晶粒总是垂直于界面方向沿焊缝中心生长。通过对比图4(a)与4(b)可以发现,焊前预热工艺对接头组织的晶粒度影响较大,即图4(b)中焊缝的柱状晶晶粒尺寸明显减小。同时,在远离熔合线的区域,温度梯度逐渐减小,熔池结晶速度增大,使得该区域的晶粒生长不充分,形成细小的等轴晶,微观上表现出晶粒的外延生长趋势较小,如图4(d)所示;而1#、3#、5#试样由于焊接热输入较大,为柱状晶的生长提供了条件,且铜的热导率较高,使得熔合线附近温度梯度较大,因此晶粒垂直于熔合线方向生长,外延生长现象明显,所生成的柱状晶晶粒也较为粗大,对接头强度产生了不利影响。

图3 焊缝宏观形貌

Fig. 3 Macroscopic morphology of weld

图4 铜侧熔合区显微组织

Fig. 4 Microstructure of copper fusion zone

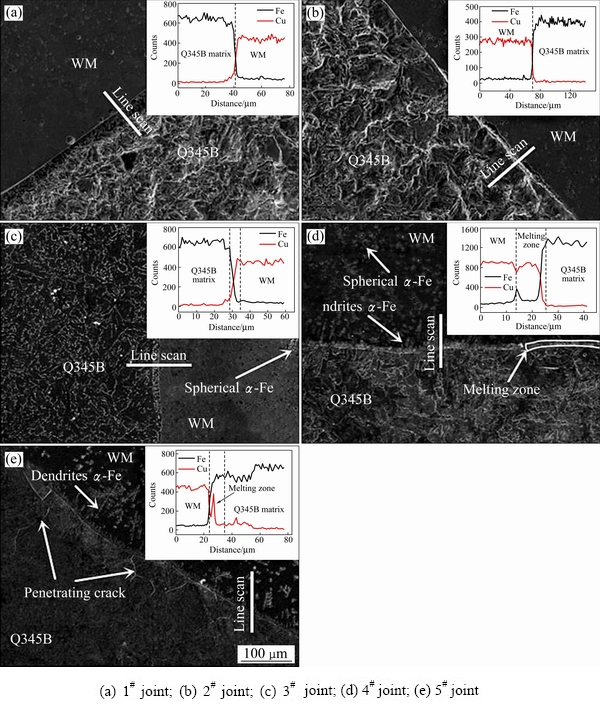

图5所示为焊接接头Q345B钢侧熔合区显微组织及线扫描分析结果。从图5(a)、(b)中可以发现,钢侧熔合线界面光滑平直,并无明显的熔合带存在,而且Fe、Cu元素在界面处发生了骤变,元素过渡现象不明显;而图5(c)、(d)、(e)均可以观察到明显的熔化带,且在焊缝中可以发现存在较多枝晶形貌及球形的α-Fe。这是因为在电弧力及浓度梯度的作用下,Fe元素发生了一定量的扩散,从而形成泛铁现象,且接头处并未发现α-Fe的团聚现象,因此,这将成为焊缝的增强相,大大提高焊接接头的强度和硬度。同时,由图中线扫描结果可以发现,图5(c)、(d)、(e)试样在熔合带处均发生了明显的元素扩散,熔合带宽度均在5~10 μm之间,说明接头在冷却结晶过程中进行了充分的冶金结合。其中,图5(e)中还可以观察到靠近熔合线附近出现Cu的渗透裂纹,这是因为在焊接过程中熔融的铜合金在电弧力的作用下向近缝区钢表面渗透,沿晶界或微裂纹渗入,形成渗透裂纹,很大程度上降低了接头强度。

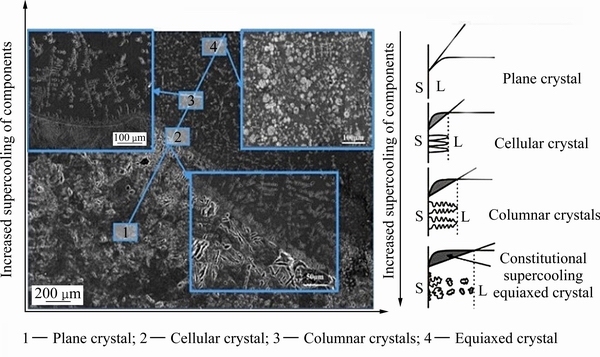

为进一步了解钢侧熔合区的组织演化过程,对熔合区金属的凝固模式进行了分析。凝固过程中固液界面前沿会发生溶质再分配,导致钢侧界面处发生成分过冷,其成分过冷对熔合区组织凝固模式的影响结果如图6所示。从图中能够看出,钢侧HAZ组织呈平面晶生长,沿垂直于熔合线方向随着成分过冷程度的增加,依次转变为钢侧熔合区的胞状晶,再到焊缝中的柱状树枝晶、等轴晶。由于凝固过程中冷却速率较小,相比于细小的树枝晶,所有由柱状晶凝固模型转变的柱状树枝晶得到了充分生长。因此,铜/钢异种材料焊接接头的不同凝固速率以及钢侧产生的成分过冷是造成不同凝固模式的根本原因,这也导致了钢侧熔合区的组织演化以及局部力学性能的变化。

图5 钢侧熔合区显微组织及线扫描结果

Fig. 5 Microstructure and line scanning results of steel side fusion zone

图6 钢侧熔合区成分过冷及(G/R)凝固模型示意图

Fig. 6 Schematic diagram of constitutional supercooling and (G/R) solidification model of the steel fusion zone

2.3 焊接接头力学性能分析

2.3.1 焊接接头拉伸性能分析

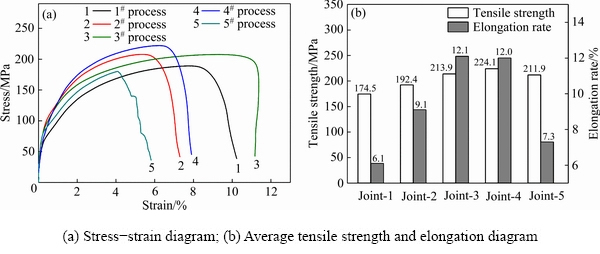

为了评价焊接接头的强度,采用室温拉伸试验对各个接头进行测试,每组工艺窗口取三件平行试样,试验件抗拉强度、延伸率取平均值,所得到的试验结果如图7所示。由图中数据及试验结果可知,1#、2#试样断裂位置为焊缝,而3#、4#、5#试样断裂位置为铜侧热影响区,其中,4#试样焊接接头抗拉强度最高,达到224.1 MPa,接近T2-Y紫铜的强度,断裂位置均出现了明显的颈缩现象,表明焊接接头的塑性较好。

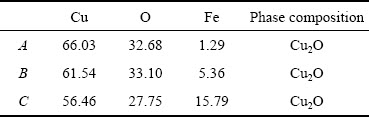

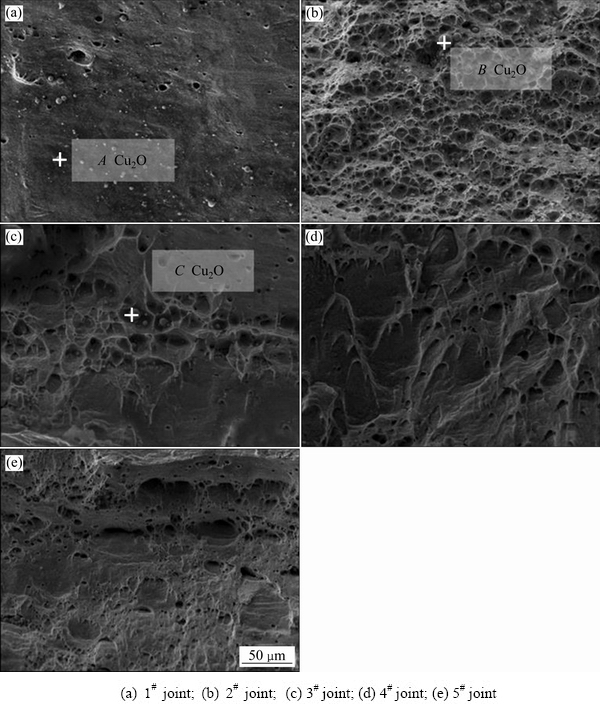

为进一步了解焊接接头的断裂机制,对拉伸断口进行了SEM观察及EDS分析,如图8所示。图8(a)为1#试样的断口形貌,可以看出断裂面平滑,断裂区域出现了少量的颗粒状夹杂及气孔,对接头强度产生了不利影响;图8(b)、(c)中能够发现断裂区域存在明显的韧窝,且韧窝周围分布有大小不一的孔洞,表明试样在拉伸断裂过程中经历了一定的塑性变形,但断裂面处也存在少量的球形夹杂,影响接头强度。而图8(d)、(e)中不仅存在明显的河流状花样,也存在较多的韧窝形貌,属于典型的准解理断裂形式。在电弧力及热输入的影响下,焊缝会出现一定量的枝晶α-Fe,对焊缝有一定的强化作用。但由于铜侧热影响区晶粒粗化严重,使得该区域成为整个焊接接头强度最薄弱的环节。因此,只有严格控制焊接热输入,才能降低铜侧HAZ的晶粒粗化倾向,从而提高接头强度。对接头断裂区域出现的夹杂进行EDS分析,结果如表4所示。通过EDS点扫描分析发现,颗粒状夹杂均为Cu2O,而Cu2O为脆性金属间化合物,会降低焊接接头韧性,增加热裂纹敏感性。结合焊接工艺可以发现,保护气体种类及焊接热输入都会对焊缝内部质量产生一定的影响。

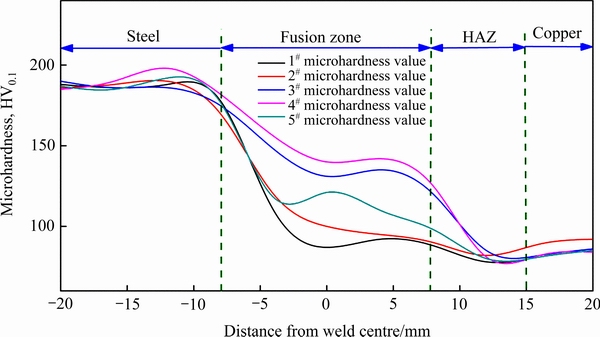

2.3.2 焊接接头显微硬度分析

5组试样的硬度测试分布曲线如图9所示,1#~4#试样的显微硬度曲线的变化趋势基本一致。从钢侧到铜侧硬度整体呈下降趋势,这是由于在焊接热循环的作用下,铜侧热影响区晶粒严重粗化,使得单位体积内的晶粒数量较少,即晶界也会变少,从而导致晶界对位错运动的阻碍减小,宏观上体现出此区域的硬度值大大降低。而焊缝区域受电弧力及结晶温度的影响,使得该区域存在大量的泛铁现象,这些弥散于焊缝中的富铁相对焊缝有第二相强化作用,从而使其显微硬度明显高于铜侧热影响区。

表4 EDS检测结果表

Table 4 Results of EDS test (mass fraction, %)

图7 拉伸试验结果

Fig. 7 Tensile test results

图8 拉伸断口形貌

Fig. 8 Fracture morphology of tensile test

图9 焊接接头硬度分布曲线

Fig. 9 Diagram of hardness curve of welded joint

3 结论

1) 采用S201纯铜焊丝对T2-Y/Q345B异质材料进行熔化极气体保护焊试验,通过对接头的宏观形貌观察发现,焊前对铜母材进行预热处理,有利于提高焊缝金属的铺展性。同时,采用不同的保护气体对焊接接头的质量也有较大影响。

2) 铜侧HAZ存在典型的孪晶组织,垂直于熔合线方向生长。而且采用30%He+70%Ar为保护气体,并进行合理的焊前预热处理,所得到的焊接接头铜侧HAZ有大量细小的等轴晶存在,晶粒粗化倾向相对较小,从而使得其试样强度也较高。另外,铜/钢焊接过程中钢侧HAZ易出现铜的渗透裂纹。

3) 焊接热输入直接影响铜侧晶粒的外延生长现象。只有采用合理的焊前预热工艺,才能有效地细化晶粒,降低铜侧晶粒的外延生长趋势,从而提高焊接件的强度。

4) 受焊接热循环的影响,焊接接头铜侧HAZ晶粒粗化,降低了接头强度;焊缝中存在大量的富铁相,对焊缝有第二相强化的作用,导致焊缝硬度高于T2-Y母材的硬度。另外,焊接过程中的保护气体种类对接头显微硬度的变化趋势也有一定的影响。

REFERENCES

[1] SUMAN P, KANWER S A, MAHADEV S, et al. Interface characteristics and performance of magnetic pulse welded copper-steel tubes[J]. Journal of Materials Processing Technology, 2017(245): 278-286.

[2] ZHANG Heng, JIAO Ke-xin, ZHANG Jian-Liang, et al. Experimental and numerical investigations of interface characteristics of copper/steel composite prepared by explosive welding[J]. Materials & Design, 2018, 154: 140-152.

[3] 蔡 鹏, 杨乾刚. 水冷铜坩埚中紫铜与不锈钢焊接工艺研究[J]. 科技视界, 2020(19): 98-101.

CAI Peng, YANG Qian-gang. Research on welding technology of red copper and stainless steel in water-cooled copper crucible[J]. Science & Technology Vision, 2020(19): 98-101.

[4] VELU M, BHAT S. On copper-steel joint arc welded with nickel based filler[J]. Advanced Materials Research, 2013, 2108: 2100-2103.

[5] 姜业欣, 娄花芬, 解浩峰, 等. 先进铜合金材料发展现状与展望[J]. 中国工程科学, 2020, 22(5): 84-92.

JIANG Ye-xin, LOU Hua-fen, XIE Hao-feng, et al. Development status and prospects of advanced copper alloy[J]. Strategic Study of CAE, 2020, 22(5): 84-92.

[6] SHIRI S J, NAZARZADEH M, SHARIFITABAR M, et al. Gas tungsten arc welding of CP-copper to 304 stainless steel using different filler materials[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(12): 2937-2942.

[7] 蔡玉博. 铜钢异种金属CMT焊接工艺及温度场模拟[D]. 哈尔滨: 哈尔滨工业大学, 2016: 2-13.

CAI Yu-bo. The welding procedure and temperature distribution of cold metal transfer joining copper to steel dissimilar metals[D]. Harbin: Harbin Institute of Technology, 2016: 2-13.

[8] RAMACHANDRAN S, LAKSHMINARAYANAN A K. An insight into microstructural heterogeneities formation between weld subregions of laser welded copper to stainless steel joints[J]. Transactions of Nonferrous Metals Society of China, 2020, 30(3): 727-745.

[9] 王厚勤, 曹 健, 张丽霞, 等. 铜合金与钢连接技术研究进展[J]. 焊接技术, 2009, 38(3): 1-6.

WANG Hou-qin, CAO Jian, ZHANG Li-xia, et al. Research status of joining between copper alloy and steel[J]. Welding Technology, 2009, 38(3): 1-6.

[10] DEEV G F, GONCHAROV A N. Embrittlement mechanism of copper-steel welded joints[J]. Materials Science, 1993, 29(1): 61-64.

[11] 张 建, 王国平, 王宜林, 等. H62黄铜与Q345钢异种材料的焊接[J]. 现代焊接, 2011(11): 25-26, 29.

ZHANG Jian, WANG Guo-ping, WANG Yi-lin, et al. Welding of H62 brass and Q345 steel disimilar materials[J]. Modern Welding Technology, 2011(11): 25-26, 29.

[12] 彭 迟, 程东海, 陈益平, 等. 铜/钢异种材料等离子弧焊接头显微组织分析[J]. 材料科学与工艺, 2015, 23(4): 105-110.

PENG Chi, CHENG Dong-hai, CHEN Yi-ping, et al. Microstructure of dissimilar material joint with T2 copper and steel 304 for plasma arc welding[J]. Materials Science and Technology, 2015, 23(4): 105-110.

[13] FABRITSIEV S A, POKROVSKY A S, EDWARDS D J, et al. The effect of copper-steel joining technology on the radiation resistance of copper alloys[J]. Plasma Devices and Operations, 2001, 8(4): 241-255.

[14] 刘 越, 张太正, 孙爱新, 等. 铜/钢双金属复合制备工艺技术研究现状[J]. 材料导报, 2015, 29(15): 10-14, 21.

LIU Yue, ZHANG Tai-zheng, SUN Ai-xin, et al. Research status of compounding technology for Cu/steel bimetal[J]. Materials Review, 2015, 29(15): 10-14, 21.

[15] 张文毓. 异种金属的焊接研究进展[J]. 现代焊接, 2011(11): 10-12.

ZHANG Wen-yu. Advances in welding of dissimilar metals[J]. Modern Welding Technology, 2011(11): 10-12.

[16] CHENG Z, HUANG J, YE Z, et al. Microstructures and mechanical properties of copper-stainless steel butt-welded joints by MIG-TIG double-sided arc welding[J]. Journal of Mechanical Working Technology, 2018, 265(8): 87-98.

[17] 陈高澎, 李瑞武, 孙少华, 等. 铜/钢复合板电子束焊接接头组织与性能研究[J]. 热加工工艺, 2018, 47(23): 70-72.

CHEN Gao-peng, LI Rui-wu, SUN Shao-hua, et al. Study on microstructure and properties of electron beam welded joint of copper/steel composite plate[J]. Hot Working Technology, 2018, 47(23): 70-72.

[18] GANDHAM P, SAMBANDAM M, PRADIP D, et al. Characterization of a continuous CO2 laser-welded Fe-Cu dissimilar couple[J]. Metallurgical and Materials Transactions A, 2005, 36(8): 2137-2147.

Study on microstructure and mechanical properties of T2-Y/Q345B bimetallic joints

ZHANG Min1, DU Ming-ke1, ZHANG Yun-long1, ZHANG Bing-xian2, LEI Long-yu1, SHI Jie1

(1.College of Material Science and Technology, Xi’an University of Technology, Xi’an 710048, China;

2. AVIC Xi’an Aircraft Industry Group Company Ltd., Xi’an 710087, China)

Abstract: In order to optimize the welding process of copper/steel composite parts and improve the mechanical properties of welded joints, and the GMAW test of dissimilar material about T2-Y and Q345B under different welding technology was carried out using S201 copper wire, and the influence of different welding processes on the microstructure and mechanical property of copper and steel welded joint was studied by metallographic test, scanning electron microscope test, tensile test and hardness tests, etc. The results showed that the preheating treatment of T2-Y copper base material is beneficial to improve the spreadability of weld metal, and the different protective gas also has a great influence on the joint quality. The heat affected zone on the copper side is mainly composed of twin crystal and that grows perpendicular to the direction of fusion line. In addition, under the action of arc force and concentration gradient, the elements in the weld are fully diffused, and Fe element has the second phase strengthening effect on the weld metal, so that the hardness of the weld was higher than the base metal of the copper side. The maximum tensile strength of the joint is 224.1 MPa, which is more than 90% of the strength of the copper side base metal. Due to the serious coarsening of HAZ grain on the copper side, so this area became the part with poor performance.

Key words: dissimilar joints; preheating treatment; microstructure; mechanical properties

Foundation item: Project(51974243) supported by National Natural Science Foundation of China; Project (2019JZ-31) supported by Natural Science Foundation of Shaanxi Provincial Department, China; Project(201805037YD15CG21(16)) supported by Xi’an Municipal Science and Technology Planning project, China

Received date: 2021-03-18; Accepted date: 2021-07-14

Corresponding author: ZHANG Min; Tel: +86-29-82312205; E-mail: zhmmn@xaut.edu.cn

(编辑 )

基金项目:国家自然科学基金资助项目(51974243);陕西省自然科学基础研究计划资助项目(2019JZ-31);西安市科技计划项目(201805037YD15CG21(16))

收稿日期:2021-03-18;修订日期:2021-07-14

通信作者:张 敏,教授,博士;电话:029-82312205;E-mail:zhmmn@xaut.edu.cn