DOI:10.19476/j.ysxb.1004.0609.2019.07.09

TC4钛合金激光双光束焊T形接头疲劳性能及断裂机理

许 良1, 2,苏居季1,周 松1, 2,回 丽1, 2,王 磊1, 2,张 璐1

(1. 沈阳航空航天大学 机电工程学院,沈阳 110136;

2. 沈阳航空航天大学 航空制造工艺数字化国防重点学科实验室,沈阳 110136)

摘 要:基于飞机机身壁板中T形接头在飞行过程中常因承受空气循环阻力而导致疲劳断裂的问题,分别采用激光双光束焊接技术和激光点焊接技术对TC4钛合金进行T形接头焊接,研究两种接头的显微组织特征、拉伸性能、疲劳性能及断裂机理。结果表明:利用两种不同激光焊接方法焊接后,熔合区组织均为针状α′马氏体组成的网篮组织;与激光双光束焊相比,激光点焊焊接接头网篮状组织中的α′网篮状组织的体积分数增大,针状α′马氏体尺寸增大且相间距减小。与母材拉伸性能相比,激光点焊接接头抗拉强度提高了5.5%,激光双光束焊接接头抗拉强度提高了5.8%。激光双光束焊接试件中值疲劳寿命提高2.23倍,主要原因在于网篮组织对焊接接头产生界面强化效果进而增加接头强度,而激光点焊试件的裂纹穿过焊点进入母材扩展导致试件的裂纹扩展抗力降低。

关键词:TC4钛合金;激光双光束焊;激光点焊;疲劳寿命;断裂机理

文章编号:1004-0609(2019)-07-1408-09 中图分类号:TG405 文献标志码:A

钛合金具有密度低、强度高且有较好的韧性、抗腐蚀性、焊接性等一系列优异的综合性能已广泛应用于现代航空工业[1-2]。随着我国航空航天事业的发展和对飞机性能要求的不断提升,飞机服役环境越来越复杂[3]。钛合金机身整体壁板作为飞机重要组成构件存在大量T形结构,飞行过程中承受多种交变载荷作用,因此要求T形结构具有高的强度、良好的刚度,以及优异的疲劳性能。目前机身整体壁板结构的蒙皮与加强筋壁主要通过激光点焊和铆接来实现连接,但其需要加强筋翻边和铆钉实现连接从而使机身质量增加。为了实现飞机轻量化以及提高蒙皮与加强筋连接的力学性能,同时进一步提高材料利用率、降低制造成本,利用激光双光束焊接飞机机身壁板中的T形结构。该技术主要是通过两个平行布置的激光束同步施焊于加强筋的两侧,解决了加强筋和蒙皮之间的焊接变形及加强筋翻边导致机身质量增加问题,同时双重激光束作用下产生较大的熔池和匙孔,提高了焊接稳定性,减少焊接过程造成的不利变形,有效控制了蒙皮表面形状误差[4-5]。因此。激光双光束焊接技术受到了航空制造业的青睐,近年来诸多学者先后对激光双束技术进行了研究。HAROONI等[6]通过CCD拍摄AZ31B镁合金采用激光双光束焊接和激光单光束焊接时等离子体形态,对比发现激光双光束焊接等离子羽流更稳定。马国龙等[7]指出双光束焊接比单光束焊接形成的熔池尺寸更大,焊接过程中匙孔稳定性更好。雷正龙等[8]研究了激光双光束焊接对铝合金焊接孔隙率的影响,与单光束激光焊接相比,发现激光双光束焊接可以有效地抑制气孔的产生而且并行排布时影响效果优于串行排布。XIE[9]指出使用激光双光束焊接技术后钢和铝合金的焊缝表面质量得到显着改善,焊缝硬度和中心线裂纹敏感性降低。然而,这些研究大多针对焊缝成形及焊缝静强度研究[10-12],鲜有针对钛合金激光双光束焊接T形接头的疲劳性能的相关报道。

本文采用激光双光束焊接技术和激光点焊技术对飞机机身壁板常用结构材料TC4钛合金进行T形接头焊接,利用光学显微镜对两种焊接接头的微观组织进行观察,分析了焊接接头疲劳断裂行为,利用扫描电子显微镜对疲劳断口进行分析,为飞机机身壁板的疲劳强度设计与飞机安全性能评估提供依据。

1 实验

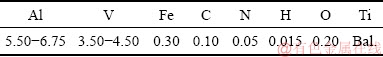

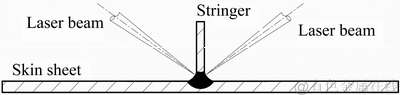

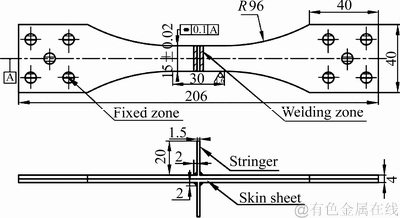

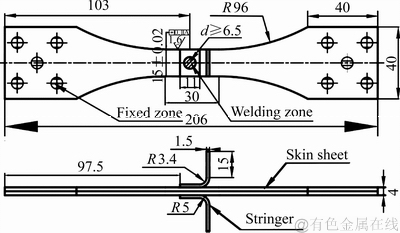

根据航空用钛及钛合金板、带材规范(GJB 2505-1995),本研究选用的蒙皮与加强筋材料分别为2 mm和1.5 mm厚退火态冷轧TC4钛合金板,填充焊丝为半径0.5 mm的TC4同质焊丝,其化学成分见表1。激光双光束焊接技术其激光功率为2.1~2.9 kW,焊接速度为4~13 m/min,送丝速度为3~9 m/min,保护气流量为25 L/min,激光束与送丝夹角为45°,保护气体为氩气,图1所示为T型接头激光双光束焊接实验布置示意图,焊接试样示意图和疲劳试样尺寸如图2所示。激光点焊工艺参数为某现役机型固定成熟工艺,焊接试样示意图和疲劳试样尺寸如图3所示。由于T型接头截面的非对称性,单面试件加载时导致受力偏心出现组合变形,所以试件夹持端通过焊点固定制成双面试验件,保证其截面对称,焊缝垂直于轧制方向,位于试样中心。由于试验件为双面试验件,因此疲劳实验中试件单面断裂的时候,应力将降为原来的一半继续试验。

参照金属材料室温拉伸试验方法(HB 5143-1996)利用INSTRON电子拉伸试验机完成室温静力拉伸试验,拉伸试验过程中采用恒速率加载控制,加载速率2 mm/min。实测静力拉伸性能结果见表2。按照金属材料轴向加载疲劳试验方法(HB 5287-1996)在朗杰100型疲劳试验机上完成疲劳试验,试验加载频率10 Hz,采用轴向拉-拉加载, 应力比为0.06,加载波形为正弦波。本研究取40%焊缝抗拉强度400 MPa作为疲劳加载的最大应力,利用金相显微镜对试样组织进行观察,利用扫描电子显微镜对低周疲劳断口进行分析。

表1 TC4钛合金化学成分

Table 1 Chemical compositions of TC4 alloy (mass fraction, %)

图1 双光束激光焊接试验布置示意图

Fig. 1 Schematic diagram of experimental setup for dual- beam welding

图2 激光双光束焊试件形状和尺寸

Fig. 2 Shape and dimension of laser double beam welding sample (Unit: mm)

图3 激光点焊试件形状和尺寸

Fig. 3 Shape and dimension of laser spot welding sample (Unit: mm)

2 结果与讨论

2.1 接头显微组织分析

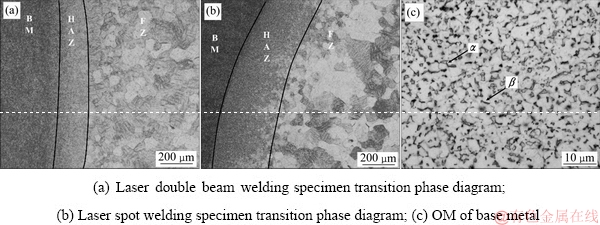

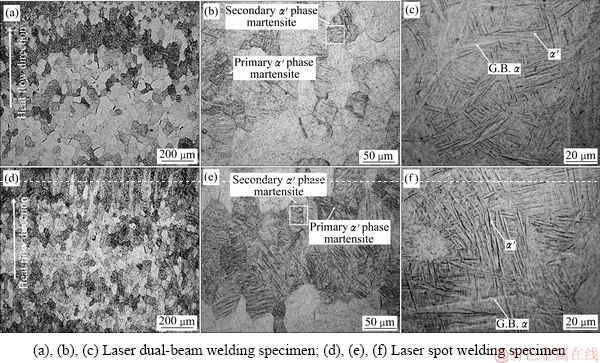

钛合金具有可逆转变特性,当温度超过一定水平时,晶体结构从α密排六方结构变为β体心立方结构,TC4合金转变温度在980~1010 ℃之间,转变相图如图4所示。试件经过两种激光焊接后存在几个组织明显不同的区域,母材区、热影响区和熔合区。母材区为TC4合金退火态冷轧板原始金相组织,如图4(c)所示,合金由α+β两相组成,其中白色为等轴α相,黑色为晶间β相。试件经激光双光束焊接后熔合区组织如图4(a)、(b)和(c)所示,熔合区为针状α′相马氏体组成的“网篮状”组织。焊缝是焊接过程中直接加热区域,焊缝区温度远高于相变点(980 ℃)达到β单相区,α相迅速向β相转变,且β柱状晶粒沿着热流方向生长,形成粗大β柱状晶(见图5(a))。图5(b)是图5(a)局部放大的微观组织形貌,分析发现合金中分布大量针状一次α′相马氏体呈网篮状,同时柱状晶内析出细小短针状二次α′相。焊接完成后熔合区合金冷却速率高于临界冷却速率(410 ℃/s)时,合金元素来不及扩散,β相以非扩散形式转变形成一次α′相马氏体。冷却过程中一次α′相马氏体在β柱状晶里面形核呈针状相互平行分布,一次α′相马氏体长大并贯穿整个晶粒形成网篮组织,这种组织有较高的蠕变抗力、持久强度和断裂韧性[13]。试件经激光点焊焊接后焊缝组织如图5(d)、(e)和(f)所示,焊核同样为针状α′相马氏体“网篮状”组织。图5(e)所示为图5(d)局部放大的微观组织形貌,与激光双光束焊显微组织比较,激光点焊α′网篮状组织的体积分数增大。图5(c)和(f)所示为两种激光焊接技术中焊接区域的针状α′相马氏体特写形貌;与激光点焊相比,激光双光束焊中的针状α′马氏体尺寸增大且相间距减小;两种焊接技术的焊接区域均沿着β晶界有少量的α相析出。

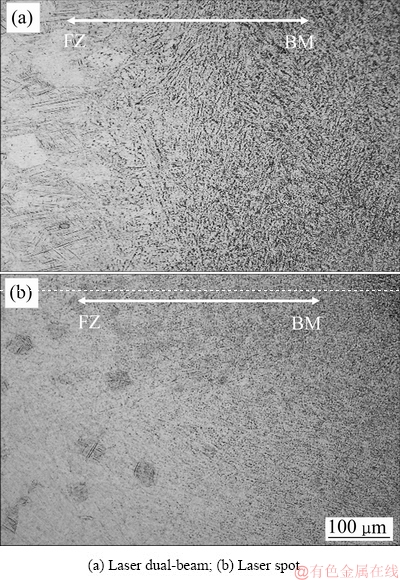

与熔合区组织相比,热影响区组织更加复杂。越靠近焊缝,网篮组织面积越大,到焊缝区域时则完全变成网篮组织;与熔合区的网篮组织相比,热影响区的网篮组织尺寸明显较小,马氏体方向无规则的杂乱分布。如图6(a)所示为激光双光束焊接接头热影响区显微组织形貌,激光双光束焊接热影响区由α相和细小的针状α′马氏体组成。在靠近熔合线的热影响区区域,焊接过程中温度达到相变点以上时,α相向β相转变,焊接完成后快速冷却到室温,析出一次针状α′马氏体,而远离熔合线的热影响区区域在焊接过程中未达到相变点,最高温度达到α+β双相区,冷却到室温过程中β相转变α相。图6(b)所示为激光点焊接接头热影响区显微组织形貌,激光点焊热影响区是由α相和细小的α′网篮状组织组成。与激光双光束焊接相比较,激光点焊热影响区的α相已经很难区分出具体的晶粒,成为了类似于基体的存在;而α′网篮状组织变得更加细小同时分布更加弥散,同时发现一些较为模糊、颜色与α相基体相近的针状α′相,说明针状α′相转变为α相[14]。

图4 焊接接头组织转变相图及母材OM照片

Fig. 4 Weld joint microstructure transformation phase diagram and OM photos of base metal

图5 焊接接头熔合区OM照片

Fig. 5 OM photos of fusion zone weld

图6 焊接接头热影响区OM照片

Fig. 6 OM photos of heat affected area of welding specimen

2.2 拉伸性能

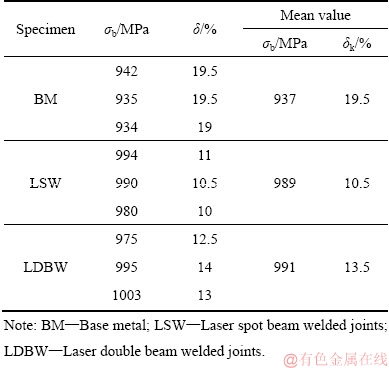

TC4钛合金母材、激光双光束焊接接头和激光点焊接接头的拉伸性能如表2中所列。结果表明,TC4钛合金通过两种激光焊接后,与母材拉伸性能相比,激光点焊接接头抗拉强度提高了5.5%,激光双光束焊接接头抗拉强度提高5.8%,两者的抗拉强度基本无差异;伸长率均显著降低,激光点焊接试件的伸长率下降了约9%,激光双光束焊接试件的伸长率下降了约6%,激光双光束焊试件的伸长率优于激光点焊试件。两种焊接接头主要的塑形变形区均在母材及靠近母材的热影响区,断裂均发生在热影响区域。这是由于在熔合区存在大量且分布密集的针状α′相马氏体(网篮组织),网篮组织将对焊缝产生界面强化效果,从而增加了焊缝强度,因此焊接接头的抗拉强度有所增加。在对试样不间歇加载拉伸载荷过程中,由于焊接接头强硬度增加,焊缝及熔合区不易发生形变,而是在母材及近母材的热影响区发生塑性形变,直到出现颈缩。由于形变的发生,母材及近母材的热影响区的真实应力不断增加,直到大于未发生形变的熔合区,同时试样采用大圆弧轮廓,热影响区横截面积小于母材,真实应力较大,故试样断裂在热影响区。

表2 不同试样的拉伸性能

Table 2 Tensile test results of different speciments

2.3 疲劳寿命统计分析

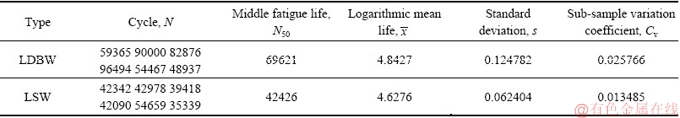

激光双光束焊接接头及激光点焊接头的低周疲劳寿命实验结果见表3,分别得出子样对数寿命平均值 、标准差s、子样异变系数Cv、中值疲劳寿命N50。查置信度γ=95%最少观测个数表(P=50%,相对误差δ=±5%)可知,激光双光束焊试件子样异变系数Cv=0.025766,小于0.0314,最少需要4个观测值,激光点焊试件Cv=0.013485,小于0.0314,最少需要4个观测值。激光双光束焊试件、激光点焊试件各自获得6个数据,表明观测值个数均已满足要求。

、标准差s、子样异变系数Cv、中值疲劳寿命N50。查置信度γ=95%最少观测个数表(P=50%,相对误差δ=±5%)可知,激光双光束焊试件子样异变系数Cv=0.025766,小于0.0314,最少需要4个观测值,激光点焊试件Cv=0.013485,小于0.0314,最少需要4个观测值。激光双光束焊试件、激光点焊试件各自获得6个数据,表明观测值个数均已满足要求。

表3 激光双光束焊接接头和激光焊接接头的低周疲劳寿命统计结果

Table 3 Low cycle fatigue life statistics of laser double beam welded joints and laser welded joints

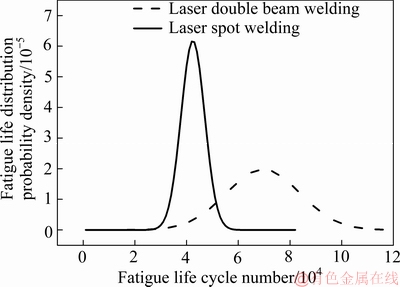

通常钛合金低周疲劳性能观测值分布规律服从正态分布规律或威布尔分布规律,由一组字样观测数据计算出字样的均值 和标准s,并将它们分别作为母体均值μ和标准差σ,估计总体参数。用数理统计学方法对疲劳寿命数据进行统计分析。激光双光束焊焊接接头、激光点焊焊接接头的疲劳寿命分布概率密度函数如图7所示。可以看出,激光双光束焊试件的疲劳寿命分布概率密度函数曲线在激光点焊试件的右边,说明激光双光束焊试件的疲劳寿命明显高于激光点焊试件的。对数正态分布的概率密度曲线越“狭高”,表明随机变量的分散性越小,因此激光点焊试件相比激光双光束焊试件的疲劳寿命分散小。在400 MPa应力水平下,激光双光束焊接试件中值疲劳寿命是激光点焊试件的2.23倍。

和标准s,并将它们分别作为母体均值μ和标准差σ,估计总体参数。用数理统计学方法对疲劳寿命数据进行统计分析。激光双光束焊焊接接头、激光点焊焊接接头的疲劳寿命分布概率密度函数如图7所示。可以看出,激光双光束焊试件的疲劳寿命分布概率密度函数曲线在激光点焊试件的右边,说明激光双光束焊试件的疲劳寿命明显高于激光点焊试件的。对数正态分布的概率密度曲线越“狭高”,表明随机变量的分散性越小,因此激光点焊试件相比激光双光束焊试件的疲劳寿命分散小。在400 MPa应力水平下,激光双光束焊接试件中值疲劳寿命是激光点焊试件的2.23倍。

图7 激光焊试件疲劳寿命分布概率密度图

Fig. 7 Life probability density function distribution of laser welding specimens

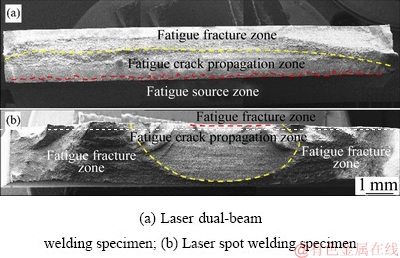

2.4 低周疲劳断口分析

图8所示为激光双光束焊和激光点焊试样宏观疲劳断口,激光点焊试件疲劳断口形貌相对激光双光束焊试件起伏较大。激光双光束焊接试件裂纹源在热影响区形成、在焊缝中扩展直至断裂,而对于激光点焊试件,裂纹在热影响区形成后,穿过焊点区域继续在母材内扩展直至最后断裂。

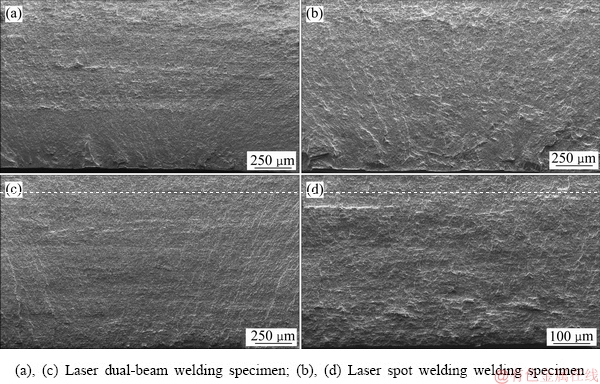

疲劳破坏大致可分为3个阶段:疲劳裂纹萌生、疲劳裂纹扩展和瞬时断裂,3个阶段分别对应低周疲劳断口的3个区域,分别为疲劳裂纹源区、疲劳裂纹稳定扩展区和瞬断区。图9(a)和(b)所示为激光双光束焊和激光点焊疲劳源区断口形貌,图9(c)和(d)所示为疲劳源局部放大形貌,图中放射状条纹汇集处确定两者疲劳均在试样热影响区表面萌生然后向试件内部扩展。这是由于在疲劳载荷作用下,试件自由表面发生位错运动,发生位错的表面发生晶粒塞积导致应力集中,而造成滑移带,随后形成侵入沟或挤出脊,最终导致微裂纹的产生;不同位置处的初始裂纹,在延伸中相遇并合并成发射条纹。

图8 宏观断口形貌

Fig. 8 Macroscopic fracture appearance

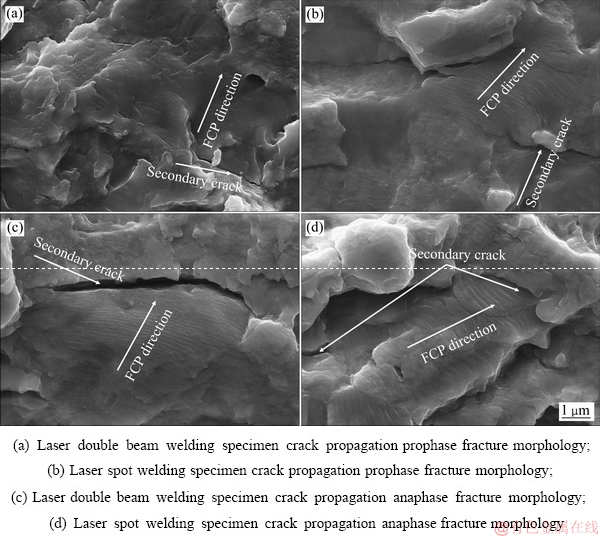

疲劳裂纹萌生后疲劳破坏进入裂纹扩展阶段,裂纹扩展分两个阶段,第一阶段裂纹扩展主要由于切应力作用,第二阶段主要由于正应力作用。扩展区显著的形貌特征是疲劳条纹,图10(a)和(b)所示分别为激光双光束和激光点焊试件疲劳裂纹扩展前期断口形貌,疲劳裂纹均在焊接区域扩展。试件在循环载荷作用下,疲劳裂纹立即沿着滑移带的主滑移面向内部扩展,疲劳裂纹与拉伸轴夹角大约为45°;在裂纹扩展前期,微裂纹大致成“Z”形曲折扩展,说明裂纹在扩展的进程中受阻,虽然前期裂纹扩展路径较短,但对疲劳寿命贡献很大[15]。前期疲劳条带间距较小,裂纹扩展速率较慢;由于裂纹扩展前期受阻,扩展的方向将发生改变逐渐向沿着垂直于正应力方向转换,扩展区裂纹呈扇形,有很多尺寸各异、凹凸不平的小断块且伴有二次裂纹产生,消耗了传导到主裂纹的大量能量,降低了裂纹扩展速率,在一定程度上增加了疲劳寿命。小断块上具有垂直于裂纹扩展方向、明暗相交且互相平行呈波浪形疲劳条纹,但每个小断块上的疲劳条纹不相连且方向不一致[16]。每一疲劳条纹代表一次载荷循环,间距表示应力循环一周裂纹扩展的距离,也表征了应力循环一周时释放能量的多少,所以在相同的试验条件下,条纹间距的大小就代表着裂纹扩展速率的快慢。两种焊接试件的疲劳条带间距较前期均明显增大,扩展速率加快(如图10(c)和(d)所示),不同的是激光点焊试件疲劳条纹间距较激光双光束试件更大,表明裂纹扩展速率加快得更加明显。这是因为熔合区存在大量且密集的针状α′相马氏体,而针状α′相具有高的位错密度和孪晶,针状组织的出现形成了大量的相界,使焊缝强度提高[17]。而激光点焊焊核呈椭圆形,焊核并未完全覆盖整个危险截面,裂纹扩展后期裂纹穿过焊核在母材和靠近母材的热影响区进行。此区域几乎没有发生微观组织变化,只形成少量的针状马氏体,对试件强度几乎没有影响,导致激光点焊试件裂纹扩展后期抗力比激光双光束试件小,在一定程度增大激光点焊试件裂纹扩展速率,降低试件的低周疲劳寿命。

图9 疲劳源断口形貌

Fig. 9 Fatigue source fracture morphologies

图10 疲劳裂纹扩展区断口形貌

Fig. 10 Fatigue crack propagation zone fracture morphologies

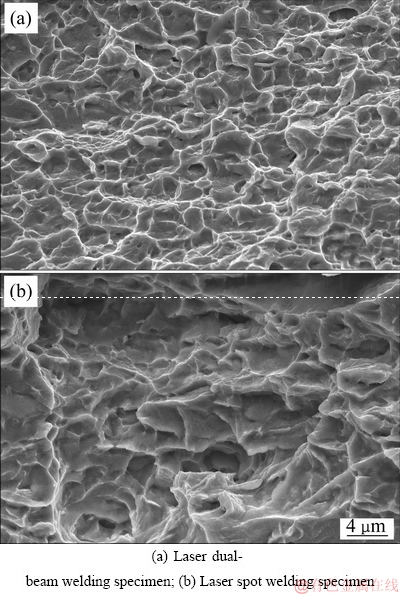

瞬时断裂是指裂纹扩展后期裂纹扩展尺寸接近临界值,试件剩余截面积不足以承受外部施加交变载荷时,两种激光焊接试样发生瞬时断裂。该区域的作用力再次由正应力过渡到切应力。图11所示为疲劳瞬时断口形貌,与裂纹扩展区有明显差异,具有韧窝断口特征,为韧性断裂。由于激光点焊试件焊核并未完全覆盖整个危险截面,瞬时断裂发生在母材,与激光双光试件断口相比,韧窝深度大数目多且分布密集,体现出较好的韧性征。

图11 瞬断区断口形貌

Fig. 11 Fractures of short interruption zones

3 结论

1) TC4钛合金原始金相组织由α和β两相组成,试件经两种激光焊接后熔合区/焊核主要为针状马氏体α'组成网篮组织,不同的是激光点焊α′网篮状组织的体积分数增大。

2) 与母材拉伸性能相比,激光点焊接接头抗拉 强度提高了5.5%,激光双光束焊接接头抗拉强度提高5.8%。

3) 在σ=400 MPa时,两种激光焊接接头相比,激光点焊试件疲劳寿命分散较小,激光双光束焊接试件中值疲劳寿命是激光点焊试件的2.23倍。

4) 激光点焊试件的宏观断口形貌相对于激光双光束焊试件的而言,韧窝起伏较大;两种激光焊接头在裂纹扩展初期扩展速率都很小,裂纹扩展后期扩展速率均明显加快,且激光点焊试件裂纹扩展后期在母材和靠近母材的热影响区进行,裂纹扩展抗力降低,裂纹扩展速率加快得更加明显。

REFERENCES

[1] SQUILLACE A, PRISCO U, CILIBERTO S, ASTARITA A. Effect of welding parameters on morphology and mechanical properties of Ti-6Al-4V laser beam welded butt joints[J]. Journal of Materials Processing Technology, 2012, 212(2): 427-436.

[2] BALASUBRAMANIAN T S, BALAKRISHNAN M, BALASUBRAMANIAN V. Influence of welding processes on microstructure, tensile and impact properties of Ti-6Al-4V alloy joints[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(6):1253-1262.

[3] 李重河, 朱 明, 王 宁, 鲁雄刚, 程申涛. 钛合金在飞机上的应用[J]. 稀有金属, 2009, 33(1): 84-91.

LI Chong-he, ZHU Ming, WANG Ning, LU Xiong-gang, CHENG Shen-tao. Application of titanium alloy on aircraft[J]. Chinese Journal of Rare Metals, 2009, 33(1): 84-91.

[4] 杨 静, 程东海, 黄继华, 张 华, 赵兴科, 郭和平. TC4钛合金激光焊接接组织与性能[J]. 稀有金属材料与工程, 2009, 38(2): 259-262.

YANG Jing, CHENG Dong-hai, HUANG Ji-hua, ZHANG Hua, ZHAO Xing-ke, GUO He-ping. Microstructure and properties of TC4 titanium alloy laser welded joint[J]. Rare Metal Materials and Engineering, 2009, 38(2): 259-262.

[5] 徐志刚, 岳 超, 侯雯中, 郑帅超, 王亚军. 钛合金整体壁板T型接头双作用激光焊接系统设计[J]. 组合机床与自动化加工技术, 2016(5): 100-102.

XU Zhi-gang, YUE Chao, HOU Wen-zhong, ZHENG Shuai-chao, WANG YA-jun. Design of double-acting laser welding system for T-joint of titanium alloy integral wall[J]. Modular Machine Tool & Automatic Manufacturing Technique, 2016(5): 100-102.

[6] HAROONI M, CARLSON B, KOVACEVIC R. Dual-beam laser welding of AZ31B magnesium alloy in zero-gap lap joint configuration[J]. Optics & Laser Technology, 2014, 56(5): 247-255.

[7] 马国龙, 李俐群, 陈彦宾. 单/双光束激光焊接熔池行为及焊缝成形特性比较[J]. 中国激光, 2017, 44(2): 225-233.

MA Guo-long, LI Li-qun, CHEN Yan-bin. Single/double beam laser welding molten pool behavior and weld forming characteristics comparison[J]. Chinese Journal of Lasers, 2017, 44(2): 225-233.

[8] 雷正龙, 李 颖, 陈彦宾, 孙忠绍, 张益坤. 双光束激光填丝焊工艺对铝合金焊接气孔率的影响[J]. 焊接学报, 2013, 34(2): 40-44.

LEI Zheng-long, LI Ying, CHEN Yan-bin, SUN Zhong-shao, ZHANG Yi-kun. Effect of double beam laser filling welding process on porosity of aluminum alloy welding[J]. Transactions of the China Welding Institution, 2013, 34(2): 40-44.

[9] XIE J. Dual beam laser welding[J]. Welding Journal, 2002(10): 223-236.

[10] 李俐群, 陈彦宾, 陶 汪. 铝合金双光束焊接特性研究[J]. 中国激光, 2008, 35(11): 1783-1788.

LI Li-qun, CHEN Yan-bin, TAO Wang. Study on welding characteristics of aluminum alloy double beam[J]. Chinese Journal of Lasers, 2008, 35(11): 1783-1788.

[11] 杨武雄, 张心怡, 肖荣诗. 2060-T8/2099-T83铝锂合金T型接头双光束激光焊接工艺[J]. 中国激光, 2013, 40(7): 83-87.

YANG Wu-xiong, ZHANG Xin-yi, XIAO Rong-shi. 2060-T8/2099-T83 aluminum-lithium alloy T-joint double beam laser welding process[J]. Chinese Journal of Lasers, 2013, 40(7): 83-87.

[12] 黄 瑞, 陈 铠, 张 松, 赵旭东. 双光束激光焊接的试验研究[J]. 激光杂志, 2007, 28(5): 66-67.

HUANG Rui, CHEN Kai, ZHANG Song, ZHAO Xu-dong. Experimental study on double beam laser welding[J]. Laser Journal, 2007, 28(5): 66-67.

[13] 程东海, 黄继华, 林海凡, 张 华. TC4钛合金激光拼焊接头显微组织及力学性能分析[J]. 焊接学报, 2009, 30(2): 103-106.

CHENG Dong-hai, HUANG Ji-hua, LIN Hai-fan, ZHANG Hua. Microstructure and mechanical properties of TC4 titanium alloy laser welded joints[J]. Transactions of the China Welding Institution, 2009, 30(2): 103-106.

[14] 乔 亮, 苏 轩, 陶 汪, 陈彦宾, 熊 俊. TC4钛合金不同焊接工艺下组织性能对比[J]. 热加工工艺, 2016(3): 19-22.

QIAO Liang, SU Xuan, TAO Wang, CHEN Yan-bin, XIONG Jun. Comparison of microstructure and properties of TC4 titanium alloy under different welding processes[J]. Hot Working Technology, 2016(3): 19-22.

[15] 杨武林, 杨晓华, 李晓延, 兑卫真, 林建航, 李晋伟. TC4钛合金薄板激光焊接接头的疲劳寿命及断口分析[J]. 焊接学报, 2012, 33(3): 105-108.

YANG Wu-lin, YANG Xiao-hua, LI Xiao-yan, DUI Wei-zhen, LIN Jian-hang, LI Jing-wei. Fatigue life and fracture analysis of laser welded joint of TC4 titanium alloy sheet[J]. Transactions of the China Welding Institution, 2012, 33(3): 105-108.

[16] 梁春雷, 李晓延, 陈 俐. TC4钛合金薄板激光焊接头疲劳性能研究[J]. 材料工程, 2006, 28(4): 48-51.

LIANG Chun-lei, LI Xiao-yan, CHEN Li. Research on fatigue performance of laser welded joint of TC4 titanium alloy sheet[J]. Journal of Materials Engineering, 2006, 28(4): 48-51.

[17] 赵锡龙, 宋 旭, 张建勋. TC4钛合金激光焊接接头力学行为的原位研究[J]. 中国有色金属学报, 2012, 22(2): 388-393.

ZHAO Xi-long, SONG Xu, ZHAO Jian-xun. In-situ study on mechanical behavior of TC4 titanium alloy laser welded joint[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(2): 388-393.

Fatigue performance and fracture mechanism of dual-beam laser welded T-joints of TC4 titanium alloy

XU Liang1, 2, SU Ju-ji1, ZHOU Song1, 2, HUI Li1, 2, WANG Lei1, 2, ZHANG Lu1

(1. School of Mechatronics Engineering, Shenyang Aerospace University, Shenyang 110136, China;

2. Key Laboratory of Fundamental Science for National Defense of Aeronautical Digital Manufacturing Process, Shenyang Aerospace University, Shenyang 110136, China)

Abstract: Based to the problem that the T-joint in the aircraft fuselage wall was often subjected to fatigue resistance during flight due to air circulation resistance, the laser double beam welding technology and laser spot welding technology were used on T-joint welding of TC4 titanium alloy. And the microstructure, tensile properties, low cycle fatigue behavior and fracture mechanism of the two joints were investigated. The results show that after welding by two different laser welding methods, the fusion zone structure is a basket structure composed of needle-shaped α′ martensite. Compared with laser double-beam welding, the volume fraction of α' basket-like structure in the laser spot welded joint mesh basket increases, the needle-shaped α′ martensite size increases and the phase spacing decreases. Compared with the tensile properties of the base metal, the tensile strength of the laser spot welded joint increases by 5.5%, and the tensile strength of the laser double beam welded joint increases by 5.8%.The median fatigue life of the laser double-beam welding specimen increases by 2.23 times. The main reason is that the mesh basket structure produces an interface strengthening effect on the welded joint and increases the joint strength, while the crack propagation of laser spot welding specimen penetrates the solder joint into the base material, causing the decrease of crack propagation resistance of the specimen.

Key words: TC4 titanium alloy; laser dual-beam welding; laser spot welding; fatigue life; fatigue fracture mechanism

Foundation item: Project(L2016033) supported by Liaoning Provincial Department of Education Higher School Scientific Research Project, China; Project(SHSYS2017006) supported by Shenyang Aerospace University Aviation Manufacturing Process Digital Defense Key Discipline Laboratory Open Fund, China; Project(18YB05) supported by the Shenyang Aerospace University Young Doctoral Research Fund, China

Received date: 2018-07-12; Accepted date: 2018-10-16

Corresponding author: ZHOU Song; Tel: +86-24-89728640; E-mail: zhousong23@163.com

(编辑 王 超)

基金项目:辽宁省教育厅高等学校科学研究项目(L2016033);沈阳航空航天大学航空制造工艺数字化国防重点学科实验室开放基金资助项目(SHSYS2017006);沈阳航空航天大学青年博士科研启动基金资助项目(18YB05)

收稿日期:2018-07-12;修订日期:2018-10-16

通信作者:周 松,讲师,博士;电话:024-89728640;E-mail:zhousong23@163.com