DOI:10.19476/j.ysxb.1004.0609.2019.08.04

Al-3B变质共晶铝硅合金的显微组织与力学性能

李宏宝1, 2,涂 浩1, 2,彭浩平1, 2,吴长军1, 2,王建华1, 2,苏旭平1, 2

(1. 常州大学 材料科学与工程学院,江苏省表面科学与技术重点实验室,常州 213164;

2. 常州大学 江苏省光伏科学与工程协同创新中心,常州 213164)

摘 要:采用Al-3B中间合金对不同温度Al-12.6Si合金熔体进行变质处理。结果表明:当变质温度相同时,随着Al-3B加入量的增加,Al-12.6Si合金中α(Al)相的面积分数呈现先增大后减小的变化趋势,当Al-3B加入量为0.4%(质量分数)时,α(Al)相面积分数达到最大值35.6%。当Al-3B加入量为0.4%时,随着变质温度的升高,Al-12.6Si合金中α(Al)相的面积分数也呈现先增大后减小的变化趋势,当变质温度为700 ℃时,合金组织中α(Al)相的面积分数最大。与未变质Al-12.6Si合金相比,在700 ℃时经0.4%Al-3B变质处理后,Al-12.6Si合金的抗拉伸强度和伸长率分别提高12%和64%,变质处理后合金的综合力学性能得到明显提高。

关键词:Al-12.6Si合金;变质处理;显微组织;力学性能

文章编号:1004-0609(2019)-08-1599-07 中图分类号:TG292 文献标志码:A

随着现代科学技术的推进,铝合金进入了新一轮快速发展阶段。由于铝合金具有易于铸造和焊接、质量轻、抗腐蚀能力强等优点在全世界范围内得到广泛应用,特别是在汽车领域、减小车身质量可以有效地减少燃料消耗和尾气排放,铝合金恰好满足了这种需求[1-2]。就铸造铝合金而言,铝硅合金占据了很大一部分。在铝合金中添加Si元素,虽然可以使其基体强度得到增加,但塑性会降低。随着Si含量的增加,铝硅合金中的共晶组织数量随之增加。共晶硅以粗大的板条状或针片状的形式存在,对铝基体造成严重的破坏,降低合金的塑性和韧性[3-5]。因此,细化铝硅合金的晶粒组织、改变合金中共晶硅的形态和尺寸及各种组织的相对数量以提高其力学性能成为科学研究的热点。改善合金显微组织的方法除了快速凝固[6]、挤压铸造[7]、超声波振动[8]外,最有效的方法是对铝硅合金进行变质处理。在生产中通常将Na盐[9]、磷[10-11]、稀土元素[12-13]等变质剂加入到铝硅合金中,从而达到改善铝硅合金显微组织的目的。LI等[14]发现,在砂铸条件下,在铝硅合金中加入0.05%Eu(质量分数)可使共晶Si由薄片状变成了纤维状。MURTY等[15]认为,Al-B体系对Al-Si合金是一种高效的晶粒细化剂。关于B元素对共晶组织的细化上有两种不同的解释,NOGITA等[16]对完全固化的样品和在共晶捕获期间的不同阶段淬火的样品进行了系统分析,认为B的添加不会引起共晶组织的改性,即硅的尺寸和形态保持不变或经历微不足道的变化;而TENGFEI等[17]在实验中发现,B元素的添加导致Al-11Si和Al-14Si合金中共晶Si薄片的长度和厚度减小,认为B元素对共晶组织的细化机制可归因于B和Si元素在共晶硅形核之前的相互作用。WANG等[18]的研究表明,Al-5Ti对Al-12.6Si合金凝固组织具有良好的变质作用,加入0.2%的Al-5(质量分数)Ti可以使Al-12.6Si合金中的初生α(Al)相数量达到最大值,并且使合金的力学性能得到明显提高。迄今为止,还没有发现采用Al-3B对Al-12.6Si合金进行变质处理的研究报道。本文研究了Al-3B变质处理对共晶铝硅合金显微组织和力学性能的影响,为进一步改善共晶铝硅合金的力学性能具有重要的指导作用,为扩大共晶铝硅合金的应用领域提供参考。

1 实验

本实验采用工业纯铝(A00,纯度为99.85%)和Al-50Si、Al-3B中间合金为原料。首先将总质量为1000 g的铝锭和Al-50Si中间合金一起放入石墨坩埚炉中在850 ℃熔炼成Al-12.6Si合金熔体,保温20 min后浇铸成小锭备用。

取150 g共晶铝硅合金在700 ℃下进行重熔,用m(NaCl):m(KCl):m(Na3AlF6)=6:9:5覆盖剂对熔体进行保护,采用0.1%的C2Cl6(质量分数)对熔体进行除气除渣,然后分别加入0、0.1%、0.2%、0.4%、0.6%和0.8%(质量分数)的Al-3B中间合金对合金熔体进行变质处理10 min,最后将Al-12.6Si合金熔体浇注到内部尺寸为d 12 mm×100 mm的100 ℃低碳钢模具中。为分析变质温度对变质效果的影响,在650、700和750 ℃下采用最佳Al-3B加入量分别对共晶铝硅合金进行上述变质处理,然后浇注合金试样。

在距铸造样品底部15 mm的位置截取金相分析样品,用Al2O3将样品抛光成镜面并用Keller’s试剂进行腐蚀。采用Leica DIM 3000光学显微镜对合金样品进行显微组织观察,用软件Image-Pro Plus 6.0分析和计算变质前后共晶铝硅合金组织中α(Al)相的面积分数,每个样品分析3个视场,取其平均值作为最终分析结果。采用DSC404F3A00差示扫描量热仪对变质前后Al-12.6Si合金进行DSC分析。按照ASTM E8标准,用WDW-300万能拉伸试验机测量变质前后共晶铝硅合金试样的力学性能,试样的规格为直径6 mm、长度30 mm。测试过程中,应变速率控制为1×10-3 s-1,每种合金测量3根试样,取测量平均值作为最终结果。最后,采用JSM-6360LV扫描电子显微镜(SEM)对变质前后Al-12.6Si合金的拉伸断口形貌进行表征。

2 结果及分析

2.1 Al-3B加入量对共晶铝硅合金显微组织的影响

图1所示为温度为700 ℃、不同Al-3B加入量变质处理Al-12.6Si合金的显微组织。如图1(a)所示,未经变质处理的Al-12.6Si合金组织中存在少量的α(Al)相及初晶硅,正如WANG等[18]解释的,这主要是因为合金熔炼过程因为成分不均匀,导致局部区域中的硅含量低于或高于共晶点的含量,从而合金凝固后出现少量的初生α(Al)相和初晶硅。此外,共晶硅以粗大的针片状形式存在。随着Al-3B变质剂加入量从0.1%到0.4%,如图1(b)~(d),变质后合金中的α(Al)相数量不断增多,其形态由块状变为细小枝晶状。此外,随着Al-3B变质剂加入量的增加,初晶硅数量减少乃至消失,而针片状共晶硅的长度和厚度明显减小,针片状特征逐渐减弱,当Al-3B变质剂加入量为0.4%时,共晶组织形态已很难分辨。由图2可以更加清晰地观察到共晶组织的变化,可见采用0.4%Al-3B变质处理Al-12.6Si合金能抑制合金凝固过程中共晶组织的生长,明显细化共晶组织。Al-3B变质处理后合金显微组织的变化,主要是由于Al-3B促进了α(Al)的形核和生长,从而抑制初生硅和共晶组织的生长。随着Al-3B加入量进一步增加,如图1(e)~(f)所示,共晶铝硅合金中α(Al)相数量明显减少,且α(Al)枝晶发生粗化,但其尺寸仍明显小于未变质合金中α(Al)相的尺寸。此外,共晶硅的针片状特征再次出现并得到加强。

图1 不同Al-3B加入量变质共晶铝硅合金的显微组织

Fig. 1 Microstructures of Al-12.6Si alloy modified with different amounts of Al-3B

图2 不同Al-3B加入量变质共晶铝硅合金中共晶硅形貌

Fig. 2 Morphologies of eutectic silicon in modified eutectic Al-Si alloy with different Al-3B addition amount

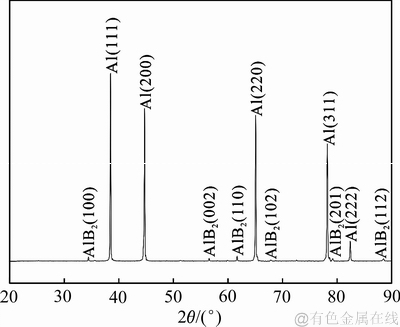

图3所示为Al-3B中间合金的XRD谱。由图3可见,该合金中只存在Al基体和AlB2相。经Al-3B变质处理后共晶铝硅合金中α(Al)相明显变细,主要得益于AlB2相的作用,但并不是Al-3B加入量越多、α(Al)相细化越好,这与LIU等[19]的研究结果一致。LIU等[19]认为,Al-3B的细化能力并不是由于未溶解的AlB2颗粒直接成核作用于α(Al)相,而是在溶解的AlB2颗粒上先形成固体铝层,然后在冷却过程中α(Al)相直接在预先形成的固体Al上成核而导致α(Al)相的细化。

图3 Al-3B中间合金的XRD谱

Fig. 3 XRD pattern of Al-3B intermediate alloy

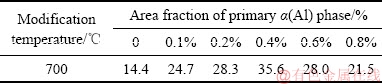

表1所列为700 ℃、不同Al-3B加入量变质处理Al-12.6Si合金中α(Al)相面积分数的定量分析结果,由表中数据可知,Al-3B变质处理后Al-12.6Si合金中α(Al)相面积分数增加,当Al-3B加入量为0.4%时,变质合金中的α(Al)相面积分数最大。

为了解释Al-3B变质处理Al-12.6Si合金中α(Al)相面积分数的变化规律,需要了解Al-3B变质处理对Al-Si合金非平衡共晶点的影响。

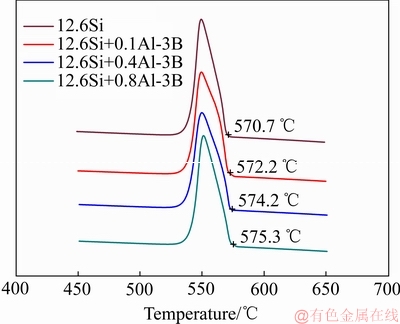

图4所示为Al-3B变质前后Al-12.6Si液态合金凝固DSC分析曲线,如图4所示,每条曲线仅有一个峰,它对应Al-12.6Si合金共晶转变。由图4可见,未变质Al-12.6Si合金的共晶转变开始温度为570.7 ℃,随着Al-3B加入量的增加,变质Al-12.6Si合金的共晶转变开始温度升高。Al-3B变质处理后,Al-12.6Si合金共晶转变温度升高的原因有两个:1) 随着Al-3B加入量增加,AlB2异质形核核心增加造成合金液凝固过冷度减小,从而导致合金共晶转变开始温度升高;2) Al-3B加入量增加造成熔体温度有所降低,使合金液与金属型的温差减小和合金液冷却速度的降低,导致合金凝固过冷度降低,从而使合金共晶转变开始温度升高。

表1 不同加入量的Al-3B变质处理Al-12.6Si合金中α(Al)相的面积分数

Table 1 Area fraction of primary α(Al) phase in Al-12.6Si alloy modified with different amount of Al-3B

图4 Al-3B变质处理前后Al-12.6Si合金的DSC曲线

Fig. 4 DSC curves of Al-12.6Si alloy before and after Al-3B modification

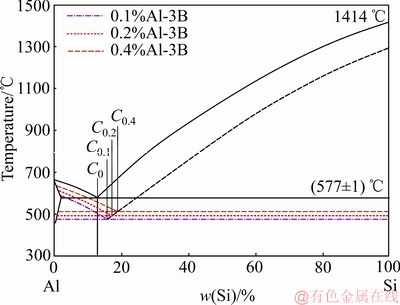

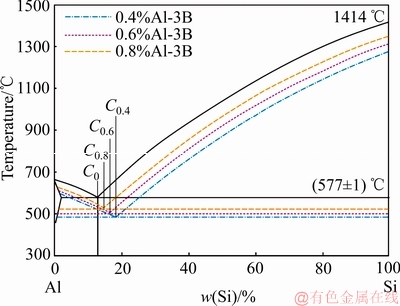

依据图4中Al-3B变质后Al-12.6Si液态合金凝固温度的变化结果,绘制了图5和6所示Al-3B变质处理对Al-Si合金非平衡共晶点位置影响的示意图。图5所示为700 ℃时、加入少量Al-3B变质Al-Si合金后非平衡共晶点变化的示意图。C0表示Al-Si二元相图中的平衡共晶点,C0.1、C0.2和C0.4分别表示0.1%、0.2%和0.4% Al-3B变质铝硅合金后的非平衡共晶点。由于Al-3B的加入量较小,因此对熔体温度的影响很小,可以忽略。Al-3B中间合金主要是对α(Al)相起变质作用,对过共晶铝硅合金中的初生硅的变质作用很小,因此,Al-3B变质处理后将导致亚共晶Al-Si合金的过冷度降低,但对过晶Al-Si合金的过冷度基本没有影响。Al-3B变质处理后将导致非平衡共晶点向右和向上移动。根据杠杆定律,随着Al-3B从0.1%增加到0.4%,Al-Si合金组织中α(Al)相的面积分数增加。

图5 少量Al-3B变质Al-Si合金共晶点的变化示意图

Fig. 5 Schematic diagram of eutectic point variation of Al-Si alloy modified with a smaller amount Al-3B

图6所示为700 ℃时、加入较多Al-3B变质Al-Si合金后非平衡共晶点变化的示意图。C0.4、C0.6和C0.8分别表示0.4%、0.6%和0.8% Al-3B变质铝硅合金后的非平衡共晶点。由于Al-3B的加入量较大,因此,在考虑Al-3B对亚共晶铝硅合金中α(Al)相的变质作用外,还需要考虑变质剂添加对合金熔体温度的影响。随着Al-3B加入量的增加,Al-Si合金熔体温度的降低使合金液的冷却速度降低,最终导致其过冷度的降低。Al-3B变质处理尽管对过共晶铝硅合金中的初生硅没有变质作用,但当其加入量较大时也会导致过共晶铝硅合金液过冷度的减小。当采用较多的Al-3B对铝硅合金进行变质处理后,将导致非平衡共晶点向左和向上移动。根据杠杆定律,随着Al-3B从0.4%增加到0.8%,Al-Si合金组织中α(Al)相的面积分数减少。

图6 较多Al-3B变质Al-Si合金共晶点的变化示意图

Fig. 6 Schematic diagram of eutectic point variation of Al-Si alloy modified with a higher amount Al-3B.

2.2 变质温度对共晶铝硅合金显微组织的影响

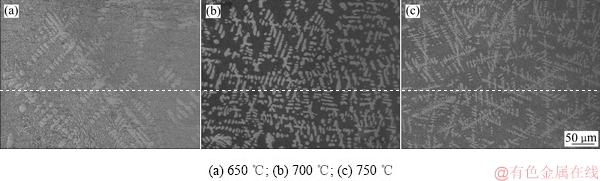

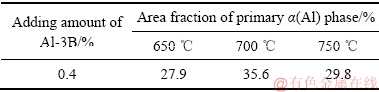

图7所示为Al-3B加入量为0.4%、不同变质温度时Al-12.6Si合金的显微组织。从图7中可以看出,与未变质的合金(见图1(a))相比,不管变质温度如何变化,变质处理Al-12.6Si合金中α(Al)相和共晶组织都得到了明显细化,α(Al)相的形态由块状转变为树枝晶状,此外,变质处理后合金中的初生硅消失。由图7可见,随着变质温度的提高,α(Al)相的细化效果不断增强;但是,变质温度对共晶组织的影响有所不同,当变质温度为700 ℃时,变质共晶铝硅合金中的共晶组织最为细小。表2所列为不同变质温度时Al-12.6Si合金中α(Al)相面积分数的定量分析结果,由表中数据可知,与未变质的合金中α(Al)相面积分数14.4%相比,不管变质温度如何变化,变质处理Al-12.6Si合金中α(Al)相都有明显的增加。随着变质温度的增加,α(Al)相的面积分数呈现先增加再减少的变化趋势,当变质温度为700 ℃时变质共晶铝硅合金中α(Al)相的面积分数最大。变质处理合金中共晶组织的细化与α(Al)相面积分数的变化密切相关,α(Al)相面积分数的增加将抑制共晶反应的发生和共晶组织的生长。当变质温度为700 ℃,最大的α(Al)相面积分数对应最为细小的共晶组织。

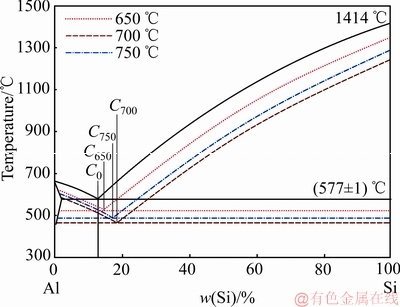

图8所示是Al-3B加入量为0.4%时、变质温度对Al-Si合金非平衡共晶点影响的示意图。在图8中,C0是Al-Si合金的平衡共晶点,C650、C700和C750分别表示采用0.4%Al-3B在650、700和750 ℃分别对铝硅合金进行变质处理后铝硅合金的非平衡共晶点。当Al-3B加入量一定时,合金液凝固时的过冷度取决于熔体体温度和金属型温度。实验中金属型的温度控制在100 ℃,温度较低的金属型对熔体的冷却能力较强。以熔体温度为650℃时熔体的过冷度作为参照点,当熔体温度增加到700 ℃时,由于熔体与金属型的温差增大,熔体的冷却速度增加,导致熔体凝固时的过冷度明显增大。当熔体温度继续增加到750 ℃时,由于高温熔体对金属型的预热作用使金属型的温度增加,导致熔体的冷却速度的增加幅度减小,最终使熔体凝固时的过冷度增加量减小。由图8可见,采用0.4%Al-3B对铝硅合金进行变质处理以后,当变质温度为650 ℃、750 ℃和700 ℃时,铝硅合金非平衡共晶点C650、C750和C700自左向右排列,Al-12.6%Si合金向左偏离非平衡共晶点的距离最远。根据杠杆定律,当采用0.4%Al-3B对Al-12.6%Si合金在700 ℃进行变质处理后,Al-12.6%Si合金组织中α(Al)相的面积分数达到最大值,理论分析结果与实际结果一致。

图7 不同变质温度时共晶铝硅合金的显微组织

Fig. 7 Microstructures of Al-12.6Si alloy modified at different temperatures

表2 不同变质温度时Al-12.6Si合金中α(Al)相的面积分数

Table 2 Area fraction of α(Al) phase in Al-12.6Si alloy at different temperatures

图8 变质温度对Al-Si合金非平衡共晶点影响的示意图

Fig. 8 Schematic diagram of eutectic point variation of Al-Si alloy modified at different temperatures

2.3 变质处理前后Al-12.6Si合金的力学性能

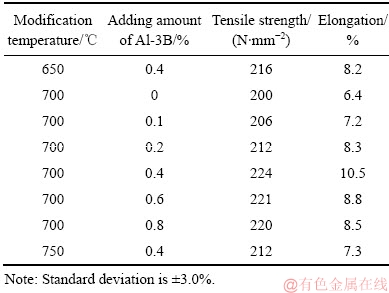

表3所列为在不同变质温度下采用Al-3B进行变质处理前后Al-12.6Si合金的力学性能。由表3中数据可以看出,在变质温度为700℃时,随着Al-3B加入量的增加,Al-12.6合金的抗拉强度与伸长率都是呈现先增加后减小的变化趋势,当Al-3B加入量为0.4%时,合金的抗拉强度与伸长率均达到最大值。此外,当Al-3B加入量为0.4%时,随着变质温度从650 ℃增加到750 ℃,合金的抗拉强度与伸长率也呈现先增大后减小的变化趋势,当变质温度为700 ℃时,合金的抗拉强度与伸长率最高。与未变质的Al-12.6Si合金相比,在700 ℃加入0.4%Al-3B变质处理后合金的抗拉强度和伸长率分别提高了12%和64%,因此变质处理可使共晶铝硅合金的综合力学性能得到显著提高。

变质处理Al-12.6Si合金力学性能的变化与变质处理后合金显微组织的变化密切相关,由上述的变质处理前后合金显微组织的变化可知,在700 ℃加入0.4%Al-3B变质处理后Al-12.6Si合金中的α(Al)相面积分数最大,由于α(Al)相的塑性比共晶组织更好,从而使合金的伸长率得到大幅度的提高;此外,细小的共晶组织使合金的抗拉强度得到一定程度的增加。

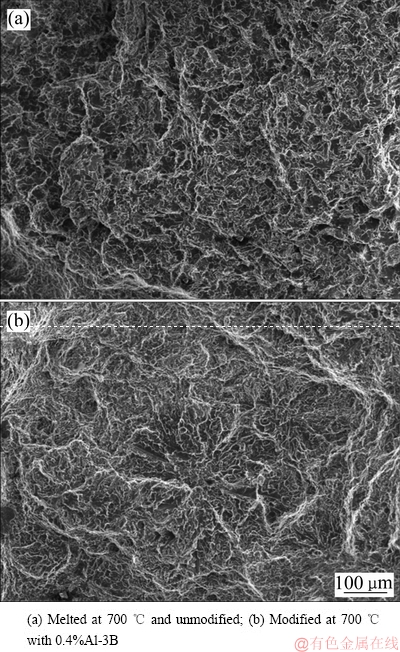

图9所示为变质处理前后Al-12.6Si合金的拉伸断口形貌,图9(a)所示为700 ℃熔炼且未变质Al-12.6Si合金的拉伸断口形貌,由图9(a)可见,未经变质处理的Al-12.6Si合金断口中包含数量较多且尺寸较大的韧窝,且撕裂棱较多。图9(b)所示为700 ℃时采用0.4%Al-3B变质处理Al-12.6Si合金的拉伸断口形貌,由图9(b)可见,合金断口上发现大量的细小的韧窝,此外可见大量复杂流向的撕裂棱。变质处理前后合金的拉伸断口形貌表明,变质处理后Al-12.6Si合金应该具有较高的抗拉强度与伸长率。

表3 变质处理前后Al-12.6Si合金的力学性能

Table 3 Mechanical properties of Al-12.6Si alloy before and after modification

图9 Al-12.6Si合金拉伸断口形貌

Fig. 9 Fracture morphologies of tensile samples of Al-12.6Si

3 结论

1) 变质温度为700 ℃时,Al-3B加入量较大时造成Al-12.6Si合金液温度降低,导致合金中α(Al)相面积分数随Al-3B的增加呈现先增加后减少的变化趋势。当Al-3B变质剂加入量为0.4%时,Al-12.6Si合金中α(Al)相的面积分数达到最大值。

2) Al-3B加入量为0.4%时,随着变质温度的升高,熔体温度与模具温之间差值的变化造成合金凝固过冷度发生变化,导致Al-12.6Si合金中α(Al)相的面积分数呈现先增大后减小的趋势。当变质温度为700 ℃时,Al-12.6Si合金中α(Al)相的面积分数达到最大值。

3) 与未变质的Al-12.6Si合金相比,在700 ℃加入0.4%Al-3B变质处理后合金的抗拉强度和伸长率分别提高了12%和64%,变质共晶铝硅合金的综合力学性能得到显著提高。

REFERENCES

[1] CHI Yi-ming, GU Guo-chao, YU Hui-jun, CHEN Chuan-zhong. Laser surface alloying on aluminum and its alloys: A review[J]. Optics & Lasers in Engineering, 2018, 100: 23-37.

[2] SU Jun-feng, NIE Xue-yuan, STOILOV V. Characterization of fracture and debonding of Si particles in AlSi alloys[J]. Materials Science & Engineering A, 2010, 527(27): 7168-7175.

[3] RAO Jin-song, ZHANG Jin, LIU Ru-xue, ZHENG Jiang, YIN Dong-di. Modification of eutectic Si and the microstructure in an Al-7Si alloy with barium addition[J]. Materials Science & Engineering A, 2018,728: 72-79.

[4] MAHATO A, XIA Shu-man, TOM P, ANIL S, BISWAS S K. Role of silicon in resisting subsurface plastic deformation in tribology of aluminium-silicon alloys[J]. Tribology International, 2010, 43(1): 381-387.

[5] LIU Xiao-rui, BEAUSIR B, ZHANG Yu-dong, GAN Wei-min, YUAN Hui, YU Fu-xiao, ESLING C, ZHAO Xiang, ZUO Liang. Heat-treatment induced defect formation in α(Al) matrix in Sr-modified eutectic Al-Si alloy[J]. Journal of Alloys & Compounds, 2017, 730: 208-218.

[6] KIM T S, LEE B T, LEE C R, CHUN B S. Microstructure of rapidly solidified Al-20Si alloy powders[J]. Materials Science & Engineering A, 2001, 304(1): 617-620.

[7] 丁永根, 王薄笑天, 李 萍, 薛克敏. 高压扭转变形的Al-Zn-Mg-Cu-Zr合金显微组织及织构[J]. 中国有色金属学报, 2017, 27(6): 1125-1131.

DING Yong-gen, WANG Bo Xiao-tian, LI Ping, XUE Ke-min. Microstructures and textures of Al-Zn-Mg-Cu-Zr alloy after high pressure torsion[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(6): 1125-1131.

[8] 罗 执, 张 杨, 赵愈亮, 张卫文. 复合场作用下Al-5.0Cu-1.0Fe合金的显微组织和力学性能[J]. 中国有色金属学报, 2016, 26(4): 707-714.

LUO Zhi, ZHANG Yang, ZHAO Yu-liang, ZHANG Wei-wen. Microstructure and mechanical property of Al-5.0Cu-1.0Fe alloy treated by compound field[J]. The Chinese Journal of Nonferrous Metals,2016, 26(4): 707-714.

[9] WU Shu-sen, TU Xiao-lin, FUKUDA Y, KANNO T, NAKAE H. Modification mechanism of hypereutectic Al-Si alloy with P-Na addition[J]. Transactions of Nonferrous Metals Society of China, 2003, 13(6): 1285-1289.

[10] QIN Q D, HUANG B W, WU Y J, SU X D. Microstructure and mechanical properties of friction stir welds on unmodified and P-modified Al-Mg2Si-Si alloys[J]. Journal of Materials Processing Technology, 2017, 250: 320-329.

[11] LIU Qing, LIU Mao-wen, XU Cong, XIAO Wen-long, YAMAGATA H, XIE Sheng-hui, MA Chao-li. Effects of Sr, Ce and P on the microstructure and mechanical properties of rapidly solidified Al-7Si alloys[J]. Materials Characterization, 2018, 140: 290-298.

[12] LI Qing-lin, XIA Tian-dong, LAN Ye-feng, LI Peng-fei, FAN Lu. Effects of rare earth Er addition on microstructure and mechanical properties of hypereutectic Al-20% Si alloy[J]. Materials Science & Engineering A, 2013, 588(1/2): 97-102.

[13] LI Qing-lin, XIA Tian-dong, LAN Ye-feng, ZHAO Wen-jun, FAN Lu, LI Peng-fei. Effect of rare earth cerium addition on the microstructure and tensile properties of hypereutectic Al-20%Si alloy[J]. Journal of Alloys & Compounds, 2013, 562(1): 25-32.

[14] LI J H, Wang X D, LUDWIG T H, TSUNEKAWA Y, ARNBERG L, JIANG J Z, SCHUMACHER P. Modification of eutectic Si in Al-Si alloys with Eu addition[J]. Acta Materialia, 2015, 84(85): 153-163.

[15] KORI S A, MURTY B S, CHAKRABORTY M. Development of an efficient grain refiner for Al-7Si alloy and its modification with strontium[J]. Materials Science & Engineering A, 2000, 280(1): 58-61.

[16] NOGITA K, DAHLE A K. Effects of boron on eutectic modification of hypoeutectic Al-Si alloys[J]. Scripta Materialia, 2003, 48(3): 307-313.

[17] GU Teng-fei, PAN Ye, LU Tao, LI Chen-lin, PI Jing-hong. Effects of boron addition on the morphology of silicon phases in Al-Si casting alloys[J]. Materials Characterization, 2018,141: 115-119.

[18] WANG Shuo, LIU Ya, PENG Hao-ping, LU Xiao-wang, WANG Jian-hua, SU Xu-ping. Microstructure and mechanical properties of Al-12.6Si eutectic alloy modified with Al-5Ti master alloy[J]. Adv Eng Mater, 2017, 255: 105-109.

[19] LIU Yuan, DING Chao, LI Yan-xiang. Grain refining mechanism of Al-3B master alloy on hypoeutectic Al-Si alloys[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(7): 1435-1440.

Microstructure and mechanical properties of eutectic Al-Si alloy modified with Al-3B

LI Hong-bao1, 2, TU Hao1, 2, PENG Hao-ping1, 2, WU Chang-jun1, 2, WANG Jian-hua1, 2, SU Xu-ping1, 2

(1. Jiangsu Key Laboratory of Materials Surface Science and Technology, Changzhou University, Changzhou 213164 , China;

2. Jiangsu Collaborative Innovation Center of Photovoltaic Science and Engineering, Changzhou University, Changzhou 213164, China)

Abstract: The Al-3B master alloy was used to modify the melt of Al-12.6Si alloy at different temperatures. The results show that when the modification temperature is the same, the area fraction of α(Al) phase in Al-12.6Si alloy increases first and then decreases with the increase of the addition amount of Al-3B, and it reaches the maximum value of 35.6% when the added amount of Al-3B is 0.4% (mass fraction). When the addition amount of Al-3B is 0.4%, the area fraction of α(Al) phase in Al-12.6Si alloy increases first and then decreases with the increase of modification temperature. When the modification temperature is 700 ℃, the area fraction of the α(Al) phase in the alloy reaches the maximum. Compared with the unmodified Al-12.6Si alloy, the tensile strength and elongation of the Al-12.6Si alloy modified by 0.4% Al-3B at 700 ℃ increases by 12% and 64%, respectively. The comprehensive mechanical properties of alloy are obviously improved after modification.

Key words: Al-12.6Si alloy; modification; microstructure; mechanical property

Foundation item: Project(51571039) supported by the National Natural Science Foundation of China

Received date: 2018-07-12; Accepted date: 2019-03-11

Corresponding author: WANG Jian-hua; Tel: +86-15961165336; E-mail: wangjh@cczu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51571039)

收稿日期:2018-07-12;修订日期:2019-03-11

通信作者:王建华,教授,博士;电话:15961165336;E-mail:wangjh@cczu.edu.cn