文章编号:1004-0609(2010)S1-s0914-04

氮气气氛下激光切割对TC11钛合金组织及焊接接头性能的影响

刘昌奎,李 莹,何玉怀,陶春虎

(北京航空材料研究院,北京 100095)

摘 要:对TC11钛合金在氮气氛下进行激光切割,并在氮气氛下进行热处理,对比热处理前后的显微组织和硬度,确定热影响层深度。去除激光切割影响层后进行电子束焊接,比较研究未激光切割和激光切割焊接接头的拉伸和疲劳性能。结果表明:激光切割热影响层深度在2~3 mm之间;未激光切割和激光切割TC11钛合金焊接接头低周疲劳性能未见明显差异,但是激光切割后的焊接接头抗拉强度和伸长率相对未激光切割焊接接头分别低45 MPa和3%左右。

关键词:钛合金;焊接;激光切割;显微组织

中图分类号:TG407 文献标志码:A

Effect of laser cutting in nitrogen atmosphere on microstructure of TC11 titanium alloy and properties of welding joints

LIU Chang-kui, LI Ying, HE Yu-huai, TAO Chun-hu

(Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: TC11 titanium alloy plates were cut by laser and then heat treated in nitrogen atmosphere. The microstructure and microhardness of the surface layers affected by laser cutting were investigated before and after heat treatment. The depth of the heat influence zones by laser cutting was tested. The influenced layers by laser cutting were removed and then the plates were joined by electron beam welding. The effect of laser cutting on the tensile and fatigue properties of the welding joints of TC11 titanium alloy was studied. The results show that the depth of the heat influence zones by laser cutting is in the range of 2 mm to 3 mm. The effect of laser cutting on the low-cycle fatigue property of the welding joint of TC11 titanium alloy is slight, but laser cutting make the tensile strength and elongation percentage decrease by 45 MPa and 3%, respectively.

Key words: titanium alloy; welding; laser cutting; microstructure

钛合金具有较高的比强度、优异的抗腐蚀性能、较宽的工作温度范围以及良好的焊接性能,且其焊接结构不仅使结构质量显著减轻,同时提高了其结构的完整性,因此,钛合金及其焊接结构在航空航天等领域的应用越来越广泛[1-2]。但钛合金的化学活性高,在热成型或热处理过程中会受到周围气氛的污染,其中影响最大的是与空气中的氧、氮、氢等气体发生反应形成的污染。如与氧发生的污染最为普遍,在表面形成氧化皮和富氧α层。富氧α层硬度高、塑性低,使钛合金在受力时导致表面开裂。氮元素也是钛的间隙固溶元素,但由于氮在钛中的扩散率低于氧的,在同样的温度下,氮对钛合污染比氧的污染轻。但是,在较高的温度下,在钛合金表面同样也会形成氮污染层,使其表面硬化,对钛合金的力学性能产生不利影响[3]。

本文作者采用在氮气氛下激光切割TC11钛合金板的方法,研究氮气氛下激光切割影响层的显微组织

和显微硬度,确定了影响层深度;将影响层去除后进行电子束焊接,比较研究未激光切割和激光切割TC11钛合金焊接接头的拉伸和疲劳性能,并与TC11钛合金材料的拉伸和疲劳性能进行对比分析。

1 实验

试验采用4.3 mm厚的TC11钛合金板材,退火状态,为双态组织。其化学成分见表1。

表1 TC11合金的化学成分

Table 1 Chemical composition of TC11 alloy (mass fraction, %)

将试件在氮气氛下进行激光切割。切割后采用双重退火热处理,具体工艺过程为:第1次退火温度950 ℃,保温60~80 min,氮气保护空冷;第2次退火温度530 ℃,保温240~260 min,氮气保护空冷。

金相试样沿垂直于激光切割面截取,磨抛后采用5%HF+12%HNO3+83%H2O溶液腐蚀。显微硬度测试由切割表面向里每0.7 mm测试一个点,得到由表面向里的显微硬度变化曲线。

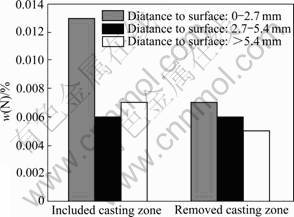

N元素含量检测分别是保留表面铸造组织和去掉表面铸造组织的状态下,在距表面2.7,2.7~5.4和大于5.4 mm范围为取试样进行检测。

采用机械加工方法去除激光切割影响层,然后进行电子束焊接。电子束焊接前保证试件焊接边无裂纹、毛刺等缺陷及油污,在酸洗后采用丙酮或汽油擦拭,焊接时从工艺垫板上引弧和收弧,焊后进行真空退火处理。

铣平焊高,按照GB/T 2651—2008和GB/T 2656—1981标准加工焊接拉伸和光滑疲劳试样。拉伸和疲劳试验温度均为150 ℃,疲劳试验主要试验参数Kt=1,R=0.05,f=3 Hz,最大应力σmax=400 MPa。

疲劳试验在HFP5100疲劳试验机上进行,显微硬度检测采用WOLPERT 401MVD显微硬度仪,采用JSM5600LV扫描电镜观察显微组织。

2 结果与讨论

2.1 显微组织

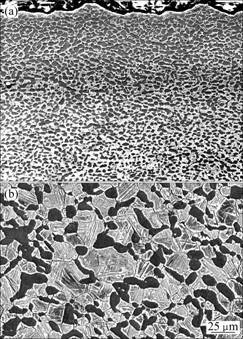

激光切割后,切割面存在铸造组织层(见图1(a))。铸造组织是由于切割后表层快速冷却形成的淬火态组织,为马氏体特征,晶粒为大约100 μm左右的等轴晶(见图1(b))。在铸造组织下面存在由于激光切割而形成的热影响层,热影响层显微组织由表面向里出现过渡变化特征。靠近铸造组织层处的近表面显微组织β相含有较多的马氏体组织。

图1 热处理前激光切割表层的显微组织

Fig.1 Microstructures of laser cutting surface before heat treating: (a) Surface layer; (b) Casting zone

经热处理后,距激光切割面大约400 μm范围内,显微组织存在过渡变化特征,靠近表面α相较多(见图2(a)),而内部相对减少(见图2(b))。组织出现过渡变化特征,一方面与受热过程有关,另一方面与氮气含量也存在较大的关系。氮元素为α稳定元素,氮元素含量增加,使得α→β转变的相变点升高,从而在相同的冷却条件下,α相含量增加。

2.2 氮元素含量的检测

带铸造组织和去掉铸造组织2种状态下,距表面不同距离的氮元素含量对比见图3。由图3可见,去掉表层铸造组织后,距表面不同距离的氮元素含量已无明显差别,并且均小于技术条件要求的(不大于0.05%)。从而说明在氮气氛下进行切割,铸造层出现了明显的增氮现象,而基体板材氮元素的增加不明显。

2.3 显微硬度

激光切割后热处理前后表面层显微硬度的检测结果如图4所示。由图4可见,热处理前距表面1 mm左右的表面层的显微硬度在410 HV左右,内部在330 HV左右。热处理后,表面层显微硬度较高,在距表

图2 热处理后激光切割表层的显微组织

Fig.2 Microstructures of laser cutting surface after heat treating: (a) Surface layer; (b) Inner

图3 氮元素含量检测结果

Fig.3 Testing results of N element content

面0.6 mm左右,硬度降低趋于一致,在340 HV左右。分析认为,表层显微硬度明显偏高,主要与表面铸造组织、显微组织中马氏体和α相含量以及表层N元素含量等因素有关[4-5]。

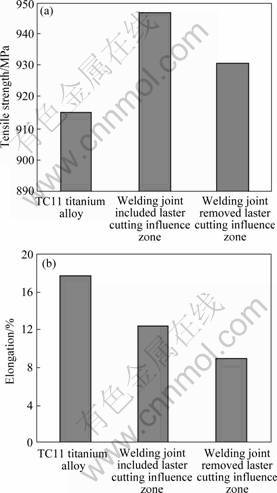

2.4 力学性能

TC11钛合金、未激光切割和激光切割后电子束焊接接头的抗拉强度和伸长率分别见图5。由图5可见,激光切割后的焊接接头抗拉强度为901 MPa和伸长率9%,相对未激光切割焊接接头分别低45 MPa和3%左右。焊接接头抗拉强度与TC11钛合金的抗拉强度相比相差较小(TC11钛合金为915 MPa),但伸长率均明显降低(TC11钛合金为18%)。研究表明[6-7],焊接接头塑性降低主要是由于热影响区及焊缝的组织变化所致。而激光切割和未激光切割焊接接头伸长率的差异,分析认为,氮元素的向内扩散也具有一定的影响。未激光切割和激光切割TC11钛合金焊接接头低周疲劳性能要求不小于20 000周次,试验结果表明均满足技术条件要求。

图4 热处理前后表面层的显微硬度

Fig.4 Microhardnesses of surface before (a) and after (b) heat treating

图5 焊接接头的抗拉强度和伸长率

Fig.5 Tensile strength (a) and elongation (b) of welding joints

3 结论

1) 未热处理时,靠近激光切割面存在含有较多马氏体组织的热影响区,热影响区在距激光切割面2 mm左右,显微硬度在370 HV左右,而基体仅在330 HV左右。热处理后,由激光切割面到基体0.5 mm范围内,显微组织中α相含量明显高于基体,并且呈现由多到少的过渡变化特征,硬度在距激光切割面0.6 mm处与基体趋于一致。

2) 激光切割热影响层深度在2~3 mm之间。

3) 未激光切割和激光切割TC11钛合金焊接接头低周疲劳性能未见明显差异,但是激光切割后的焊接接头抗拉强度和伸长率相对未激光切割焊接接头分别低45 MPa和3%左右。两者的抗拉强度和TC11钛合金相比相差较小,但伸长率均明显降低。

REFERENCES

[1] 刘昌奎, 刘新灵. TA15钛合金焊缝及热影响区疲劳裂纹扩展行为[J]. 失效分析与预防, 2006, 2(1): 10-13.

LIU Chang-kui, LIU Xin-ling. Fatigue crack propagation behavior in FA and HAZ of TA15 titanium alloy welds[J]. Failure Analysis and Prevention, 2001, 2(1): 10-13.

[2] 李兴无, 沙爱学. TA15合金及其在飞机结构中的应用前景[J]. 钛工业进展, 2003, 20(4/5): 90-94.

LI Xing-wu, SHA Ai-xue. TA15 titanium alloy and its applying prospects on airframe[J]. Titanium Industry Progress, 2003, 20(4/5): 90-94.

[3] 陶春虎, 刘庆瑔, 曹春晓, 张卫方. 航空用钛合金的失效及其预防[M]. 北京: 国防工业出版社, 2002.

TAO Chun-hu, LIU Qing-quan, CAO Chun-xiao, ZHANG Wei-fang. Failure and prevention of aeronautical titanium alloy[J]. Beijing: National Defence Industry Press, 2002.

[4] 王焕琴. 钛及钛合金焊接接头的组织、性能和断裂特性[J]. 焊接, 2001(11): 27-29.

WANG Huan-qin. Properties, microstructure and fracture behavior of welded joints Ti and Ti alloy[J]. Welding and Joining, 2001(11): 27-29.

[5] HONGOH M, TADROS R N. Fracture mechanics assessment of EB-welded blisked rotors[J]. Canadian Aeronautics and Space Journal, 1990, 36(1): 4-10.

[6] 刘昌奎, 刘 华. TA15钛合金焊接接头性能与断裂行为研究[J]. 失效分析与预防, 2006, 1(2): 45-48.

LIU Chang-kui, LIU Hua. Welded joints properties and fracture behavior of TA15 titanium alloy[J]. Failure Analysis and Prevention, 2006, 1(2): 45-48.

[7] KHALED T. An investigation of pore cracking in titanium welds[J]. Material Engineering and Performance, 1994, 3(1): 21-36.

(编辑 陈爱华)

通信作者:刘昌奎;电话:010-62496237;E-mail: changkuiliu621@sohu.com