文章编号:1004-0609(2007)10-1592-05

预退火对纳米晶Fe86Zr7B6Cu1合金显微组织

和软磁性能的影响

唐建成1,吴爱华2,张 萌1,刘文胜3

(1. 南昌大学 材料科学与工程学院,南昌 330031;

2. 南昌硬质合金有限责任公司,南昌 330013;

3. 中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:研究在常规退火前的高温短时间预退火对非晶Fe86Zr7B6Cu1合金晶化过程的影响,通过分析温度对形核速率和晶粒长大速率的影响规律,讨论预退火对非晶Fe86Zr7B6Cu1合金晶化过程的影响机制。结果表明,合适的预退火引起纳米晶Fe86Zr7B6Cu1合金中结晶α-Fe相的晶粒尺寸的减小和体积分数的增加。非晶Fe86Zr7B6Cu1合金经600 ℃退火1 h后的结晶α-Fe相的晶粒尺寸和体积分数分别为13.2 nm和65.2%,而在750 ℃保温2 min再在600 ℃退火1 h后的结晶α-Fe相的晶粒尺寸和体积分数分别为9.5 nm和72.4%。 在750 ℃保温2 min再在600 ℃退火1 h后的试样比常规退火得到的试样具有更为优良的软磁性能。

关键词:Fe86Zr7B6Cu1合金;纳米材料;磁性材料;显微组织;非晶相;结晶

中图分类号:TG 132.2+71 文献标识码:A

Effect of pre-annealing on microstructures and

soft magnetic properties of nanocrystalline Fe86Zr7B6Cu1 alloy

TANG Jian-cheng1,WU Ai-hua2,ZHANG Meng1,LIU Wen-sheng3

(1. School of Materials Science and Engineering, Nanchang University, Nanchang 330031, China;

2. Nanchang Cemented Carbide Limited Liability Company, Nanchang 330013, China;

3. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The effect of pre-annealing at higher temperature for short duration before conventional annealing at 600 ℃ for 1 h on the crystallization process of amorphous Fe86Zr7B6Cu1 alloy was studied. The affecting mechanism of pre-annealing on the crystallization process of amorphous Fe86Zr7B6Cu1 alloy is discussed by analyzing the temperature dependence of the nucleation rate and the grain growth rate. It is shown that proper pre-annealing leads to the decrease of the grain size and the increase of the volume fraction of crystalline α-Fe in nanocrystalline Fe86Zr7B6Cu1 alloy. BCC α-Fe with grain size of 9.5 nm and volume fraction of 72.4% is formed in ribbon after it has been pre-annealed at 750 ℃ for 2 min followed by conventional annealing at 600 ℃ for 1 h. The grain size and volume fraction of crystalline α-Fe in ribbon annealed at 600 ℃ for 1 h are 13.2 nm and 65.2%,respectively. Complex permeability spectra show that pre-annealing at 750 ℃ for 2 min before conventional annealing at 600 ℃ for 1 h results in a distinct improvement of soft magnetic properties.

Key words: Fe86Zr7B6Cu1 alloy; nanomaterial; magnetic material; microstructures; amorphous phase; crystallization

纳米晶Fe-Zr-B-Cu合金因具有高的饱和磁化强度和高的初始磁导率而成为目前研究最为热门的软磁材料之一[1?2]。纳米晶Fe-Zr-B-Cu合金的显微组织由Fe基非晶基体和分布于非晶基体中的体心α-Fe纳米颗粒组成,其中体心立方α-Fe纳米颗粒的体积分数约为60%~80%[3?4]。

优化显微组织是改善纳米晶Fe基合金软磁性能的一种重要物理冶金方法[5?8]。依据Herzer等[5?6]提出的随机各向异性模型,纳米晶Fe基合金中体心立方α-Fe纳米颗粒的晶粒尺寸和体积分数对其平均磁晶各向异性和磁致伸缩系数有重要的影响。减小体心立方α-Fe纳米颗粒的晶粒尺寸会显著降低纳米晶Fe基合金的平均磁晶各向异性,这是因为纳米晶Fe基合金中畴壁厚度超过体心立方α-Fe纳米颗粒的晶粒尺寸,所以畴壁钉扎对在晶粒尺寸范围内的磁晶各向异性振荡没有明显影响。因非晶Fe基基体具有大的磁致伸缩系数,所以为了获得接近0的磁致伸缩系数,就要求体心立方α-Fe纳米颗粒的体积分数尽可能大,以抵消非晶Fe基基体大的磁致伸缩系数。因此,减小体心立方α-Fe纳米颗粒的晶粒尺寸和提高其体积分数可以降低纳米晶Fe基合金的平均磁晶各向异性和磁致伸缩系数,从而改善其软磁性能。

非晶晶化由形核和长大2个步骤组成,其晶化过程决定于形核速率和晶粒长大速率[1, 9]。提高形核速率和降低晶粒长大速率有利于获得晶粒尺寸细小的纳米晶颗粒,而要获得高的纳米颗粒的体积分数则需要高的形核速率和大的晶粒长大速率。因此,提高形核速率是减小纳米颗粒的晶粒尺寸和提高其体积分数最有效的方法。因形核速率和长大速率主要决定于晶化温度,而非晶合金常规的晶化工艺是在某一固定温度下进行,所以其形核速率和晶粒长大速率往往是固定的。

本文作者研究了在晶化前的高温短时间预退火对非晶Fe86Zr7B6Cu1合金晶化过程的影响,以期为人们提供一种优化纳米晶材料的显微组织和改善其软磁性能的方法。

1 实验

采用单辊快淬的方法制备非晶Fe86Zr7B6Cu1条带,其厚度约为20 mm,宽度约为1 mm。利用DSC测得其晶化温度为546 ℃。

非晶Fe86Zr7B6Cu1合金的晶化过程采用预退火加常规退火相结合的方法。预退火工艺为在600、650、700、750和800 ℃中的一个温度保温2 min后空冷到室温。常规退火工艺为在600 ℃保温1 h后随炉冷却。Suzuki等[10?11]的研究表明,在600 ℃保温1 h后随炉冷却是非晶Fe86Zr7B6Cu1合金最优的常规退火工艺。

利用XRD的方法对纳米晶Fe86Zr7B6Cu1合金进行相结构分析。体心立方α-Fe纳米颗粒的晶粒尺寸采用Scherrer公式,利用α-Fe相(110)衍射峰的半高宽进行计算。在分析退火试样的XRD衍射谱时,利用Hindeleh方法,将结晶α-Fe相的衍射峰从非晶基体的衍射峰中分离出来[12]。结晶α-Fe相体积分数φc的计算公式为[12]

利用HP4284A阻抗分析仪对退火后的试样进行磁谱测量,测量磁谱时采用的外加交流磁场强度为0.2,0.4,2和5 A/m,测量的频率范围为100 Hz~1 MHz。为了测量退火试样的磁谱,将非晶条带绕成内径为5 mm,外径为6.5 mm的环形样品后进行退火。

2 实验结果

2.1 预退火对显微组织的影响

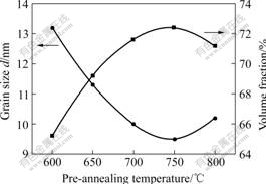

非晶Fe86Zr7B6Cu1合金经预退火加常规退火后的X射线衍射谱如图1所示。退火后的试样中含有体心立方的结晶相和尚未结晶的非晶相基体。具有体心立方的结晶相为α-Fe相。从图1可以看出,结晶α-Fe相的衍射峰具有宽化现象,退火试样的衍射峰宽化主要是因为晶粒细化引起的。对比不同的X射线衍射谱可以发现(110)衍射峰的半高宽随预退火温度的改变而改变。当预退火温度从600 ℃增加到750 ℃时,结晶α-Fe相的(110)衍射峰的半高宽变得越来越宽,但预退火温度提高到800 ℃时,结晶α-Fe相的(110)衍射峰的半高宽变窄。将结晶α-Fe相的(110)衍射峰的半高宽代入Scherrer公式可以计算出结晶α-Fe相的晶粒尺寸,计算结果如图2所示。当预退火温度从600 ℃增加到750 ℃时,结晶α-Fe相的晶粒尺寸由13.2 nm减小到9.5 nm,但预退火温度提高到800 ℃时,结晶α-Fe相的晶粒尺寸增大到10.2 nm。

图1 非晶Fe86Zr7B6Cu1合金经预退火加常规退火后的X射线衍射谱

Fig.1 X-ray diffraction patterns of ribbons annealed at 600 ℃ for 1 h after pre-annealed at 600?800 ℃ for 2 min

图2 预退火温度对结晶α-Fe晶粒尺寸和体积分数的影响

Fig.2 Dependences of grain size and volume fraction of crystalline α-Fe phase on pre-annealing temperature

利用式(1)可以计算出结晶α-Fe相的体积分数,计算结果如图2所示。当预退火温度从600 ℃增加到750 ℃时,结晶a-Fe相的体积分数由65.2%增加到72.4%,但预退火温度增加到800 ℃时,结晶α-Fe相的体积分数反而会减少到71.2%。

对试样显微组织分析结果表明,适当的预退火可以控制非晶合金的晶化过程和优化纳米晶材料的显微组织。

2.2 预退火对软磁性能的影响

退火试样的磁谱曲线如图3所示。磁谱显示出典型的弛豫型特性。在低频时,μ′基本上保持不变,频率升高后发生弛豫,μ″峰值对应的频率为弛豫频率。由于测量磁场很小,因此所测的磁导率值μ′可近似地认为与初始磁导率相等。根据畴壁钉扎模型,当外加磁场低于钉扎场时,畴壁被钉扎在缺陷处,畴壁只随外磁场在其平衡位置附近振动。当频率低时,这种振动过程是可逆的,即在低频情况下,磁导率与频率无关。而当频率增加到一定程度时,由于畴壁的振动跟不上外磁场的变化,从而发生弛豫。在600 ℃退火1 h后的试样的实数磁导率和弛豫频率分别为1.2×104和2.5×105 Hz,而经750 ℃保温2 min后再在600 ℃退火1 h后的试样的实数磁导率和弛豫频率分别为3.1×104和9.5×104 Hz。对退火试样的磁谱测量结果表明,适当的预退火可以改善纳米晶软磁材料的软磁性能。

图3 退火试样的磁谱曲线

Fig.3 Complex permeability spectra of annealed ribbons: (a) Annealed at 600 ℃ for 1 h; (b) Pre-annealed at 750 ℃ for 2 min followed by annealing at 600 ℃ for 1 h

3 讨论

非晶合金的结晶是结晶相的形核和长大过程。依据经典的形核长大理论,结晶相的晶粒尺寸和体积分数决定于形核速率和晶粒长大速率。结晶α-Fe相的晶粒尺寸由形核速率和晶粒长大速率的比值决定,大的形核速率和小的晶粒长大速率会降低结晶α-Fe相的晶粒尺寸。结晶相的体积分数φc的表达式为[9, 13]

由式(2)可见,结晶相的体积分数随形核速率和晶粒长大速率的增大而增大。因此,提高形核速率不仅可以细化结晶相的晶粒尺寸,而且可以提高结晶相的体积分数。

均匀形核时的形核速率表达式为[14?15]

由式(3)可知,形核速率与DGa和DGk有关。DGa随温度的升高而增大。

由式(4)可知,当温度从Tm往下降低时,DGk不断增加。当退火温度由晶化温度增加到熔点时,形核速率与温度的关系如图4所示。当退火温度由晶化温度增加到Ta时,形核速率增加到极大值,然后随着温度的继续增加而不断减少。

晶粒长大速率的表达式为[14?15]

由式(5)可知,晶粒长大速率与DGa和Dg 有关。晶粒长大速率与温度的关系如图4所示。当退火温度由晶化温度增加到Tb时,形核速率增加到极大值,然后随着温度的继续增加而不断减少。当温度由晶化温度开始增加时,形核速率的增长速度大于晶粒长大速率,因此图4中的Ta小于Tb[14]。实验结果表明,当预退火温度为750 ℃时,结晶α-Fe相的晶粒尺寸达到极小值,其体积分数达到极大值,因此图4中的Ta应当约为750 ℃。

图4 形核速率和晶粒长大速率与温度的关系

Fig.4 Temperature dependences of nucleation rate and grain growth rate

预退火对非晶Fe86Zr7B6Cu1合金晶化过程的影响机制可以通过分析温度对形核速率和晶粒长大速率的影响规律进行研究。预退火影响非晶Fe86Zr7B6Cu1合金晶化过程主要是因为高温短时间预退火会引起晶化开始阶段形核速率的变化,而晶化开始阶段形核速率对非晶合金的结晶过程具有决定性的作用。提高晶化开始阶段的形核速率是获得具有细小晶粒尺寸和大的体积分数的显微组织的有效方法[14]。采用预退火加常规退火的工艺对非晶合金进行处理时,其形核速率主要是由预退火决定的,而晶粒长大速率主要由常规退火决定。当预退火温度为750 ℃时,可以获得具有细小晶粒尺寸和大的体积分数的显微组织正是750 ℃预退火产生的高形核速率和600 ℃常规退火时低的晶粒长大速率相结合的结果。当预退火温度超过Ta时,提高预退火温度会引起形核速率的降低,所以在800 ℃保温2 min引起结晶α-Fe相晶粒尺寸的增大和其体积分数的降低。

对晶化试样的磁谱测量(图3)也表明,经750 ℃保温2 min后再在600 ℃退火1 h后的试样比常规退火得到的试样具有更为优良的软磁性能。因此,预退火工艺也许提供了一种优化纳米晶材料的显微组织和改善其软磁性能的方法。

4 结论

1) 在常规退火前的高温短时间预退火对非晶Fe86Zr7B6Cu1合金晶化过程具有显著的影响。当预退火温度从600 ℃增加到750 ℃时,结晶α-Fe相的晶粒尺寸由13.2 nm减小到9.5 nm,但预退火温度增加到800 ℃时,结晶α-Fe相的晶粒尺寸增大到10.2 nm。当预退火温度从600 ℃增加到750 ℃时,结晶α-Fe相的体积分数由65.2%增加到72.4%,但预退火温度增加到800 ℃时,结晶α-Fe相的体积分数反而会减少到71.2%。

2) 经750 ℃保温2 min后再在600 ℃退火1 h后的试样比常规退火得到的试样具有更为优良的软磁性能。因此,预退火工艺也许为我们提供了一种优化纳米晶材料的显微组织和改善其软磁性能的方法。

REFERENCES

[1] McHenry M E, Willard M A, Laughlin D E. Amorphous and nanocrystalline materials for application as soft magnets[J]. Prog Mater Sci, 1999, 44: 291?433.

[2] Hasegawa R. Present status of amorphous soft magnetic alloys[J]. J Mag Mag Mater, 2000, 215/216: 240?245.

[3] Tang J C, Liu W S, He Y H, et al. Effect of biasing magnetic field on the complex permeability of nanocrystalline Fe86Zr7B6Cu1 alloy[J]. Phy B, 2007, 389: 343?346.

[4] Tang J C, Li S D, Mao X Y, Du Y W. Effect of electric field on the crystallization process of amorphous Fe86Zr7B6Cu1 alloy[J]. J Phy D: Appl Phy, 2005, 38(5): 729?732.

[5] Tang J C, Wu A H, Mao X Y, Li S D, Gao W L, Du Y W. Effects of hot isothermal pressing on the microstructures and soft magnetic properties of nanocrystalline Fe86Zr7B6Cu1 ribbons[J]. J Phy D: Appl Phy, 2004, 37: 151?154.

[6] 彭 坤, 成奋强, 胡爱平, 唐元洪. 双层复合材料的软磁性能[J]. 中国有色金属学报, 2004, 14(7): 1129?1132.

PENG Kun, CHENG Fen-qiang, HU Ai-ping, TANG Yuan-hong. Magnetic properties of Fe-based bilayer composite materials[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(7): 1129?1132.

[7] Tang J C, Mao X Y, Li S D, Gao W L, Du Y W. Effects of two-step heat treatment on the microstructures and soft magnetic properties of nanocrystalline Fe86Zr7B6Cu1 ribbons[J]. J Alloys Compd, 2004, 375: 233?236.

[8] Lu K. Nanocrystalline metals crystallized from amorphous solids: nanocrystallization, structure, and properties[J]. Mater Sci Eng R, 1996, R 16: 161?221.

[9] Suzuki K, Herzer G, Cadogan J M. The effect of coherent uniaxial anisotropies on the grain size dependence of coercivity in naonocrystalline soft magnetic alloys[J]. J Mag Mag Mater, 1998, 177/181: 949?950.

[10] Tang J C, Zhou L, Tan D Q, Du Y W. Crystallization process of amorphous Fe86Zr7B6Cu1 alloy under hot isothermal pressing[J]. J Alloys Comp, 2005, 394: 215?218.

[11] Huang S. Structure and structure analysis of amorphous materials[M]. Oxford: Oxford Publishing/Clarendon Press, 1984: 48?56.

[12] Porter D, Easterling K. Phase transformation in metals and alloys[M]. New York: Van Nostrand Reinhold Publishing House, 1981: 263?268.

[13] 冯 端, 师昌绪, 刘治国. 材料科学导论[M]. 北京: 化学工业出版社, 2002: 555?574.

FENG Duan, SHI Chang-xu, LIU Zhi-guo. Introduction of materials Sciences[M]. Beijing: Chemical Industry Press, 2002: 555?574.

[14] Liu W S, Tang J C, Huang B Y, Du Y W. Electric-enhanced crystallization of amorphous Fe86Zr7B6Cu1 alloy[J]. J Alloys Comp, 2006, 420: 171?174.

收稿日期:2007-03-06;修订日期:2007-06-18

通讯作者:唐建成,教授,博士;电话:0791-6053590;E-mail: jchtangcn@yahoo.com.cn

(编辑 陈爱华)