DOI: 10.11817/j.ysxb.1004.0609.2021-36531

稀土钇对铸态Mg-8Li-3Al-3Zn合金显微组织和力学性能的影响

宋文杰1,董会萍1,刘 洁1,张 光2,刘延辉1

(1. 陕西科技大学 机电工程学院,西安 710021;

2. 西北工业大学 航空学院,西安 710072)

摘 要:镁锂(Mg-Li)合金是现今最轻的金属结构材料,在航空航天及交通运输等领域具有重大的应用价值。但铸造镁锂合金绝对强度低限制了其发展和应用。在Mg-Li二元合金中添加铝(Al)、锌(Zn)和稀土元素钇(Y)三种强化元素制备Mg-Li-Al-Zn-Y五元铸态镁锂合金来提高镁锂合金的力学性能。利用X射线衍射仪(XRD)、扫描电子显微镜(SEM)和力学性能测试对比研究添加稀土Y前后铸态Mg-8Li-3Al-3Zn合金中相组成、微观组织和力学性能,揭示稀土元素Y对铸态Mg-8Li-3Al-3Zn合金的增强机制和断裂机理。结果表明:铸态Mg-8Li-3Al-3Zn合金主要包含3种相:基体α-Mg、第二相AlLi和MgLi2Zn。添加1.0%(质量分数)Y后,铸态镁锂合金中AlLi相消失,并析出了大量富集在α-Mg晶界处的硬质Al2Y相,合金的晶粒发生细化。与Mg-8Li-3Al-3Zn(抗拉强度134.40 MPa、屈服强度96.46 MPa和伸长率7.5%)相比,Mg-8Li-3Al-3Zn-1Y抗拉强度、屈服强度和伸长率依次为189.99 MPa、128.2 MPa和7.8%,分别提高了41.4%、32.9%和4%。合金的断裂方式由解理断裂转变为准解理断裂。铸态镁锂合金力学性能的提高主要归因于Al2Y的形成及其对α-Mg相的细化作用。

关键词:镁锂合金;稀土钇;显微组织;力学性能;增强机制

文章编号:1004-0609(2021)-01-0001-08 中图分类号:TG292 文献标志码:A

引文格式:宋文杰, 董会萍, 刘 洁, 等. 稀土钇对铸态Mg-8Li-3Al-3Zn合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2021, 31(2): 1-8. DOI: 10.11817/j.ysxb.1004.0609.2021-36531

SONG Wen-jie, DONG Hui-ping, LIU Jie, et al. Effect of Y on microstructure and mechanical properties of as-cast Mg-8Li-3Al-3Zn alloy[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(2): 1-8. DOI: 10.11817/j. ysxb.1004.0609.2021-36531

镁锂(Mg-Li)合金是迄今为止最轻的金属结构材料,其密度仅为1.30~1.65 g/cm3。同时,镁锂合金具有较高的比强度和比刚度、优异的减震性能、良好的切削加工性能及抗电磁干扰等诸多优势,因此,被广泛应用在航空航天、武器装备、交通运输和电子产品等众多领域[1]。我国研制的一种新型军机吊舱采用镁锂合金材料制造,相对于铝合金质量减轻了46%[2]。然而,铸造镁锂合金绝对强度不高、塑性差是其大规模应用与发展的主要瓶颈。因此,如何实现铸造镁锂合金强韧化成为轻质结构材料亟待解决的基础问题。

目前,国内外提高镁锂合金抗拉强度的方法主要包括多元合金化[3-5]、变质处理[6]、冷轧和时效处理[7-9]、挤压[10]等。冷轧和挤压等变形方式明显提高了镁锂合金的强度,但这种变形加工方式很难应用在具有结构复杂的铸造镁锂合金件中。改善铸造镁锂合金强度和塑性的关键是获得更加细小稳定的晶粒和弥散分布的第二相。多元合金化是改善Mg-Li合金性能的常用方法。通过在镁锂合金中添加其他合金元素,使其产生稳定的金属间化合物。其中,Mg-Li-Al、Mg-Li-Zn和Mg-Li-RE系是近几年来研究热度较高的镁锂合金体系[11]。

铝(Al)在Mg中的固溶度高达12.5%,存在固溶强化的可能性。此外,Al的密度为2.7 g/cm3,添加Al后,Mg-Li合金的整体密度变化较小,且易与Mg形成Mg17Al12、MgLi2Al和AlLi等第二相实现析出强化。SINGH等[12]研究不同含量的Al对α相Mg-Li合金显微组织和力学性能的影响。结果表明Al元素的加入极大地细化了铸造Mg-Li合金的晶粒,且合金的晶粒尺寸与Al的含量呈负相关趋势。另外由于Al的加入,合金中析出了Mg17Al12、AlLi、Al3Li等第二相,晶粒的细化及第二相的存在协同提高了合金的强度。PARK等[13]研究了轻质元素Al对β相Mg-15Li合金组织和力学性能的影响,随着Mg-15Li合金中Al含量从0增加到5%(质量分数),镁锂合金中形成了AlLi金属间化合物,同时合金中β相的晶粒尺寸从250 μm减小到51 μm,力学性能也得到了明显的提高,这主要归因于Al的加入形成的第二相和细晶强化作用。

同样的,锌(Zn)也是Mg-Li合金中研究较广泛的强化元素之一,Zn与Mg同为密排六方结构,Zn的加入对合金伸长率影响不大。在力学性能方面,韩国工业技术研究院KIM等[5]在Mg-11Li合金中添加了Zn,形成Mg2Zn3Li第二相,合金的抗拉强度和伸长率分别为217 MPa和42%。于爽[14]研究了Mg-7Li、Mg-7Li-3Zn-6Y和Mg-3Zn-6Y三种合金,通过对比研究发现在镁锂合金中同时添加Zn、Y后,Mg-7Li-3Zn-6Y合金的晶粒明显细化,平均晶粒尺寸低于5 μm,抑制了合金的塑性不稳定现象。以上结果均表明,Zn既可以与基体合金元素形成MgLi2Zn、Mg2Zn3Li等第二相对合金实现析出强化,又可以通过细化晶粒改善合金的力学性能。

稀土元素钇(Y)能够与Mg-Li合金形成Al2Y或Al3Y等多种高熔点金属间化合物,能大幅度改善合金的铸造力学性能。PENG等[15]研究了Y对Mg-9Li-3Al合金微观组织、力学性能的影响。结果表明,Y的加入可以改变α相的微观结构形貌,降低其体积分数,同时可以形成主要分布在β相内的Al2Y相,有效地改善了合金的力学性能。当添加1.6%Y(质量分数)时,合金的抗拉强度达到最佳,高达190 MPa;当Y含量为2%(质量分数)时,合金的伸长率达到19.3%。此外,Y的加入能促进Mg-Li合金晶粒细化,改变基体相形貌,提高合金高温强度。袁亲松等[16]研究了Mg-8Li-xY(x = 0, 2, 4, 6, 8, 10,质量分数,%)合金的显微组织和力学性能。结果表明,Y的加入细化了α-Mg的尺寸使其形态由长条状变为粒状,并生成弥散分布的网状Mg24Y5相。在合金拉伸的过程中,晶界处弥散分布的Mg24Y5相起到钉扎晶界的作用,在一定程度上提高了合金的抗拉强度。Y的含量为4%(质量分数)时,合金的综合力学性能最优。综上可知,在Mg-Li合金中加入Y,可以通过细晶强化和析出强化(第二相)两种方式来共同提高合金的力学性能。然而以上研究主要集中于Mg-Li合金中单一强化元素的添加,有关加入3种及以上强化元素的五元合金体系尚未引起人们的广泛关注。

本文研究的Mg-8Li合金在Mg-Li二元合金相图中处于α+β双相区域,具有较高的强度和良好的塑性。Al和Zn被用作Mg-8Li合金中固溶强化和析出强化的元素,形成Mg-Li-Al-Zn多元系铸态镁锂合金。此外,稀土元素Y的加入可以进一步优化合金的力学性能。因此,Mg-8Li-3Al-3Zn-xY(x = 0, 1, %,质量分数)合金在氩气和覆盖剂双重保护下浇铸制备。并对上述合金的显微组织和力学性能进行了系统性的研究,探讨了稀土Y的添加对铸态Mg-8Li-3Al-3Zn合金的增韧机制,为后续Mg-Li双相铸态合金抗拉强度的提高及其在航空航天、武器装备、电子产品和轨道交通等领域的应用提供一定的理论和技术支持。

1 实验

本实验所用原料为镁(99.9%)、铝(99.9%)、锌(99.9%)、Mg-30Y和中间合金LA141。合金成分如表1所示。实验合金通过HCXJ-13高温电阻炉在覆盖剂和氩气保护下熔炼浇铸得到。熔炼温度为700~750 ℃。在700 ℃保温5 min后,将合金熔液迅速浇铸到长方形钢制模具中使得合金熔液迅速凝固,待完全冷却后将合金锭从模具中取出,合金锭经砂纸打磨抛光后放入手套箱中保存,防止氧化。

采用X射线衍射仪(XRD,D/max-2500pc)分析了铸态镁锂合金的相组成,工作电压和电流分别为40 kV和20 mA,扫描速度7 (°)/min,扫描范围10°~80°;采用扫描电镜(SEM,JOELJSM6460LV)和能谱仪(EDS)对铸态镁锂合金进行显微组织和成分分析;采用电子万能拉伸试验机进行拉伸试验,拉伸速度为1 mm/min(拉伸试样见图1)。

表1 设计的合金成分

Table 1 Designed compositions of as-cast alloys

图1 拉伸试样示意图

Fig. 1 Schematic diagram of tensile specimen (Unit: mm)

2 结果与分析

2.1 Y对铸态Mg-8Li-3Al-3Zn合金显微组织的影响

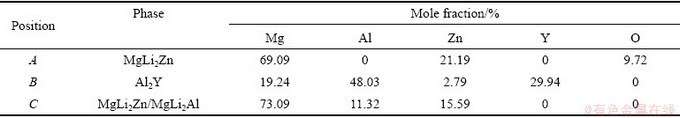

图2和3所示分别为铸态Mg-8Li-3Al-3Zn-xY (x = 0, 1,质量分数,%) 合金的XRD和SEM分析结果。结果表明,在未添加Y之前,合金晶粒尺寸较粗大且白色析出物较少,析出物呈现块状或针状。结合表2的EDS能谱分析得到(Li元素在EDS中不能被检测到)白色析出物为MgLi2Zn相。因此,铸态合金主要由基体相α-Mg、AlLi和白色骨状MgLi2Zn相组成。当 w(Zn)>2%时,根据Mg-Li-Zn三元合金相图可知,在Mg-Li合金中易形成第二相MgLi2Zn。MgLi2Zn相一般呈现为短蠕虫状,且为亚稳态强化相,可以提高镁锂合金的强度,但其在时效处理后容易粗化且转变为稳定相(MgLiZn),影响合金的力学性能[17]。另外,Zn可以提高镁锂合金的抗蠕变能力,原因是Zn主要固溶于合金基体中,可以产生固溶强化的效果,且其对合金塑性的影响低于Al元素。

XRD表明在Mg-8Li-3Al-3Zn合金中添加Y后会导致Al2Y相的形成和AlLi相的消失。SEM结果印证了这一现象,从SEM观察到合金晶界或晶粒内出现了大量骨状或颗粒状的白色析出物,结合表2的EDS能谱分析可知,骨状白色析出物中Al和Zn的原子占比相近,分别为11.32%和15.59%(摩尔分数)。从文献中得知,当Al含量在3%左右时,在Mg-Li合金中易形成MgLi2Al和AlLi相,其中MgLi2Al相为亚稳态强化相,可以提高镁锂合金的强度[12]。同样的,Zn元素既能以固溶态存在于合金中,又可以与Mg和Li元素形成亚稳态相MgLi2Zn。因此考虑到Al和Zn元素在Mg中的固溶度相差不大,且EDS中Al和Zn的摩尔比接近,因此,判断此相为MgLi2Al/MgLi2Zn。白色不规则颗粒状为Al2Y相。因此,铸态合金相组成主要是基体α-Mg、MgLi2Zn/MgLi2Al和Al2Y相。

Al2Y大量富集在合金的晶界处,仅有少量分布在α-Mg基体内。Y是一种表面活性较高的元素,容易与其他合金元素结合,从而增加形核位点。加入Y后,根据Al-Y二元相图[18],Al和Y易形成金属间化合物Al2Y或Al3Y,Al2Y的熔点为1455 ℃,因此在合金凝固过程中Al2Y首先从合金液中析出且富集在初生相晶界周围,这样优先析出的Al2Y会阻碍其他晶粒的长大,从而造成晶粒细化。在图3(a)和(c)中,并不能观察到明显的晶界,可以根据分布在晶界处的第二相颗粒和晶界不同的图像衬度来估算晶粒尺寸。图3(a)中的晶粒尺寸较大,晶粒尺寸>500 μm。图3(c)的晶粒尺寸约为100~200 μm,加入Y后晶粒得到明显细化。根据Hall-Perch公式得知晶粒的减小可以提高合金的强度。此外,Al与Y的结合消耗了大量Al元素,因此在一定程度上也减少了AlLi相的析出,有益于提高合金的力学性能。

图2 铸态合金Mg-8Li-3Al-3Zn-xY (x = 0, 1)的XRD谱

Fig. 2 XRD patterns of as-cast Mg-8Li-3Al-3Zn-xY (x = 0, 1) alloys

图3 铸态镁锂合金的SEM像

Fig. 3 SEM image of as-cast Mg-Li alloys

表2 铸态镁锂合金Mg-8Li-3Al-3Zn-xY (x = 0, 1) 能谱分析结果

Table 2 EDS results of each phase in as-cast Mg-8Li-3Al-3Zn-xY (x = 0, 1) alloy

2.2 Y对铸态Mg-8Li-3Al-3Zn合金力学性能的影响

图4所示为铸态镁锂合金Mg-8Li-3Al-3Zn-xY (x=0, 1)的真应力-应变曲线图。图5所示为铸态Mg-8Li、Mg-8Li-3Al-3Zn及Mg-8Li-3Al-3Zn-1Y合金抗拉强度和屈服强度的对比。结合图4和5可知,未添加Y时,铸态Mg-8Li-3Al-3Zn的抗拉强度为134.40 MPa,屈服强度为96.46 MPa;与PUGAZHENDHI等[19]在常温下测定的铸态Mg-8Li的力学性能相比,Al和Zn的加入使合金的抗拉强度从103 MPa增长到134.40 MPa,屈服强度从63 MPa增长到96.46 MPa。强化元素Al和Zn的加入明显的提高了Mg-8Li合金的抗拉强度和屈服强 度。但Al和Zn的加入会形成脆性相,因此使合金的伸长率从14.0%降为7.5%。本文在加入Al和Zn的基础上再添加1% Y(质量分数)后,铸态Mg-8Li-3Al-3Zn-Y合金的抗拉强度和屈服强度分别为189.99 MPa和128.2 MPa,合金的抗拉强度、屈服强度再次提高了41.4%、32.9%。此外,稀土Y的加入,使合金的伸长率增长为7.8%,较之前略有改善。

Y的添加一方面大幅度提高了合金的抗拉强度和屈服强度。归因于Y与Al元素之间大的电负性差值优先形成的Al2Y相,大量的Al被Y消耗,AlLi相逐渐被Al2Y相取代。研究表明[20],AlLi相为软化相,Al2Y相为热稳定性较高的强化相,当Y含量较低时,Al2Y相主要弥散分布在晶界处,在塑性变形时对晶粒起到钉扎作用,同时,阻碍位错运动起到屏障作用。

另一方面Y的添加在一定程度上改善了合金的塑性。推测是Y元素的加入弱化了合金α-Mg相的基面织构,促进 锥面滑移系的启动,有助于协调合金沿c轴方向的变形,从而改善合金的延展性[21]。另外,晶粒越细小,拉伸时变形会分散在更多的晶粒内进行,在一定程度上保障了合金的塑性。但可能是由于第二相颗粒主要分布在主相的晶界处,导致拉伸过程中割裂基体相,对合金塑性不利。因此,综合两方面因素,添加Y后合金的塑性仅有少量提高。

锥面滑移系的启动,有助于协调合金沿c轴方向的变形,从而改善合金的延展性[21]。另外,晶粒越细小,拉伸时变形会分散在更多的晶粒内进行,在一定程度上保障了合金的塑性。但可能是由于第二相颗粒主要分布在主相的晶界处,导致拉伸过程中割裂基体相,对合金塑性不利。因此,综合两方面因素,添加Y后合金的塑性仅有少量提高。

图4 铸态镁锂合金的真应力-应变曲线对比

Fig. 4 Comparison of true stress-strain curves of as-cast Mg-Li alloys

图5 铸态Mg-8Li、Mg-8Li-3Al-3Zn及Mg-8Li-3Al- 3Zn-1Y合金的抗拉强度和屈服强度的对比

Fig. 5 Comparison of tensile and yield strength of as-cast Mg-8Li, Mg-8Li-3Al-3Zn and Mg-8Li-3Al-3Zn-1Y alloys

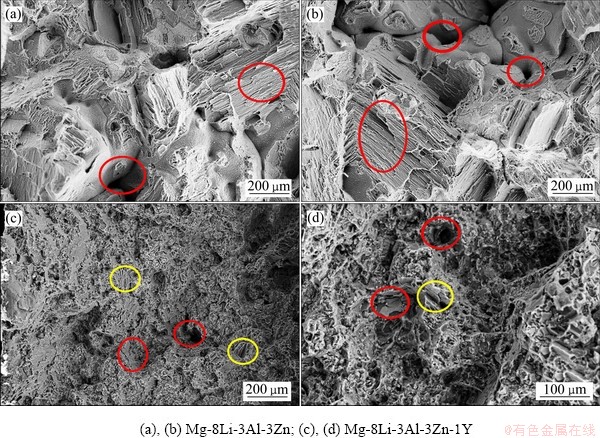

2.3 断口形貌分析

图6所示为铸态镁锂合金的断口形貌。图6(a)和(b)所示分别为Mg-8Li-3Al-3Zn铸态合金断口形貌。合金断口呈现明显的解理大平面和铸造缺陷(红圈),是典型的解理断裂。解理断裂通常情况下是宏观的脆性断裂,脆性断裂伴随着低的伸长率,因此合金的伸长率从14.0%降至7.5%。造成脆性断裂的原因可能是合金的晶粒尺寸粗大或合金内部存在宏观的裂纹源[22]。

图6(c)和(d)所示分别为Mg-8Li-3Al-3Zn-1Y铸态合金断口形貌。合金断口存在大量的解理小平面、缺陷(红圈)和撕裂棱(黄圈),是典型的准解理断裂,这是一种介于解理断裂和韧窝断裂之间的一种过渡断裂的形式。合金发生准解理断裂时,其内部不同部位会产生解理裂纹源,随后在拉伸过程中扩展成一个一个的小解理平面,且周围会存在较多的撕裂棱。准解离断裂发生可归因于晶粒尺寸较大或铸造合金中存在缩松缩孔等缺陷[23]。

3 增强机制

3.1 析出强化

析出强化本质上就是第二相强化,在本文中将稀土元素Y添加到Mg-8Li-3Al-3Zn中,铸态合金析出了高熔点、高硬度的Al2Y相。Al2Y相在合金凝固过程中富集在晶界处,在之后合金的拉伸过程中,阻碍位错运动以提高合金的抗变形能力。同时,还可以消耗合金中的Al,减少了软化相AlLi的析出。因此,添加稀土元素Y后合金的强度得到较大提升。

3.2 细晶强化

通常在Mg-Li多元系中合金晶粒细化存在两种可能的机理:一是合金凝固过程中添加的稀土元素可以形成第二相并作为α-Mg基体的异质形核核心,通过增加形核率来细化晶粒;二是在合金凝固过程中,形成第二相富集在晶界周围,阻碍其他相的长大,起到细化晶粒的作用[24]。

图6 铸态镁锂合金的断口形貌

Fig. 6 Fracture morphologies of as-cast Mg-Li alloys

一般新生相能够满足在基体上形核的要求是各自的低指数晶面之间的失配度要小于15%。已知Al2Y为FCC结构,a=0.7885 nm,(100)面、(110)面和(111)面是其低指数面,α-Mg的低指数面为(0001)面。宋晓杰[25]将以上参数代入到Bramfitt失配度计算公式[26]得出Al2Y相与α-Mg基体相之间的失配度已经超过了15%,所以Al2Y作为α-Mg的异质形核核心细化晶粒的机理不成立。因此,在合金凝固的过程中,液相中首先生成α-Mg相,稀土元素Y被排挤到固/液界面前沿发生偏析,并与Al形成高温硬化相Al2Y且其弥散分布在α-Mg的晶界处,阻碍了合金中后续生成相的长大,从而起到细化晶粒的作用。

4 结论

1) 铸态Mg-8Li-3Al-3Zn合金主要由基体α-Mg及析出相AlLi和MgLi2Zn相组成,加入1% Y(质量分数)后,铸态镁锂合金AlLi相消失,形成大量白色颗粒状Al2Y相,合金的晶粒发生细化。

2) Mg-8Li-3Al-3Zn-1Y与Mg-8Li-3Al-3Zn (抗拉强度134.40 MPa、屈服强度96.46 MPa和伸长率7.5%) 相比,其抗拉强度、屈服强度和伸长率分别为189.99 MPa、128.2 MPa和7.8%,分别提高了41.4%、32.9%和4%。断裂方式由解理断裂转变为准解理断裂,有向韧性断裂发展的趋势。

3) 添加1% Y(质量分数)后,铸态Mg-8Li-3Al- 3Zn合金主要的强化机制为细晶强化和析出强化(第二相),两者协同作用明显改善了铸态合金的力学性能。

REFERENCES

[1] HAFERKAMP H, NIEMEYER M, BOEHM R, et al. Development, processing and applications range of magnesium lithium alloys[J]. Materials Science Forum, 2000, 350/351: 31-42.

[2] 王祝堂. 中国军机吊舱首次用国产Mg-Li合金制造[J]. 轻合金加工技术, 2018, 46(1): 48-48.

WANG Zhu-tang. Chinese military aircraft pods first made of domestic Mg-Li alloy[J]. Light Alloy Fabrication Technology, 2018, 46(1): 48-48.

[3] PENG X, WU G H, XIAO L, et al. Effects of Ce-rich RE on microstructure and mechanical properties of as-cast Mg-8Li-3Al-2Zn-0.5Nd alloy with duplex structure[J]. Progress in Natural Science(Materials International), 2019, 29(1): 103-109.

[4] GUO J, CHANG L L, ZHAO Y R, et al. Effect of Sn and Y addition on the microstructural evolution and mechanical properties of hot-extruded Mg-9Li-3Al alloy[J]. Materials Characterization, 2019, 148: 35-42.

[5] KIM J H, KIM Y H, YOO H S, et al. Effects of Zn and Ca additions on microstructure and mechanical properties of Mg-11Li based alloys[J]. Journal of Nanoscience And Nanotechnology, 2016, 16(11): 11233-11237.

[6] KROL M. Effect of grain refinements on the microstructure and thermal behaviour of Mg-Li-Al alloy[J]. Journal of Thermal Analysis & Calorimetry, 2018, 133(1): 237-246.

[7] JI H, PENG X, ZHANG X L, et al. Balance of mechanical properties of Mg-8Li-3Al-2Zn-0.5Y alloy by solution and low- temperature aging treatment[J]. Journal of Alloys and Compounds, 2019, 791: 655-664.

[8] ZHAO J, LI Z Q, LIU W C, et al. Influence of heat treatment on microstructure and mechanical properties of as-cast Mg-8Li-3Al-2Zn-xY alloy with duplex structure[J]. Materials Science and Engineering A, 2016, 669: 87-94.

[9] WU S K, WANG J Y, LIN K C, et al. Effects of cold rolling and solid solution treatments on mechanical properties of β-phase Mg-14.3Li-0.8Zn alloy[J]. Materials Science and Engineering A, 2012, 552(9): 76-80.

[10] 崔崇亮, 刘旭贺, 吴立斌, 等. 挤压变形态Mg-5Li-3Al-2Zn-xY合金的显微组织和力学性能[J]. 稀有金属材料与工程, 2013, 42(1): 89-93.

CUI Chong-liang, LIU Xu-he, WU Li-bin, et al. Microstructure and mechanical properties of as-extruded Mg-5Li-3Al-2Zn-xY alloy[J]. Rare Metal Materials and Engineering, 2013, 42(1): 89-93.

[11] 郑晓东, 董天顺, 王 拓, 等. Mg-Li合金研究现状及其发展趋势[J]. 轻合金加工技术, 2017, 45(2): 6-11.

ZHENG Xiao-dong, DONG Tian-shun, WANG Tuo, et al. Research status and development prospects of Mg-Li alloy[J]. Light Alloy Fabrication Technology 2017, 45(2): 6-11.

[12] SINGH P B, SABAT R K, KUMARAN S, et al. Effect of aluminum addition on the evolution of microstructure, crystallographic texture and mechanical properties of single phase hexagonal close packed Mg-Li alloys[J]. Journal of Materials Engineering And Performance, 2018, 27(2): 864-874.

[13] PARK G H, KIM J T, PARK H J, et al. Development of lightweight MgLiAl alloys with high specific strength[J]. Journal of Alloys & Compounds, 2016, 680:116-120.

[14] 于 爽. Mg-Li-Zn-Y合金的组织与性能研究[D]. 沈阳: 沈阳航空航天大学, 2017.

YU Shuang. The research of microstructure and mechanical properties of Mg-Li-Zn-Y alloy[D]. Shenyang: Shenyang Aerospace University, 2017.

[15] PENG X D, LI J C, LI W J, et al. Effect of Y on microstructure and mechanical properties as well as corrosion resistance of Mg-9Li-3Al alloy[J]. Rare Metal Materials & Engineering, 2013, 42(10): 1993-1998.

[16] 袁亲松, 赵 平, 赵 亮. Y对铸态Mg-Li合金显微组织和力学性能的影响[J]. 铸造, 2009, 58(5): 494-497.

YUAN Qin-song, ZHAO Ping, ZHAO Liang. Effect of Y on as-cast microstructure and mechanical properties of Mg-Li alloy[J]. Foundry, 2009, 58(5): 494-497.

[17] LIU D Y, MA Y L, LI J F, et al. The influence of Zn addition on microstructure of an Al-1.7 Cu-4.0 Li-0.4 Mg alloy[J]. Journal of Materials Research and Technology, 2020.

[18] LIU S H, DU Y, XU H H, et al. Experimental investigation of the Al-Y phase diagram[J]. Journal of Alloys and Compounds, 2006, 414(1): 60-65.

[19] PUGAZHENDHI B S, KAR A, SINNAERUVADI K, et al. Effect of aluminium on microstructure, mechanical property and texture evolution of dual phase Mg-8Li alloy in different processing conditions[J]. Archives of Civil and Mechanical Engineering, 2018, 18(4): 1332-1344.

[20] XU T C, PENG X D, JIANG J W, et al. Microstructure and mechanical properties of superlight Mg-Li-Al-Zn wrought alloy[J]. Rare Metal Materials & Engineering, 2014, 43(8): 1815-1820.

[21] XU D K, LI C Q, WANG B J, et al. Effect of icosahedral phase on the crystallographic texture and mechanical anisotropy of duplex structured Mg-Li alloys[J]. Materials & Design, 2015, 88: 88-97.

[22] PINEAU A, BENZERGA A A, PARDOEN T. Failure of metals I: Brittle and ductile fracture[J]. Acta Materialia, 2016, 107: 424-483.

[23] MCEVILY A J. Brittle and ductile fractures metal failures[M]. Hoboken: John Wiley & Sons, Inc, 2013.

[24] CUI C L, WU L B, WU R Z, et al. Influence of yttrium on microstructure and mechanical properties of as-cast Mg-5Li-3Al-2Zn alloy[J]. Journal of Alloys and Compounds, 2011, 509(37): 9045-9049.

[25] 宋晓杰. 稀土元素Y、Gd对AZ61镁合金组织及性能的影响[D]. 洛阳: 河南科技大学, 2014.

SONG Xiao-jie. Effects of rare earth elements Y and Gd on microstructure and properties of AZ61 magnesium alloy[D]. Luoyang: Henan University of Science and Technology, 2014.

[26] BRAMFITT B L. The effect of carbide and nitride additions on the heterogeneous nucleation behavior of liquid iron[J]. Metallurgical & Materials Transactions B, 1970, 1(7): 1987-1995.

Effect of Y on microstructure and mechanical properties of as-cast Mg-8Li-3Al-3Zn alloy

SONG Wen-jie1, DONG Hui-ping1, LIU Jie1, ZHANG Guang2, LIU Yan-hui1

(1. College of Mechanical and Electrical Engineering, Shaanxi University of Science and Technology, Xi’an 710021, China;

2. School of Aeronautics, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: The magnesium-lithium alloy is the lightest metal structural material and has great application value in the fields of aerospace and transportation at present. However, the development and application of as-cast magnesium-lithium alloy are greatly limited because of the low absolute strength. Three strengthening elements of aluminum (Al), zinc (Zn) and rare-earth element yttrium (Y) were added to obtain the as-cast Mg-Li-Al-Zn-Y alloy. The purpose is to use alloying to enhance the mechanical properties of Mg-Li alloy. The phase composition, microstructure and mechanical properties of as-cast Mg-8Li-3Al-3Zn-xY (x=0, 1) alloy were compared and analyzed by X-ray diffractometer (XRD), scanning electron microscope (SEM) and mechanical properties testing to reveal the reinforcement and fracture mechanism of rare-earth element Y on as-cast Mg-8Li-3Al-3Zn alloy. The results show that the microstructure of the as-cast Mg-8Li-3Al-3Zn alloy mainly consists of matrix α-Mg, AlLi and MgLi2Zn phases. With adding 1% Y (mass fraction), the AlLi phase disappears and a large amount of high-temperature hard phase Al2Y enrich at the primary α-Mg grain boundary. Moreover, the microstructure is significantly refined. Comparing with Mg-8Li-3Al-3Zn alloy (134.40 MPa, 96.46 MPa and 7.5%), the Mg-8Li-3Al-3Zn-1Y exhibits an optimum combination of tensile properties with the tensile strength, yield strength and elongation of 189.99 MPa, 128.2 MPa and 7.8%, which are improved by about 41.4%, 32.9% and 4%, respectively. The improvement of the mechanical properties is attributed to the secondary phase and grain refinement strengthening. By analyzing the fracture morphology, the fracture mode of as-cast alloy is changed from cleavage fracture to quasi-cleavage fracture.

Key words: Mg-Li alloys; yttrium; microstructure; mechanical properties; enhancement mechanism

Foundation item: Project(61409220408) supported by the National Defense Basic Scientific Research program of China; Project(201808615136) supported by the Program of China Scholarships Council, China; Project(2019KW-023) supported by the Key Research and Development Plan Project of Shaanxi Province, China; Project(2016GBJ-02) supported by the Doctoral Scientific Research Starting Foundation of Shaanxi University of Science and Technology, China

Received date: 2020-02-25; Accepted date: 2020-07-15

Corresponding author: SONG Wen-jie; Tel: +86-29-86168976; E-mail: songwenjie@sust.edu.cn

(编辑 李艳红)

基金项目:装备预研领域基金资助项目(61409220408);国家留学基金资助项目(201808615136);陕西省重点研发计划资助项目(2019KW- 023);陕西科技大学博士启动基金资助项目(2016GBJ-02)

收稿日期:2020-02-25;修订日期:2020-07-15

通信作者:宋文杰,副教授,博士;电话:029-86168976;E-mail:songwenjie@sust.edu.cn