电磁搅拌制备半固态材料非枝晶组织的形成机制

来源期刊:中国有色金属学报2000年第4期

论文作者:张景新 张奎 刘国钧 徐骏 石力开

文章页码:511 - 515

关键词:半固态加工; 非枝晶组织;电磁搅拌

Key words:semi-solid processing; non-dendritic structure; electromagnetic stirring

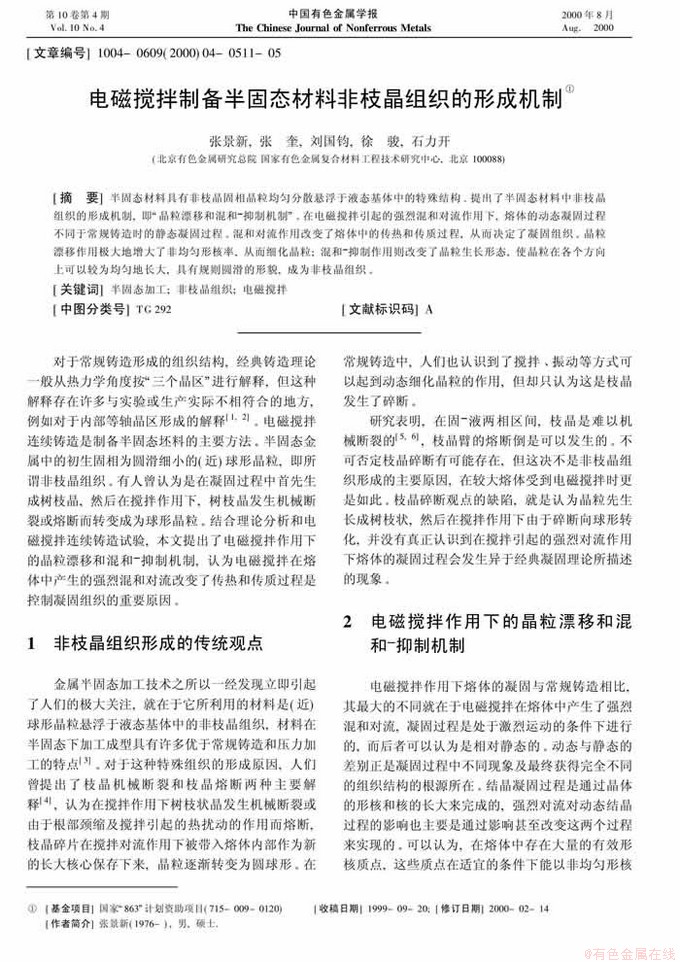

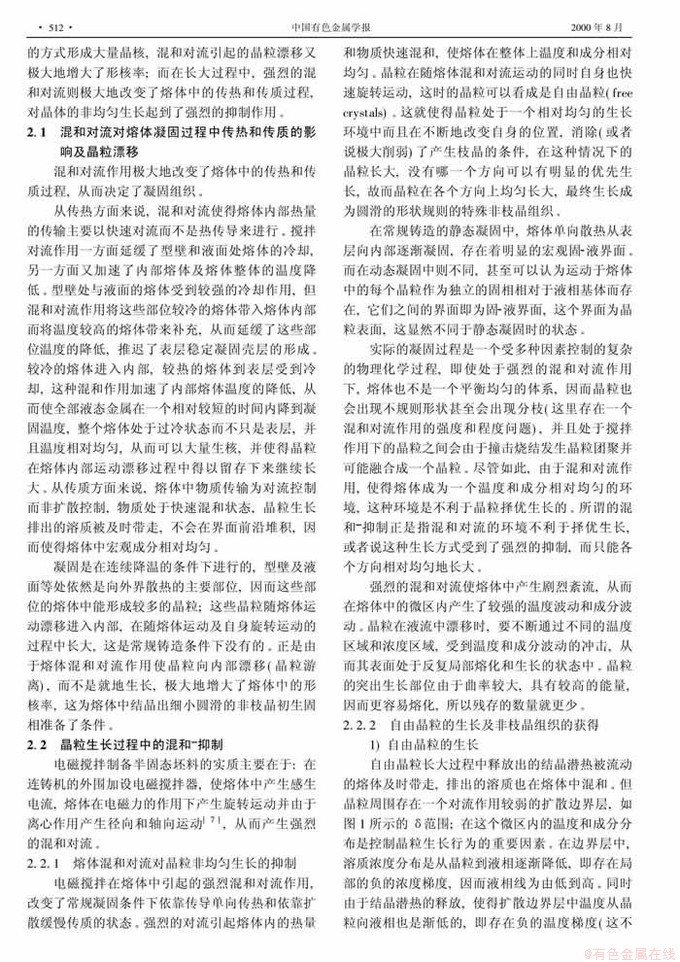

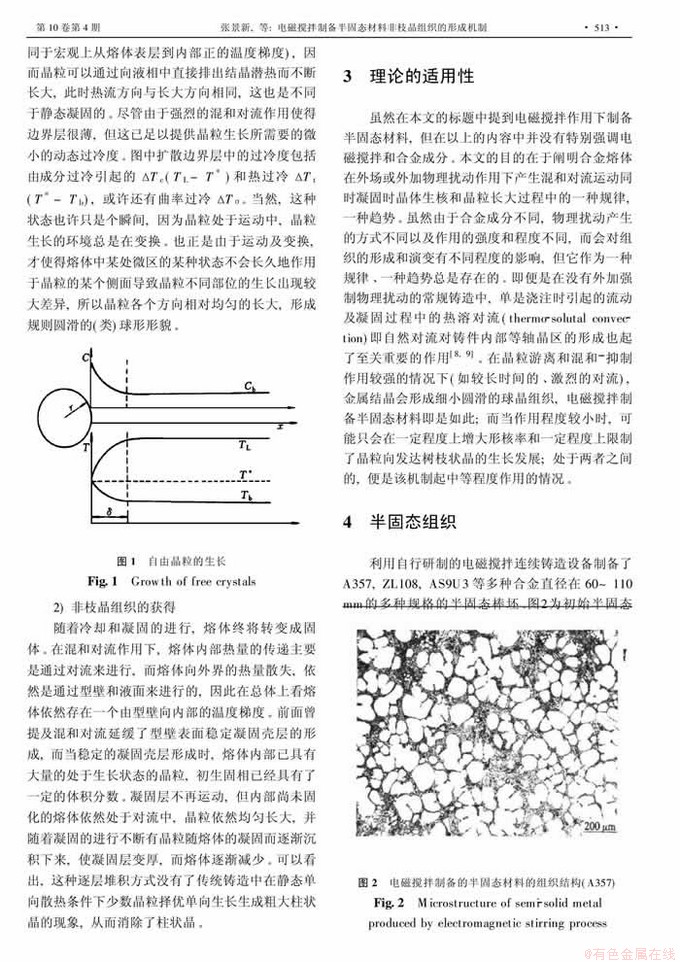

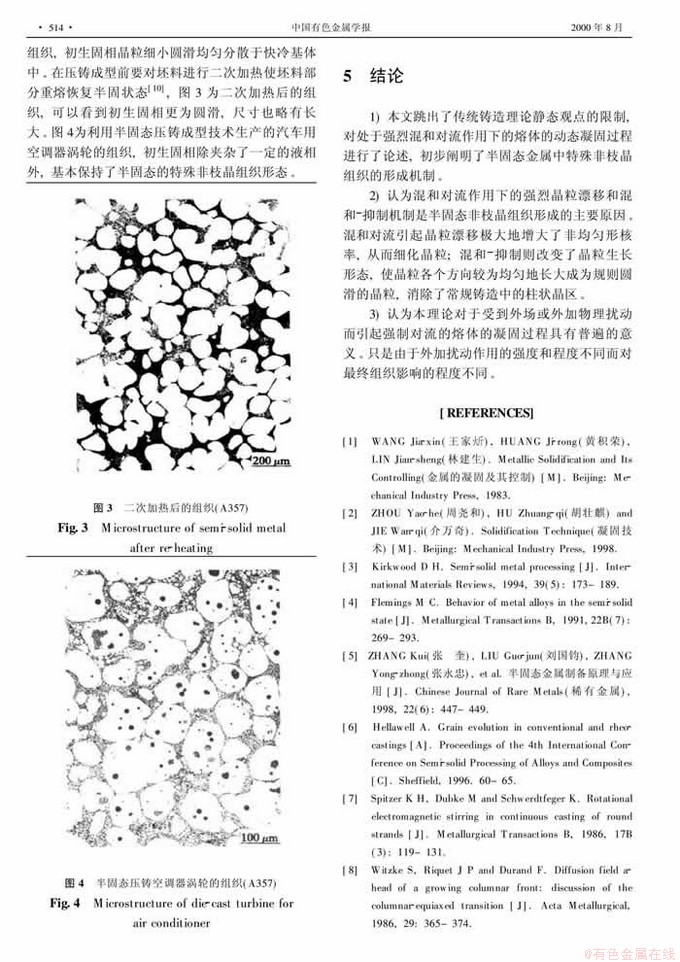

摘 要:半固态材料具有非枝晶固相晶粒均匀分散悬浮于液态基体中的特殊结构。提出了半固态材料中非枝晶组织的形成机制, 即“晶粒漂移和混和-抑制机制”。 在电磁搅拌引起的强烈混和对流作用下,熔体的动态凝固过程不同于常规铸造时的静态凝固过程。 混和对流作用改变了熔体中的传热和传质过程, 从而决定了凝固组织。 晶粒漂移作用极大地增大了非均匀形核率, 从而细化晶粒;混和-抑制作用则改变了晶粒生长形态, 使晶粒在各个方向上可以较为均匀地长大, 具有规则圆滑的形貌, 成为非枝晶组织。

Abstract: The microstructure of semi-solid metal comprises non-dendritic solid phase grains suspended in liquid matrix, which is the key technological foundation for semi-solid processing. In this paper, the formation mechanism for nondendritic structure in semi-solid metal is proposed, namely mechanism of particle-drift and blendingcompressing. Under vigorous convection caused by intense electromagnetic stirring, the dynamic solidification process of melt is quite different from that of conventional casting which is relatively static. The transferring of heat and mass during solidification is greatly changed by vigorous convection,and determined the microstructure. Particle-drift greatly increases the heterogeneous nucleation and so refines the grains; Blending-compressing changes the growing morphology of primary grains and makes grains grow relatively uniformly in all directions into near globular shape, and results in non-dendritic structure.