DOI:10.19476/j.ysxb.1004.0609.2018.05.06

喷射成形Al22Si5Fe3Cu1Mg的高温耐磨机制

赵军峰1,袁晓光1,孙剑飞2,黄宏军1,曹福洋2,左晓姣1,于雷2,王玉龙1

(1. 沈阳工业大学 材料科学与工程学院,沈阳 110016;

2. 哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001)

摘 要:采用常规铸造和喷射成形两种工艺制造Al22Si5Fe3Cu1Mg高硅铝合金,研究磨损温度对合金摩擦行为和磨损机理的影响。结果表明:由于喷射成形高硅铝合金具有组织细小、成分均匀等特征,在磨擦过程中表现出更好的抗磨损性能。合金的磨损机制随着温度的升高而发生转变,低于临界温度时为磨粒和黏着磨损混合形式,高于临界温度后转变为剥层磨损。合金在高温下磨擦时,由于氧化速度较快,形成的氧化物改善合金的抗磨损性能,但存在一个临界温度,当超过临界温度时,两种工艺下的合金均由轻微磨粒和黏着磨损混合形式转变为严重的剥层磨损,喷射成形合金在不同高温下的抗磨损性能均显著优于铸造合金的,且其磨损机制转变临界温度比常规铸造合金的高约100 ℃。

关键词:高硅铝合金;高温摩擦;磨损机制

文章编号:1004-0609(2018)-05-0907-09 中图分类号:TG146.2 文献标志码:A

随着汽车轻量化的发展趋势,高硅铝合金由于其具有低密度、低膨胀系数和高耐磨性等特点,广泛应用于汽车领域的耐磨性工况中[1],如刹车片和制动盘。由于喷射成形高硅铝合金具有大量的第二相,磨损行为与常规过共晶Al-Si合金存在差异,其磨损问题的研究对此类合金的开发与应用具有重要的意义。苏斌等[2]对喷射沉积技术制备的不同硅含量铝基功能梯度复合材料在室温条件下的摩擦学性能进行了研究,研究表明随基体中硅含量的增加,磨损率呈降低趋势,材料在摩擦过程中生成的机械混合层(MML)厚度呈减小趋势。朱学卫等[3]认为,过共晶Al22Si合金在常温下的磨损机理主要为黏着磨损和氧化磨损。窦玉海等[4]认为由于高硅铝合金中含有较多的铝,因此容易发生黏着磨损,增大合金的磨损率。沈军等[5]发现粉末冶金法制备的过共晶铝硅合金摩擦过程中以氧化磨损和磨粒磨损为主。ALSHMRI等[6]采用快速凝固制备了过共晶铝硅合金,认为硅含量过高时,初生硅在磨损时容易脱落,合金的磨损机理以黏着磨损和磨粒磨损为主。目前,针对常规铸造和喷射成形制备的高硅铝合金的磨损行为研究主要是在常温条件下进行的,对于高硅铝合金而言,其实际服役多是在高于室温下,这与常温状态下的磨损行为可能存在一定差异,特别是快速凝固的高硅铝合金在一定温度条件下具有较高的耐磨性,可能是温度影响磨损机制所致。因此,有必要对此类材料的高温摩擦磨损行为进行深入研究。本文作者以Al22Si5Fe3Cu1Mg高硅铝合金为研究对象,对比研究不同温度下常规铸造和喷射成形工艺下该合金的抗磨损性能及其磨损机制,为此类合金的进一步开发与应用奠定基础。

1 实验

合金选用Al22Si5Fe3Cu1Mg高硅铝合金,常规铸造采用工业纯铝、工业纯镁和结晶硅,Al-50%铜合金和Al-10%Fe中间合金熔炼而成,铸造过程中采用磷铜变质。由于喷射成形是在高速高压惰性气体的冲击作用下完成,熔体中会有气体卷入而导致在沉积锭存在一定量的空隙等缺陷,故喷射成形后进行了挤压比为6:1的热挤压。其详细过程可参考文献[7]。

常温及高温拉伸试验在Instron5569万能拉伸试验机上进行,拉伸速率为0.2 mm/min。拉伸试样尺寸符合GBT 228-2002拉伸试样国家标准。

高温摩擦实验在MMU-5G材料端面高温摩擦磨损试验机上进行。本实验中采用销盘式滑动摩擦磨损试验方法。合金式样尺寸d 4 mm×15 mm的销试样,对磨盘为直径43 mm的GCr15钢。摩擦实验在干摩擦条件下进行,试样合金分别在25、100、200和300 ℃ 4种不同的温度下磨损5 min,载荷均为100 N。每种试样在正式摩擦之前,先在800目砂纸上预磨5 min,以提高试样磨损面与摩擦轮相吻合程度。试样磨损前用丙酮超声波清洗,吹干后用精度为0.01 mg的分析天平测量。采用摩擦质量损失描述待测材料的耐磨性能。采用HELIOS NANOLAB 600i扫描电子显微镜观察对比两种工艺不同温度的表面磨损形貌,并通过EDX能谱分析磨损表面。

2 结果与分析

2.1 合金的组织与力学性能

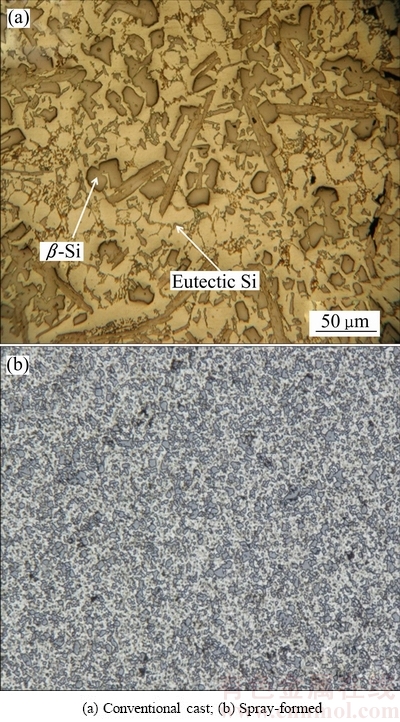

图1所示分别为Al22Si5Fe3Cu1Mg的常规铸造和喷射成形后的组织。由图1可以看出,常规铸造中硅相也呈短片状(见图1(a))。喷射成形合金的组织与常规铸造相比,组织十分细小,特别是初晶硅相和(Al, Si, Fe)相均变为细小的颗粒状(见图1(b))。合金的这种组织形态差异主要是冷却速度不同引起的,由于喷射沉积工艺的冷却速度可以达到1×103~1×104 K/s[3],再加上喷射沉积过程中雾滴对熔池的冲击作用,导致初晶硅相、共晶硅相和(Al, Si, Fe)相来不及长大及被进一步冲击破碎,使合金中的第二相得到了较大程度的细化并均匀分布基体上。硅相和(Al, Si, Fe)相是一种脆性相,条状及尺寸粗大均会加剧对合金基体的割裂作用,引起合金强度的降低,磨损过程中更易使脆性耐磨相从合金基体上脱落,结果会导致合金耐磨性也降低。

图1 常规铸造和喷射成形Al22Si5Fe3Cu1Mg的组织

Fig. 1 Microstructures of Al22Si5Fe3Cu1Mg

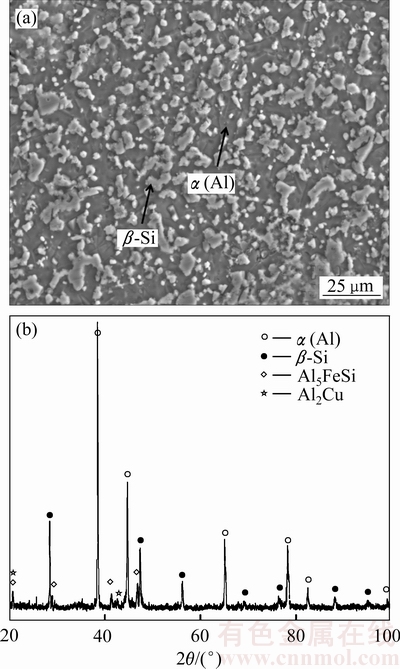

图2(a)所示为喷射成形热挤压之后的表面形貌。由图2(a)可以看出,在热挤压之后喷射成形过程中形成的空隙已基本实现致密化,初晶相和(Al, Si, Fe)相也得到了进一步细化,尺寸为3~5 μm。图2(b)所示为合金的XRD谱,合金中含有的第二相分别是β-Si相、Al5FeSi相和Al2Cu相。

图2 喷射成形热挤压之后Al22Si5Fe3Cu1Mg的表面SEM像及XRD谱

Fig. 2 Surface SEM image(a) and XRD patterns(b) of spray-formed Al22Si5Fe3Cu1Mg alloys

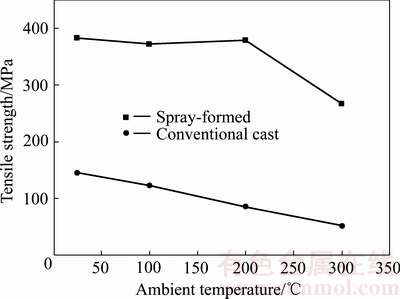

图3所示为喷射成形和常规铸造Al22Si5Fe3Cu1Mg合金在不同温度下的拉伸强度。由图3可知,喷射成形合金具有较高的强度,常温抗拉强度达到380 MPa,比常规铸造合金的高约230 MPa,且在200 ℃以下,抗拉强度随着温度的升高几乎保持稳定。而常规铸造该合金,随着温度的升高,强度持续降低,到200 ℃时抗拉强度降低约50%。说明喷射沉积该合金的耐热性远优于常规铸造合金的。当温度超过200 ℃后,喷射沉积该合金的抗拉强度也显著降低,但300 ℃时合金的抗拉强度仍然保持在250 MPa以上,此时常规铸造合金的抗拉强度已降低到50 MPa。喷射沉积该合金具有较高耐热性与合金中加入Fe元素及快速凝固有关。一方面,含Fe元素的金属间化合物具有一定的耐热性,可以提高合金的耐热性能;另一方面,快速凝固提高了Fe元素在基体中的固溶度,对合金基体耐热性具有改善作用,同时细小的含Fe金属间化合物均匀分布在基体上更进一步发挥了其提高合金耐热性的作用[8]。

图3 喷射成形和常规铸造Al22Si5Fe3Cu1Mg合金的拉伸强度与温度之间的关系

Fig. 3 Relationship between tensile strength and temperature for conventional cast and spray-formed Al22Si5Fe3Cu1Mg alloy

2.2 合金的磨损性能

2.2.1 磨损质量损失

图4所示为实验合金的磨损质量损失-温度的变化曲线。由图4可以看出,合金的磨损量随着温度的升高呈先下降后上升趋势。在100 ℃时,喷射成形和常规铸造Al22Si5Fe3Cu1Mg合金的耐磨性均达到最佳;在200 ℃时,常规铸造的Al22Si5Fe3Cu1Mg合金摩擦质量损失大幅度上升,从100 ℃的11 mg升高到78 mg,说明此时由轻微磨损向严重磨损转变。喷射成形Al22Si5Fe3Cu1Mg合金在300 ℃质量损失小幅度上升,从200 ℃的8 mg升至20 mg。两种合金磨损质量损失比较而言,温度超过200 ℃后,喷射沉积合金的磨损质量损失是小幅度且缓慢增大,而常规铸造该合金质量损失急剧增大。如果以100 ℃时常规铸造该合金的磨损质量损失量为标准定义轻微磨损和严重磨损边界点,可将该磨损质量损失量定为磨损质量损失临界点,此时的温度定义为临界磨损温度。则喷射沉积合金的临界磨损温度为200 ℃,而常规铸造合金的为100 ℃,即喷射沉积合金的临界温度比常规铸造合金的高约100 ℃。

2.2.2 摩擦因数对摩擦特性的影响

图4 喷射成形和常规铸造Al22Si5Fe3Cu1Mg合金的摩擦质量损失与摩擦温度之间的关系

Fig. 4 Relationship between friction temperature and wear loss for conventional cast and spray-formed Al22Si5Fe3Cu1Mg alloy

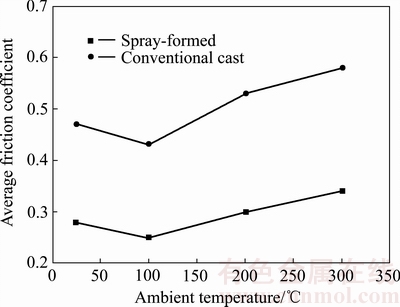

图5 喷射成形和常规铸造Al22Si5Fe3Cu1Mg合金的平均摩擦因数与摩擦温度之间的关系

Fig. 5 Relationship between average friction coefficient and friction temperature for conventional cast and spray-formed Al22Si5Fe3Cu1Mg alloy

图5所示为两种合金在干摩擦时摩擦因数随摩擦温度的变化关系曲线。由图5可以看出,在不同的磨损温度条件下,喷射成形合金的摩擦因数均远小于常规铸造合金的。随着磨损温度的提高,两种合金的摩擦因数均出现先降低后升高的变化,这一变化趋势与磨损质量损失相同,转变温度发生在100℃。说明随着高温氧化,摩擦因数逐渐减小,继续升高温度可能导致氧化膜发生变化,反而使摩擦因数逐渐增大。由此可见,磨损表面氧化对减小摩擦因数的作用与温度有关,这种影响与磨损质量损失随温度变化相对应。但总体来说,喷射成形的高硅铝合金摩擦因数远小于常规铸造合金的。

2.3 磨损机制分析

由图4可知,合金的磨损机制与合金组织密切相关,当组织中存在硬质第二相时,其尺寸、形态与分布对磨损机制产生影响。由于喷射成形Al22Si5Fe3Cu1Mg合金和常规铸造Al22Si5Fe3Cu1Mg合金组织中均含有硅相、富铁相,但两者的尺寸与分布存在较大差异,其磨损机制可能存在不同。以下将对干摩擦情况下第二相颗粒数目和尺寸不同对摩擦质量损失的影响进行分析。

假设一个第二相颗粒划过距离l1造成材料一个沟槽质量损失上限为mi,所以 。其中,C1是沟槽宽度;

。其中,C1是沟槽宽度; 是材料的密度;h1是沟槽的深度,正比于磨粒压印的半径a;而a与载荷pi和材料硬度H间有关系为

是材料的密度;h1是沟槽的深度,正比于磨粒压印的半径a;而a与载荷pi和材料硬度H间有关系为 。

。

由文献[9]可知, 。其中:pi为作用在磨粒上的载荷;K1为材料的断裂韧性。这样mi可写为

。其中:pi为作用在磨粒上的载荷;K1为材料的断裂韧性。这样mi可写为

(1)

(1)

对于单位面积上有N个磨粒和M个沟槽造成材料的磨损上限为

(2)

(2)

单位面积上的第二相颗粒数为 ,第二相颗粒的半径为a;所以一个颗粒的载荷为

,第二相颗粒的半径为a;所以一个颗粒的载荷为 。其中,p是单位面积上的载荷,将其代入式(2),摩擦质量损失总量为

。其中,p是单位面积上的载荷,将其代入式(2),摩擦质量损失总量为

(3)

(3)

(4)

(4)

所以,摩擦过程中质量损失总量为

(5)

(5)

由式(5)看到,随硅相颗粒增大,作用在单个颗粒的载荷增大,裂纹形成与扩展趋势更严重,从而磨损增大。由于喷射成形Al22Si5Fe3Cu1Mg合金与常规铸造合金相比,其颗粒粒径尺寸远小于常规铸造的第二相尺寸,其微粒数目又远多于常规铸造合金的,所以喷射成形该合金的磨损量总是小于常规铸造该合金的磨损量,但随着温度的升高,硅相颗粒的增大,材料的摩擦机制也会发生变化。文献[10-11]表明,一定载荷下存在临界磨粒粒径,当磨料半径大于一定值时,摩擦磨损过程中作用在单个磨粒上的载荷会导致断 裂-剥落的发生。

图6所示为两种工艺下的高硅铝合金在常温和100 ℃下摩擦表面形貌的SEM像。高硅铝合金在常温下的摩擦过程主要表现为磨粒磨损和黏着磨损[12]。从图6(a)和(b)可以看出,喷射成形该合金的磨痕相对较窄,而常规铸造该合金的磨痕相对较宽。可以推测在摩擦过程中,基体中α相塑性比较好,在摩擦力作用下很容易产生塑性变形,而硬质硅相塑性差,不易变形,在受到摩擦力的作用时硬质硅相能够阻碍α相塑性流动,同时起到保护基体的作用。由于喷射成形Al22Si5Fe3Cu1Mg合金的硬质颗粒细小且分布均匀,所以在阻止α相产生塑性变形时更加有效,磨痕相对较窄。图6(c)和(d)所示为两种工艺下Al22Si5Fe3Cu1Mg合金在100℃时的磨痕形貌,可以看出该温度下的磨痕相对于常温下比较细小而且较浅,同时其磨损表面剥落物尺寸小且数量少。这与图4所示在该温度下磨损量有所下降的实验结果是一致的,可以认为当表面微凸体即硅相颗粒与对磨材料GCr15表面上的微凸体相接触时,发生了快速氧化和氧化膜的生长。由于此温度下氧化膜成长速度较快,磨痕较为平滑,导致摩擦因数稍微下降,也说明氧化膜的存在一定程度上起到了润滑作用。

氧化膜对磨损的影响可以进行如下分析,由Quinn的氧化磨损理论可知氧化物增长质量 与氧化温度之间To的关系为[13]

与氧化温度之间To的关系为[13]

(6)

(6)

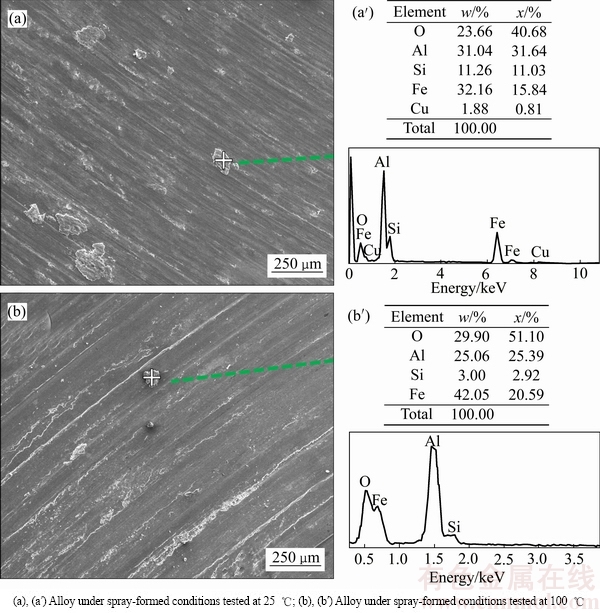

式中:Ap是Arrhenius常数;Qp是抛物线氧化激活能;R是摩尔气体常数;tc是氧化作用时间。所以随着温度的升高,界面处的氧化反应会更加剧烈。同时由图7可知,通过对磨屑进行EDS能谱分析,发现O元素含量在100℃时比在常温下有所增加,O元素含量由常温下的40.68%增加到了100 ℃下的51.10%。这说明在100 ℃时,材料发生氧化磨损程度的确比常温下剧烈。相关文献表明[14-15],在铝硅合金的干摩擦磨损过程中,氧化磨损能够减缓摩擦。在干摩擦中,氧化膜能够阻止摩擦界面直接接触,所以在此温度下具有较小的摩擦损耗[16-17]。但是在更高的温度下,硅相颗粒在软的铝基体上很容易聚集在一起,从而导致材料更容易产生开裂倾向[2]。

图6 不同温度下喷射成形和常规铸造Al22Si5Fe3Cu1Mg合金的磨损表面形貌

Fig. 6 Wearing surface morphologies of spray-formed and conventional casting Al22Si5Fe3Cu1Mg alloy under different temperature conditions

图7 不同温度下喷射成形Al22Si5Fe3Cu1Mg合金的磨损表面形貌及EDS分析结果

Fig. 7 Surface morphologies((a), (b)) and EDS analysis results((a′), (b′)) of wear surface of Al22Si5Fe3Cu1Mg alloy at different temperatures

图8所示分别为喷射成形和常规铸造Al22Si5Fe3Cu1Mg合金在高温下不同温度时的磨损表面形貌。随着温度的升高,在两种工艺下制备的合金表面均发现了剥层现象。在200 ℃时,常规铸造Al22Si5Fe3Cu1Mg合金表面发现由于摩擦过程中发生剥落所形成的剥落坑,但尺寸较小,这说明在这个温度下,常规铸造该合金的摩擦机制已经开始出现剥落磨损机制,而在快速凝固制备该合金的磨损表面上只观察到犁沟磨痕,未观察到剥落坑。在300 ℃时,常规铸造和喷射成形制备的Al22Si5Fe3Cu1Mg合金表面均发现剥落坑。但快速凝固形成的剥落坑比较浅。有文献表明一个磨粒形成一个磨沟所产生的热大约为3.5 J/mm3[18]。所以伴随着摩擦过程中产生的局部高温会发生硬质相的焊合现象[3, 19]。还有一个原因就是根据铝硅合金球化理论,高温下的Si相颗粒呈现粗化的趋势[20]。随着温度的升高,两种工艺下的Al22Si5Fe3Cu1Mg合金均发生了剥落磨损机制,但发生的温度不同。

图9所示为常规铸造Al22Si5Fe3Cu1Mg合金发生剥离磨损时的裂纹扩展,在摩擦接触力作用下,铝硅合金表层发生严重塑性变形,变形累积到一定程度,在表面的一定深度或缺陷处导致裂纹的产生。裂纹一旦出现,在外界载荷作用下扩展,会与邻近的裂纹相连接,当这些裂纹最后向表面剪切时,导致焊合在一起的长而薄的磨损薄片“脱落”[21]。所以在摩擦过程中,粗大的Si相更容易断裂脱落,产生剥落磨损。对比图7(b)和(d)可以看出,由于喷射成形形成的颗粒较小,发生焊合现象的硬质颗粒只能在摩擦表面,故喷射成形中Al22Si5Fe3Cu1Mg合金发生的剥落磨损比常规铸造较浅。由图4可知,在100 ℃之后,摩擦因数随着温度的继续增加,摩擦因数均有所提高。这是因为此时发生了剥落磨损,表面形貌粗糙不平导致。由于表面两个平面之间存在分子间吸引力,在微凸起颗粒之间发生了“焊合—剪切”作用,此时界面处的犁削作用越大,剥落磨损越严重,粗糙度就会越大,进而使摩擦因数得到提高。

图8 喷射成形和常规铸造Al22Si5Fe3Cu1Mg在不同温度下的磨损表面形貌

Fig. 8 Wearing surface morphologies of spray-forming and conventional casting Al22Si5Fe3Cu1Mg under different temperature conditions

图9 Al22Si5Fe3Cu1Mg发生剥离磨损时的裂纹扩展

Fig. 9 Crack propagation in Al22Si5Fe3Cu1Mg alloy during peeling wear

发生剥落磨损时,摩擦质量损失是由两部分组成。此时磨粒划过距离L造成的摩擦由两部分组成:一是由于磨粒“犁”作用磨掉的体积 ;一是由于局部裂纹扩展造成的剥落

;一是由于局部裂纹扩展造成的剥落 。即总的损失为

。即总的损失为

。朱穆嘎尔给出了单个磨粒由上述两种机制产生的磨损总量为[22]

。朱穆嘎尔给出了单个磨粒由上述两种机制产生的磨损总量为[22]

(7)

(7)

式中:第一项为 ,第二项为

,第二项为 ;k1c是基体组织的断裂韧度;

;k1c是基体组织的断裂韧度; ,k1是磨屑形成的相对几率;

,k1是磨屑形成的相对几率; 是微颗粒之间的平均间距;

是微颗粒之间的平均间距; 是划过距离L与硅相颗粒接触的次数。另外必须指出,朱穆嘎尔认为仅当表面压力p大于临界压力,pkr时才会发生剥落磨损[22],即:

是划过距离L与硅相颗粒接触的次数。另外必须指出,朱穆嘎尔认为仅当表面压力p大于临界压力,pkr时才会发生剥落磨损[22],即:

(8)

(8)

式中:f为摩擦因数; 和D分别为磨粒与对磨材料夹角和粒径大小。由于实验中只有温度发生改变,随着温度的升高,硅相颗粒汇聚成大颗粒硅相的几率大大增加,因此粒径D大大增加,f增加,临界压力pkr就会降低,即发生剥离磨损的几率也大大增加。由此可知,Al22Si5Fe3Cu1Mg合金在摩擦过程中如果压力一定,当温度超过临界温度之后,就会形成剥落磨损。有研究表明[8]在常规铸造Al-Si合金中,Fe是最有害的元素,因冷却速度较慢,能形成粗大的硬而脆针状β(Al5FeSi)相,导致合金的力学性能大幅下降。但采用快速凝固技术,可以避免粗大β(Al5FeSi)相。在Al-Fe-Si合金中,有亚稳相δ(Al, Si, Fe)、γ(Al, Si, Fe)的形成,加热后亚稳相形成平衡相β,此时β相具有较高的热稳定性,起主要弥散强化作用[23]。所以随着温度的升高,喷射成形的合金具有更好的耐热性。原始形态硅相尺寸的形成对其耐磨性和磨损机制也有较大的影响。当硅相尺寸较大时会在相对较低的温度下导致大块剥落而产生较大磨损的几率大幅增加。常规铸造由于存在较大尺寸的硬质硅相,与喷射成形该合金相比,具有较低的临界温度。而喷射成形的高硅铝合金由于原始晶粒尺寸较小,在相对较高温度发生了剥落磨损。

和D分别为磨粒与对磨材料夹角和粒径大小。由于实验中只有温度发生改变,随着温度的升高,硅相颗粒汇聚成大颗粒硅相的几率大大增加,因此粒径D大大增加,f增加,临界压力pkr就会降低,即发生剥离磨损的几率也大大增加。由此可知,Al22Si5Fe3Cu1Mg合金在摩擦过程中如果压力一定,当温度超过临界温度之后,就会形成剥落磨损。有研究表明[8]在常规铸造Al-Si合金中,Fe是最有害的元素,因冷却速度较慢,能形成粗大的硬而脆针状β(Al5FeSi)相,导致合金的力学性能大幅下降。但采用快速凝固技术,可以避免粗大β(Al5FeSi)相。在Al-Fe-Si合金中,有亚稳相δ(Al, Si, Fe)、γ(Al, Si, Fe)的形成,加热后亚稳相形成平衡相β,此时β相具有较高的热稳定性,起主要弥散强化作用[23]。所以随着温度的升高,喷射成形的合金具有更好的耐热性。原始形态硅相尺寸的形成对其耐磨性和磨损机制也有较大的影响。当硅相尺寸较大时会在相对较低的温度下导致大块剥落而产生较大磨损的几率大幅增加。常规铸造由于存在较大尺寸的硬质硅相,与喷射成形该合金相比,具有较低的临界温度。而喷射成形的高硅铝合金由于原始晶粒尺寸较小,在相对较高温度发生了剥落磨损。

3 结论

1) 喷射成形Al22Si5Fe3Cu1Mg合金具有组织细小、第二相颗粒分布均匀的特点,在200 ℃的温度范围内强度保持稳定,且其常温和高温强度远优于常规铸造合金的。

2) 由于磨损表面氧化作用,喷射成形与常规铸造工艺下的Al22Si5Fe3Cu1Mg合金的磨损质量损失和摩擦因数均随磨损温度的升高逐渐减小,磨损温度超过100 ℃后,两者均逐渐增大;两种工艺下的合金摩擦因数随磨损温度增加速率几乎相同,但喷射成形该合金的磨损质量损失随磨损温度提高而增大的速率远低于常规铸造合金的。

3) 常规铸造Al22Si5Fe3Cu1Mg合金的磨损临界温度为100 ℃,而喷射沉形Al22Si5Fe3Cu1Mg合金的临界温度为200 ℃;超过临界磨损温度时,合金的磨损质量损失显著增大,磨损机制也从磨粒和黏着磨损混合形式变为严重的剥层磨损。

REFERENCES

[1] 叶春生, 叶康生, 张新平, 潘 冶, 吴海棠. 二次加热和冷却方式对过共晶铝硅合金半固态组织的影响[J]. 中国有色金属学报, 2002, 12(S1): s236-s240.

YE Chun-sheng, YE Kang-sheng, ZHANG Xin-ping, PAN Ye, WU Hai-tang. Influence of partial reheating and cooling method on semi-solid microstructure of hypereutectic Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(S1): s236-s240.

[2] 苏 斌, 严红革, 陈吉华, 陈 刚, 杜嘉庆. 硅含量对喷射沉积SiCp/Al Si功能梯度复合材料摩擦磨损性能的影响[J]. 中国有色金属学报, 2013, 23(1): 201-211.

SU Bin, YAN Hong-ge, CHEN Ji-hua, CHEN Gang, DU Jia-qing. Effect of silicon content of substrate on wear properties of spray-deposited SiCp/Al-Si functionally gradient composites[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 201-211.

[3] 朱学卫, 王日初, 王小锋, 彭 健. 高硅铝合金的摩擦磨损性能[J]. 功能材料, 2015, 46(8): 8063-8066.

ZHU Xue-wei, WANG Ri-chu, WANG Xiao-feng, PENG Jian. Investigation of friction behavior and wear mechanism of high-silicon content Al-Si alloy[J]. Journal of Functional Materials, 2015, 46(8): 8063-8066.

[4] 窦玉海, 刘 咏, 刘延斌, 夏庆兵, 徐 菲. 机械合金化结合热压制备高硅铝合金的组织及性能[J]. 粉末冶金材料科学与工程, 2013, 18(4): 566-571.

DOU Yu-hai,LIU Yong,LIU Yan-bin,XIA Qing-bing,XU Fei. Microstructures and properties of high-silicon aluminum alloys fabricated by mechanical alloying and hot pressing[J].Materials Science and Engineering of Powder Metallurgy, 2013, 18(4): 566-571.

[5] 谢壮德, 沈 军, 孙剑飞, 周彼德. 快速凝固Al-Si合金干摩擦条件下的磨损特性[J]. 材料工程, 2002(10): 7-10.

XIE Zhuang-de, SHEN Jun, SUN Jian-fei, ZHOU Bi-de. Wear characteristics of a rapidly solidified Al-Si alloy under dry sliding[J]. Journal of Materials Engineering, 2002(10): 7-10.

[6] ALSHMRI F, ATKINSON H V, HAINSWORTH S V, HAIDON C, LWAES S D A. Dry sliding wear of aluminium-high silicon hypereutectic alloys[J]. Wear, 2014, 313(1/2): 106-116.

[7] JIA Y D, CAO F Y, NING Z L, SUN X B, SUN J F. Hot deformation behavior of spray formed Al-22Si-5Fe-3Cu-1Mg alloy[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(S1): s299-s303.

[8] 时海芳. 喷射沉积耐热高硅铝合金组织及性能[D]. 沈阳: 沈阳工业大学, 2009.

SHI Hai-fang. The microstructures and mechanical properties of sparay deposited heat resistant high-silicon aluminum alloy[D]. Shenyang: Shenyang University of Technology, 2009.

[9] EVANS A G, WILSHAW T R. Quasi-static solid particle damage in brittle solids—Ⅰ. Observations analysis and implications[J]. Acta Metallurgica, 1976, 24(10): 939-956.

[10] LUDEMA K C. Wear of materials 1983[M]. American Society of Mechanical Engineers, 1983.

[11] GAHR K H Z. Microstructure and wear of materials[M]. Oxford: Elsevier, 1987.

[12] KORI S A, CHANDRASHEKHARAIAH T M. Studies on the dry sliding wear behaviour of hypoeutectic and eutectic Al-Si alloys[J]. Wear, 2007, 263(1/6): 745-755.

[13] QUINN T F J. Review of oxidational wear Part Ⅰ: The origins of oxidational wear[J]. Tribology International, 1983, 16(5): 257-271.

[14] ABOUEI V, SAGHAFIAN H, SHABESTARI S G, ZARGHAMI M. Effect of Fe-rich intermetallics on the wear behavior of eutectic Al-Si piston alloy (LM13)[J]. Materials & Design, 2010, 31(7): 3518-3524.

[15] DWIVEDI D K. Adhesive wear behaviour of cast aluminium-silicon alloys: Overview[J]. Materials & Design, 2010, 31(5): 2517-2531.

[16] PERRINC, RAINFORTHW. M. Work hardening behaviour at the worn surface of AlCu and AlSi alloys[J]. Wear, 1997, s203/204: 171-179.

[17] RAZAVIZADEH K, EYRE T S. Oxidative wear of aluminium alloys: Part Ⅱ[J]. Wear, 1983, 87(3): 261-271.

[18] WATERMAN N A. Treatise on materials science and technology (volume 13)[J]. Tribology International, 1979, 12(6): 281-281.

[19] MONTGOMERY R S. Friction and wear at high sliding speeds[J]. Wear, 1980, 36(3): 275-298.

[20] SHARMA A. Influence of silicon morphology and mechanical properties of piston alloys[J]. Advanced Manufacturing Processes, 2005, 20(5): 777-791.

[21] 李继文, 王爱琴, 谢敬佩, 王文焱, 李洛利. 快速凝固过共晶铝硅合金的微观组织特征及耐磨性研究[J]. 摩擦学学报, 2010, 30(2): 111-117.

LI Ji-wen, WANG Ai-qin. XIE Jing-pei, WANG Wen-yan, LI Luo-li. Microstructure and wear resistance of rapidly solidified hypereutectic Al-Si alloys[J]. Tribology, 2010, 30(2): 111-117.

[22] 赫鲁朔夫, 巴比契夫. 金属的磨损[M]. 胡绍衣, 译. 北京: 机械工业出版社, 1966.

HEROSHOV, BOBBY CHEV. The wear of the metal[M]. HU Shao-yi, transl. Beijing: China Machine Press, 1966.

[23] 袁晓光, 徐达鸣. 喷射沉积Al-Si-Fe-Cu-Mg合金的微观组织和力学行为[J]. 金属学报, 1997, 20(3): 248-252.

YUAN Xiao-guang, XU Da-ming. Microstructure and mechanical properties of spray deposited Al-Si-Fe-Cu-Mg alloy[J]. Acta Metallurgica Sinica, 1997, 20(3): 248-252.

Wear resistance mechanism of spray-formed Al22Si5Fe3Cu1Mg at high temperature

ZHAO Jun-feng1, YUAN Xiao-guang1, SUN Jian-fei2, HUANG Hong-jun1, CAO Fu-yang2, ZUO Xiao-jiao1, YU Lei2, WANG Yu-long1

(1. School of Materials Science and Engineering, Shenyang University of Technology, Shenyang 110178, China;

2. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China)

Abstract: The effects of temperature on friction behavior and wear mechanism for high-silicon aluminum alloy were systematically studied by comparing two processes of conventional cast and spray-formed for manufacturing Al22Si5Fe3Cu1Mg alloy. The result shows that Al22Si5Fe3Cu1Mg alloy by spray-form process shows better abrasion and wear properties than that by conventional casting. The wear mechanism changes with temperature, which shows mixed wear of abrasive and adhesive at temperature lower than the critical temperature and shows delamination wear at temperature higher than the critical temperature. When explored at high temperature, the formation of oxidation improves the wear resistance for the Al22Si5Fe3Cu1Mg alloy due to the fast oxidation and there exiting a critical temperature when wear increases significantly. The wear mechanism of two materials changes into delamination wear with wear rate increasing dramatically by low wear. Notably, the Al22Si5Fe3Cu1Mg alloy by spray-formed process shows superior wear resistance than that from conventional cast both at high and low temperatures. Moreover, the Al22Si5Fe3Cu1Mg alloy by spray-formed process has higher critical temperature of wear mechanism than that by conventional cast.

Key word: high silicon aluminum alloy; high temperature friction and wear; worn mechanism

Foundation item: Projects(51375110, U1530108) supported by the National Natural Science Foundation of China

Received date: 2016-11-29; Accepted date: 2017-04-28

Corresponding author: YUAN Xiao-guang; Tel: +86-24-25499088; E-mail: yuanxg@sut.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51375110,U1530108)

收稿日期:2016-11-29;修订日期:2017-04-28

通信作者:袁晓光,教授;电话:024-25499088;E-mail: yuanxg@sut.edu.cn