文章编号:1004-0609(2010)05-0833-07

高硅铝合金标准样品的热变形行为

凌 闯1,王敬丰1,赵 亮1,潘复生1,朱学纯2

(1. 重庆大学 国家镁合金材料工程技术研究中心,重庆400044;

2. 西南铝业(集团)有限责任公司,重庆401326)

摘 要:对高硅铝合金光谱标准样品在应变速率为0.01~1 s-1、变形温度为350~500 ℃条件下的热压缩变形行为进行实验研究。结果表明:高硅铝合金热压缩变形中发生了明显的动态回复与动态再结晶,流变应力随应变速率的增加而增加,随温度的增加而降低;通过线性回归分析计算出高硅铝合金材料的应变硬化指数n以及变形激活能Q,获得了高硅铝合金高温条件下的流变应力本构方程;研究工艺参数(变形温度t、应变速率 )对晶粒尺寸的影响,确定最佳工艺参数:t=400 ℃,

)对晶粒尺寸的影响,确定最佳工艺参数:t=400 ℃, =0.1 s-1。

=0.1 s-1。

关键词:高硅铝合金;热变形;流变应力;激活能

中图分类号:TG146.2 文献标志码:A

Hot deformation behavior of high silicon aluminum alloy as standard sample

LING Chuang1, WANG Jing-feng 1, ZHAO Liang1, PAN Fu-sheng1, ZHU Xue-chun2

(1. National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing 400044, China;

2. Southwest Aluminum(Group)Co., Ltd., Chongqing 401326, China)

Abstract: The flow stress behavior of high silicon aluminum alloy standard sample was investigated in the temperature range of 350-500 ℃and strain rate of 0.01-1 s-1. The results show that the dynamic recovery and dynamic recrystallization occur obviously during hot compression of high silicon aluminum alloy. The flow stress increases with increasing strain rates and decreases with increasing temperature. The strain hardening coefficient n and deformation activation energy Q are evaluated by linear regression analysis. And the flow stress constitutive equation of high silicon aluminum alloy during hot compression is obtained. The influence of the processing parameters (deformation temperature t, strain rate ) on grain sizes was studied. The optimal processing parameters, t=400 ℃,

) on grain sizes was studied. The optimal processing parameters, t=400 ℃,  =0.1 s-1 were determined.

=0.1 s-1 were determined.

Key words: high-silicon aluminum alloy; hot deformation; flow stress; activation energy

随着国内外仪器分析的发展以及对工业分析快速、准确的要求,标准样品的研制和应用领域也发生了新的变化[1]。为了提高Al-Si合金分析准确度,减少配料和调整成分的误差,进而提高铝合金铸锭质量,必须研制Al-Si合金光谱标准样品。随着Si含量的增加,初晶硅和共晶硅越来越粗大,故要保证高硅铝合金标准样品主要元素和杂质元素化学成分均匀很困难。但是,光谱标准样品对成分和组织均匀性要求很高,因此,如何提高Al-Si合金尤其高硅铝合金的成分和组织均匀性是有待解决的技术难题。目前,最常用的方法是通过添加变质剂,使初晶硅和共晶硅晶粒细化。由于此法只能使Al-Si合金达到某种程度的成分和组织均匀化,与预期的理想结果还有一定差距,因此在变质的基础上,寻找一种最佳的热挤压工艺使其组织和成分更加细小均匀,显得尤为重要。高硅铝合金中粗大的初晶硅和共晶硅导致材料塑性和韧性变差,不易于加工[2]。加工工艺的制定取决于合金流变应力的大小,然而流变应力又主要受变形温度和应变速率的影响,因此,研究变形温度和应变速率对流变应力的影响对指导压力加工过程有重要的理论和实际意义[3-5]。

本文作者采用圆柱体轴对称高温单道次压缩试验,对不同应变速率和变形温度下Al-22Si铝合金热压缩变性行为进行研究,为进行计算机模拟和制定合理的热加工工艺提供理论和实践依据。

1 实验

1.1 合金制备

实验选用工业用的高纯铝(99.99%)和高纯晶体硅片(99.9999%)配置成Al-22%Si的过共晶铝硅合金。首先将原料预热后放入坩埚电阻炉进行熔炼,直至结晶硅全部熔化,然后除去表面熔渣,静置5~10 min后,进行变质处理。为了能够准确地控制变质剂的添加量,减少元素的烧损,变质剂以Cu-10%P中间合金的形式加入,搅拌均匀后,迅速浇铸,以防止在高温停留时间过长,变质剂发生氧化等反应而失效。

1.2 实验方法

将材料加工成d10 mm×12 mm的圆柱体试样,然后加热到520 ℃,均匀化24 h后空冷。将试样放到Gleeble-1500热模拟机上进行恒应变速率等温热压缩实验。变形温度为350、400、450和500 ℃,应变速率为0.01、0.1和1 s-1,热模拟实验升温速率为5 ℃/s-1,加热至预定温度后保温2 min,然后进行压缩实验,总压缩变形量为1(真应变),数据采集频率为10 kHz。压缩后的试样立即进行水淬处理,以保留变形后的组织。

2 结果及讨论

2.1 真应力—真应变曲线

Al-22Si高硅铝合金在应变速率分别为0.01、0.1和1 s-1的热压缩变形时,其实测真应力—真应变曲线如图1所示。由图1可见:①材料的流变应力在变形初期,随变形程度的增加,呈现明显的加工硬化趋势,随变形程度的进一步增加,加工硬化被动态回复和连续动态再结晶的软化过程所抵消,流变应力增幅减小,达到峰值应力后流变应力缓慢下降,随后流变应力不再随真应变而变化,加工硬化与动态回复和连续动态再结晶的软化过程趋于动态平衡,流变应力从而也趋于稳定。②流变应力随变形温度的升高而降低,因为随着温度的升高,热激活的作用增强,原子间的动能

图1 不同应变速率下的真应力—真应变曲线

Fig.1 True stress—strain curves at different strain rates

增大,原子间的临界切应力减弱,此外,动态回复及动态再结晶引起的软化程度也随温度的升高而增大,从而导致合金的应力水平下降。同时,从图1(a)~(c)还可以看出,变形温度为350和400 ℃的曲线相比,真应力值变化较大;变形温度大于400 ℃以后,真应力仍然随着变形温度的增大而降低,但真应力值幅度变化较小。

Al-22Si高硅铝合金在变形温度分别为350、400、450和500 ℃时的真应力-真应变曲线如图2所示。由图2可见:在同一变形温度下,材料的真应力水平随应变速率的增大而增大,表明材料是正应变速率敏感材料,这主要是因为应变速率越大,塑性变形进行得越不充分,使弹性变形量增大,从而导致流变应力增大[6]。同时,从图2(a)~(d)还可以看出,在真应变略小于0.05或者更小时,流变应力达到峰值应力,随后应力值趋于恒定不变;当变形温度较低时,曲线呈现明显的应力峰,这是因为在低温下进行试验,加工硬化对合金的影响占主要地位;当变形温度升高时,曲线表现为稳态特征,说明合金在压缩过程中,发生了动态回复和动态再结晶等软化效应[7];随着温度升高,峰值应变也逐渐减小,尤其是当变形温度为500 ℃、变形速率为0.01 s-1时,即使应变很小,试样的流变应力也达到峰值。这一方面是因为温度升高造成的热激活可以立即引起回复现象的出现而不需要孕育期;另一方面,随着温度的升高,滑移系的临界切应力下降,导致镁合金的变形抗力降低[8]。

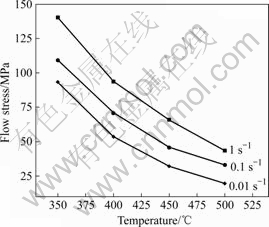

图3所示为变形温度、应变速率对流变应力的影响。从图3可以看出:流变应力随变形温度的增加而降低,随应变速率的增加而增加。图3中的流变应力均为峰值应力,为以下拟合直线计算本构方程提供数据支持。

2.2 热变形流变应力本构方程

在高温塑性变形条件下一种包含激活能Q和温度T在内的双曲正弦函数通过修正Arrhenius关系来描述这种热激活稳态变形行为[9-13],并且该公式还可用来估算各种合金的激活能Q[4, 14]。

图2 不同变形温度下的真应力—真应变曲线

Fig.2 True stress—strain curves at different deformation temperature

图3 变形温度、应变速率对流变应力(峰值)的影响

Fig.3 Effects of deformation temperature and strain rate on flow stress

也可以表示稳态流变应力或者是峰值应力(MPa)。在低应力水平条件下,由于ασ值较小,对式(3)中的sinh(ασ)进行泰勒级数展开后忽略高次项,可近似得到式(1);在高应力水平条件下,对式(3)中的sinh(ασ)进行泰勒级数展开后忽略其中的exp(-ασ)项,可近似得到式(2)?

根据Zener和Hollomon的研究,材料在高温塑性变形时应变速率受热激活过程控制,应变速率与温度之间的关系可用Z参数表示[15]:

对式(1)和式(2)两边分别求对数得:

(5)

(5)

(6)

(6)

依据式(5),取σ为峰值应力,以 和lnσ为坐标作

和lnσ为坐标作

图4 峰值应力σ与应变速率 的关系

的关系

Fig.4 Relationship between peak stress σ and strain rate : (a)

: (a)  —lnσ; (b)

—lnσ; (b)  —σ

—σ

图,n1取峰值应力较低的直线斜率的平均值(见图4(a)),得n1=7.896 805;同理β取峰值应力较高直线的斜率的平均值(见图4(b)),求得β=0.134 926 MPa-1,对应的α=β/n1= 0.017 086 MPa-1。

根据双曲正弦函数的定义以及式(4),可将σ表达成Zener-Hollomon参数Z值的函数:

(7)

(7)

在一定应变和应变速率下,对式(3)求导可得:

(8)

(8)

式中: 的斜率可通过图5求得,斜率的平均值为5 868.597 76,再将此值和前面得到的常数n以及气体常数R代入式(8)得:Q=385.297 1 kJ/mol,式(3)两边求对数得:

的斜率可通过图5求得,斜率的平均值为5 868.597 76,再将此值和前面得到的常数n以及气体常数R代入式(8)得:Q=385.297 1 kJ/mol,式(3)两边求对数得:

(9)

(9)

式(9)中的截距 可通过图6得到,将Q、R、T、n的值代入求A,并求其平均值可得:A=5.75×1026 s-1。将求得的Q、α、n、A系数代入式(3),即可得到适用于所有应力状态的流变应力本构方程:

可通过图6得到,将Q、R、T、n的值代入求A,并求其平均值可得:A=5.75×1026 s-1。将求得的Q、α、n、A系数代入式(3),即可得到适用于所有应力状态的流变应力本构方程:

流变应力方程亦可用Z参数表述为

图5 ln[sinh(ασ)]与温度的倒数1/T的关系

Fig.5 Relationship between ln[sinh(ασ)] and deformation temperature

图6 ln[ sinh (ασ) ]- 关系

关系

Fig.6 Relationship between ln[sinh(ασ)] and

此实验条件下获取的高硅铝合金热压缩变形时的变形激活能比文献所报道的其它一些铝合金的变形激活能高,一方面可能是本实验采用铸造态粗晶试样,与热挤压态细晶试样相比,其热变形变得较为困难所致;另一方面是高Si含量对位错阻碍作用加大,导致热变形激活能增加[8]。

图7所示为变形激活能随变形温度和应变速率变化关系曲线。从图7中可以看出,变形激活能间接受到应变速率的影响,直接受到变形温度的影响[7]。应变速率在10-2~1 s-1区间时,合金的变形激活能先下降后上升(见图7(a))。当应变速率为0.1 s-1时,合金的激活能有所下降,说明快速变形引起的热效应对其起到了重要作用。当合金的应变速率继续增加时,合金的激活能升高,加工硬化效应明显。从激活能的角度考虑,合金合适的应变速率为0.1 s-1。随着变形温度升高,合金的变形激活能呈现下降趋势(见图8(b)),说明合金在高温下容易变形,这是因为合金在高温下的回复、再结晶以及共晶组织等的软化作用占据了主导地位,溶质原子等缺陷对位错的阻碍作用占据次要地

图7 变形温度和应变速率对激活能的影响

Fig.7 Effects of strain rate and deformation temperature on activation energy

图8 不同变形温度下样品的显微组织

Fig.8 Microstructures of samples at different deformation temperature ( =0.1 s-1): (a) 350 ℃; (b) 400 ℃; (c) 450 ℃; (d) 500 ℃

=0.1 s-1): (a) 350 ℃; (b) 400 ℃; (c) 450 ℃; (d) 500 ℃

位,另外随着温度的升高,滑移系增加、滑移系的临界切应力下降等也导致变形抗力下降,激活能降低。

在制定挤压方案时,考虑到变形速率大时,应选择在较高温度下挤压;而考虑到提高材料挤压后的力学性能和减少热裂时,应选择在较低温度下挤压[16]。鉴于上述原因,需要对比热变形后的微观组织,找出适合的变形温度。图8所示为应变速率0.1 s-1时,不同变形温度下合金的OM形貌,变形温度为350 ℃时,大量的初晶硅颗粒密集地分布在基体中。初晶硅颗粒呈现多边形化趋势,此时合金可能发生了一定程度的动态回复。。当变形温度为400 ℃时,显微组织均匀,初晶硅颗粒细小,晶界模糊。当变形温度为450 ℃时,初晶硅颗粒粗大,数量较少,有团聚现象,显示出动态再结晶趋势。当变形温度为500 ℃时,晶粒增多,晶粒细小,合金正在动态再结晶。根据细晶强化或霍尔佩奇公式,变形温度为400 ℃时,合金的综合性能较好。结合应力—应变曲线和微观组织,可初步确定 =0.1 s-1时的最佳变形温度为400 ℃。

=0.1 s-1时的最佳变形温度为400 ℃。

3 结论

1) Al-22Si高硅铝合金在高温压缩时的流变应力强烈取决于变形温度和应变速率。在同一变形温度下流变应力随应变速率的提高而增加,在同一应变速率下流变应力随温度的上升而减小。在高温压缩变形过程中有明显的动态回复与动态再结晶现象。流变应力经历了过渡变形与稳态变形两个阶段,即流变应力先随应变的增加迅速升高,出现应力峰值后逐渐下降,后趋于稳态流变应力值,出现近似稳态流变特征。

2) 可采用 Zener-Hollomon参数的双曲正弦形式来描述Al-22Si铝合金高温变形时的流变应力行为;获得的流变应力σ解析表达式中A、α和n值分别为5.75×1026s-1、 0.017 086 MPa-1和7.896 805;其热变形激活能Q为385.2971 kJ/mol。

(3)合金的变形激活能直接受到变形温度的影响,间接受到应变速率的影响。随着变形温度升高,合金的变形激活能呈现下降趋势;应变速率在10-2~1 s-1区间时,合金的变形激活能先下降后上升。从激活能的角度考虑,并结合真应力—真应变曲线,可以初步确定Al-22Si的最优的热挤压工艺参数为t=400 ℃, =0.1 s-1。

=0.1 s-1。

REFERENCES

[1] 朱学纯, 尹晓辉, 韦志宏, 胡永利, 范顺科. 含31个元素铝基光谱标准样品的制备及定值结果[J]. 铝加工, 2009(1): 4-9.

ZHU Xue-chun, YIN Xiao-hui, WEI Zhi-hong, HU Yong-li, FAN Shun-ke. Preparation and certification result of spectrum standard samples containing 31 elements[J]. Aluminum Process, 2009(1): 4-9.

[2] GERMAN R M, HENS K F, JOHNSON J I. Powder metallurgy processing of thermal management materials for microelectronic applications[J]. International Journal of Powder Metallurgy, 1994, 30(2): 205-216.

[3] SHEPPARD T, JACKSON A. Constitutive equations for use in prediction of flow stress during extrusion of aluminium alloys[J]. Materials Science and Technology, 1997, 13(3): 203-209.

[4] SHI H, MCLAREN A J, SELLARS C M, SHAHANIR, BOLINGBROKER. Constitutive equations for high temperature flow stress of aluminum alloys[J]. Materials Science and Technology, 1997, 13(3): 210-216.

[5] SHEN G, SEMIATANTIN S L, ALTAN T. Investigation of flow stress and microstructure development in non-isothermal forging of Ti-6242[J]. Journal of Materials Processing Technology, 1993, 36(3): 303-319.

[6] 张 伟, 杨伏良, 甘卫平, 欧定斌.Al-35Si高硅铝合金热变形行为的研究[J]. 材料导报, 2005, 19(10): 136-138.

ZHANG Wei, YANG Fu-liang, GAN Wei-ping, OU Ding-bin. Study of the hot deformation behavior of the Al-35Si high silicon aluminum alloy[J]. Materials Review, 2005, 19(10): 136-138.

[7] 马鸣龙, 张 奎, 李兴刚, 李永军, 张 康.铸态Mg-7Gd-5Y-1.2Nd-Zr镁合金热变形行为研究[J]. 特种铸造及有色合金, 2009, 29(3):197-201.

MA Ming-long, ZHANG Kui, LI Xing-gang, LI Yong-jun, ZHANG Kang. Hot deformation behavior of as-cast Mg-7Gd-5Y-1.2Nd-Zr magnesium alloy [J]. Special Casting & Nonferrous Alloys, 2009, 29 (3): 197-201.

[8] 张 昊, 张 辉, 陈振华, 傅定发, 夏伟军. AM60镁合金的高温热压缩流变应力行为的研究[J]. 矿冶工程, 2006, 26(6): 92-94.

ZHANG Hao, ZHANG Hui, CHEN Zhen-hua, FU Ding-fa, XIA Wei-jun. Flow stress behavior of AM60 magnesium alloy during hot compression deformation at elevated temperatures[J]. Mining and Metallurgical Engineering, 2006, 26(6): 92-94.

[9] SELLARS C M, TEGART W J. Relationship between strength and structure in deformation at elevated temperatures[J]. Mem Sci Rev Met, 1966, 63(9): 731-745.

[10] SELLARS C M, TEGART W J. On the mechanism of hot deformation[J]. Acta Metallurgica, 1966, 14(9): 1136-1138.

[11] JONAS J J, SELLARS C M, TEGART W J. Strength and structure under hot working conditions[J]. International Materials Reviews, 1969, 14(1): 1-24.

[12] SELLARS C M, TEGART W J. Hot workability[J]. International Materials Reviews, 1972, 17(1): 1-24.

[13] SHEPPARD T, PARSON N C, ZAIDI M A. Dynamic recrystallization in Al-7Mg alloy[J]. Metal Science, 1983, 17(10): 481-490.

[14] YU Kun, LI Wen-xian, ZHAO Jun, MA Zheng-qing, WANG Ri-chu. Plastic deformation behaviors of a Mg-Ce-Zn-Zr alloy [J]. Scripta Materialia, 2003, 48(9): 1319-1323.

[15] ZENER C, HOLLOMON J H. Effect of strain rate upon plastic flow of steel[J]. Journal of Applied Physics, 1944, 15(1): 22-32.

[16] 石 岩, 易幼平. 7050铝合金热压缩变形行为与组织演化研究[D]. 长沙: 中南大学, 2007.

SHI Yan, YI You-ping. Study of the Hot comprehensive Deformation Behavior and Microstructure development of 7050 aluminum alloy[D]. Changsha: Central South University, 2007.

(编辑 何学锋)

基金项目:重庆市科技攻关计划资助项目(CSTC, 2009AB4007); 国家自然科学杰出青年基金资助项目(50725413); 国家科技支撑计划资助项目(2007BAG06B04)

收稿日期:2009-09-13; 修订日期:2009-12-20

通信作者:王敬丰, 教授, 博士; 电话:023-65112153; E-mail: jfwang@cqu.edu.cn