文章编号: 1004-0609(2005)07-1062-07

碳纳米管复合镀层在不同摩擦组合下的摩擦学行为

陈传盛, 陈小华, 李绍禄, 周灵平, 李德意, 李学谦

(湖南大学 材料科学与工程学院, 长沙 410082)

摘 要: 对CVD法制备的碳纳米管进行了表面改性和修饰, 然后通过化学共沉积方法制备了高硬度的碳纳米管复合镀层, 并研究了碳纳米管复合镀层在不同摩擦组合下的摩擦学行为。 结果表明: 经过改性处理后的碳纳米管表面拥有丰富的表面官能团, 这使大量的碳纳米管复合于镀层中, 从而导致了镍磷复合镀层的硬度显著提高, 达到946 HV。 摩擦实验得出, 在润滑状态下以钢环为摩擦副, 碳纳米管增强的镍磷复合镀层比传统耐磨材料SiC增强的镍磷复合镀层具有更低的摩擦系数和磨损率。 此外, 不同摩擦组合下的摩擦结果表明, SiC复合镀层相互摩擦时尽管拥有较低的磨损率, 但其摩擦系数仍然较高, 而碳纳米管复合镀层相互摩擦时表现出最低的摩擦系数和磨损率, 其摩擦系数和磨损率分别为0.1087和1.49×10-3g/m。

关键词: 碳纳米管; 表面改性; 复合镀层; 摩擦行为 中图分类号: TB332; TG172.63

文献标识码: A

Tribological behavior of carbon nanotubes composite coatings at different frictional combination

CHEN Chuan-sheng, CHEN Xiao-hua, LI Shao-lu,

ZHOU Ling-ping, LI De-yi, LI Xue-qian

(College of Materials Science and Engineering, Hunan University, Changsha 410082, China)

Abstract: After multi-walled carbon nanotubes(MWNTs)were modified and dispersed uniformly in electrolyte, the MWNTs nickel-phosphorus based composite coatings of high hardness were prepared by chemical deposition technique. The results show that hydroxylic groups and carboxylic groups exist on the surface of carbon nanotubes after acid treatment. The loading capacity and disperision ability of MWNTs within the composite coating can be improved effectively by surface modification with surfactant. Due to the addition of MWNTs, the microhardness of MWNTs composite coating is improved and the value of microhardness reaches HV 946. The Ni-P-MWNTs composite coatings revealed a lower wear rate and friction coefficient compared with SiC composite coatings, especially, their triboligical properties are more excellent at the combination of MWNTs composite coatings. Their friction coefficient and wear rate are 0.1087 and 1.49×10-3g/m, respectively.

Key words: MWNTs; surface modification; composite coating; tribological behavor

自从1991年日本NEC公司Iijima[1]发现碳纳米管以来, 这种纳米尺寸的新型碳材料, 由于具有独特的结构、 力学、 电学、 热学和场发射等性能, 可望在场发射显示器件、 纳米电子器件、 超强度复合材料、 储氢材料等诸多领域得到应用。 特别是由于碳纳米管管径为纳米级, 长径比可达1000以上, 比表面大且其抗拉强度是钢的100倍, 碳纤维的20倍, 而密度仅为钢的1/6, 具有很好的柔韧性[2]; 同时碳纳米管的化学稳定性高, 具有优异的自润滑性能[3], 还是电和热的良导体[4, 5]。 因此, 碳纳米管被认为是制备纳米复合材料较理想的选择。 近年来, 利用碳纳米管作为增强相在提高金属基复合材料的力学性能、 电学性能、 热学性能和耐腐蚀性能等方面取得了一定的成绩[6-12]。 但是, 由于碳纳米管是典型的一维纳米材料, 其尺寸与金属晶格比显得太大, 表面活性低, 与金属基体的相容性差, 并且很难与金属基体形成有效的界面作用。 所以碳纳米管在金属基复合材料中的增强效果还远没有达到其理论值, 特别是在力学性能方面。 如Kuzumaki[12]等用热压法制备的碳纳米管/铝基复合材料, 研究结果表明其和普通碳纤维/铝界面不同, 退火后碳纳米管仍保持原状, 碳纳米管/铝界面之间没有发生化学反应而生成Al4C3, 制备的碳纳米管复合材料虽然提高了材料的热稳定性, 但力学性能提高并不理想。

然而, 王等[13]首次通过电沉积技术制备了具有减摩抗磨性能的碳纳米管复合镀层以来, 拓宽了碳纳米管在金属基复合材料中的应用。 目前, 通过电沉积技术和化学共沉积技术已经制备了具有减摩抗磨性能和耐腐蚀的碳纳米管复合镀层, 在活塞、 内燃机汽缸、 轴承和活塞环等方面具有广阔的工业应用前景[14-16]。 Chen等[17, 18]采用化学共沉积方法也制备了均匀分散、 高硬度的碳纳米管复合镀层, 这种复合镀层在干摩擦和润滑条件下均具有优异的减摩抗磨性能。 尽管以前的报道已经说明碳纳米管复合镀层比SiC复合镀层具有更好的减摩抗磨性能, 但是由于复合材料的摩擦学行为是一个复杂的过程。 为了使碳纳米管复合镀层在工业中得到应用, 进一步研究碳纳米管复合镀层的制备工艺和摩擦学行为是很有必要。 因此, 本文作者不仅研究了碳纳米管的表面改性, 而且研究了碳纳米管复合镀层在润滑条件下与钢环相互摩擦时的摩擦学行为。 此外, 还研究了碳纳米管复合镀层与不同摩擦副(不同复合镀层)相互摩擦时的摩擦学行为。

1 实验

1.1 碳纳米管的制备与纯化

实验用碳纳米管是用催化热分解法制备, 由溶胶-凝胶法制备镍催化剂, 乙炔作为碳源, 700℃下催化热分解法生长碳纳米管。 碳纳米管先经过的混合酸(V(硫酸)∶V(硝酸)=3∶1)在100℃下加热回流0.5h, 然后用2mol/L的盐酸在100℃下加热回流2h, 再用去离子水冲洗, 使滤液pH值至中性, 最后烘干研磨后在氮气保护下球磨10h。 利用透射电子显微镜(H800, TEM)、 红外光谱(300E Jasco)和拉曼光谱(Jobin Yvon, Labran-010)表征了碳纳米管的结构。

1.2 碳纳米管复合镀层的制备

基材采用圆柱形45号钢柱(d=34mm, h=10mm)和45号钢环(dout=32mm, din=20mm)。 施镀前经过打磨、 除油、 除锈、 酸洗活化, 然后用去离子水冲洗干净。 处理好的基材浸入化学镀液中进行化学共沉积反应。 采用的镀液配方主要成分为: NiSO4·6H2O 28g/L, NaH2PO2·H2O 26g/L, NaC2H3O2 18g/L, Na3C6H5O7·2H2O 15g/L, 硫脲作为稳定剂。 用NH3·H2O调pH值至4.5左右, 温度(86±3)℃。 碳纳米管含量0.5g/L, 十二烷基硫酸钠为分散剂。 为了作比较, 在相同条件下制备了Ni-P和Ni-P-SiC复合镀层, 碳化硅含量为7.5g/L, 粒度为0.8μm。

1.3 结构和摩擦学性能实验

复合镀层的硬度测试在MM-6卧式金相显微镜进行, 载荷为0.25N, 采用三点取平均值。 复合镀层形貌用JE200型扫描电镜观察。 摩擦学实验在MPX-2000型销盘式摩擦磨损实验机上进行。 摩擦副为45号钢环和复合镀层(外径d=32mm, 内径d= 20mm), 转速为n=384r/min, 实验在常温下进行, 使用江苏太仓生产的美浮润滑油为润滑剂, 实验时间为30min。 实验前后样品经过去离子水清洗、 无水乙醇超声清洗、 真空干燥。 磨损率是根据摩擦盘和摩擦环的质量变化来确定。 实验前后的质量采用FA1604S型电子天平(精度为0.1mg)称量。 复合镀层形貌用JE200型扫描电镜观察。

2 结果与讨论

2.1 碳纳米管的结构

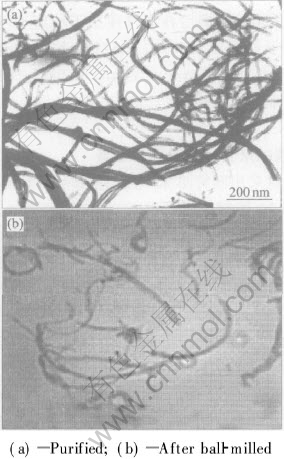

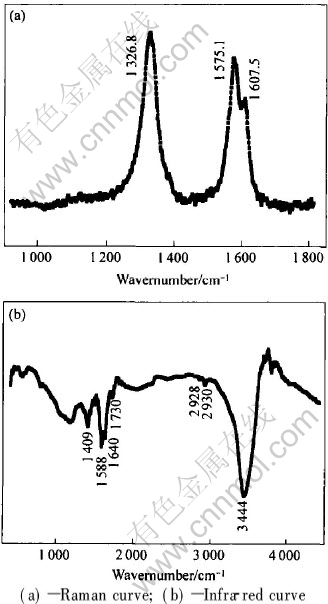

图1所示为酸处理碳纳米管和球磨碳纳米管的TEM像。 从图1(a)中可以看出, 碳纳米管经过酸处理后不仅除去碳纳米管中的杂质, 而且使碳纳米管细化, 但是碳纳米管形成碳纳米管束。 图1(b)中可以看出, 经过球磨的碳纳米管基本上被打断, 成为较短的碳纳米管碎片, 但是其结构仍然保持完好。 从图2(a)碳纳米管的拉曼光谱中可以看到, 经[CM(22]过球磨的碳纳米管在1326.8cm-1和1607.5cm-1处出现典型的多壁碳纳米管的D模和D′模, 而且在1575.1cm-1处出现多壁碳纳米管的G模。 这说明实验中使用的碳纳米管为多壁碳纳米管, 而且球磨并没有破坏碳纳米管的管状结构。 另外, 从图1(b)中还可以看出, 经过10h球磨后的碳纳米管彼此分开, 很少相互缠绕在一起, 这有利于碳纳米管在镀液中的分散。 图2(b)为碳纳米管的红外光谱图。 从图2(b)中可以看到, 碳纳米管经过球磨和混合酸处理, 在3444cm-1处和1730cm-1处分别出现了羟基和羧酸的羰基吸收峰, 而且在1588cm-1处出现了碳环结构的平面吸收峰。 这表明经过混合酸纯化后的碳纳米管表面具有丰富的含氧官能团, 这些含氧官能团有利于碳纳米管对表面活性剂的吸收, 提高了碳纳米管在镀液中的分散能力。

图1 碳纳米管的TEM像

Fig.1 TEM images of CNTs

图2 碳纳米管的光谱

Fig.2 Spectrum of MWNTs

2.2 复合镀层的形貌

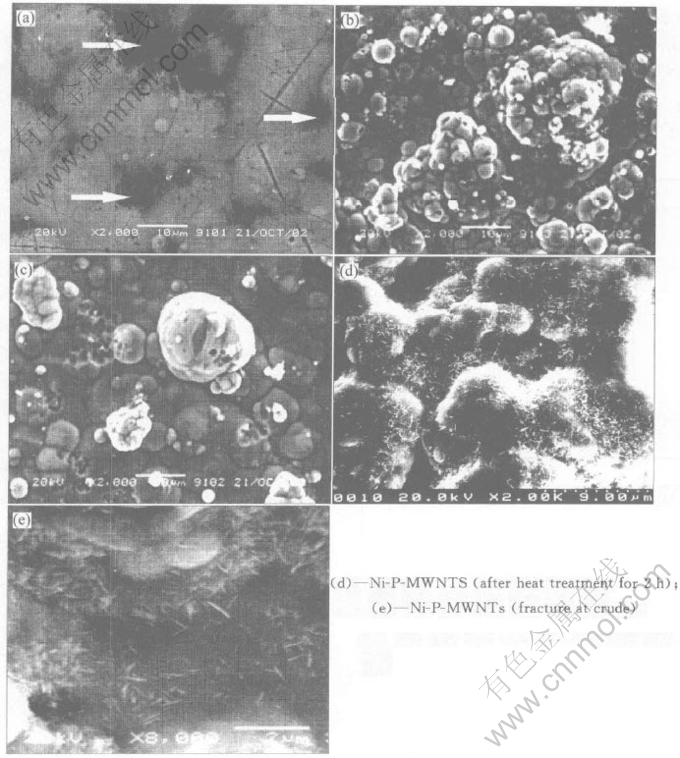

图3所示为复合镀层磨损前的SEM像。 从图3(a)中可以看到, 镍磷复合镀层表面比较平坦, 而且镀层表面结构不是很紧密, 出现了一些大的凹坑, 如图3(a)中箭头所示。 然而SiC复合镀层表面晶粒凸起, 但晶粒间还是存在明显的间隙, 结构也显得松散(图3(b))。 图3(c)显示碳纳米管复合镀层表面晶粒凸起, 晶粒间间隙不明显, 结构紧密, 但不能明显地观察到纤维状的碳纳米管。 从图3(d)热处理后的碳纳米管镀层中可见, 镀层表面均匀分布着许多细小纤维状物, 这是分布在镀层中的碳纳米管。 这是因为复合于镀层中的碳纳米管在未热处理前被均匀地嵌埋在镍磷基体中, 而在热处理过程中由于基体原子的扩散、 迁移和重组, 使得碳纳米管暴露出来。 此外, 从碳纳米管复合镀层的断面中(图3(e))可以看到碳纳米管复合镀层中均匀分散着一些纤维状的物质, 这是分散在复合镀层中的碳纳米管。 这充分说明了碳纳米管均匀无序地分布在基体中, 呈网络交连状态, 显然起到弥散强化作用, 提高了碳纳米管复合镀层的致密性和硬度。

2.3 复合镀层的硬度和摩擦学性能

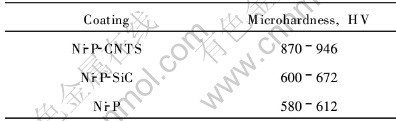

表1列出各种复合镀层的硬度值。 从表1中可知, 碳纳米管增强的镍磷复合镀层的硬度HV为870~946, SiC增强的镍磷复合镀层的硬度HV为600~672, 然而镍磷复合镀层的硬度HV仅有580~612。 从这结果中可以看出, 碳纳米管增强的镍磷复合镀层比SiC增强的镍磷复合镀层的硬度HV高270左右, 而比镍磷复合镀层的硬度HV高[CM(22]出330。 复合镀层硬度提高的原因可能是由于碳纳米管的管径为纳米级尺寸以及拥有高强高韧的特性, 当碳纳米管嵌埋于镍磷复合镀层中并达到一定含量时, 碳纳米管将起到“钢筋骨架”作用, 增强晶格的抗畸变能力, 从而提高了复合镀层的致密性和硬度。

图3 磨损前复合镀层的SEM像

Fig.3 SEM images of composite

coating before wearing

表1 镀层的显微硬度

Table 1 Microhardness of coatings

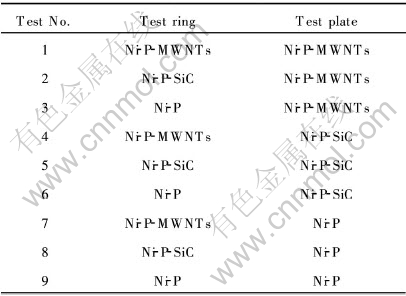

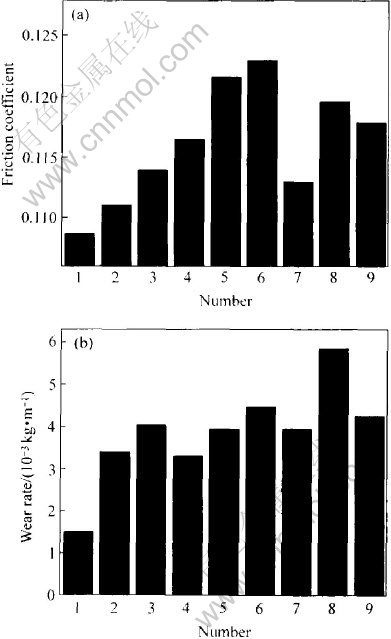

对测试环和测试盘分别镀覆Ni-P、 Ni-P-SiC和Ni-P-MWNTs 3种复合镀层, 并测试了9种不同摩擦组合的摩擦学性能。 表2列出了测试盘和测试环之间的不同组合。 图4所示为300N载荷下, 不同摩擦组合的摩擦系数和磨损率。 摩擦环和磨损盘磨损的质量总和作为磨损量。 从图4中可以看到, 组合1~4和7包含碳纳米管复合镀层的摩擦系数和磨损率都比其他组合的要低, 这表明了碳纳米管复合镀层具有很好的减摩抗磨性能。 从图4中还可以看出, 由两个Ni-P-SiC复合镀层组成的摩擦组合(组合5)比由两个Ni-P复合镀层组成的组合(组合9)的摩擦系数要高, 但其磨损率要低。 这些结果表明了由两个Ni-P-SiC复合镀层组成的摩擦组合表现出较好的抗磨能力, 但其减摩性能较差, 这也表明SiC复合镀层具有减摩性能较差而耐磨性能较好的特点, 这结果与文献[19]的一致。 其原因是由于Ni-P复合镀层比Ni-P-SiC复合镀层的柔软性要好。 然而, 由两个Ni-P-MWNTs复合镀层组成的摩擦组合(组合1)不仅拥有最低的摩擦系数, 而且拥有最低的磨损率, 其摩擦系数和磨损率分别为0.1087和1.49×10-6kg/m。 这结果表明了由两个Ni-P-MWNTs复合镀层组成的摩擦组合要比其它复合镀层组成的摩擦组合表现出更加优异的减摩抗磨性能。

表2 测试盘和测试环之间的不同摩擦组合

Table 2 Different friction combinations of test rings and test plates

图4 载荷为300N时不同组合的摩擦系数和磨损率

Fig.4 Friction coefficient (a) and wear rate (b) of different combinations under load of 300N

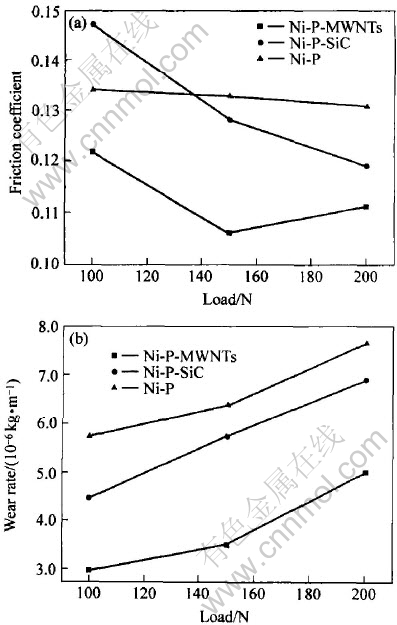

图5所示为在润滑条件下, 3种复合镀层与轴承钢环相互摩擦时的摩擦系数和磨损率。 从图5中可以看出, 在相同载荷条件下, 碳纳米管复合镀层的摩擦系数和磨损率都比SiC复合镀层和Ni-P复合镀层的要低。 这充分说明了碳纳米管复合镀层比SiC复合镀层和Ni-P复合镀层具有更好的减摩抗磨性能。 此外, 从图5中可以看出, 在低载荷下SiC复合镀层的摩擦系数比镍磷复合镀层的摩擦系数要高, 但是在高载荷条件下SiC复合镀层的摩擦系数比镍磷复合镀层的摩擦系数要低。 相同条件下SiC复合镀层的磨损率一直都比镍磷复合镀层的磨损率要低, 这表明了SiC粒子的复合提高了镍磷复合镀层的抗磨性能。 其原因是因为SiC粒子复合于镀层中, 提高了镍磷基体的硬度, 从而增强了它的抗磨性能。 但是由于SiC粒子是一种刚性粒子, 本身的减摩性能差, 当SiC粒子复合于镍磷镀层中, 导致了复合镀层的延展性降低。 所以, 在低载荷时SiC复合镀层的摩擦系数比镍磷复合镀层的要高。 但是随着载荷的增加, 复合镀层的磨损加剧, 由于SiC纳米粒子复合于镍磷镀层中提高了镍磷复合镀层的抗磨性能, 有效地减轻了摩擦表面之间磨粒磨损的形成, 从而降低了摩擦系数。 此外, 随着磨损的加剧, 更多的SiC纳米粒子从基体中脱落, 这些脱落的SiC粒子将对凹凸摩擦表面起到填充作用, 所以在高载荷条件下SiC复合镀层的摩擦系数较低。

图5 3种不同复合镀层的摩擦系数和磨损率随载荷的变化

Fig.5 Variations of friction coefficient(a) and wear rate(b) of different composite coatings with load under lubricant conditions

2.4 复合镀层磨损表面的SEM像

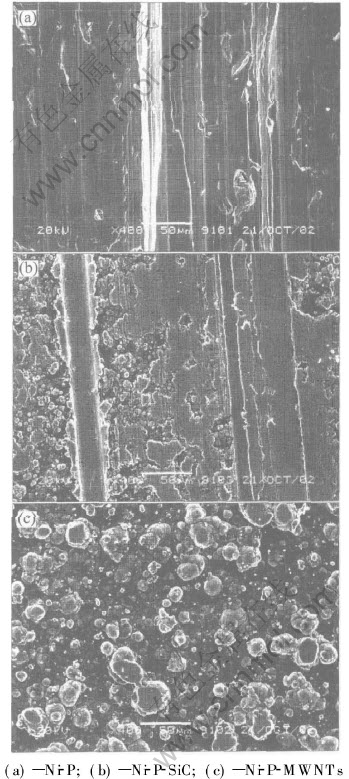

图6所示为100N载荷下3种镀层在同样条件下磨损表面的SEM像。 从图6中可以发现, 镍磷复合镀层有明显的磨痕, 而且磨痕最宽, 完全露出基体, 磨损后塑性流变和脱落严重, 磨损表面表现为严重的粘着磨损和磨粒磨损。 而SiC复合镀层磨损表面也存在明显的磨痕, 但是磨痕较窄, 并未露出基体, 脱落和塑性流变都不及镍磷复合镀层严重。 这说明SiC增强了镍磷基体的抗塑性流变能力和耐磨性能, 但是SiC复合镀层还是表现出一定的粘着磨损和磨粒磨损。 然而碳纳米管复合镀层的磨损表面表现出完全不同的形貌, 磨损表面平滑, 并无明显的磨痕, 只有凸起的晶粒被磨损, 脱落现象和塑性流变都不明显, 粘着磨损和磨粒磨损得到明显地降低。 可见, 碳纳米管的增强效果明显。

图6 100N载荷下3种镀层在润滑条件下磨损表面的SEM像

Fig.6 SEM images of wear surface under lubricant condition at load of 100N

通过以上分析得出碳纳米管复合镀层具有很好的减摩耐磨性能, 这都归功于碳纳米管自身的管状结构和高强高韧特性以及在镀层中均匀分布。 首先, 碳纳米管均匀分布在镍磷基体中, 呈网络交连状态, 起弥散强化作用, 提高了复合相的粘结力和复合镀层的硬度, 导致抗粘着磨损能力增加, 增强了镀层的抗流变和犁削能力, 提高了复合镀层的耐磨能力; 碳纳米管复合镀层表面晶粒凸起, 从而降低了摩擦系数和磨损率。 其次, 在摩擦过程中, 部分碳纳米管被磨断脱落, 这些脱落的碳纳米管将分散在润滑油中, 覆盖在摩擦面上形成一层保护模, 对凹凸摩擦表面起到填充和修复作用, 阻隔了摩擦双方的充分接触, 同时由于碳纳米管的管状结构和高强高韧性以及优异的自润滑性能, 脱落的碳纳米管在摩擦双方可以自由滚动, 起到支承负荷的“滚动轴承”作用, 提高了润滑油膜的耐磨能力, 从而降低了碳纳米管复合镀层的摩擦系数和摩擦双方的磨损率。

3 结论

1) 通过对碳纳米管进行表面改性以及利用表面活性剂修饰碳纳米管, 可以制备均匀分布、 高含量和高硬度的碳纳米管复合镀层, 碳纳米管复合镀层在镀态时的硬度HV达到946。

2) 在钢环摩擦副下, 碳纳米管复合镀层比SiC复合镀层表现出更优异的减摩抗磨性能。

3) 由两个Ni-P-SiC复合镀层组成的摩擦组合时拥有较低的磨损率, 但是其摩擦系数还是很大。 而由两个Ni-P-MWNTs复合镀层组成的摩擦组合要比其它复合镀层组成的摩擦组合表现出更加优异的减摩抗磨性能, 其摩擦系数和磨损率分别为0.1087和1.49×10-3g/m。

REFERENCES

[1]Iijima S. Helical microtubules of graphitic carbon[J]. Nature, 1991, 354: 56-58.

[2]Treacy M M J, Ebbesen T W, Gibsom J M, et al. Exceptionally high Youngs modulus observed for individual carbon nanotubes[J]. Nature, 1996, 381: 678-680.

[3]Salvetat J P, Bonard J M, Thomson N H, et al. Mechanical properties of carbon nanotubes[J]. Appl Phys A, 1999, 69(3): 255-260.

[4]Berber S, Kwon Y K, Tomanek D, et al. Unusually high thermal conductivitity of carbon Nanotubes[J]. Phys Rev Lett, 2000, 84(20): 4613-4616.

[5]Tans S J, Devoret M H, Dai H, et al. Individual single-wall carbon nanotubes as quantum wires[J]. Nature, 1997, 386: 474-477.

[6]马仁志, 朱艳秋, 魏秉庆, 等. 铁-碳纳米管复合材料的研究[J].复合材料学报, 1997, 2: 37- 42.

MA Ren-zhi, ZHU Yan-qiu, WEI Bing-qing, et al. Study on the iron-buckytube composite material[J]. Acta Materiae Compositae Sinica, 1997, 2: 37-42.

[7]Xu C L, Wei B Q, Ma R Z, et al. Fabrication of aluminum-carbon nanotube composites and their electrical properties[J]. Carbon, 1999, 37: 855-858.

[8]钟蓉, 丛洪涛, 成会明, 等. 单壁纳米碳管增强纳米铝基复合材料的制备[J]. 材料研究学报, 2002, 16(4): 344-348.

ZHONG Rong, CONG Hong-tao, CHENG Hui-ming, et al. Preparation of SWNTs/nano-Al composites[J]. Chinese Journal of Materials Research, 2002, 16(4): 344-348.

[9]DONG Shu-rong, ZHANG Xiao-bin. Mechanical pro-perties of Cu-based composites reinforced by carbon nanotubes[J]. Trans Nonferrous Met Soc China, 1999, 9(3): 457-461.

[10]张刚, 李绍禄, 陈小华, 等. 碳纳米管/镍基复合镀层的腐蚀行为[J]. 中国有色金属学报, 2003, 13(4): 996-1000.

ZHANG Gang, LI Shao-lu, CHEN Xiao-hua, et al. Corrosion behavior of carbon nanotubes/Ni composite coating[J]. Trans Nonferrous Met Soc China, 2003, 13(4): 996-1000.

[11]王浪云, 涂江平, 杨友志, 等. 多壁纳米碳管/Cu基复合材料的摩擦磨损特性[J]. 中国有色金属学报, 2001, 11(3): 367-371.

WANG Lang-yun, TU Jiang-ping, YANG You-zhi, et al. Frication and wear behavior of multi-walled carbon nanotube/Cu matrix composites[J]. Trans Nonferrous Met Soc China, 2001, 11(3): 367-371.

[12]Kuzumaki T, Miyazawa K, Ichinose H, et al. Processing of carbon nanotube reinforced aluminum composites[J]. J Mater Res, 1998, 13(9): 2445-2449.

[13]王淼, 李振华, 鲁阳, 等. 纳米材料应用技术的新进展[J]. 材料科学与工程, 2000, 18(1): 103 - 105.

WANG Miao, LI Zhen-hua, LU Yang, et al. The new progress in the application technology of nanophase materials[J]. Mater Sci Eng, 2000, 18(1): 103-105.

[14]Chen X H, PENG J C, LI X Q, et al. Tribological behavior of carbon nanotubes-reinforced nickel matrix composite coatings[J]. J Mater Sci Lett, 2001, 20(22): 2057-2060.

[15]Chen W X, Tu J P, Wang L Y, et al. Tribological application of carbon nanotubes in a metal-based composite coating and composites[J]. Carbon, 2003, 4: 215-222.

[16]Wang L Y, Tu J P, Chen W X, et al. Friction and wear behavior of electroless Ni-based CNTs composite coatings[J]. Wear, 2003, 254: 1289-1293.

[17]陈传盛, 陈小华, 李学谦, 等. 碳纳米管增强镍磷基复合镀层研究[J]. 物理学报, 2004, 2: 531-536.

CHEN Chuan-sheng, CHEN Xiao-hua, LI Xue-qian, et al. Carbon nanotubes reinforced nickel- phosphorus base composite coating[J]. Acta Physica Sinca, 2004, 2: 531-536.

[18]Chen X H, Zhang G, Chen C S, et al. Carbon nanotubes composite deposits with high hardness and high wear resistance[J]. Advanced Engineering Materials, 2003, 5: 514-518.

[19]Chen M, Kato K, Adachi K. Friction and wear of self-mated SiC and Si3N4 sliding in water[J]. Wear, 2001, 250: 246-255.

基金项目: 国家自然科学基金资助项目(50372020; 59972031); 湖南省自然科学基金资助项目(01JJY2052)

收稿日期: 2004-12-17; 修订日期: 2005-03-31

作者简介: 陈传盛 (1972-), 男, 博士研究生.

通讯作者: 陈小华, 教授; 电话: 0731-8821610; E-mail: Hudacxh@sohu.com

(编辑 陈爱华)