Ni-P-多壁碳纳米管复合镀层的制备及摩擦磨损性能

来源期刊:中国有色金属学报(英文版)2012年第11期

论文作者:孟振强 李溪滨 熊拥军 湛 菁

文章页码:2719 - 2725

关键词:Ni-P镀层;碳纳米管;复合镀层;球磨;化学镀;自润滑;摩擦磨损性能;摩擦因数;体积磨损率

Key words:Ni-P coating; carbon nanotubes; composite coating; ball milling; electroless plating; self-lubrication; tribological performance; friction coefficient; volume wear rate

摘 要:采用湿式球磨对多壁碳纳米管(MWNTs)预处理,通过化学镀制备Ni-P-MWNTs复合镀层;对45钢、传统Ni-P镀层和Ni-P-MWNTs复合镀层在干摩擦条件下的摩擦磨损性能进行考察和比较。结果表明,球磨后MWNTs长径比降低,长度均匀,且多数端部处于敞开状态。与45钢和Ni-P镀层相比,Ni-P-MWNTs复合镀层的减摩耐磨能力显著强化。当复合镀层中MWNTs的质量分数为0.74%~1.97%时,其摩擦因数和磨损率随MWNTs含量的增加而减少;对于MWNTs质量分数为1.97%的复合镀层,其摩擦因数和磨损率仅为0.08和6.22×10-15 m3/(N·m)。复合镀层优良的摩擦磨损性能归因于MWNTs优异的力学性能和自润滑特性。

Abstract: Multi-walled carbon nanotubes (MWNTs) were wet-milled in the presence of ammonia and cationic surfactant and then used as reinforcements to prepare Ni-P-MWNTs composite coatings by electroless plating. The tribological performances of the composite coatings under dry condition were investigated in comparison with 45 steel and conventional Ni-P coating. Micrographs show that short MWNTs with uniform length and open tips were obtained through the wet-milling process. The results of wear test reveal that the Ni-P-MWNTs composite coatings posses much better friction reduction and anti-wear performances when compared with 45 steel and Ni-P coating. Within the MWNTs content range of 0.74%-1.97%, the friction coefficient and the volume wear rate of the composite coatings decrease gradually and reach the minimum values of 0.08 and 6.22×10-15 m3/(N·m), respectively. The excellent tribological performances of the composite coatings can be attributed to the introduction of MWNTs, which play both roles of reinforcements and solid lubricant during the wear process.

Trans. Nonferrous Met. Soc. China 22(2012) 2719-2725

MENG Zhen-qiang, LI Xi-bin, XIONG Yong-jun, ZHAN Jing

State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China

Received 28 November 2011; accepted 26 October 2012

Abstract: Multi-walled carbon nanotubes (MWNTs) were wet-milled in the presence of ammonia and cationic surfactant and then used as reinforcements to prepare Ni-P-MWNTs composite coatings by electroless plating. The tribological performances of the composite coatings under dry condition were investigated in comparison with 45 steel and conventional Ni-P coating. Micrographs show that short MWNTs with uniform length and open tips were obtained through the wet-milling process. The results of wear test reveal that the Ni-P-MWNTs composite coatings posses much better friction reduction and anti-wear performances when compared with 45 steel and Ni-P coating. Within the MWNTs content range of 0.74%-1.97%, the friction coefficient and the volume wear rate of the composite coatings decrease gradually and reach the minimum values of 0.08 and 6.22×10-15 m3/(N·m), respectively. The excellent tribological performances of the composite coatings can be attributed to the introduction of MWNTs, which play both roles of reinforcements and solid lubricant during the wear process.

Key words: Ni-P coating; carbon nanotubes; composite coating; ball milling; electroless plating; self-lubrication; tribological performance; friction coefficient; volume wear rate

1 Introduction

Since the discovery of carbon nanotubes (CNTs) in 1991 by IIJIMA [1], lots of researches on the structures and properties have been done. According to theoretical calculations and in-situ measurements, CNTs have exceptional optical, electrical and mechanical properties, which predicate that CNTs possess promising applications in many fields such as physics, chemistry and materials [2-4]. Considered as the strongest fiber [5], CNTs have elastic modulus as high as 1.8 TPa and the tensile strength reaches 67 GPa. Moreover, because of the closed tubular structure of graphite sheets, CNTs are expected to form the desirable weak interaction with the contacting couple during wear process [6]. Thus, more and more studies have been investigated to use CNTs to prepare composite materials with excellent tribological performances [7-9].

However, the poor dispersion of CNTs is an urgent problem to be solved due to their high length-diameter ratio and their van der Waals interactions [10]. To improve the dispersion, most researchers aimed to functionalize CNTs with various chemical groups [11, 12], but less attention was paid to cutting CNTs by ball milling. Ball milling is a mechanical process during which the high-pressure is generated locally by the collision of milling balls. Many researchers [13,14] found that milling CNTs under dry condition, alone or with other powder, can substantially reduce the length of CNTs. Accordingly, good dispersion is available due to a mild entanglement degree of CNTs. CHEN et al [15] and DENG et al [16] have used the dry-milled CNTs to prepare Ni-P based composite coating by electroless plating, which shows desirable tribological performances under the lubrication condition. Recent researches indicated that the CNTs obtained by wet-milling have more open tips and functional groups than those obtained by dry-milling [17,18]. These features are effective to enhance the wettability and thus improve the dispersion of CNTs in aqueous solution.

In this work, multi-walled carbon nanotubes (MWNTs) were wet-milled in the presence of a new milling medium. The milling effect was studied in comparison with ordinary dry-milling. The wet-milled MWNTs were used as reinforcements to prepare Ni-P-MWNTs composite coatings by electroless plating. The tribological performances of the composite coatings under dry condition were investigated and the mechanism was discussed. The tribological performances of conventional Ni-P coating and 45 steel were also tested for comparative purpose.

2 Experimental

2.1 Milling of MWNTs

MWNTs used in the study were prepared by a catalytic chemical vapor deposition (CVD) method with purity higher than 95%, 1-2 μm in length and 20-40 nm in outer diameter. Milling experiments were carried out in a planetary ball milling apparatus. To obtain wet-milled MWNTs, 2.0 g of MWNTs, 0.5 g of cetyltrimethyl benzyl ammonium bromide (CTAB), 60 g of ammonia, and 100 g of milling ball (GCr15 steel) were put into a stainless steel container. The container was then rolled at a rotor speed of 300 r/min for 6 h. After ball milling, MWNTs were purified in 4 mol/L HNO3 at 80 °C for 0.5 h, followed by centrifugation, repeated washing with deionized water until pH>6.5 and drying. Dry-milled MWNTs were also obtained through a similar process for comparative purpose. The sole difference from the wet-milling process is that MWNTs were milled under dry condition and none of ammonia or CTAB was involved. The morphological characteristics of MWNTs, before and after millings, were observed using a JEM-2100F transmission electron microscopy (TEM).

2.2 Preparation of Ni-P coating and Ni-P-MWNTs composite coatings

In the present study, 45 steel was adopted as the substrate for the plating of Ni-P-MWNTs composite coatings. The basic bath compositions are listed in Table 1. To improve the bonding force between the composite coatings and the steel substrate, a Ni-P interlayer coating was firstly deposited for 0.5 h on the substrate. Then, Ni-P-MWNTs composite coatings were deposited for 3 h on the interlayer coating. In order to obtain different composite coatings, six concentrations of MWNTs in the plating bath (0.1, 0.3, 0.4, 0.5, 0.6 and 0.7 g/L) were adopted in the experiments. During the course of plating, the temperature of the bath was held at (87±1) °C and pH was maintained at 4.6±0.1. Meanwhile, agitation was used to disperse MWNTs in the plating bath.

Ni-P coating was also prepared with a similar bath composition and operating parameters. In order to avoid hydrogen brittleness and increase the hardness, the as-prepared Ni-P-MWNTs composite coatings and Ni-P coatings were annealed in vacuum at 400 °C for 1h before the wear test.

The surface and cross-section morphological features of the Ni-P-MWNTs composite coating were investigated by a JSM-6360LV scanning electron microscopy (SEM) and a MeF3A optical microscopy, respectively. The contents of MWNTs in the composite coatings were tested using a LECO/CS-600 carbon- sulfur analyzer.

Table 1 Bath compositions for electroless plating

2.3 Friction and wear tests

The tribological experiments of 45 steel, Ni-P coating and the composite coatings were performed using a reciprocating ball-on-flat tribometer (UMT-3, CETR, USA) under dry condition in ambient air. The relative humidity was 45%-50% and the temperature was 20-25 °C. Standard GCr15 steel balls (d9.5 mm) were used to slide against the samples over a wear track of 6.0 mm with a speed of 0.1 m/s. The applied load was 10 N and the test time was 0.5 h. The friction coefficients were recorded throughout the tests. The cross-sectional areas of wear tracks were measured using a profilometer and the volume losses were calculated with the help of corresponding software. The worn surfaces of the tested samples were observed by SEM. The elemental information of the worn surface of the steel ball sliding against the Ni-P-MWNTs composite coatings were also analyzed by a K-Alpha 1063 X-ray photoelectron spectrometer (XPS).

3 Results and discussion

3.1 Morphology and structure of MWNTs

TEM images of MWNTs are shown in Fig. 1. The MWNTs before milling (Fig. 1(a)) are long, curved and entangled together, while the milled MWNTs are obviously shorter. Compared with the dry-milled MWNTs (Fig. 1 (b)), the wet-milled MWNTs (Fig. 1 (c)) are more uniform in length. The milling medium seems to play a key role for the differences between the dry-milled and wet-milled MWNTs. During the course of dry-milling, MWNTs tend to be compacted by the milling balls and form large agglomerates [17]. When impacts are generated on the agglomerates, MWNTs of the outer part adsorb the majority of the collision energy. As a result, MWNTs of the inner part of the agglomerates are not easy to crack, while MWNTs of the outer part will fracture and their structure may suffer a serious damage, which is harmful to the mechanical properties of MWNTs. For the wet-milling, there is little chance to form large agglomerates due to both effects of the liquid media which alter the van der Waals interaction among MWNTs, and the surfactant (CTAB) which helps to keep MWNTs well dispersed in the liquid. In other words, ammonia combining with CTAB helps to greatly diminish the agglomeration of MWNTs and thus offers possibilities to uniformly cut the tubes without severe structural damage.

Fig. 1 TEM images of MWNTs

Another important difference between the dry-milled and wet-milled MWNTs is their tips. The tips of the wet-milled MWNTs are mainly open, while a large portion of the tips are closed for the dry-milled MWNTs. The reason for the phenomenon is likely to involve the structural stability of these tips. Due to the high strain energy of dangling bonds generated from fractures of MWNTs, the broken and opened MWNTs are metastable and thus tend to close their tips to form stable structures. However, strain energy can be substantially reduced during the wet-milling process by adsorption and combination of chemical groups, or by intermolecular attraction between the MWNTs and the liquid [17]. As a result, more open tips are available for the wet-milled MWNTs. This feature helps to obtain improved wettability and chemical activity, and thus contributes to the subsequent dispersion of MWNTs in the plating bath.

Figure 1(d) presents a typical HRTEM image of an open tip of the wet-milled MWNTs, which was generated from the fracture of MWNTs. It can be observed that the graphite planes around the fracture field are curved and deformed, while in most of other fields the width between the adjacent planes keeps constant, suggesting that the structural damage of MWNTs was local and the tubular nature was conserved after the wet-milling process.

3.2 Characterization of Ni-P-MWNTs composite coatings

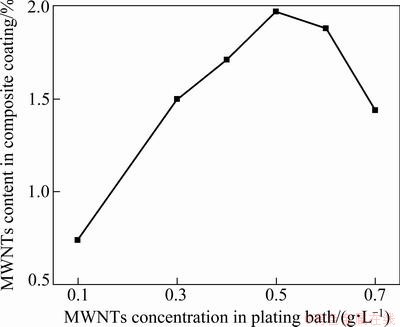

With the help of surfactant and agitation, the wet-milled MWNTs can be well dispersed in the plating bath and thus co-deposited with nickel and phosphorus to form Ni-P-MWNTs composite coatings. Figure 2 shows the relations between the concentrations of MWNTs in the plating bath and their mass fraction in the corresponding coatings. The content of MWNTs in the composite coatings enhances with the increase of MWNTs concentration in the bath and hits the maximum value, 1.97%, at the concentration of 0.5 g/L. It can be attributed to the increasing physical collusions of MWNTs with the surface, following the trapping of more MWNTs in the mechanical locks of the coatings. When the MWNTs concentration in the bath is over 1.97%, however, their content in the coating begins to decrease. The reason for the decrease can be ascribed to the agglomeration of MWNTs. It may lead to settling down of nanotubes and reduction in their actual availability on the specimen surface.

Fig. 2 Variation of MWNTs contents in composite coating with their concentrations in plating bath

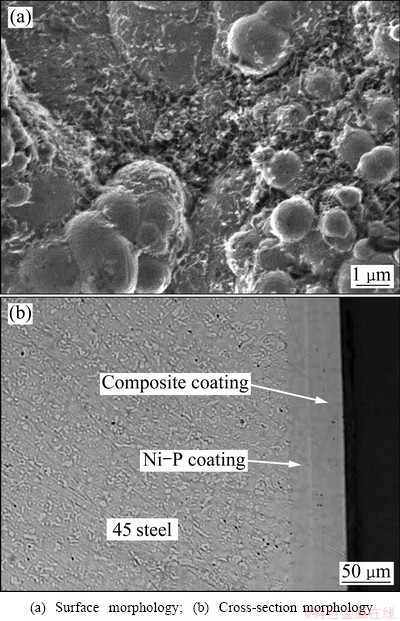

Images of the Ni-P-1.97%MWNTs composite coating are given in Fig. 3. The coating shows a rougher surface than that of conventional Ni-P coating due to the introduction of MWNTs. It is observed that there are many spherical nodules on the surface (Fig. 3(a)). Most of MWNTs distribute around the nodules in the form of fibers. This can be explained by the factor that MWNTs tend to be gradually pushed away from the crystal core during the crystallization of Ni-P alloy. In addition, from the cross-section morphology (Fig. 3(b)), it can be observed that the composite coating is well bonded with the interlayer and the thickness is uniform.

Fig. 3 Images of Ni-P-1.97%MWNTs composite coating after heat treatment

3.3 Tribological performances and mechanism

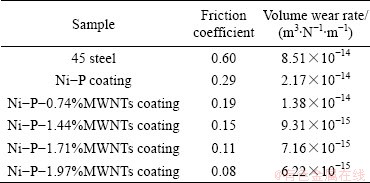

The results of wear tests for 45 steel, Ni-P coating and the Ni-P-MWNTs composite coatings are given in Table 2. It is seen that both Ni-P coating and the composites coatings have lower friction coefficients and lower volume wear rates than those of 45 steel. Comparing with Ni-P coating, the composite coatings possess both better friction-reducing ability and better wear resistance. When the MWNTs content is 0.74%, the friction coefficient and the volume loss rate decrease by 1/3 and by near 1/2, respectively, as compared with Ni-P coating. With increasing MWNTs content from 0.74% to 1.97%, the friction coefficient and the wear volume rate decrease gradually. When the MWNTs content is 1.97%, the friction coefficient and the volume wear rate of the composite coating are only 0.08 and 6.22×10-15 m3/(N·m), respectively. These results demonstrate that the introduction of MWNTs can remarkably improve the tribological performances of Ni-P coating.

Table 2 Friction coefficients and volume wear rates of 45 steel, Ni-P coating and Ni-P-MWNTs composite coatings

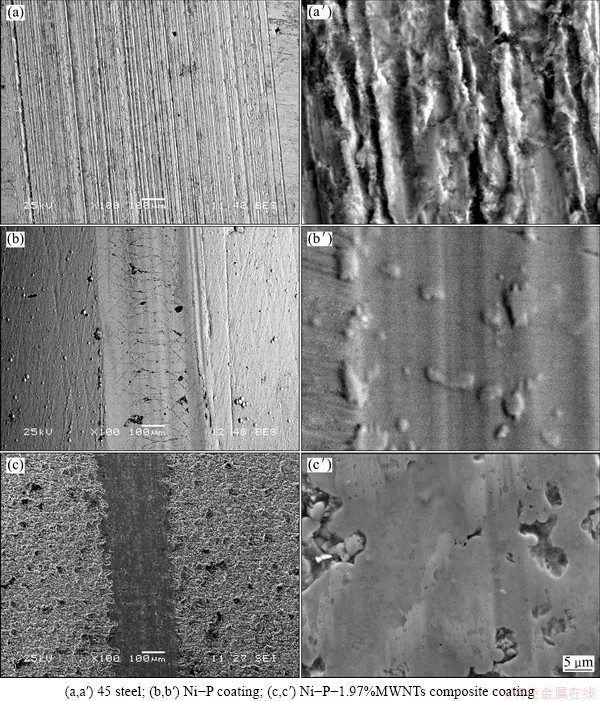

Micrographs of the worn surfaces of 45 steel, Ni-P coating and the Ni-P-1.97% MWNTs composite coatings are shown in Fig. 4. Deep grooves and dramatic deformation are observed on the worn surface of 45 steel (Fig. 4(a)), suggesting a severe abrasive sliding wear. Ni-P coating shows improved plough wear resistance with shallow abrasive grooves on the worn surface, while cracks and flaky debris are visible (Fig. 4(b)). The morphological characteristics of Ni-P coating can be attributed to the presence of Ni3P phase, which is formed during the course of annealing. On one hand, Ni3P is hard and consequently enhances the wear resistance of Ni-P coating. On the other hand, the brittle nature of Ni3P makes Ni-P coating easy to crack and to develop fatigue spalling during the wear process.

By contrast, the composite coating displays the narrowest wear track, as well as a rather smooth worn surface without visible abrasive grooves or cracks (Fig. 4 (c)), indicating a mild sliding wear. It has been reported that MWNTs presented at the grain boundaries can lock the crack propagation and also strengthen the grain boundaries via a pinning mechanism [19]. Furthermore, the presence of MWNTs within the grain may also act as a barrier for cracks generated on the worn surface, terminating further propagation inside the grains, via a crack bridging phenomenon [20]. Hence, MWNTs can substantially enhance the toughness and hardness and thus contributes to a higher wear resistance of the composite coating.

Fig. 4 Images of worn surfaces

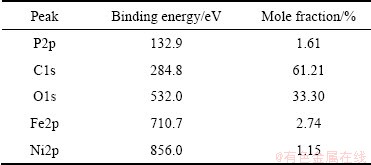

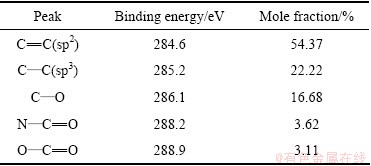

To further explore the effects of MWNTs on the tribological performance, XPS was used to determine the chemical composition and the natures of chemical bonds presented on the worn surface of the steel ball sliding against the Ni-P-1.97% MWNTs composite coatings. A survey spectrum is shown in Fig. 5(a). The main peaks are distinguished as P2p, C1s, O1s, Fe2p and Ni2p signals, corresponding binding energy at 132.9, 284.8, 532.0, 710.7 and 856.0 eV. Quantitative analysis, given in Table 3, shows that the mole fraction of Fe, as the main constituent of the balls, is only 2.74%, while the mole fraction of C reaches 61.21%. The curve fitting of C1s peak was also performed and the results are given in Fig. 5(b). These bonding energy peaks are assigned to C=C (sp2) at 284.6 eV, C—C (sp3) at 285.2 eV, C—O at 286.1 eV, N—C=O at 288.2 eV and O—C=O at 288.9 eV [21,22]. Quantitative results of the curve fitting are summarized in Table 4. The content of C=C (sp2) reaches 54.37%, indicating that graphic carbon plays a dominate role on the worn surface of the steel ball.

All these XPS results suggest that a transfer film, with the basic constitute being graphitic carbon, has been formed on the worn surface during the wear process. It is understood that the graphitic carbon is originated from MWNTs and their debris, which serves as a good solid lubricant. In that way, the direct contact between the friction pairs is avoid and the sliding is well lubricated. Thus, a very low friction coefficient is available and the wear volume rate is further decreased.

Fig. 5 XPS spectra of worn surface of steel ball sliding against Ni-P-1.97% MWNTs composite coatings

Table 3 Analysis of XPS survey spectrum for worn surface of steel ball sliding against Ni-P-1.97% MWNTs composite coatings

Table 4 Summarized results obtained by curve fitting of C1s peaks

4 Conclusions

1) Short MWNTs with uniform length and open tips were obtained through a wet-milling process in the presence of ammonia and CTAB. The milled MWNTs were successfully co-deposited with Ni-P to form Ni-P-MWNTs composite coatings by electroless plating. With increasing the MWNTs content in the plating bath, the MWNT content in the composite coating goes through an earlier increase and later decrease.

2) In contrast to 45 steel and Ni-P coating, the Ni-P-MWNTs composite coatings reveal significantly improved friction reduction and anti-wear performances. With increasing the MWNT content from 0.74% to 1.97%, the friction coefficient and wear volume rate decrease gradually. As for the Ni-P-1.97% MWNTs composite coating, the friction coefficient and the volume wear rate are only 0.08 and 6.22×10-15 m3/(N·m), respectively.

3) The improved tribological performances of the Ni-P-MWNTs composite coatings can be attributed to two aspects. On one hand, the introduction of MWNTs can enhance the toughness and hardness and consequently lead to a higher wear resistance of the composite coatings. On the other hand, MWNTs and their debris can make a main contribution to a transfer film on the worn surface of the counter steel ball during wear process, which can provide lubricating properties to the interface.

References

[1] IIJIMA S. Helical microtubules of graphitic carbon [J]. Nature, 1991, 354(6348): 56-58.

[2] YU M F, LOURIE O, DYER M J,MOLONI K, KELLY T F, RUOFF R S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load [J]. Science, 2000, 287(5453): 637-640.

[3] CANESTRARO C D, SCHNITZLER M C, ZARBIN A J P, LUZ M G E, ROMAN L S. Carbon nanotubes based nanocomposites for photocurrent improvement [J]. Applied Surface Science, 2006, 252(15): 5575-5578.

[4] GAO B, CHEN S Y, FU Q B, YUAN C Z, ZHANG X G. Preparation and electrochemical capacitive performance of Co(OH)2/benzoic acid functionalized carbon nanotubes [J]. The Chinese Journal of Nonferrous Metal, 2009, 19(9): 1642-1648. (in Chinese)

[5] EBBESEN T W. Carbon nanotubes: Preparation and properties [M]. United States: CRC Press, 1996: 304-305.

[6] HIRATA A, YOSHIOKA N. Sliding friction properties of carbon nanotube coatings deposited by microwave plasma chemical vapor deposition [J]. Tribology International, 2004, 37(11-12): 893-898.

[7] HWANG H J, JUNG S L, CHO K H, KIM Y J, JANG H. Tribological performance of brake friction materials containing carbon nanotubes [J]. Wear, 2010, 268(2-3): 519-525.

[8] LAHIRI D, SINGH V, KESHRI A K, SEAL S, AGARWAL A. Carbon nanotube toughened hydroxyapatite by spark plasma sintering: Microstructural evolution and multiscale tribological properties [J]. Carbon, 2010, 48(11): 3103-3120.

[9] LIN C B, CHANG Z C, TUNG Y H, KO Y Y. Manufacturing and tribological properties of copper matrix/carbon nanotubes composites [J]. Wear, 2011, 270(5-6): 382-394.

[10] RASTOGI R, KAUSHAL R, TRIPATHI S K, SHARMA A L, KAUR I, BHARADWAJ L M. Comparative study of carbon nanotube dispersion using surfactants [J]. Journal of Colloid and Interface Science, 2008, 328(2): 421-428.

[11] MEN X H, ZHANG Z Z, SONG H J, WANG K, JIANG W. Functionalization of carbon nanotubes to improve the tribological properties of poly(furfuryl alcohol) composite coatings [J]. Composites Science and technology, 2008, 68(3-4): 1042-1049.

[12] PARK O K, JEEVANANDA T, KIM N H, KIM S I, LEE J H. Effects of surface modification on the dispersion and electrical conductivity of carbon nanotube/polyaniline composites [J]. Scripta Materialia, 2009, 60(7): 551-554.

[13] LIU F, ZHANG X B, CHENG J P, TU J P, KONG F H, HUANG W Z, CHEN C P. Preparation of short carbon nanotubes by mechanical ball milling and their hydrogen adsorption behavior [J].Carbon, 2003, 41(13): 2527-2532.

[14] KONYA Z, ZHU J, NIESZ K, MEHN D, KIRICSI I. End morphology of ball milled carbon nanotubes [J]. Carbon, 2004, 42(10): 2001-2008.

[15] CHEN W X, GAN H Y, TU J P, CHEN W L, XIA J B, WANG J G, XU Z D, ZHOU G Z. Friction and wear behavior of Ni-P-carbon nanotubes (CNTs) electroless composite coating [J]. Tribology, 2002, 22(4): 241-244.

[16] DENG Fu-ming, CHEN Xiao-hua, CHEN Wei-xiang, LI Wen-zhou. Electroless plating Ni-P matrix composite coating reinforced by carbon nanotubes [J]. Transactions of Nonferrous Metals Society of China, 2004, 14(4): 681-685.

[17] AHN J H, SHIN H S, KIM Y J, CHUNG H. Structural modification of carbon nanotubes by various ball milling [J]. Journal of Alloys and Compounds, 2007, 434(suppl): 428-432.

[18] CHEN L F, XIE H Q. Surfactant-free nanofluids containing double- and single-walled carbon nanotubes functionalized by a wet-mechanochemical reaction [J]. Thermochimica Acta, 2010, 497(1-2): 67-71.

[19] AHMAD I, KENNEDY A, ZHU Y Q. Wear resistant properties of multi-walled carbon nanotubes reinforced Al2O3 nanocomposites [J]. Wear, 2010, 269(1-2): 71-78.

[20] CORRAL E L, GARARY J, BARRERA E V. Engineering nanostructure for single-walled carbon nanotubes reinforced silicon nitride nanocomposites [J]. American Ceramic Society Bulletin, 2008, 91(10): 3129-3137.

[21] MA P C, KIM J Q, TANG B Z. Functionalization of carbon nanotubes using a silane coupling agent [J]. Carbon, 2006, 44(15): 3232-3238.

[22] WAGNER C D, RIGS W M, DAVIS L E, MOULDER F, MUILENBERG G E. Handbook of X-ray photoelectron spectroscopy (physical electronic division) [M]. United States: Perkin Elmer Corporation, 1979: 38-39.

孟振强,李溪滨,熊拥军,湛 菁

中南大学 粉末冶金国家重点实验室,长沙 410083

摘 要:采用湿式球磨对多壁碳纳米管(MWNTs)预处理,通过化学镀制备Ni-P-MWNTs复合镀层;对45钢、传统Ni-P镀层和Ni-P-MWNTs复合镀层在干摩擦条件下的摩擦磨损性能进行考察和比较。结果表明,球磨后MWNTs长径比降低,长度均匀,且多数端部处于敞开状态。与45钢和Ni-P镀层相比,Ni-P-MWNTs复合镀层的减摩耐磨能力显著强化。当复合镀层中MWNTs的质量分数为0.74%~1.97%时,其摩擦因数和磨损率随MWNTs含量的增加而减少;对于MWNTs质量分数为1.97%的复合镀层,其摩擦因数和磨损率仅为0.08和6.22×10-15 m3/(N·m)。复合镀层优良的摩擦磨损性能归因于MWNTs优异的力学性能和自润滑特性。

关键词:Ni-P镀层;碳纳米管;复合镀层;球磨;化学镀;自润滑;摩擦磨损性能;摩擦因数;体积磨损率

(Edited by LI Xiang-qun)

Foundation item: Project (JPPT-115-5-1759) supported by the National Defense Science and Technology Industry Committee of China; Project (20090162120080) supported by Research Fund for the Doctoral Program of Higher Education of China; Project (2010FJ3012) supported by the Program of Science and Technology of Hunan Province, China

Corresponding author: XIONG Yong-jun; Tel: +86-731-88876566; E-mail: yongjunxiong@csu.edu.cn

DOI: 10.1016/S1003-6326(11)61523-9