文章编号:1004-0609(2012)05-1371-06

超音速火焰喷涂WC-10Co4Cr涂层的耐滑动磨损行为

李松林1, 2,向锦涛1, 3,周伍喜4,李玉玺4,陈 文2

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 莱芜职业技术学院 莱芜市粉末冶金先进制造重点实验室,莱芜 271100;

3. 湖南大学 化学化工学院,长沙 410082;4. 自贡长城硬面材料有限公司,自贡 643011)

摘 要:采用超音速火焰喷涂(HVOF)工艺制备微米结构WC-10Co4Cr涂层,分别采用金相显微镜、扫描电镜 (SEM)、X射线衍射(XRD)和滑动磨损设备分析涂层的微观结构和滑动磨损行为。结果表明:采用液体煤油燃料HVOF喷涂的微米结构WC-10Co4Cr涂层的脱碳程度较低,涂层中仅出现WC和W2C相,而无η相(Co3W3C、 Co6W6C)以及软相W。涂层微观结构致密,孔隙率约为1%,平均显微硬度为1 322HV0.3;在相同试验条件下,WC-10Co4Cr涂层的摩擦因数(约0.8)高于不锈钢(1Cr18Ni9Ti)的摩擦因数(约0.5),其滑动体积损失量仅为不锈钢涂层的1/146,具有优异的抗滑动磨损性能。涂层在滑动磨损过程中首先是粘结相的脱落,然后是WC颗粒的磨损。

关键词: WC-10Co4Cr涂层;超音速火焰喷涂(HVOF);滑动磨损

中图分类号:TG174 文献标志码:A

Sliding wear behavior of

high-velocity oxy-fuel sprayed WC-10Co4Cr coatings

LI Song-lin1, 2, XIANG Jin-tao1, 3, ZHOU Wu-xi4, LI Yu-xi4, CHEN Wen2

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Key Laboratory for Powder Metallurgy in Advanced Manufacturing,

Laiwu Vocational and Technical College, Laiwu 271100, China;

3. School of Chemistry and Chemical Engineering, Hunan University, Changsha 410082, China;

4. Zigong Cement Carbide Co., Ltd., Zigong 643011, China)

Abstract: The micro-structured WC-10Co4Cr coatings were deposited by the high-velocity oxy-fuel (HVOF) spray process. The microstructure and sliding wear behavior of the coatings were respectively characterized by optical microscopy, scanning electron microscopy (SEM), X-ray diffraction (XRD) and sliding wear test. The results show that decarborization of the coating is low by using liquid kerosene as fuel. Only WC and W2C exist in the sprayed coating, while there is no η phase (Co3W3C, Co6W6C) or the soft phase W. The coating is highly densified with porosity as low as about 1% and the microhardness of the coating is 1 322 HV0.3. The coefficient of friction for WC-10Co4Cr coating (about 0.8) is higher than that for 1Cr18Ni9Ti stainless steel (about 0.5) and the volume loss of sliding wear is only 1/146 of that of 1Cr18Ni9Ti, indicating the excellent sliding wear resistance performance of the WC-10Co4Cr coating. The failure of the WC-10Co4Cr coating during sliding wear is due to binder phase loss followed by wearing of WC particles.

Key words: WC-10Co4Cr coating; high-velocity oxy-fuel (HVOF) spray; sliding wear

热喷涂WC-Co金属陶瓷涂层具有良好的耐磨性和耐腐蚀性,广泛应用于航空航天、钢铁、汽车、冶金及电力等领域[1],目前,普遍采用大气等离子(APS)和超音速火焰(HVOF)喷涂技术制备WC-Co涂层。与APS技术相比,采用HVOF技术能提高涂层与基体的结合力,涂层孔隙率较低、不良品数量减少。HVOF系统中,由于喷枪的设计和使用的燃料类型不同而导致系统种类繁多,但其演变的主要驱动力还是燃料,由于使用燃料的不同,又分为气体燃料超音速火焰喷涂(HVOGF)和液体燃料超音速火焰喷涂(HVOLF)两大类。HVOLF系统较HVOGF系统具有燃料更加 低廉,可以获得高动量输出从而获得较高颗粒流速的优点,已越来越得到研究者的关注[2-5]。

迄今为止,HOVF热喷涂的研究主要集中在实验和燃料燃烧模型两大块,国内对于WC-CoCr体系的研究集中在HVOGF系统的实验制备和表征方面,如微观结构表征和磨粒磨损、冲蚀疲劳性能以及抗化学腐蚀性能的研究。张忠诚等[6]研究了粉末粒度和WC颗粒尺寸对涂层性能的影响;周克崧等[7]研究了300M 钢基体上高速火焰喷涂WC-17Co 和WC-10Co4Cr 涂层的疲劳和抗盐雾腐蚀性能,指出高速火焰喷涂WC-10Co4Cr 涂层是更好的电镀硬铬替代材料;张光华等[8]研究了DJ-2700(丙烷燃料)和TAFA JP-5000(航空煤油燃料)制备的WC-10Co4Cr 涂层的抗砂浆冲蚀行为,发现由TAFA JP-5000(航空煤油燃料)制备的涂层的硬度均高于DJ-2700(丙烷燃料)系统制备的涂层的硬度,且气孔率也低一些。国外对于WC-CoCr体系的研究较为深入,如应用HVOGF和HVOLF喷涂制备WC-Co涂层的滑动磨损性能研究、液体丙烷燃料的模型研究以及液体航空煤油的3-D模型研究 等[5, 9-10]。SCHWETZKE和KREYE[4]研究了使用不同的燃料(丙烷、乙烯以及航空煤油)引起涂层相转变对于涂层性能的影响,通过对比发现,使用航空煤油脱碳产生W2C新相的量明显少于使用丙烷和乙烯脱碳产生W2C新相的量。ZHANG等[11]对于涂层微观结构的研究也表明,液体燃料系统相比于气体燃料系统能获得更致密、结合更好而无过熔粉末颗粒的涂层结构。

WC-Co涂层耐腐蚀性能较差制约了其在许多领域的应用,WC-CoCr涂层在传统硬质合金中添加金属铬后形成钴铬粘结相,从而具有更优异的耐腐蚀性能,可用于水性溶液和湿气腐蚀环境中,如纸辊、球阀、压缩机轴等[12-13]。超音速火焰喷涂WC-CoCr金属陶瓷涂层可有效替代镀硬铬层而广泛应用于冷轧工艺辊,使辊子寿命大大延长[14]。实际应用过程中WC- CoCr涂层耐滑动磨损性能对延长工件的使用寿命至关重要,如钢铁行业的结晶器铜板、输送辊和炉辊等工件表面涂层的耐滑动磨损性能对于改善钢板质量、降低成本至关重要[15]。然而,有关使用航空煤油做燃料的HVOF制备WC-10Co4Cr 涂层耐滑动磨损的研究报道还很少,因此,本文作者将研究采用液体燃料(航空煤油),以TAFA JP-5000喷涂系统制备WC- 10Co4Cr涂层,研究涂层的微观结构和耐滑动磨损行为,为工件表面涂层在抗滑动磨损的实际应用提供理论依据。

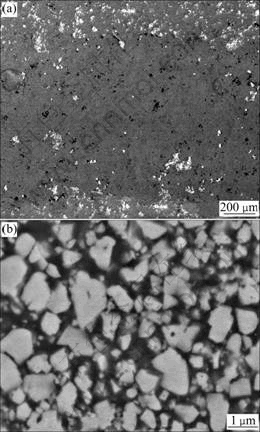

1 实验

1.1 实验原料

喷涂原料为团聚烧结法制备的WC-10Co4Cr粉末(自贡长城硬面材料有限公司生产),粉末粒度20~45 μm,松装密度5.09 g/cm3,其形貌如图1所示。图1(a)显示粉末球形度高,流动性好、且表面粗糙多孔,这种粉末形貌有利于HVOF过程;图1(b)显示粉末结构致密、WC晶粒形状不规则,平均晶粒尺寸约1 μm。WC-10Co4Cr的化学成分如表1所列。

图1 WC-10Co4Cr粉末的SEM像

Fig. 1 SEM images of WC-10Co4Cr starting powders: (a) Low magnification; (b) High magnification

表1 WC-10Co4Cr粉末的化学成分

Table 1 Chemical composition of WC-10Co4Cr starting powder (mass fraction, %)

1.2 涂层制备

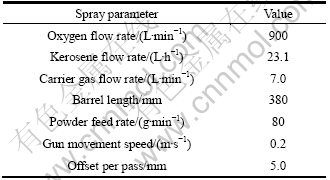

将尺寸为25 mm×16 mm×6 mm的不锈钢(1Cr18Ni9Ti)片先后用丙酮进行清洗除油、16#棕刚玉喷砂粗化、酒精清洗、烘干等前处理,然后采用美国TAFA JP-5000超音速火焰喷枪系统制备热喷涂涂层。喷涂工艺参数的选择是基于获得较低的喷涂温度和较高的喷涂速率而定,本实验基于此确定的工艺参数如表2所列。通过有效的遮挡和水冷,高速火焰喷涂过程中基体的温度始终控制在100 ℃以下,喷涂的涂层厚度300 μm。用于滑动磨损性能检测的涂层和1Cr18Ni9Ti不锈钢表面采用相同工艺磨样和抛光。涂层截面镶样后采用相同工艺磨样和抛光,用于微观结构和金相分析。

表2 HVOF喷涂工艺参数

Table 2 Processing parameters of HVOF spraying

1.3 性能表征

采用Nova Nano SEM 230场发射扫描电镜分析涂层微观结构;采用Rigaku D/max 2500型X衍射仪分析粉末和涂层的物相;应用MeF3A 6532-01金相显微镜观察涂层结构、分析涂层的孔隙率;采用美国标乐公司生产的5104型微氏硬度计测定涂层截面的显微硬度,加载载荷为3 N,保压时间为10 s,测5个值取平均值;涂层和不锈钢材料的耐滑动磨损性能采用美国CETR公司生产的UMT-3的滑动磨损设备测定,摩擦副为直径10.5 mm的氧化锆小球,实验载荷为10 N,转数为600 r/min,测试时间均为120 min,每个样品都采用一颗新的氧化锆小球。

2 结果与讨论

2.1 物相分析

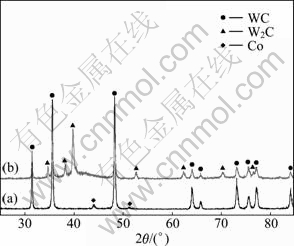

图2所示为WC-10Co4Cr粉末喷涂前后的X射线衍射谱。由图2可知:粉末的XRD谱中仅有WC相和Co相,无Co3W3C等的衍射峰,这与MURTHY和VENKATARNMAN的研究结果相似[16]。与粉末相比,涂层XRD图中WC的峰位基本相同,涂层中没有Co相的衍射峰,这是由于沉积过程中WC在Co相的溶解,在2θ=44°附近涂层有一较宽泛的衍射峰,这可能是喷涂过程中熔融颗粒撞击基体材料,粒子以极高的速度冷却从而形成非晶或纳米晶相所致。SUDAPRASERT等[9]的研究也表明采用HVOGF喷涂制备的WC-Co涂层中W2C相的峰强度明显高于HVOLF制备的WC-Co涂层中W2C相的峰强度,且采用HVOGF喷涂制备的WC-Co涂层中非晶光环也比HVOLF制备的WC-Co涂层中非晶光环明显,且前者有W产生。XRD分析结果表明,在喷涂过程中 WC相出现了一定程度的脱碳,产生了W2C 脱碳相,但脱碳不严重,没有出现脆性的η相(Co3W3C、 Co6W6C)或W相。因为航空煤油液体燃料喷枪JP- 5000与气体燃料和其他喷枪相比具有较低的焰流温度和较高的颗粒速度,WC-10Co4Cr粉末在焰流飞行过程中氧化程度低,从而易于获得相结构较为单一和高性能的WC-10Co4Cr涂层。

图2 WC-10Co4Cr粉末和涂层的XRD谱

Fig. 2 XRD patterns of WC-10Co4Cr powder and coating: (a) WC-CoCr powder; (b) WC-CoCr coating

2.2 微观结构分析

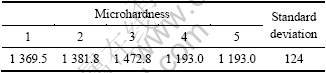

涂层截面的金相结构如图3所示。由图3可以看出,涂层非常致密,孔隙细小、分散均匀,使用图像分析软件测得涂层的截面孔隙率约为1%。涂层的显微硬度如表3所列,其平均显微硬度为1 322 HV0.3,标准偏差为124。GHABCHI等[17]采用气体燃料DJ喷枪制备的WC-10Co4Cr常规结构涂层其孔隙率为2%,显微硬度为1 265 HV0.3。ZHANG等[11]对于涂层微观结构的研究也表明:液体燃料系统相比于气体燃料系统能获得更致密、结合更好而无过熔粉末颗粒的涂层结构。因此,使用航空煤油燃料和JP-5000喷枪系统制备的WC-10Co4Cr涂层具有更致密的结构和更高的显微硬度。

图3 涂层截面的金相图

Fig. 3 Cross-section morphology of sprayed coating

表3 不同涂层样品的显微硬度及标准差

Table 3 Microhardness (HV0.3) of different coatings and standard deviation

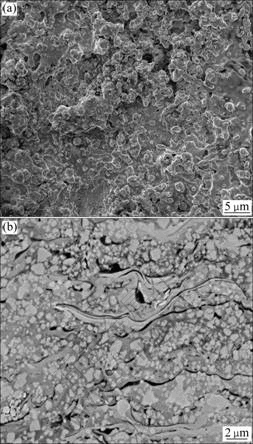

涂层的表面形貌如图4(a)所示。由图4(a)可以看出,粉末颗粒在撞击基体后,绝大多数已充分摊平,呈菜花型或薄饼状,说明由于加热温度高,颗粒在喷涂过程中能在焰流中充分熔融、变形,具有较强的填充孔隙的能力且颗粒之间相互咬合作用强,使得涂层致密,且层与层间结合能力增强。图4(b)所示为涂层截面的背散射电镜照片。可以看出:有带圆边的WC颗粒,这是WC粒子在粘结相部分分解所致。随着熔融粒子高速撞击基体,新相从过饱和的粘结相中析出,从而形成W2C包覆WC颗粒的形貌特征。另外,截面的显微图中还出现一些沿着层间边界分布的小块的黑色形貌,可能是较小的孔隙或者氧化物包裹体。

2.3 抗滑动磨损性能

分别选取涂层和不锈钢(1Cr18Ni9Ti)各一个试样在相同转速、载荷和时间下进行滑动磨损试验,涂层磨损后的表面能谱分析结果如图5所示。由图5可以看出,涂层经过磨损后表面未发现锆元素,涂层的质量损失是由涂层本身成分的变化导致。

涂层的累积质量损失为0.2 mg (换算成体积损失量为1.37×10-5 cm3),不锈钢的累积质量损失为15.8 mg (换算成体积损失量为0.002 0 cm3),不锈钢体积损失量约为涂层的146倍。涂层表现出很高的耐滑动磨损性能,这应该是两个因素共同作用的结果。首先是WC-10Co4Cr涂层本身优良的耐磨性,其次与HVOLF喷涂制备WC-10Co4Cr涂层出现的少量W2C有关,一些研究者已发现抗滑动磨损性能的增加与涂层产物分解程度有关,特别是W2C,因为W2C的硬度比WC的硬度高[18-19]。涂层与不锈钢的摩擦因数曲线如图6所示。起始阶段不锈钢的摩擦因数在500 s后在0.2上下波动缓慢增加,在3 000 s左右在0.55上下波动;涂层的摩擦因数在1 000 s前迅速从0.49变化到0.77,然后在1 000 s后在0.8上下波动。

图4 WC-10Co4Cr涂层的形貌

Fig. 4 Micrographs of of WC-10Co4Cr coating: (a) Surface, (b) Cross section

图5 磨损后涂层表面的EDS分析结果

Fig. 5 EDS results of worn surface of coating

图6 涂层滑动摩擦因数的变化曲线

Fig. 6 Friction coefficient of coating as function of test time for sliding wear

滑动磨损后涂层的表面形貌如图7所示。结合图6的摩擦曲线可以分析涂层的滑动磨损行为。如图7(a)可以清晰看到涂层表面磨损后的凹痕,这可能是由于氧化锆摩擦副对涂层表面的犁沟作用,微观表面经犁沟、剪切和切削产生槽状磨痕[20]。结合摩擦曲线,磨损初期涂层中粘结相硬度比氧化锆的低,氧化锆小球与粘结相的相互作用使得磨损剧烈,摩擦因数在短时间内迅速增大。通过背散射电子照片(见图7(b))可知,磨损后的表面出现大量与粉末颗粒形貌类似的棱角状WC颗粒,WC颗粒部分或完全开裂,并有略微的突出,这可能是由于犁削作用造成的隆起,之后碎裂的WC颗粒伴随着粘结相的转移而被移除[17]。移除的WC颗粒一部分被摩擦副挤出,另一部分成为接触表面的三体研磨颗粒而加剧涂层的磨损,随着研磨时间的增长这些碎屑更加细小,细小的研磨颗粒对涂层接触表面的破坏作用减轻,磨屑对涂层的磨损作用随着WC粒子尺寸的降低而降低[21]。结合摩擦因数变化图(见图6)分析,粘结相移除后,摩擦主要发生在硬质相的WC和摩擦副间,摩擦因数增大,但磨损过程中剥落的WC颗粒部分转化为磨粒继续与涂层摩擦,从曲线上也可以看出在1 000~4 500 s过程中还有略微的起伏,正是这个缘故。通常WC颗粒与Co之间结合越差,涂层的耐磨性越差,在采用航空煤油作为液体燃料的HVOF过程中,只产生了WC和少量W2C相,而无软相W的出现,且有研究证明,少量的W2C有利于增加涂层的抗滑动磨损性。这个综合的因素导致HVOLF制备的涂层表现出优异耐滑动磨损性能。

图7 磨损后涂层的SEM像

Fig. 7 SEM images of coating after wear: (a) Low magnification; (b) High magnification

3 结论

1) 采用高速火焰喷涂技术(HVOF)制备的WC- 10Co4Cr涂层物相为WC相和W2C相,出现一定程度的脱碳,但无脆性η相(Co3W3C、Co6W6C)以及软相W出现,表明使用液体航空煤油作燃料的JP-5000喷枪系统能获得脱碳少、相结构较单一的涂层。

2) 采用JP-5000喷枪、液体航空煤油作燃料的系统喷涂制备的WC-10Co4Cr涂层微观结构致密,其平均显微硬度为1 322 HV0.3,孔隙率约1%。

3) 在磨损载荷为10 N、转速为600 r/min、磨损时间为120 min的条件下,不锈钢的体积损失量约为WC-10Co4Cr涂层的146倍;WC-10Co4Cr涂层的摩擦因数在1 000 s后稳定在0.8左右,WC-10Co4Cr涂层在滑动磨损过程中首先是粘结相的磨损,然后是WC颗粒的突出、开裂、剥落和磨损,涂层的磨损机制以WC的碎裂和三体磨粒磨损为主。

REFERENCES

[1] HE J H, SCHOENUNG J M. Nanostructured coatings [J]. Materials Science and Engineering A, 2002, 336(1/2): 274-319.

[2] SMITH R W, KNIGHT R. Thermal spraying: I. Powder consolidation from coating to forming [J]. Journal of Metals, 1995, 47(8): 32-39.

[3] SOBOLEV V V, GUILEMANY J M. Dynamic processes during high velocity oxyfuel spraying [J]. International Materials Reviews, 1996, 41(1): 13-32.

[4] SCHWETZKE R, KREYE H. Microstructure and properties of tungsten carbide coatings sprayed with various high-velocity oxygen fuel spray systems [J]. Journal of Thermal Spray Technology, 1999, 8(3): 433-439.

[5] KAMNIS S, GU S. Numerical modelling of propane combustion in a high velocity oxygen-fuel thermal spray gun [J]. Chemical Engineering and Processing, 2006, 45(4): 246-253.

[6] 张忠诚, 邓春明, 朱晖朝, 倪伟邦, 赵 利. 不同粉末超音速火焰喷涂WC-l0%Co4%Cr涂层的性能[J]. 硬质合金, 2009, 26(2): 87-91.

ZHANG Zhong-cheng, DENG Chun-ming, ZHU Hui-chao, NI Wei-bang, ZHAO Li. WC-10%Co4%Cr coatings prepared by different feedstocks [J]. Cemented Carbide, 2009, 26(2): 87-91.

[7] 周克崧, 邓春明, 刘 敏, 宋进兵, 邓畅光. 300M钢基体上高速火焰喷涂WC-17Co和WC-10Co4Cr涂层的疲劳和抗盐雾腐蚀性能[J]. 稀有金属材料与工程, 2009, 38(4): 671-676.

ZHOU Ke-song, DENG Chun-ming, LIU Min, SONG Jin-bing, DENG Chang-guang. Characterizations of fatigue and salt spray corrosion resistance of HVAF sprayed WC-17Co and WC-10Co4Cr coatings on the substrate of 300M steel [J]. Rare Metal Materials and Engineering, 2009, 38(4): 671-676.

[8] 张光华, 李 曙, 刘 阳, 王华仁. HVOF喷涂WC-10Co-4Cr涂层的砂浆冲蚀行为[J]. 中国表面工程, 2007, 20(4): 16-28.

ZHANG Guang-hua, LI Shu, LIU Yan, WANG Hua-ren. Slurry erosion behavior of HVOF sprayed WC-10Co-4Cr coatings [J]. China Surface Engineering, 2007, 20(4): 16-28.

[9] SUDAPRASERT T, SHIPWAY P H, MCCARTNEY D G. Sliding wear behaviour of HVOF sprayed WC-Co coatings deposited with both gas-fuelled and liquid-fuelled systems [J]. Wear, 2003, 255(7/12): 943-949.

[10] KAMNIS S, GU S. 3-D modelling of kerosene-fuelled HVOF thermal spray gun [J]. Chemical Engineering Science, 2006, 61(16): 5427-5439.

[11] ZHANG D, HARRIS S J, MCCARTNEY D G. Microstructure formation and corrosion behaviour in HVOF-sprayed Inconel 625 coatings [J]. Material Science and Engineering A, 2003, 344(1/2): 45-56.

[12] SIDHU T S, PRAKASH S, AGRAWAL R D. Studies on the properties of high-velocity oxy-fuel thermal spray coatings for higher temperature applications [J]. Materials Science, 2005, 41(6): 805-823.

[13] HEARLEY J A, LITTLE J A, STURGEON A J. The effect of spray parameters on the properties of high velocity oxy-fuel NiAl intermetallic coating [J]. Surface and Coating Technology, 2000, 123(2/3): 210-218.

[14] RAMNATH V, JAYARAMAN N. Characterization and wear performance of plasma sprayed WC-Co coatings [J]. Materials Science and Technology, 1989, 5(4): 382-388.

[15] MATTHEWS S, JAMES B. Review of thermal spray coating applications in the steel industry: Part 1. Hardware in steel making to the continuous annealing process [J]. Journal of Thermal Spray Technology, 2010, 19(6): 1267-1276.

[16] MURTHY J K N, VENKATARAMAN B. Abrasive wear behaviour of WC-CoCr and Cr3C2-20(NiCr) deposited by HVOF and detonation spray processes [J]. Surface and Coating Technology, 2006, 200(8): 2642-2652.

[17] GHABCHI A, VARIS T, TURUNEN E. Behavior of HVOF WC-10Co4Cr coatings with different carbide size in fine and coarse particle abrasion [J]. Journal of Thermal Spray Technology, 2010, 19(1/2): 368-377.

[18] QIAO Y, FISCHER T E, DENT A. The effects of fuel chemistry and feedstock powder structure on the mechanical and tribological properties of HVOF thermal-sprayed WC-Co coatings with very fine structures [J]. Surface and Coating Technology, 2003, 172(1): 24-41.

[19] HARVEY M D F, STURGEON A J, BLUNT F J, DUNKERTON S B. Investigation into the relationship between fuel gas selection, wear performance and microstructure of HVOF sprayed WC-Co coatings [C]// Thermal Spraying: Current Status and Future Trends. Kobe, 1995: 471-475.

[20] GAHR K H Z. Wear by hard particles [J]. Tribology International, 1998, 31(10): 587-596.

[21] 马 光, 于艳爽, 王国刚, 孙冬柏, 樊自拴, 孟惠民, 俞宏英. 活性燃烧高速燃气喷涂WC-CoCr涂层的微观组织及性能[J]. 金属热处理, 2008, 32(2): 36-40.

MA Guang, YU Yan-shuang, WANG Guo-gang, SUN Dong-bai, FAN Zi-shuan, MENG Hui-min, YU Hong-ying. Microstructure and properties of AC-HVAF sprayed WC-CoCr coating [J]. Heat Treatment of Metals, 2008, 32(2): 36-40.

(编辑 陈卫萍)

基金项目:湖南省自然科学基金重点项目(10JJ2037);莱芜市粉末冶金先进制造重点实验室开放基金资助项目

收稿日期:2011-04-22;修订日期:2011-09-16

通信作者:李松林,教授,博士;电话:0731-88830614;E-mail: lisl@csu.edu.cn