DOI: 10.11817/j.ysxb.1004.0609.2021-40080

激光选区熔化成形含锆Al-Cu-Mg合金的显微组织与力学性能

王凯冬,刘允中,程 文,刘小辉,周志光

(华南理工大学 国家金属材料近净成形工程技术研究中心,广州 510640)

摘 要:采用激光选区熔化(Selective laser melting,SLM)技术制备含锆Al-Cu-Mg合金,通过SEM、EBSD、TEM、拉伸实验等方法研究沉积态和热处理态试样的显微组织与力学性能。结果表明:当激光能量密度为370 J/mm3时,试样的致密度最高。原位生成Al3Zr使试样的平均晶粒尺寸细化为1.28 μm,消除了SLM成形Al-Cu-Mg合金中的热裂纹。尺寸为50~300 nm的Al3Zr亚稳态相(L12-Al3Zr)分布于基体,L12-Al3Zr可充当α(Al)非均匀形核的有效衬底,与α(Al)晶面的错配度低,也能阻碍晶界迁移,抑制晶粒长大。工艺优化后,沉积态试样的室温抗拉强度为(369±9) MPa,伸长率为(12.4±0.6)%;T6热处理后,试样的抗拉强度提升至(485±10) MPa,伸长率略降为(11.2±0.5)%。细晶强化和弥散强化分别主导了沉积态和热处理态试样的强度提升。

关键词:激光选区熔化;Al-Cu-Mg合金;Al3Zr;显微组织;力学性能

文章编号:1004-0609(2021)-08-2069-12 中图分类号:TG146 文献标志码:A

引文格式:王凯冬,刘允中,程 文, 等. 激光选区熔化成形含锆Al-Cu-Mg合金的显微组织与力学性能[J]. 中国有色金属学报, 2021, 31(8): 2069-2080. DOI: 10.11817/j.ysxb.1004.0609.2021-40080

WANG Kai-dong, LIU Yun-zhong, CHENG Wen, et al. Microstructure and mechanical properties of Zr modified Al-Cu-Mg alloy processed by selective laser melting[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(8): 2069-2080. DOI: 10.11817/j.ysxb.1004.0609.2021-40080

激光选区熔化技术(SLM)可以实现金属零件高形状自由度、高精度、高性能成形,是国内外研究的热点[1]。轻金属铝合金在SLM成形领域的早期研究集中于焊接性较好的Al-Si系合金(AlSi10Mg[2]、AlSi12[3]等),为了扩展其应用领域,其他系铝合金的研究也逐渐展开[4]。Al-Cu-Mg合金(AA2024, AA2618等)在工业领域应用广泛,与SLM技术结合可实现复杂结构件的精确成形,发展前景广阔。但是Al-Cu-Mg合金凝固区间宽,在SLM成形过程中易产生周期性热裂纹[5],研究进展缓慢。

文献[6-8]中指出提高激光能量密度可以消除SLM成形Al-Cu系合金的热裂纹,但是合金的热裂倾向仍然很大。SISTIAGA等[9]等利用Si改性7075铝合金粉末,缩窄凝固区间,细化晶粒,消除了裂纹,提升了成形件性能,证明了复合粉末微合金化可避免SLM成形高强铝合金热裂,Al-Zr、Al-Ti-B、Al-Ti-C等中间合金开始成为SLM成形Al-Cu系合金的研究重点。ZHANG等[10]和NIE等[11]在Al-Cu-Mg合金粉末中添加了2% Zr(质量分数)粉,生成以Al3Zr为主的形核剂,无裂纹的合金试样抗拉强度提升至493 MPa,但是仅6%的伸长率可能和纯Zr粉氧化有关;WANG等[12]和胡亮等[13]均借助TiB2改善Al-Cu系合金SLM成形件的力学性能;张书雅[14]在2024铝合中掺杂了1.5%Al-Ti-C(质量分数)合金,弥散分布的TiCx纳米颗粒促进α(Al)异质形核,提升了合金成形性,但是成形件的伸长率小于3%。以上研究表明,添加中间合金形核剂消除了SLM成形Al-Cu系合金的热裂纹,但是形核剂团聚长大、元素粉氧化、复合粉末包含杂质等问题仍然亟待解决。MARTIN等[15]在Al-Zn系合金的相关问题研究中,利用ZrH2高温分解出单质Zr,在铝熔体中原位生成Al3Zr,解决形核剂氧化和团聚问题,首次制备出高强度沉积态Al-Zn系合金,但是粉末的静电自组装工艺易引入杂质,涂诚[16]则通过低能球磨组装修饰法解决了该问题。与外加形核剂相比,原位生成的形核剂分散均匀,不易团聚长大,形核效果更佳,原位反应也可避免形核剂氧化,减少了硬脆合金氧化物的数量。目前,在Al-Cu系合金SLM成形领域鲜有相关的文献报道。

Al3Zr的亚稳态面心立方相(L12-Al3Zr)与α(Al)晶格错配度低[17],是铝合金理想的异质形核剂。本文利用ZrH2稳定Zr元素,以L12-Al3Zr为原位形核质点,采用低能球磨工艺组装1.5%ZrH2/Al-Cu-Mg (质量分数)合金复合粉末。通过SLM技术、T6热处理工艺获得原位Al3Zr细化晶粒的含锆Al-Cu-Mg合金。对比沉积态Al-Cu-Mg合金以及沉积态和热处理态含锆Al-Cu-Mg合金的显微组织和力学性能,讨论相关的晶粒细化机制以及强化机制,为SLM成形Al-Cu合金的应用提供一定实验依据和技术参考。

1 实验

1.1 实验材料与方案

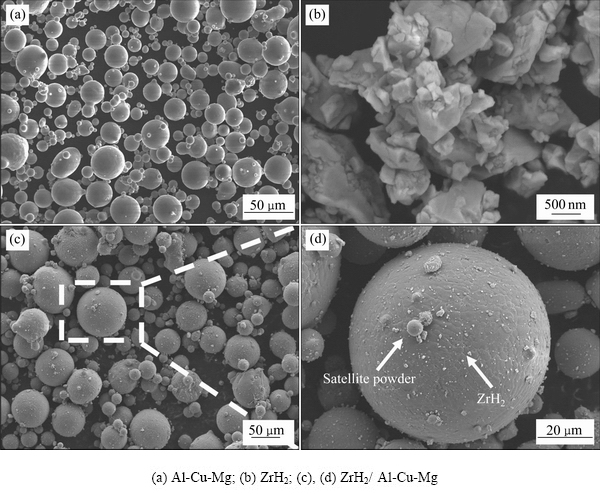

采用组合雾化法制备的Al-Cu-Mg合金球形粉末平均粒径约为28 μm,显微形貌如图1(a)所示,化学成分采用2024铝合金成分(见表1)。亚微米ZrH2颗粒由高能球磨法制得,平均粒径约为500 nm,显微形貌如图1(b)所示。采用低能球磨组装修饰法制备ZrH2/Al-Cu-Mg合金复合粉末。图1(c)和(d)所示为复合粉末形貌图,复合粉末球形度良好,便于打印过程中粉末铺展,不规则形状的ZrH2均匀镶嵌于铝合金粉末表面,为机械结合。

图1 原始粉末和ZrH2/Al-Cu-Mg合金复合粉末的显微形貌

Fig. 1 Micro-morphologies of raw powders and ZrH2/Al-Cu-Mg composite powders

采用EOS-M290激光选区熔化设备制备含锆Al-Cu-Mg合金,打印参数为:激光功率150~250 W,扫描速率200~1000 mm/s,扫描间距90 μm,铺粉层厚30 μm,相邻粉层扫描角度旋转67°,基板预热温度180 ℃,氩气气氛保护。采用体能量密度E(J/mm3)[18]表征试样成形质量:

(1)

(1)

式中:P为激光功率;v为扫描速率;h为扫描间距;t为铺粉层厚。

采用TNX1100-20箱式热处理炉进行固溶处理,试样水淬至室温,固溶温度为520 ℃,固溶时间为1 h;采用DF-101S恒温油浴锅进行时效处理,时效温度为150 ℃,时效时间为10 h,试样空冷至室温。

1.2 性能表征

采用Archimedes排水法测量致密度;采用Leica DM 15000M光学显微镜(OM)观察试样表面缺陷;采用Bruker Advance X射线衍射仪(XRD)分析材料物相;采用搭载背散射电子衍射探头(EBSD)的Nova Nano SEM 430 场发射扫描电子显微镜(SEM)观察试样的显微组织、晶粒度和晶粒取向;采用JEM-2100F场发射透射电子显微镜(TEM)观察试样的物相及其分布;采用UTM5105电子万能实验机测试试样的室温拉伸性能,加载速率为1 mm/min。

2 结果与讨论

2.1 致密度与内部缺陷

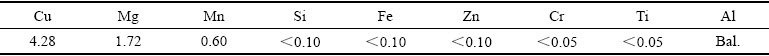

激光能量密度与沉积态含锆Al-Cu-Mg合金致密度的关系如图2(a)所示。由图2(a)可见,试样的致密度随着能量密度的增加呈现先上升后下降的趋势,在370 J/mm3时最高,为97.2%。激光能量不足时,试样的不规则形状工艺孔和球形孔数量较多,致密度偏低。低能量密度使熔池液相温度低、黏度大、铺展性差,导致熔池不完全搭接,同时,未熔粉末也会阻碍粉层间熔合,工艺孔由此产生[6];ZrH2在540 ℃左右开始分解,熔池温度低时,ZrH2分解出的部分氢气来不及逸出,以球形孔的形式残留在组织中,增加了试样球形孔数量,如图2(b)所示。激光能量增加,液相的凝固时间延长、流动性变好,有利于氢气逸出和熔池搭接,试样孔洞数量减少,如图2(c)所示。但是当激光能量密度超过400 J/mm3时,熔池内氢气的固溶度提高,湍流加剧熔池的也会吸入更多保护气体和低熔点金属蒸汽,试样孔洞数量重新增多[19],如图2(d)所示。当激光能量密度为370 J/mm3(扫描速率200 mm/s,激光功率200 W)时,致密度最高,试样成形质量最好,以此参数为基础进行后续研究。

表1 Al-Cu-Mg合金粉末的化学成分

Table 1 Chemical composition of Al-Cu-Mg alloy powders (mass fraction, %)

图2 激光能量密度与沉积态含锆Al-Cu-Mg合金致密度的关系以及典型试样的横截面金相

Fig. 2 Relationship between laser energy density and relative density of as-deposited Zr-modified Al-Cu-Mg alloy(a), and OM images of cross section of representative samples((b)-(d))

2.2 显微组织

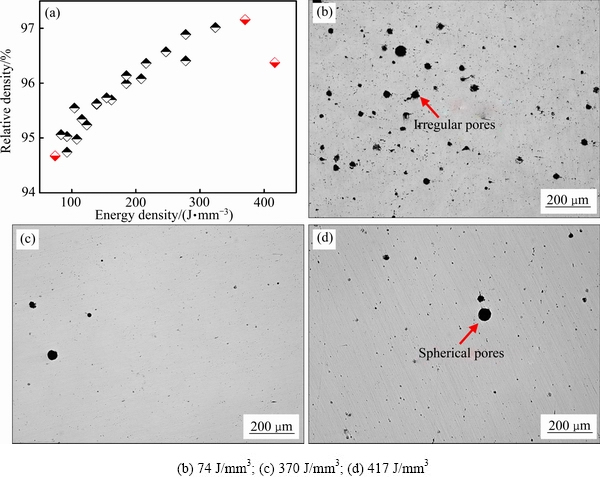

图3所示为沉积态试样的纵截面显微组织形貌。如图3(a)和(b)所示,在沉积态Al-Cu-Mg合金的纵截面,扇贝形熔池的搭接界面较为清晰,熔池深约30~70 μm,宽约100~200 μm,大量粗大柱状枝晶沿竖直方向贯穿整个熔池;存在长达数百微米的纵向裂纹,裂纹尾端尖锐,为常见的热应力裂纹。而图3(c)和(d)则显示添加ZrH2后,沉积态含锆Al-Cu-Mg合金以细小等轴晶为主,包含少量短柱状晶,晶粒细化使得熔池搭接界面消失,仅局部区域存在小熔池特征,熔池深度降低至5~25 μm,宽度缩短至40~70 μm,热裂纹完全消除。

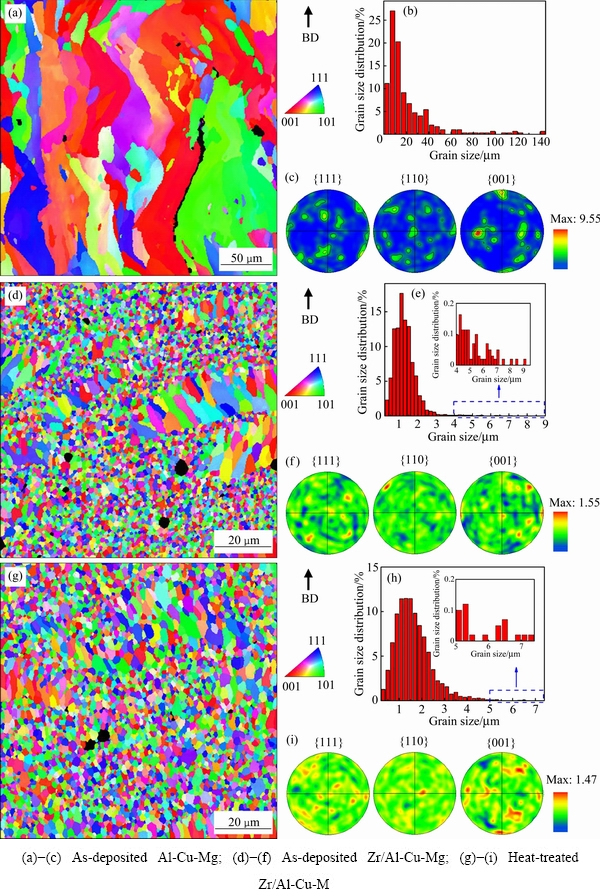

沉积态和热处理态试样的EBSD测试分析结果如图4所示。由图4(a)~(c)可知,沉积态Al-Cu-Mg合金平均晶粒尺寸约为15.69 μm,粗大柱状枝晶多为[001]取向,极图{001}晶面极密度最高为9.55;合金在竖直方向织构明显;裂纹在粗大柱状枝晶间的交界处萌生。由图4(d)~(f)可知,添加形核剂使得沉积态含锆Al-Cu-Mg合金平均晶粒尺寸细化至1.28 μm,裂纹消失,晶粒随机取向,极图最高极密度降至1.55,可认为织构几乎完全消失。如图4(g)~ (i)所示,热处理后,合金组织仍然以等轴晶为主,平均晶粒尺寸略增至1.59 μm,晶粒保持随机取向,极图的最高极密度为1.47。

图3 沉积态试样的纵截面显微组织

Fig. 3 Microstructures of vertical section of as-deposited samples

图4 沉积态和热处理态试样纵截面的IPF图、晶粒尺寸分布图和极图

Fig. 4 IPF maps((a), (d), (g)), grain size distributions((b), (e), (h)) and pole figures((c), (f), (i)) of vertical section of as-built and heat-treated samples

GAUMANN等[20]根据Hunt柱状枝晶向等轴晶转变(CET)模型提出了CET临界条件:

(2)

(2)

式中:a、n为材料相关常数;G为温度梯度;v为凝固速率;N0为形核质点密度; 为等轴晶体积分数。沉积态Al-Cu-Mg合金缺少形核衬底,粗大柱状晶(见图4(a))表明,SLM成形过程中的Gn/v值难以满足合金形成大量等轴晶的条件。SLM成形熔池尺寸小,沿打印方向温度梯度高(105~106 ℃/s)[21],熔池内过冷区较窄且易被后输入能量覆盖,因此,铝熔体无法通过自身热过冷和成分过冷大量形核[22],液相更易依附于已有晶粒外延生长,形成粗大柱状枝晶,“自下而上”的成形方式决定了柱状枝晶多沿[001]晶向生长。而在Gn/v值未明显改变的条件下,Al3Zr形核剂的添加为铝熔体固液界面前沿提供了大量形核衬底,促进了α(Al)形核,抑制了晶粒的外延生长模式,因此,合金试样晶粒细化,织构削弱。热处理态试样晶粒未发生明显长大的原因可能是第二相粒子阻碍了晶界迁移;同时,在热处理过程中,晶粒各个方向均匀受热,晶粒随机取向未受影响。

为等轴晶体积分数。沉积态Al-Cu-Mg合金缺少形核衬底,粗大柱状晶(见图4(a))表明,SLM成形过程中的Gn/v值难以满足合金形成大量等轴晶的条件。SLM成形熔池尺寸小,沿打印方向温度梯度高(105~106 ℃/s)[21],熔池内过冷区较窄且易被后输入能量覆盖,因此,铝熔体无法通过自身热过冷和成分过冷大量形核[22],液相更易依附于已有晶粒外延生长,形成粗大柱状枝晶,“自下而上”的成形方式决定了柱状枝晶多沿[001]晶向生长。而在Gn/v值未明显改变的条件下,Al3Zr形核剂的添加为铝熔体固液界面前沿提供了大量形核衬底,促进了α(Al)形核,抑制了晶粒的外延生长模式,因此,合金试样晶粒细化,织构削弱。热处理态试样晶粒未发生明显长大的原因可能是第二相粒子阻碍了晶界迁移;同时,在热处理过程中,晶粒各个方向均匀受热,晶粒随机取向未受影响。

根据Scheil-Gulliver凝固模型[22]可知,沉积态Al-Cu-Mg合金在液相凝固后期,枝晶交叉接触形成空腔,铝液相无法对其进行补缩[15];Al-Cu系合金凝固区间宽,固相凝固收缩导致热应力增大,裂纹在晶界空腔处萌生,纵向扩展。添加形核剂促进了α(Al)在铝熔体内大量形核,在半固态熔体中,细小等轴晶或短柱状晶可通过旋转、变形避免在晶界间产生空腔,液相补缩容易[15],晶界处应力缓解,热裂纹消失。

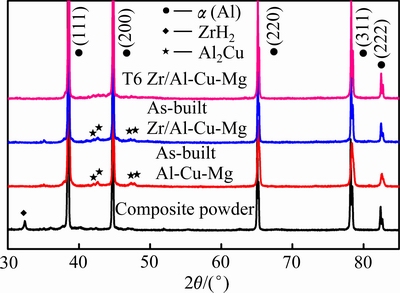

2.3 物相

图5所示为复合粉末、沉积态Al-Cu-Mg合金以及沉积态和热处理态含锆Al-Cu-Mg合金的XRD谱。由图5可看出,ZrH2的衍射峰在SLM成形后消失,θ-Al2Cu相为沉积态试样的主要沉淀相,其他物相含量较少,衍射峰过于微弱或无法检测到,未予标定。

图5 沉积态和热处理态试样以及复合粉末的XRD谱

Fig. 5 XRD patterns of as-deposited and heat-treated samples and composite powders

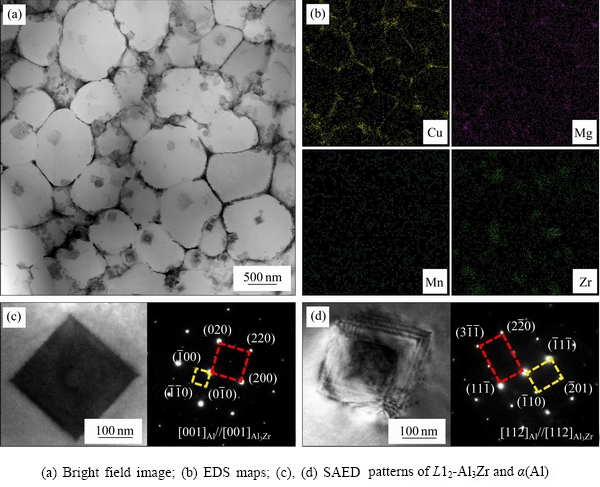

由沉积态含锆Al-Cu-Mg合金的明场像(见图6(a))和EDS谱(见图6(b))可知,基体中分布有尺寸为50~300 nm的L12-Al3Zr立方相,未见含锆氧化物以及Al3Zr平衡相(D023-Al3Zr),Cu、Mg元素存在晶界富集现象,Mn元素分布均匀。图6(c)和(d)所示为α(Al)和L12-Al3Zr界面的电子衍射花样,从图中可知

(3)

(3)

部分L12-Al3Zr与α(Al)位向关系良好,晶格匹配度高;L12-Al3Zr在基体中充当了α(Al)形核的有效衬底,而其他未作为形核衬底的L12-Al3Zr与α(Al)位向差较大。

ZrH2高温分解出的单质Zr除了在熔体中直接原位反应生成L12-Al3Zr外,还会溶于熔体并在冷却过程中以L12-Al3Zr形式原位析出[23],高冷却速率使得L12-Al3Zr未发生平衡相变。在凝固过程中,L12-Al3Zr在熔体中作为形核质点,促进α(Al)形核,被包裹晶内,与α(Al)晶格错配度低。在α(Al)晶粒长大过程中,L12-Al3Zr也会阻碍晶界的迁移运动,晶粒长大受到抑制,文献[24]也报道了相似的现象。此外,JOHNSSON[25]提出溶质生长限制因子(Q)与成分过冷正相关,溶质生长限制因子表示为

(4)

(4)

式中:m为液相线斜率;c0为溶质在熔体中的浓度;k为溶质再分配系数。熔体中总的生长限制因子等于不同溶质的生长限制因子之和,各溶质相互独立。一般认为Zr在660 ℃铝熔体中的最大固溶度约为0.27%[26],受高冷却速率影响,来不及析出的Zr元素在熔体内固溶度增大。根据文献[27]可知,溶质浓度mZr(kZr-1)约为6.8,因此,本研究中Al-Cu-Mg合金的生长限制因子(Q)约为15,添加ZrH2后,合金液相总的生长限制因子可增加约10%。液相生长限制因子增加,成分过冷度随增大,α(Al)的形核势垒降低。

图6 沉积态含锆Al-Cu-Mg合金的TEM像

Fig. 6 TEM images of as-deposited Zr-modified Al-Cu-Mg alloy

ZrH2颗粒可减少单质Zr与O的接触,从而避免显微组织中出现ZrO等硬脆的氧化物。以ZrH2颗粒替代Zr粉可保护Zr元素在制粉过程中免于氧化;同时,在SLM成形过程中,ZrH2高温分解出的氢气会和粉仓内残余氧气反应生成水蒸汽,进一步降低了成形气氛中的O含量。

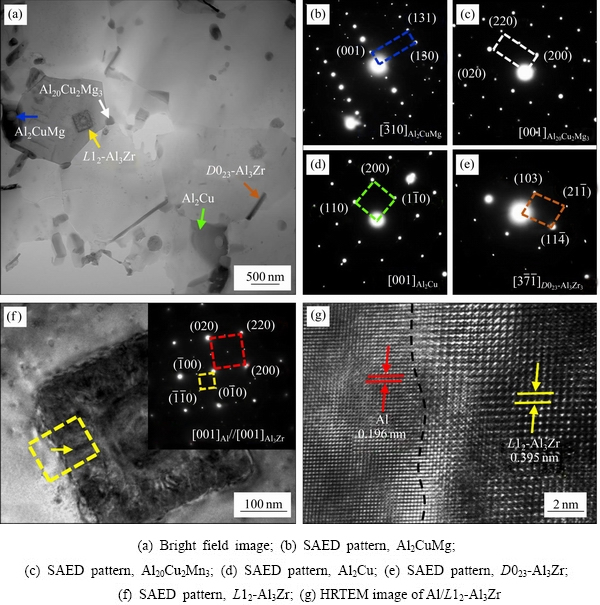

图7所示为热处理态含锆Al-Cu-Mg合金的TEM像。如图7(a)~(e)所示,沉积态含锆Al-Cu-Mg合金部分第二相在固溶处理过程中溶于基体,并在时效后析出。热处理态试样中除了弥散分布有L12-Al3Zr、θ相、T-Al20Cu2Mn3相、S-Al2CuMg相等第二相外,在晶界处析出长约500 nm的针棒状D023-Al3Zr。根据图7(f)和(g)可知,部分L12-Al3Zr与α(Al)仍然保持良好的位向关系,界面高度共格,热处理后仍然稳定存在,也从侧面反映了沉积态试样中部分L12-Al3Zr与α(Al)晶格匹配度高。

D023-Al3Zr在晶界析出的原因可能有两点: 1) 热处理过程中,晶界处的L12-Al3Zr与α(Al)位向差较大,界面能较高,部分L12-Al3Zr会向D023-Al3Zr转变[28];2) 在时效过程中,α(Al)内过饱和Zr元素会在晶界以D023-Al3Zr形式析出[29]。

2.4 力学性能与断口形貌

图7 热处理态含锆Al-Cu-Mg合金的TEM像

Fig. 7 TEM images of heat-treated Zr-modified Al-Cu-Mg alloy

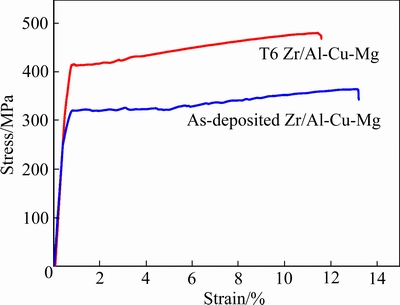

图8 含锆Al-Cu-Mg合金试样的拉伸曲线

Fig. 8 Tensile curves of Zr modified Al-Cu-Mg alloy samples

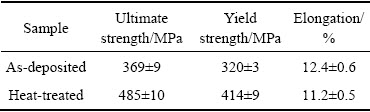

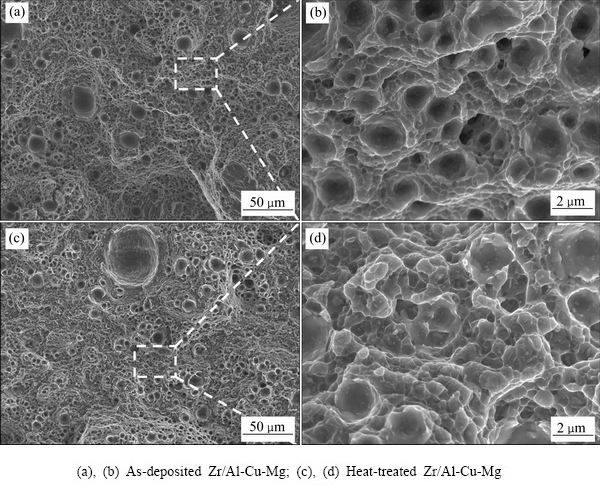

沉积态Al-Cu-Mg合金热裂纹较多,通常在低应力下发生断裂,抗拉强度约为250 MPa,屈服强度约为200 MPa,伸长率不及3%[13, 30]。图8所示为含锆Al-Cu-Mg合金试样热处理前后的拉伸曲线,具体力学性能数据见表2。在L12-Al3Zr作用下,含锆Al-Cu-Mg合金综合性能优异,室温抗拉强度提升了约120 MPa,达到(369±9) MPa,伸长率为12.4%±0.6%;热处理后,抗拉强度提升至(485±10) MPa,伸长率略有降低,为11.2%±0.5%。图9所示为含锆Al-Cu-Mg合金试样的断口形貌。从图9可知,沉积态和热处理态试样的断口处的韧窝特征明显,断裂方式均为韧性断裂。与沉积态试样相比,热处理态试样断口的韧窝直径更大,韧窝内分布有较多第二相粒子,强化了铝基体。

表2 含锆Al-Cu-Mg合金的拉伸性能

Table 2 Tensile properties of Zr/Al-Cu-Mg alloy samples

虽然添加ZrH2增加了含锆Al-Cu-Mg合金试样的孔隙率,但是成功消除了热裂纹,避免基体存在严重的割裂现象。合金试样力学性能的提升还与以下三种强化机制密切相关。

1) 细晶强化。原位形核剂使得沉积态试样平均晶粒尺寸细化至1.28 um,可用Hall-Petch公式[12]描述合金强度与晶粒尺寸的关系:

(5)

(5)

式中:b为Hall-Petch常数(取0.13 MPa/m2[11]);d0、d1为合金的晶粒尺寸,晶粒细化使合金的强度增加了约82 MPa,超过合金试样抗拉强度提升值的50%,细晶强化是合金强度提升的主要原因。

2) 弥散强化。L12-Al3Zr在与位错的交互作用中强化了铝合金基体。L12-Al3Zr属于中间合金,显微硬度远高于Al基体;同时,部分充当形核质点的L12Al3Zr在晶内与α(Al)界面共格度高,界面结合强度大。强化过程可用Orowan强化机制描述,分布较为均匀的L12-Al3Zr阻碍了位错在滑移面的运动,位错弯曲,易在L12-Al3Zr附近留下位错环,合金变形抗力增加。

3) 固溶强化。SLM成形温度高、凝固速率大,铝熔体内Zr元素来不及析出,α(Al)内少量过饱和Zr元素增大了晶格畸变,起一定固溶强化作用。由于Zr元素在基体内的固溶量未知,弥散强化和固溶强化的强度提升值无法计算。沉积态试样的伸长率超过10%主要是因为L12-Al3Zr细化了基体晶粒组织,削弱了[001]织构。试样受外力作用时,各晶粒间相互协调,变形较均匀,应力集中得到缓解。其次,部分L12-Al3Zr钉扎于晶界,一定程度上可抑制裂纹在晶界处扩展。另外,低能球磨法制备复合粉末和原位生成L12-Al3Zr可减少杂质引入、防止生成硬脆的含锆氧化物、避免形核剂团聚长大,也有助于提升合金的塑性。

热处理态含锆Al-Cu-Mg合金仍以等轴晶为主,平均晶粒尺寸略增至1.59 um,细晶强化对合金屈服强度的贡献降至约70 MPa。热处理后,弥散相颗粒T相以及析出强化相S相和θ相在基体中分布较为均匀,钉扎位错运动,强化合金性能,弥散强化主导了热处理后试样的强度提升[31]。由于四方晶格的D023-Al3Zr与α(Al)无固定位向关系,界面非共格或半共格[32],与基体结合较弱,针棒状形貌也引起一定应力集中,试样的塑性略有降低。

图9 含锆Al-Cu-Mg合金试样的断口形貌

Fig. 9 Fracture morphologies of Zr/Al-Cu-Mg alloy samples

3 结论

1) 随着激光能量密度的增加,沉积态含锆Al-Cu-Mg合金试样的致密度先上升后下降。激光能量密度370 J/mm3下成形的试样致密度最高,为97.1%。添加ZrH2后,试样的平均晶粒尺寸由15.69 mm细化至1.28 μm,组织热裂纹完全消除,晶粒呈现随机取向。

2) 沉积态含锆Al-Cu-Mg合金的Zr元素沉淀均为L12-Al3Zr相。L12-Al3Zr可充当α(Al)非均匀形核的有效衬底,促进α(Al)形核,与α(Al)位向关系良好;也能阻碍晶界迁移,抑制晶粒长大。

3) 晶粒细化后的沉积态含锆Al-Cu-Mg合金抗拉强度可达(369±9) MPa,伸长率为12.4%±0.6%。热处理后,在第二相弥散强化作用下,试样的抗拉强度提升至(485±10) MPa;伸长率受D023-Al3Zr影响略降低至11.2%±0.5%。

REFERENCES

[1] 杨永强, 陈 杰, 宋长辉, 等. 金属零件激光选区熔化增材制造技术现状及进展[J]. 激光与光电子学进展, 2018, 55(1): 9-21.

YANG Yong-qiang, CHEN Jie, SONG Chang-hui, et al. Current status and progress on technology of selective laser melting of metal parts[J]. Laser & Optoelectronics Progress, 2018, 55(1): 9-21.

[2] Gu Dong-dong, Wang Hong-qiao, Dai Dong-hua, et al. Rapid fabrication of Al-based bulk-form nanocomposites with novel reinforcement and enhanced performance by selective laser melting[J]. Scripta Materialia, 2015, 96: 25-28.

[3] Siddique S, Imran M, Wycisk E, et al. Influence of process-induced microstructure and imperfections on mechanical properties of AlSi12 processed by selective laser melting[J]. Journal of Materials Processing Technology, 2015, 221: 205-213.

[4] Li Rui-di, Wang Min-bo, Li Zhi-ming, et al. Developing a high-strength Al-Mg-Si-Sc-Zr alloy for selective laser melting: crack-inhibiting and multiple strengthening mechanisms[J]. Acta Materialia, 2020, 193: 83-98.

[5] 马如龙, 彭超群, 王日初, 等. 选区激光熔化铝合金的研究进展[J]. 中国有色金属学报, 2020, 30(12): 2773-2788.

MA Ru-long, PENG Chao-qun, WANG Ri-chu, et al. Progress in selective laser melted aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2020, 30(12): 2773-2788.

[6] Ahuja B, Karg M, Nagulin K Y, et al. Fabrication and characterization of high strength Al-Cu alloys processed using laser beam melting in metal powder bed[J]. Physics Procedia, 2014, 56: 135-146.

[7] Zhang Hu, Zhu Hai-hong, Nie Xiao-jia, et al. Fabrication and heat treatment of high strength Al-Cu-Mg alloy processed using selective laser melting[C]// Laser 3D Manufacturing Ⅲ. San Francrsco: Society of Photo-Optical Instrumentation, 2016: 1-7.

[8] Karg M C H, Ahuja B, Wiesenmayer S, et al. Effects of process conditions on the mechanical behavior of aluminium wrought alloy EN AW-2219 (AlCu6Mn) additively manufactured by laser beam melting in powder bed[J]. Micromachines, 2017, 8(1): 1-7.

[9] Sistiaga M L M, Mertens R, Vrancken B, et al. Changing the alloy composition of Al7075 for better processability by selective laser melting[J]. Journal of Materials Processing Technology, 2016, 238: 437-445.

[10] Zhang Hu, Zhu Hai-hong, Nie Xiao-jia, et al. Effect of zirconium addition on crack, microstructure and mechanical behavior of selective laser melted Al-Cu-Mg alloy[J]. Scripta Materialia, 2017, 134: 6-10.

[11] Nie Xiao-jia, Zhang Hu, Zhu Hai-hong, et al. Effect of Zr content on formability, microstructure and mechanical properties of selective laser melted Zr modified Al-4.24Cu-1.97Mg-0.56Mn alloys[J]. Journal of Alloys and Compounds, 2018, 764: 977-986.

[12] Wang Pei, Gammer C, Brenne F, et al. A heat treatable TiB2/Al-3.5Cu-1.5Mg-1Si composite fabricated by selective laser melting: microstructure, heat treatment and mechanical properties[J]. Composites Part B: Engineering, 2018, 147: 162-168.

[13] 胡 亮, 刘允中, 涂 诚, 等. 纳米TiB2对激光选区熔化2024铝合金显微组织与力学性能的影响[J]. 粉末冶金材料科学与工程, 2019, 24(4): 365-373.

HU Liang, LIU Yun-zhong, TU Cheng, et al. Effects of nano-TiB2 particles on microstructure and mechanical properties of AA2024 deposited by selective laser melting[J]. Materials Science and Engineering of Powder Metallurgy, 2019, 24(4): 365-373.

[14] 张书雅. 形核剂对增材制造铝合金显微组织及力学性能的影响[D]. 济南: 山东大学, 2020.

ZHANG Shu-ya. Effect of nucleating agent on microstructure and mechanical properties of additive manufactured aluminum alloys[D]. Jinan: Shandong University, 2020.

[15] Martin J H, Yahata B D, Hundley J M, et al. 3D printing of high-strength aluminium alloys[J]. Nature, 2017, 549(7672): 365-369.

[16] 涂 诚. ZrH2/AA6060复合粉末的激光选区熔化成形工艺与组织性能[D]. 广州: 华南理工大学, 2019.

TU Cheng. Selective laser melting of ZrH2/AA6060 composite powders: process, microstructures and mechanical properties[D]. Guangzhou: South China University of Technology, 2019.

[17] Guo J Q, Ohtera K. An intermediate phase appearing in Ll2-Al3Zr to DO23-Al3Zr phase transformation of rapidly solidified Al-Zr alloys[J]. Materials Letters, 1996, 27(6): 343-347.

[18] Simchi A. Direct laser sintering of metal powders: Mechanism, kinetics and microstructural features[J]. Materials Science and Engineering A, 2006, 428(1/2): 148-158.

[19] Zhang Bi, Li Yong-tao, Bai Qian. Defect formation mechanisms in selective laser melting: A review[J]. Chinese Journal of Mechanical Engineering, 2017, 30(3): 515-527.

[20] GAumann M, Bezencon C, Canalis P, et al. Single-crystal laser deposition of superalloys: Processing- microstructure maps[J]. Acta Materialia, 2001, 49(6): 1051-1062.

[21] Tradowsky U, White J, Ward R M, et al. Selective laser melting of AlSi10Mg: Influence of post-processing on the microstructural and tensile properties development[J]. Materials & Design, 2016, 105: 212-222.

[22] Zhang Du-yao, Qiu Dong, Gibson M A, et al. Additive manufacturing of ultrafine-grained high-strength titanium alloys[J]. Nature, 2019, 576(7785): 91-95.

[23] Croteau J R, Griffiths S, Rossell M D, et al. Microstructure and mechanical properties of Al-Mg-Zr alloys processed by selective laser melting[J]. Acta Materialia, 2018, 153: 35-44.

[24] Li Lan-bo, Li Rui-di, Yuan Tie-chui, et al. Microstructures and tensile properties of a selective laser melted Al-Zn-Mg-Cu (Al7075) alloy by Si and Zr microalloying[J]. Materials Science and Engineering A, 2020, 787: 139492.

[25] Johnsson M. Grain refinement of aluminium studied by use of a thermal analytical technique[J]. Thermochimica Acta, 1995, 256(1): 107-121.

[26] Murray J, Peruzzi A, Abriata J P. The Al-Zr (aluminum-zirconium) system[J]. Journal of Phase Equilibria, 1992, 13(3): 277-297.

[27] Easton M, StJohn D. Grain refinement of aluminum alloys: Part I. the nucleant and solute paradigms—A review of the literature[J]. Metallurgical and Materials Transactions A, 1999, 30(6): 1613-1623.

[28] Srinivasan D, Chattopadhyay K. Non-equilibrium transformations involving L12-Al3Zr in ternary Al-X-Zr alloys[J]. Metallurgical and Materials Transactions A, 2005, 36(2): 311-320.

[29] 李 飞. 熔盐法制备Al-Zr中间合金的工艺与理论研究[D]. 沈阳: 东北大学, 2017.

LI Fei. Study on the technology and theory of Al-Zr master alloy prossed by fused salt reaction[D]. Shenyang: Northeastern University, 2017.

[30] Tan Qi-yang, Zhang Jing-qi, Sun Qiang, et al. Inoculation treatment of an additively manufactured 2024 aluminium alloy with titanium nanoparticles[J]. Acta Materialia, 2020, 196: 1-16.

[31] GENG Pei-hao, QIN Guo-liang, ZHOU Jun, et al. Parametric optimization and microstructural characterization of friction welded aeronautic aluminum alloy 2024[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(12): 2483-2495.

[32] Khvan A V, Eskin D G, StaroduB K F, et al. New insights into solidification and phase equilibria in the Al-Al3Zr system: Theoretical and experimental investigations[J]. Journal of Alloys and Compounds, 2018, 743: 626-638.

Microstructures and mechanical properties of Zr modified Al-Cu-Mg alloy processed by selective laser melting

WANG Kai-dong, LIU Yun-zhong, CHENG Wen, LIU Xiao-hui, ZHOU Zhi-guang

(National Engineering Research Center of Near-Net-Shape Forming for Metallic Materials, South China University of Technology, Guangzhou 510640, China)

Abstract: Zr-modified Al-Cu-Mg alloy was processed by selective laser melting (SLM) technique. The microstructures and mechanical properties of as-deposited and heat-treated(T6) samples were systematically analyzed. The results show that samples with the highest density can be achieved when the energy density is 370 J/mm3. The in-situ formed Al3Zr refines the grain size to 1.28 μm and therefore eliminates the common hot tearing in SLMed Al-Cu-Mg alloys. The metastable phase of Al3Zr (L12-Al3Zr) with a size range of from 50 nm to 300 nm is observed, which is responsible for the grain refinement. L12-Al3Zr particles act as the nucleus of heterogenous nucleation of α(Al) due to their minimal mismatch. Besides, the L12-Al3Zr particles can further refine the grains by hindering the migration of grain boundaries. The ultimate strength of (369±9) MPa and the elongation of (12.4±0.6)% are achieved for the as-deposited samples after process parameter optimization. After T6 heat treatment, the ultimate strength greatly increases to (485.2±10) MPa with a slight decrease in plasticity (elongation of (11.2±0.5)%). The strength enhancements of the as-deposited and heat-treated samples can be mainly attributed to the Hall-Petch strengthening and the Orowan strengthening mechanisms, respectively.

Key words: selective laser melting; Al-Cu-Mg alloy; Al3Zr; microstructure; mechanical properties

Foundation item: Project(2019B090907001) supported by Research and Development Program Project in Key Areas of Guangdong Province, China; Project(2014B010129002) supported by Major Special Project for Science and Technology Program of Guangdong Province, China

Received date: 2020-12-08; Accepted date: 2021-03-09

Corresponding author: LIU Yun-zhong; Tel: +86-20-87110081; E-mail: yzhliu@scut.edu.cn

(编辑 李艳红)

基金项目:广东省重点领域研发计划项目(2019B090907001);广东省科技计划项目(2014B010129002)

收稿日期:2020-12-08;修订日期:2021-03-09

通信作者:刘允中,教授,博士;电话:020-87110081;E-mail:yzhliu@scut.edu.cn