文章编号: 1004-0609(2005)06-0854-06

金属切削加工中航空铝合金板材的本构模型

杨 勇, 柯映林, 董辉跃

(浙江大学 流体传动及控制国家重点实验室, 杭州 310027)

摘 要: 针对金属切削加工中材料的高温度、 高应变、 高应变率数据难以获取, 无法建立动态本构模型这一技术难题, 提出基于有限元模拟和“单因素”流动应力公式计算的联合建模策略。 由“单因素”流动应力公式反复计算与模拟应变率对应的流动应力, 基于新的流动应力有限元模拟迭代的进行并追求模拟值与实验结果的一致, 获取能反映切削材料力学性能的“三高”数据和流动应力数据。 数据分析表明, 应变率对流动应力具有强化作用, 温度对流动应力具有弱化作用, 稳态变形后, 各应力—应变曲线都变为一条趋于与应变坐标轴平行的直线。 根据影响规律选取Zerilli-Armstrong经验模型, 采用非线性回归分析建立起航空铝合金板材在铣削加工中的动态本构模型。 最后进行实验验证, 证明了该本构模型的正确性。

关键词: 金属切削加工; 有限元模拟; 回归分析; 本构模型

中图分类号: TG50; TG659 文献标识码: A

Constitutive model of aviation aluminum-alloy material in metal machining

YANG Yong, KE Ying-lin, DONG Hui-yue

(State Key Laboratory of Fluid Power Transmission and Control,

Zhejiang University, Hangzhou 310027, China)

Abstract: High temperature, high strain and high strain-rate of metal material in machining were not easy to get with a general measure method, which made it quite difficult to establish the dynamic constitutive model. To solve this problem, a combined modeling method based on “single factor” flow stress formula calculating and FEM simulation was proposed. The flow stress was repeated by calculated using the “single factor” flow stress formula, the metal machining process was simulated interatively with new flow stress. When simulating value was in good consistent with experimental result, the “three-high” data and flow stress data were obtained. By analyzing these data, it indicates that strain-rate can enhance the flow stress, while temperature will lower flow stress, and after remained in a steady state, each stress—strain curve will be parallel to the strain coordinate axis. Zerilli-Armstrong experience model was selected correspondingly. With the non-liner regression analysis, a dynamic constitutive model of aviation aluminum-alloy material during milling process was established. At last, the constitutive model is proved to be reasonable through test verification.

Key words: metal cutting process; finite element simulation; regression analysis; constitutive model

材料在切削加工中的性能一直是金属切削研究领域密切关注的问题, 掌握材料性能变化规律, 建立材料本构模型, 对制定科学的材料切削加工工艺具有重要的指导意义。

金属切削加工是一个高度非线性的动态过程, 涉及加工硬化、 材料剪切断裂和高应变率等现象, 使材料的本构模型变得极为复杂[1]。 在工件材料微观组织结构给定的情况下, 材料的动态本构模型可以表示为流动应力同温度、 应变、 应变率之间的数学关系式[2]。 实验研究表明: 实际切削加工中, 第一变形区温度范围为100~1400℃, 应变率范围为103~105 s-1, 真应变为1左右[3], 受测量仪器和测量方法的限制, 要同时准确测出切削过程中的高温度、 高应变、 高应变率等“三高”数据及流动应力数据是相当困难的, 因此建立基于“三高”数据及流动应力数据的动态本构模型一直成为国内外学者研究的难点。 国内该问题研究主要集中在冷轧、 温锻等工艺, 对于切削工艺则未见有相关的报道[4, 5], Oxley[6]用理论解析法计算切削加工中的“三高”数据及流动应力数据, 他把切削加工中刀屑接触面上的摩擦因数看为是一个不变量, 这与实际现象不符; Maekawa等[7, 8]利用高速压缩实验数据直接拟合材料本构关系, 但实验中材料的应变率小于2×104 s-1, 真应变小于1, 所建立的本构关系难以描述金属切削中材料的变化性能; Shatla等[3]基于金属切削加工理论开发了专用软件系统来建立切削加工中的材料本构模型。 综合前期研究, 尽管国内外学者对该问题进行了大量研究, 但所建立的材料本构模型仍不令人满意, 而且这些研究也没有对应变率、 温度等影响因素进行全方位的分析。 为此, 本文作者针对航空铝合金板材7050-T7451, 提出有限元迭代模拟和“单因素”流动应力公式反复计算的联合建模策略, 通过不断修改材料力学模型和有限元迭代模拟, 来获取反映切削材料力学性能的 “三高”数据和流动应力数据, 并对这些数据进行深入分析, 研究温度和应变率对流动应力的影响规律, 基于这些数据和规律建立起航空铝合金板材7050-T7451在铣削过程中的动态本构模型。

1 辅助实验

1.1 直角铣削实验

为了对有限元模拟的合理性进行验证, 采用直齿圆柱铣刀(直径18mm, 2齿)进行直角铣削试验。 试验在MV-5A数控铣削加工中心上进行, 机床主轴最高转速3000r/min, 干铣削, 材料为航空铝合金预拉伸板材7050-T7451, 铣削速度分别为1963.3, 2473.3, 3116.7, 3926.7mm/s, 每齿进给量分别为0.05, 0.069, 0.097, 0.127mm, 铣削深度和铣削宽度都为10mm, 采用电阻应变式三向动态铣削测力仪进行切削力测试, 为减小误差, 对同一实验条件进行多次试验测量, 取平均值作为实验结果。

1.2 SHPB动态压缩实验

利用SHPB动态压缩试验获取应力、 应变、 应变率和温度数据, 作为有限元模拟的初始塑性数据, 近似描述材料的动态行为。 实验采用直径为14.5mm的SHPB设备, 用电子加热炉升至高温, 试样为直径8mm、 长度4mm的圆柱体, 应变率为5×102, 1.2×103, 2.4×103, 0.6×104 s-1, 温度为20, 100, 200, 300℃, 为保证实验测试结果的可靠性, 试样两端面的平行度、 平面度和表面粗糙度等均作了严格处理。

2 联合建模策略

2.1 “单因素”流动应力公式

“单因素”流应力公式如下式描述, 该公式反映了金属切削过程中材料流动应力和应变率之间的关系, 能真实的反映材料在高应变率下的应力变化情况, 它和有限元分析配合, 能够逐渐修正材料塑性数据, 确保最终获得反映真实材料变化性能的应力应变等物理量数据。

式中  为流动应力;

为流动应力;  为等效应变率; σ0为静态屈服应力; D, p为材料参数。

为等效应变率; σ0为静态屈服应力; D, p为材料参数。

按照文献[9], σ0=0.06MPa, D=1.6275×105, p=1.75。

2.2 有限元迭代模拟

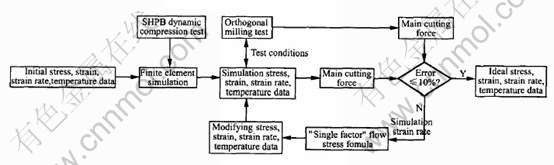

本文采用二维正交切削有限元模型模拟铣削过程, 动态显示工件的热流、 相变、 温度和应力等分布, 探索材料变化性能[10, 11]。 铣削模拟条件与直角铣削试验相同, 保持铣削深度和铣削宽度不变, 铣削速度和进给量逐一相配, 共16种方案, 采用处理非线性问题功能强大的软件包ABAQUS进行模拟分析。 根据弹塑性力学理论, 若处理误差在10%内, 可认为是小变形问题, 对处理结果影响不大[12], 又由于有限元模型是在一定假设条件下建立, 因此相对误差在10%之内的模拟过程可以被认为是合理的。 以主切削力试验值为正交切削模拟验证指标, 对每种切削加工方案, 第一次有限元模拟时采用数量级较低的动态压缩试验数据, 计算机求解精度低, 将第一次模拟得到的应变率代入“单因素”流动应力公式计算出流动应力, 此时流动应力接近实际切削过程中产生的塑性流动屈服应力, 基于新的应力和应变、 应变率、 温度模拟数据进行第二次有限元模拟, 比较主切削力模拟值和实验值, 若两值误差较大, 则将第二次模拟得到的应变率带入“单因素”流动应力公式计算流动应力, 以新的流动应力和第二次模拟得到的应变、 应变率、 温度模拟数据输入到ABAQUS中进行第三次模拟, 并继续比较主切削力模拟值和实验值, 如此反复进行, 直至主切削力模拟值和实验值相对误差在10%之内停止迭代模拟, 模拟过程如图1所示。

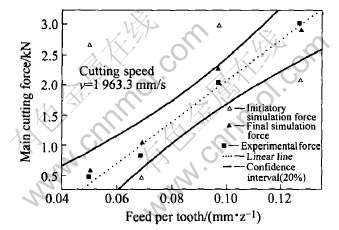

主切削力模拟值与实验值比较情况见图2, 从图中可见, 经多次修正模拟, 主切削力模拟值最终同实验值趋于一致, 保证了正交切削模拟精度。

3 有限元模拟数据分析

3.1 正交切削有限元模拟物理量计算及设计

金属切削加工中剪切区和刀屑接触区内的温度、 应变、 应变率和流动应力等物理量变化最为显著, 以这两个区域内的物理量代表整个工件切削过程中的物理量变化情况, 同时为降低单元离散误差, 将它们用这两个区域内单元面积的平均值ave表示, 计算式如下:

式中 i为物理量i单元模拟值; Ai为单元i的面积; n为剪切区或刀屑接触区内单元数量。

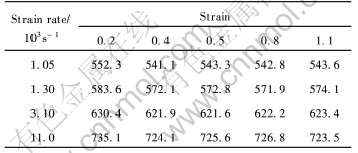

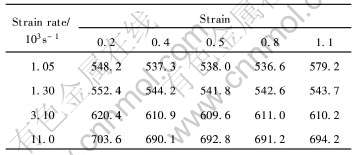

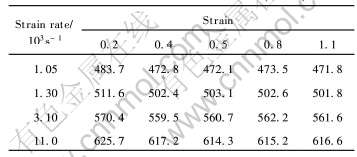

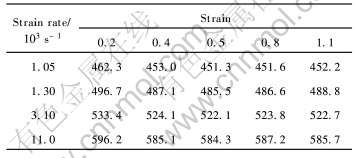

为深入分析材料温度、 应变率对流动应力的影响规律, 从上述16种铣削方案的最终模拟结果中, 按照式(2)计算出4个温度和4个应变率下的若干应变和对应流动应力数据, 计算数据设计列于表1~4。

表1 110℃时不同应变率下的应变和流动应力

Table 1 Flow stress and strain for different strain rates at 110℃(MPa)

表2 113℃时不同应变率下的应变和流动应力

Table 2 Flow stress and strain for different strain rates at 113℃(MPa)

表3 132℃时不同应变率下的应力和应变数据

Table 3 Flow stress and strain for different strain rates at 132℃(MPa)

图1 正交切削有限元迭代模拟过程

Fig.1 Orthogonal cutting finite element iterative simulation process

图2 模拟切削力与实验切削力的比较

Fig.2 Comparison between simulation and experimental value of cutting force

表4 138℃时不同应变率下的应力和应变数据

Table 4 Flow stress and strain for different strain rates at 138℃(MPa)

3.2 应变率对流动应力的影响规律

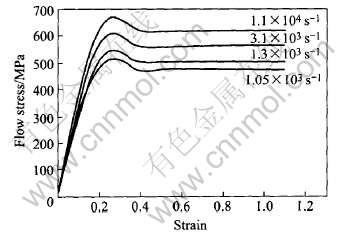

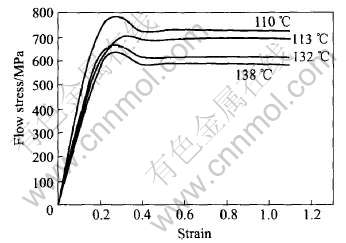

利用上述数据绘制同一温度下不同应变率的流动应力—应变曲线, 并考虑到材料为热-黏弹塑性模型, 曲线如图3所示。

图3 132℃下不同应变率的流动应力—应变曲线

Fig.3 Flow stress—strain curves for different strain rates at 132℃

从图3中可知:

1) 不同应变率下的流动应力—应变曲线在变形初期, 流动应力都随应变的增大而增大, 两者呈线性关系, 当应变增大到一定程度后, 流动应力略有下降, 主要是因为变形热导致温度上升, 使材料软化, 进入稳态变形后, 随应变增长, 流动应力增长缓慢, 各流动应力—应变曲线都变为一条趋于与应变坐标轴平行的直线, 主要是因为软化和应变硬化作用达到平衡状态, 导致流动应力基本保持不变。

2) 随着应变率的增大, 流动应力增大, 应变率对流动应力具有强化作用, 主要是随着应变率的增大, 单位时间内的应变增加, 材料内部位错产生、 运动的数目增大, 位错运动的速度也增大, 从而导致切削加工中铝合金变形的临界剪切应力增大。

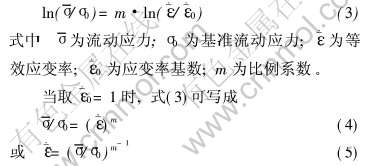

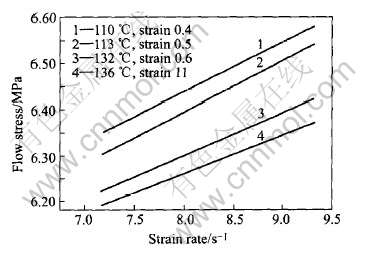

在双对数坐标系中绘制流动应力—应变率曲线, 如图4所示, 从图中可知: 在双对数坐标系中流动应力与应变率呈线性关系, 因此可将流动应力与应变率的关系用双对数形式表示:

式(5)同式(1)形式相近, 说明 “单因素”流动应力公式在金属切削中经得起实践检验, 是比较合理的, 同时也说明有限元模拟精度较高, 数据比较准确。

图4 双对数坐标系中流动应力—应变率曲线

Fig.4 Flow stress—strain rate curves in double logarithm coordinate system

3.3 温度对流动应力的影响规律

绘制同一应变率下不同温度的流动应力—应变曲线, 如图5所示。 从图中可以看出:

1) 不同温度下的流动应力—应变曲线与不同 应变率下的流动应力—应变曲线类似, 反映规律相同。

图5 应变率为1.1×104 s-1时不同温度的流动应力—应变曲线

Fig.5 Flow stress—strain curves under strain rate of 1.1×104 s-1 at different temperatures

2) 随着温度的升高, 流动应力减小, 温度对流动应力具有弱化作用, 主要是因为温度升高, 导致材料内部原子活动加剧, 原子间结合力降低, 从而使流动应力减小。

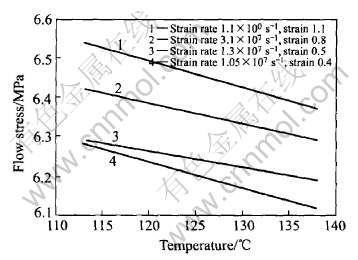

在单对数坐标系中绘制流动应力—温度曲线, 如图6所示, 从图中可知: 在单对数坐标系中流动应力与温度呈线性关系, 因此可将流动应力与温度的关系用指数形式表示为

式中  为流动应力; k, r为材料常参数; t为温度。

为流动应力; k, r为材料常参数; t为温度。

图6 单对数坐标系中流动应力—温度曲线

Fig.6 Flow stress—temperature curves in single logarithm coordinate system

4 航空铝合金板材动态本构模型的建立及验证

4.1 航空铝合金板材动态本构模型的建立

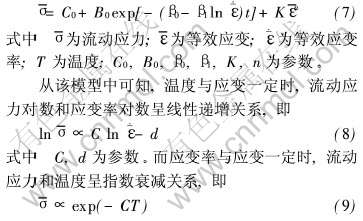

在塑性金属材料的工程应用中常采用两种经验本构模型描述其流动应力与温度、 应变、 应变率之间的关系: 经验型的Johnson-Cook(JC)模型和基于位错动力学的Zerilli-Armstrong(ZA)模型。 这两个模型都考虑了温度软化效应和应变率强化效应, 但表现形式有所不同, 对ZA模型其数学表达式如下:

比较式(3)和式(8), 式(6)和式(9)可见, ZA模型中流动应力和应变率、 温度之间的关系与上节从大量计算数据中分析出的流动应力同应变率、 温度之间的规律一致, 因此采用ZA模型描述航空铝合金材料的动态本构行为是相当合理的。

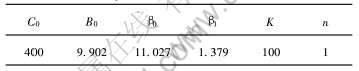

表5 航空铝合金材料7050-T7451的ZA模型回归参数

Table 5 Regression parameters of ZA model for aviation aluminum alloy material 7050-T7451

利用表1~4中的数据, 对ZA模型进行基于阻尼最小二乘法的非线性回归分析[13, 14], 得到ZA模型中的具体参数值如下。

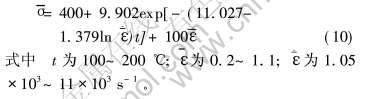

即航空铝合金板材7050-T7451铣削过程中的动态本构模型为

4.2 航空铝合金板材动态本构模型验证

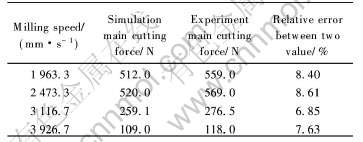

在上述直角铣削实验条件下, 利用本文建立的材料本构模型直接进行有限元模拟, 模拟主切削力与实验值进行对比, 比较结果列于表6。

表6 不同铣削速度下的主切削力模拟值与实验值的比较

Table 6 Comparison between simulation and experiment value of main cutting force at different milling speeds

从表6可以看出, 利用材料本构模型的主切削力模拟值与实验值随速度变化趋势一致, 两值相对误差在10%以内, 说明材料本构模型在有限元模拟中起着重要作用, 同时表明本文建立的航空铝合金板材本构模型是较为合理的。

5 结论

1) 通过“单因素”流动应力公式反复计算和有限元迭代模拟获得了铣削过程中的“三高”数据及流动应力数据, 解决了在试验中难以获取真实铣削过程物理量数据的难点。

2) 通过对模拟数据的分析, 显示出铣削过程中物理量应变率对流动应力具有强化作用, 在双对数坐标系中两者呈线性关系; 温度对流动应力具有弱化作用, 在单对数坐标系中两者呈线性关系; 进入稳态变形后, 各应力应变曲线都变为一条趋于与应变坐标轴平行的直线。

3) 通过对ZA模型作非线性回归分析, 建立了铣削过程中航空铝合金板材7050-T7451的具体本构模型。

4) 本文建模方法的工程应用, 可以为构建其他材料、 其他加工工艺过程中材料动态本构模型提供相应的理论依据和技术支持。

REFERENCES

[1]周泽华. 金属切削原理[M]. 上海: 上海科学技术出版社, 1993. 166-167.

ZHOU Ze-hua. Mechanics of Metal Cutting[M]. Shanghai: Science and Technology of Shanghai Press, 1993. 166-167.

[2]刘建生. 金属塑性加工有限元模拟技术与应用[M]. 北京: 冶金工业出版社, 2003. 5.

LIU Jian-sheng. Finite Element Simulation Technology and Application of Metal Plastic Machining[M]. Beijing: Metallurgy Industry Press, 2003. 5.

[3]Shatla M, Kerk C, Altan T. Process modeling in machining(part Ⅰ): determination of flow stress data[J]. International Journal of Machine Tools & Manufacture, 2001, 41: 1511-1534.

[4]聂蕾, 李付国, 方勇. TC4合金的新型本构关系[J]. 航空材料学报, 2001, 21(3): 13-18.

NIE Lei, LI Fu-guo, FANG Yong. New constitutive relation of TC4 alloy[J]. The Aeronautics Material Journal, 2001, 21(3): 13-18.

[5]郭乃成. GH169合金的本构关系研究[J]. 航空学报, 1991, 13(9): 552-556.

GUO Nai-cheng. Constitutive relation of GH169 alloy[J]. The Aeronautics Journal, 1991, 13(9): 552-556.

[6]Oxley P L B. Mechanics of Machining[M]. New York: Halsted Press, 1989.

[7]Oyane M, Takashima F, Osakada K. The behavior of some steels under dynamic compression[A]. Proceedings of 10th Japan Congress on Testing Material[C]. Kyoto: Society of Materials Science, 1967. 72-76.

[8]Maekawa K, Shirakashi T, Usui E. Flow stress of low carbon steel at high temperature strain rate(part 2) [J]. Bull Jpn Soc, Prec Engrs, 1983, 17(3): 167-172.

[9]Potdar Y K. Measurement and Simulations of Temperature and Deformation Fields in Transient Orthogonal Metal Cutting[D]. The Cornel University, 2001. 76.

[10]Strenkowski J S, Carroll J T. A finite element model of orthogonal metal cutting[J]. Transactions of the ASME, Journal of Engineering for Industry, 1985, 107: 349-354.

[11]Shih A J. Finite element simulation of orthogonal metal cutting[J]. Transactions of the ASME, Journal of Engineering for Industry, 1995, 117: 84-93.

[12]孙炳楠, 洪滔, 杨骊先. 工程弹塑性力学[M]. 杭州: 浙江大学出版社, 1998. 104.

SUN Bing-nan, HONG Tao, YANG Li-xian. Elastics and Plastic Mechanics of Engineering[M]. Hangzhou: Zhejiang University Press, 1998. 104.

[13]Bates D M, Watts D G. 非线性回归分析及其应用[M]. 韦博成, 译. 北京: 中国统计出版社, 1997. 45-70.

Bates D M, Watts D G. Non-liner regression analysis and application[M]. WEI Bo-cheng, transl. Beijing: China Statistics Press, 1997. 45-70.

[14]王学仁, 温忠粦. 应用回归分析[M]. 重庆: 重庆大学出版社, 1991. 172-181.

WANG Xue-ren, WEN Zhong-lin. Applying Regression Analysis[M]. Chongqing: Chongqing University Press, 1991. 172-181.

[11]Shih A J. Finite element simulation of orthogonal metal cutting[J]. Transactions of the ASME, Journal of Engineering for Industry, 1995, 117: 84-93.

[12]孙炳楠, 洪滔, 杨骊先. 工程弹塑性力学[M]. 杭州: 浙江大学出版社, 1998.

SUN Bing-nan, HONG Tao, YANG Li-xian. Elastics and Plastice Mechanics of Engineering[M]. Hangzhou: Zhejiang University Press, 1998.

[13]Benedict R P. Engineering analysis of experimental data[J]. Transactions of the ASME, Journal of Engineering for Power, Jan, 1969.

[14]王学仁, 温忠粦. 应用回归分析[M]. 重庆: 重庆大学出版社, 1991.172-181

WANG Xue-ren, WEN Zhong-lin. Applying Regression Analysis[M]. Chongqing: Chongqing University Press, 1991.172-181

(编辑 陈爱华)

基金项目: 国家自然科学基金资助项目(50435020)

收稿日期: 2004-11-29; 修订日期: 2005-03-09

作者简介: 杨 勇(1976-), 男, 博士研究生.

通讯作者: 杨 勇, 电话: 0571-87951061; E-mail: yy253200@21cn.com; yy253200@zju.edu.cn