文章编号:1004-0609(2015)02-0293-08

AZ31B镁合金挤压材料的力学性能与本构分析

吴章斌,桂良进,范子杰

(清华大学,汽车安全与节能国家重点实验室,北京 100084)

摘 要:通过单向拉伸与压缩试验,研究AZ31B镁合金挤压材料的力学性能,并建立相应的本构模型。结果表明:室温下AZ31B镁合金挤压材料的宏观力学性能存在显著的各向异性和拉压非对称屈服的现象,且在塑性流动过程中,屈服面的演化也呈现出各向异性的特点,即畸变硬化特性。基于系统的试验结果,结合考虑了各向异性和拉压非对称性的CPB06屈服面函数,采用解析函数形式的本构参数来描述畸变硬化特性,建立了一种唯象的镁合金材料塑性流动本构模型。通过用户材料子程序VUMAT,将本构模型应用于缺口试件拉伸的有限元模拟中,计算结果与试验结果吻合较好,证实了本构模型的适用性。

关键词:镁合金;畸变硬化;本构模型;有限元模拟

中图分类号:TG146.22 文献标志码:A

Mechanical properties and constitutive analysis of extruded AZ31B magnesium alloy

WU Zhang-bin, GUI Liang-jin, FAN Zi-jie

(Tsinghua University, State Key Laboratory of Automotive Safety and Energy, Beijing 100084, China)

Abstract: By conducting uniaxial tension and compression tests, the mechanical properties of extruded AZ31B magnesium alloy were studied and a suitable constitutive model was established. The results show that the yielding response of extruded AZ31B alloy exhibits significant anisotropy and tension-compression asymmetry, and the evolution of yield surface during plastic flow also exhibits great anisotropy, known as distortional hardening effect. By introducing an analytical evolving law for the distortional hardening effect, a phenomenological constitutive model was established based on the CPB06 yield function, which accounts for both anisotropy and tension-compression asymmetry. The model was programmed to the user material subroutine interface VUMAT and applied to the finite element simulation of the tension tests of a grooved specimen. The computational results coincide well with the experimental ones, which demonstrates the predictive efficiency of this constitutive model.

Key words: magnesium alloys; distortional hardening; constitutive model; finite element simulation

镁合金材料具有低密度、高比刚度和高比强度等优点,是一种极具竞争力的轻量化材料[1-2]。然而,由于镁合金具有密排六方(Hexagonal close packed, HCP)晶体结构,常温下的塑性变形机制除了位错滑移外,还有特殊的孪生变形现象,导致镁合金在受到拉伸与压缩时的力学性能存在很大的差别,即拉压非对称 性[3-4]。且对挤压镁合金材料而言,其内部存在织构现象,从而在宏观力学性能上表现出显著的各向异性特征[3, 5-8]。镁合金材料力学性能的这些特殊性具体反映在两个方面[3, 8-9]:1) 初始屈服强度的各向异性和拉压非对称性;2) 在塑性流动过程中屈服面的演化存在各向异性,也称为畸变硬化特性。这些独特的力学性能给镁合金材料的本构表征带来很大的挑战,传统的钢、铝合金等金属材料上常用的本构模型并不适用于挤压镁合金材料。

目前,对于立方体晶体结构(体心立方BCC、面心立方FCC)的金属材料,已经有很多的唯象本构模型可以很好地描述其各向异性的力学性能,如常用的Hill系列[10]、Barlat系列[11]模型,但这些模型都没有考虑由晶体孪生变形引起的拉压非对称现象。近年来,随着对HCP材料(如镁合金、钛合金等)应用研究的深入,逐渐有学者提出了一些针对HCP材料力学特性的屈服面模型。CAZACU等[12]提出了基于应力偏量不变量的拉压非对称性屈服面函数(CPB04模型),并将之推广到各向异性材料上;随后CAZACU等[13]又提出另一种考虑所有应力偏量主值的拉压非对称屈服屈服面模型(CPB06模型),并通过对应力偏量进行线性变换把模型推广至各向异性材料;NIXON等[14]同样采用对应力线性变换的方法将CPB04模型推广至各向异性材料上;类似地,ARETZ等[15]采用线性变换的方法将Hill’79屈服面函数推广到正交各向异性材料上;而YOON等[16]则通过线性变换将BAI等[17]提出的基于应力三轴度和Lode参数的拉压非对称模型推广到各向异性材料上。与前述模型不同地,KHAN等[18]将Hill各向异性屈服面函数与一个基于Lode参数的拉压非对称性项相乘构造了一个新的屈服面模型。在这些屈服面模型的基础上,为了考虑单调加载时材料在塑性流动过程的畸变硬化特性,NIXON等[14]、GILLES等[19]以及TUNINETTI等[20]采用离散插值的方法描述在塑性流动过程中屈服面参数的变化,而ERT RK等[21]、YOON等[22]则将屈服面各参数拟合为等效塑性应变的解析函数,以此来描述畸变硬化过程中屈服面参数的变化。

RK等[21]、YOON等[22]则将屈服面各参数拟合为等效塑性应变的解析函数,以此来描述畸变硬化过程中屈服面参数的变化。

在此,本文作者研究AZ31B挤压管件的材料力学性能,并建立相应的镁合金本构模型以进行有限元计算分析。首先,通过数字图像相关技术(Digital image correlation, DIC)试验研究管件材料沿不同方向单向拉伸与压缩时发生屈服和塑性流动的各向异性和拉压非对称性;然后,建立考虑了畸变硬化特性的塑性流动本构模型,并进行参数拟合;最后,基于Abaqus/ Explicit模块的用户材料子程序接口VUMAT,将本构模型应用于管件材料的有限元模拟分析中。

1 实验

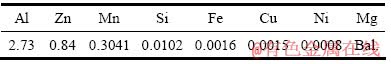

管件是工程上最常用的结构形式之一,且镁合金材料通过挤压工艺可高效地生产不同截面形状的管件,因此,本实验中以常用的AZ31B镁合金挤压矩形截面管件为试验材料。AZ31B材料的化学成分如表1所列,管件的截面尺寸为60 mm×40 mm×3 mm。

表1 AZ31B镁合金的化学成分

Table 1 Chemical compositions of AZ31B magnesium alloy (mass fraction, %)

试验分别沿着管件轴向,即材料挤压方向(Extrusion direction, ED)、45°斜向(AD)、横向(Transverse direction, TD)进行单向拉伸与压缩测试。单向拉压试件主要从矩形管60 mm宽的侧面上加工得到,同时在其他3个侧面上沿ED方向各进行一次单向拉伸试验,以验证管件不同侧面上材料力学性能的一致性。最后,进行一组缺口试件(缺口半径R=3 mm)的拉伸试验,用于验证本构模型的预测效果。试样几何尺寸如图1所示,每种试样重复3次试验。

图1 试件的几何尺寸

Fig. 1 Geometry of specimens (Unit: mm)

试验在WDW-100材料万能试验机上进行,采用位移加载模式,加载速度为0.4 mm/min,试验机记录载荷数据。材料变形用非接触式的数字图像相关(Digital image correlation, DIC)测试系统Aramis 3D进行测试,单向拉伸试验测量试件中间7 mm标距段的平均应变,单向压缩试验测量试件中间3 mm标距段的平均应变,缺口拉伸试验测量试件中间10 mm标距段的相对位移。

2 结果与分析

矩形管4个侧面沿ED方向单向拉伸的工程应力-工程应变关系曲线如图2所示,可以看出,4个侧面上的材料力学性能基本一致,因此,可以只测试某个侧面上的材料力学性能(本实验中选择60 mm宽的侧面)。

图2 管件4个侧面ED拉伸的工程应力-应变关系曲线

Fig. 2 Engineering stress-strain curves of uniaxial tension tests on 4 sides of AZ31B rectangular tubes along ED direction

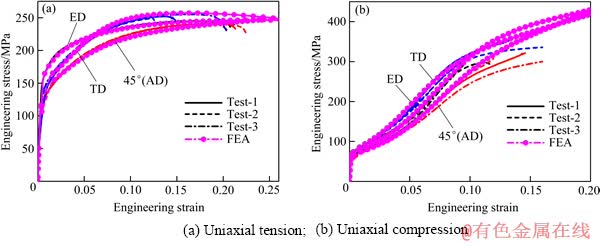

试验测得的单向拉伸与压缩的工程应力与工程应变关系曲线如图3所示,将每组试样3次重复试验的曲线进行平均,并计算真应力与塑性应变的关系曲线,如图4所示。

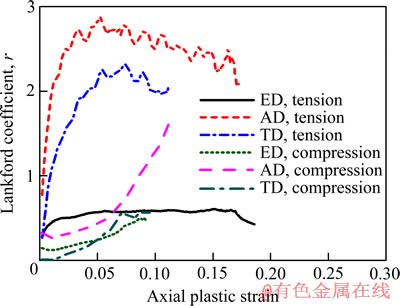

从DIC测试结果中可以计算得到材料的塑性应变比 (Lankford coefficients),即宽度方向的塑性应变与厚度方向的塑性应变之比:

(Lankford coefficients),即宽度方向的塑性应变与厚度方向的塑性应变之比:

式中: 、

、 、

、 分别为平板试件宽度方向、厚度方向和纵向的塑性应变率。

分别为平板试件宽度方向、厚度方向和纵向的塑性应变率。

计算得到沿不同方向拉伸与压缩的塑性应变比与纵向塑性应变的关系曲线如图5所示。

从图4可以观察到:AZ31B挤压板材的力学性能存在明显的各向异性和拉压非对称性。首先,材料屈服存在显著的各向异性和拉压非对称性,沿挤压方向ED拉伸的屈服应力明显比沿ED压缩和沿其他方向拉伸或压缩时的屈服应力高;其次,材料在塑性流动过程中,屈服面的演化也呈现出显著的各向异性,即畸变硬化特性,具体表现在沿不同方向拉伸或压缩时硬化率不相等,而且拉伸与压缩的应力-应变曲线形状明显不同,压缩曲线表现出特殊的“S”形。本文作者在前期研究结果[8]对AZ31B材料的力学特性及其变形机理进行了较系统的分析与讨论。

图3 AZ31B镁合金材料单向与压缩的工程应力-工程应变关系曲线

Fig. 3 Engineering stress-strain curves of uniaxial tension and compression tests of AZ31B magnesium alloy

图4 AZ31B镁合金材料单向与压缩后平均真应力-塑性应变关系曲线

Fig. 4 Average true stress-plastic strain curves of uniaxial tension and compression tests of AZ31B magnesium alloy

图5 AZ31B镁合金材料单向与压缩的塑性应变比-纵向塑性应变关系曲线

Fig. 5 Lankford coefficient-axial plastic strain curves of uniaxial tension and compression tests of AZ31B magnesium alloy

3 本构模型

弹塑性材料的本构模型包含屈服准则和塑性硬化规律两方面。

本模拟中对AZ31B挤压材料各向异性和拉压非对称屈服的描述引用CPB06屈服面函数[13]:

式中:k为描述材料拉压非对称性的参数;a为齐次方程的阶次,镁合金材料取a=2; 为常数,

为常数, 为沿ED单向拉伸的应力;

为沿ED单向拉伸的应力; 、

、 、

、 是应力张量

是应力张量 的3个主值;其中:

的3个主值;其中: ;S为Cauchy应力偏张量;C为描述各向异性屈服的线性变换张量:

;S为Cauchy应力偏张量;C为描述各向异性屈服的线性变换张量:

3.1 畸变硬化规律

对于AZ31B挤压材料特殊的畸变硬化特性,传统的各向同性硬化和随动硬化模型不能有效地予以描述。由于在畸变硬化过程中,沿不同方向加载时材料硬化率的变化是不同的,在本构模型中则表现为材料参数不是定值,而是随着塑性流动发生变化。因此,本文作者通过在材料参数与等效塑性应变之间建立解析的函数关系,实现对畸变硬化过程的唯象描述。

由于参数k反映了材料的拉压非对称性,从ED方向单向拉压的流动应力比值与等效塑性应变的关系可以发现其曲线形状近似于Gauss分布曲线,因此,参数k用Gauss函数来描述:

式中: 为等效塑性应变;K0、K1、w和

为等效塑性应变;K0、K1、w和 为4个待定系数。

为4个待定系数。

而对于线性变换参数,考虑到材料硬化到一定程度后流动应力基本处于一个稳定值,即硬化过程中,硬化率逐渐减小,最后趋于0。因此,将线性变换参数用Voce函数来描述:

式中:Hij、Mij、Nij为线性变换参数Cij对应的3个待定系数。

3.2 本构模型参数的确定

1) ED拉伸的硬化规律

选择幂函数对ED方向拉伸的真应力-等效塑性应变关系进行拟合:

式中: 、K和n为3个待定参数。

、K和n为3个待定参数。

由试验结果拟合得到的系数如表2所示,拟合得到的真应力-塑性应变关系曲线与试验结果的对比如图6所示。

表2 ED拉伸硬化规律的幂函数拟合结果

Table 2 Fitting results of power law hardening parameters for ED tensile curve

2) 畸变硬化参数的确定

图6 曲线拟合结果与ED拉伸试验结果对比

Fig. 6 Comparison between fitting and measured stress-strain curves for ED tension test

考虑屈服面函数的齐次性和线性变换的特点,可取C11=1;由于单向拉伸与压缩试验都是沿着板面内进行,取C55=C66=C44。因此,模型中需确定的参数共有7个,即参数k和线性变换张量C中的6个分量[C22, C33, C12, C23, C13, C44],根据硬化规律式和式,共有22个待定系数。采用数学优化的方法进参数拟合,建立误差函数:

式中: 和

和 分别表示由本构模型预测得到的应力和塑性应变比;下标ij表示沿着第i条加载路径加载到等效塑性应变

分别表示由本构模型预测得到的应力和塑性应变比;下标ij表示沿着第i条加载路径加载到等效塑性应变 时的应力或塑性应变比;

时的应力或塑性应变比; 为加权系数,取

为加权系数,取 。

。

优化得到的各个系数如表3和4所列,相应的各个参数与等效塑性应变的关系如图7所示。不同等效塑性应变时对应的屈服面在 平面内的投影如图8所示。图8中采用由ED拉伸屈服强度归一化后的无量纲应力坐标轴,最内圈为初始屈服面,接着从内往外依次是等效塑性应变从0.02变化到0.12、每间隔0.02所对应的后继屈服面。

平面内的投影如图8所示。图8中采用由ED拉伸屈服强度归一化后的无量纲应力坐标轴,最内圈为初始屈服面,接着从内往外依次是等效塑性应变从0.02变化到0.12、每间隔0.02所对应的后继屈服面。

3.3 本构模型的应用

根据拟合得到的模型参数,通过Abaqus/Explicit显式模块的用户自定义材料子程序接口VUMAT,将本构模型应用到单向拉伸、压缩和缺口试件拉伸的有限元模拟中。根据对称性取试件厚度方向的1/2建立有限元模型,采用实体单元C3D8R划分网格,半厚度1.5 mm划分8个单元,单元尺寸为0.1875 mm。

表3 参数K的拟合结果

Table 3 Fitting results of parameters K

表4 线性变换参数C的拟合结果

Table 4 Fitting results of linear transformation parameters C

图7 各参数与等效塑性应变的关系

Fig. 7 Relationship of constitutive model parameters with effective plastic strain

图8 屈服面在 平面内的投影

平面内的投影

Fig. 8 Theoretical yield loci in  plane normalized by ED tensile initial yield stress (

plane normalized by ED tensile initial yield stress ( =156.48 MPa)

=156.48 MPa)

单向拉伸与压缩的有限元计算结果与每组3次重复试验测得的工程应力-工程应变关系曲线的对比如图9所示。可以看到,有限元模拟结果与试验曲线较好地吻合。

缺口试件拉伸的有限元计算结果与试验测得的载荷-标距段位移关系曲线的对比如图10所示。图11给出了试验和有限元计算得到的不同方向缺口试件临近拉断时刻的最大主应变分布云图,图中应变云图的标尺范围均为0~0.25。可以看到,有限元计算结果与试验测得的载荷-位移关系曲线较好地吻合,且临近拉断时,应变分布与DIC试验结果也较好地吻合。

图9 有限元计算的工程应力-应变关系与试验对比

Fig. 9 Comparison between simulated(FEA) and experimental engineering stress-strain curves in 3 directions

图10 缺口试件有限元计算的载荷-位移曲线与试验对比

Fig. 10 Comparison between simulated (FEA) and experimental force-displacement curves for 3 mm grooved specimens in 3 directions

图11 临近拉断时缺口试件的应变分布云图

Fig. 11 Distributions of maximum principal strain for grooved specimen at incipient fracture (U is displacement of gage length)

4 结论

1) 建立了描述AZ31B挤压镁合金材料畸变硬化特性的本构模型。首先,沿不同方向单向拉伸与压缩的试验结果揭示出AZ31B在发生屈服时存在显著的各向异性和拉压非对称性,且在塑性流动过程存在畸变硬化的现象。

2) 基于考虑了各向异性和拉压非对称性的CPB06屈服面函数,通过构建屈服面各参数随等效塑性应变变化的解析函数关系式,实现对畸变硬化过程的描述,从而建立了镁合金材料的唯象本构模型。

3) 将参数拟合后的本构模型应用于缺口拉伸试件的有限元模拟中,计算结果与试验较好地吻合。为镁合金后续的应用研究工作奠定了基础。

REFERENCES

[1] KULEKCI M K. Magnesium and its alloys applications in automotive industry[J]. The International Journal of Advanced Manufacturing Technology, 2008, 39(9): 851-865.

[2] 柳百成, 熊守美. 汽车工业镁合金压铸成形技术及模拟仿真[J]. 汽车安全与节能学报, 2011, 2(1): 1-11.

LIU Bai-cheng,XIONG Shou-mei. High pressure die casting process of magnesium alloys and its modeling and simulation for automobile industry[J]. Journal of Automotive Safety and Energy, 2011, 2(1): 1-11.

[3] LOU X Y, LI M, BOGER R K, AGNEW S R, WAGONER R H. Hardening evolution of AZ31B Mg sheet[J]. International Journal of Plasticity, 2007, 23(1): 44-86.

[4] 刘 筱, 娄 燕, 李落星, 朱必武, 何凤亿. AZ31镁合金热压缩过程中晶粒取向和织构的演变[J]. 中国有色金属学报, 2012, 22(8): 2141-2147.

LIU Xiao, LOU Yan, LI Luo-xing, ZHU Bi-wu, HE Feng-yi. Grain orientation and texture evolution of AZ31 magnesium alloy during hot compression[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(8): 2141-2147.

[5] AGNEW S R, DUYGULU  . Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B[J]. International Journal of Plasticity, 2005, 21(6): 1161-1193.

. Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B[J]. International Journal of Plasticity, 2005, 21(6): 1161-1193.

[6] 余 琨, 芮守泰, 王日初, 彭超群, 薛新颖. AZ31镁合金挤压薄板织构及力学各向异性[J]. 中国有色金属学报, 2008, 18(12): 2127-2131.

YU Kun, RUI Shou-tai, WANG Ri-chu, PENG Chao-qun, XUE Xin-ying. Texture and mechanical anisotropy of AZ31 extruded sheets[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(12): 2127-2131.

[7] 唐伟琴, 张少睿, 范晓慧, 李大永, 彭颖红. AZ31镁合金的织构对其力学性能的影响[J]. 中国有色金属学报, 2010, 20(3): 371-377.

TANG Wei-qin,ZHANG Shao-rui,FAN Xiao-hui,LI Da-yong,PENG Ying-hong. Texture and its effect on mechanical properties of AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 371-377.

[8] 吴章斌, 桂良进, 范子杰. AZ31B镁合金挤压板材力学性能的各向异性[J]. 材料研究学报, 2012, 26(2): 218-224.

WU Zhang-bin, GUI Liang-jin, FAN Zi-jie. The mechanical properties of extruded AZ31B magnesium alloy sheets[J]. Chinese Journal of Materials Research, 2012, 26(2): 218-224.

[9] KHAN A S, PANDEY A, HEROLD T G, MISHRA R K. Mechanical response and texture evolution of AZ31 alloy at large strains for different strain rates and temperatures[J]. International Journal of Plasticity, 2011, 27(5): 688-706.

[10] HILL R. A theory of the yielding and plastic flow of anisotropic metals[J]. Proceedings of the Royal Society of London. Series A, Mathematical and Physical Sciences, 1948, 193(1033): 281-297.

[11] BARLAT F, LEGE D, BREM J C. Six-component yield function for anisotropic materials[J]. International journal of plasticity, 1991, 7(7): 693-712.

[12] CAZACU O, BARLAT F. A criterion for description of anisotropy and yield differential effects in pressure-insensitive metals[J]. International Journal of Plasticity, 2004, 20(11): 2027-2045.

[13] CAZACU O, PLUNKETT B, BARLAT F. Orthotropic yield criterion for hexagonal closed packed metals[J]. International Journal of Plasticity, 2006, 22(7): 1171-1194.

[14] NIXON M E, CAZACU O, LEBENSOHN R A. Anisotropic response of high-purity α-titanium: Experimental characterization and constitutive modeling[J]. International Journal of Plasticity, 2010, 26(4): 516-532.

[15] ARETZ H, BARLAT F. New convex yield functions for orthotropic metal plasticity[J]. International Journal of Non-Linear Mechanics, 2013, 51: 97-111.

[16] YOON J W, LOU Y, YOON J, GLAZOFF M V. Asymmetric yield function based on the stress invariants for pressure sensitive metals[J]. International Journal of Plasticity, 2014, 56: 184-202.

[17] BAI Y L, WIERZBICKI T. A new model of metal plasticity and fracture with pressure and lode dependence[J]. International Journal of Plasticity, 2008, 24(6): 1071-1096.

[18] KHAN A S, YU S, LIU H. Deformation induced anisotropic responses of Ti-6Al-4V alloy Part Ⅱ: A strain rate and temperature dependent anisotropic yield criterion[J]. International Journal of Plasticity, 2012, 38(0): 14-26.

[19] GILLES G, HAMMAMI W, LIBERTIAUX V, CAZACU O, YOON J H, KUWABARA T, HABRAKEN A M, DUCH NE L. Experimental characterization and elasto-plastic modeling of the quasi-static mechanical response of TA-6 V at room temperature[J]. International Journal of Solids and Structures, 2011, 48(9): 1277-1289.

NE L. Experimental characterization and elasto-plastic modeling of the quasi-static mechanical response of TA-6 V at room temperature[J]. International Journal of Solids and Structures, 2011, 48(9): 1277-1289.

[20] TUNINETTI V, GILLES G, MILIS O, PARDOEN T, HABRAKEN A M. Anisotropy and tension–compression asymmetry modeling of the room temperature plastic response of Ti-6Al-4V[J]. International Journal of Plasticity, 2015, 67: 53-68.

[21] ERT RK S, STEGLICH D, BOHLEN J, LETZIG D, BROCKS W. Thermo-mechanical modelling of indirect extrusion process for magnesium alloys[J]. International Journal of Material Forming, 2009, 2: 49-52.

RK S, STEGLICH D, BOHLEN J, LETZIG D, BROCKS W. Thermo-mechanical modelling of indirect extrusion process for magnesium alloys[J]. International Journal of Material Forming, 2009, 2: 49-52.

[22] YOON J, CAZACU O, MISHRA R K. Constitutive modeling of AZ31 sheet alloy with application to axial crushing[J]. Materials Science and Engineering A, 2013, 565: 203-212.

(编辑 龙怀中)

收稿日期:2014-06-20;修订日期:2014-11-14

通信作者:桂良进,副研究员,博士;电话:010-62789096;E-mail: gui@tsinghua.edu.cn