文章编号:1004-0609(2010)S1-s0048-06

钛合金厚板窄间隙TIG焊接接头的组织和力学性能

胡伟民,李国林,刘希林,张建欣,王 岗

(中国船舶重工集团公司,洛阳 471039)

摘 要:通过窄间隙TIG自动焊接方法,完成40 mm TA2试板的对接焊接,获得无缺陷的焊缝,对全焊缝厚度进行组织和力学性能检验。结果表明:各层焊缝性能均合格,采用窄间隙焊接方法可以获得优质的焊接接头。先焊区域由于受压缩塑性变形,焊缝的冲击韧性有了明显的提高。并初步分析了冲击韧性提高的原因。

关键词:钛合金;厚板;焊接接头;组织;冲击韧性

中图分类号:TG 407 文献标志码:A

Microstructure and mechanical property of narrow-gap TIG welding joint of titanium alloys thick plate

HU Wei-min, LI Guo-lin, LIU Xi-lin, ZHANG Jian-xin, WANG Gang

(Luoyang Ship Material Research Institute, Luoyang 471039, China)

Abstract: By the method of narrow gap TIG welding, TA2 plate with a depth of 40 mm and without defects was jointed. The microstructure of the joint was analyzed and the mechanical properties were tested about the whole welding line. The results show that every layer can be eligible and the TA2 joints welded by narrow gap TIG welding are of high-quality. Furthermore, the impact toughness of welding joints in the areas of welded foregoing increase obviously because of being compressed, leading to plastic distortion. The reasons that the impact toughness can be increased were analyzed also.

Key words: titanium alloy; thick plate; welding joint; microstructure; impact toughness

随着现代工业生产和国防装备中焊接结构的日益大型化,厚板的应用越来越广泛。使用传统的焊接方法进行厚板焊接,焊接速度慢,焊后应力变形大,焊接效果较差[1]。而采用窄间隙焊接不仅可大幅度地减少坡口截面积、大大减少焊缝金属的填敷量,而且可以在较小的焊接热输入条件下,实现焊接,因而被作为一种经济的、能够得到优良力学性能和变形较小的优质焊接接头的焊接方法,广泛应用于各种大型重要结构[2-4]。

窄间隙TIG焊是焊接质量可靠的窄间隙焊接工艺之一。由于氩气的保护作用,TIG焊可用于焊接易氧化的有色金属及其合金、不锈钢、高温合金、钛及钛合金以及难熔的活性金属(如钼、铌、锆)等,其接头具有良好的韧性,焊缝金属中的氢含量很低。所以,窄间隙TIG焊接方法成为钛合金厚板常用的焊接方 法[5]。在相关文献[2, 6-7],研究者们对钛合金的窄间隙TIG焊接工艺和特点进行了探索。随着研究的深入,窄间隙TIG焊接方法在钛合金中的应用将越来越多。

1 实验

试验材料选用40 mm TA2退火态板材,板材的初始力学性能如表1所列。

表1 TA2板材的拉伸性能

Table 1 Tensile properties of TA2 plate

采用窄间隙焊接方法实现40 mm TA2试板的对接焊接。经对焊接完成的试板进行X射线无损检验,焊缝内部无焊接缺陷,符合JB/T 4730.2 I级的焊缝要求。

2 结果与分析

2.1 室温拉伸试验结果

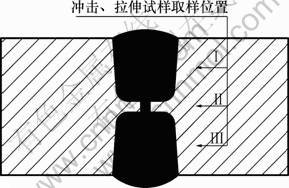

进行焊缝全厚度拉伸、冲击试验,沿焊缝厚度取样位置如图1所示。各层试样的拉伸试验结果(均值)见表2。

图1 拉伸冲击试样取样位置

Fig.1 Sampling position of tensile and impact test

表2 TA2窄间隙焊接接头的室温拉伸试验结果

Table 2 Tensile test results of TA2 narrow gap weld joint at room temperature

由表2可以看出,全焊缝厚度焊接接头拉伸试验的断裂均在母材,说明窄间隙TIG焊接接头的由于啮合强化而使焊缝强度得到了提高[2]。

2.2 室温冲击试验结果

按照GB/T 2650—2008进行40 mm TA2焊接接头全厚度V型缺口冲击试验,冲击试验结果如表3所列。

表3 TA2窄间隙焊接接头的冲击试验结果

Table 3 Impact testing results of TA2 narrow-gap weld joint

由表3可以看出,焊缝中部区域的冲击韧性aKV远大于其他区域的。这可能是由于焊缝中部先焊区域在后期焊接过程中由于焊缝收缩而出现部分压缩塑性变形,使焊缝组织在焊接变形和焊接热处理共同作用下变得错综复杂,从而提高焊缝冲击断裂过程的阻力,提高了焊缝冲击韧性。以下通过对金相和冲击试验断口的扫描电镜研究,进一步分析焊缝冲击值提高的 原因。

2.3 焊缝显微组织和硬度

40 mm TA2全焊缝厚度低倍金相如图4所示。由图4可看出,未发现裂纹、孔穴、固体夹杂、未熔合和未焊透、形状和尺寸不良等缺陷。

选择近表面、1/4焊缝厚度、1/2焊缝厚度3个特征区域进行高倍金相分析,具体位置如图2中的1区、2区、3区所示。

图2 焊接点的低倍金相

Fig.2 Metallograph of joint

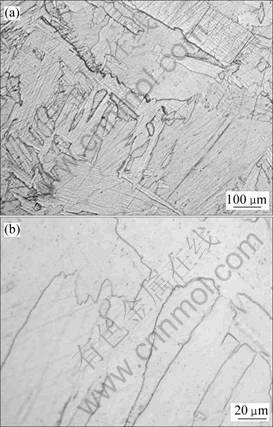

对3个特征区域进行高倍金相分析,结果如图3~5所示。图6为常规TIG焊接焊缝的金相组织。

由图3~5可以看出,40 mm TA2窄间隙TIG焊缝的组织主要由基体α、片状α和针状α构成,可以看到交错复杂的组织。由图6可以看出,常规TIG焊接接头的组织主要由大块状、锯齿状α相构成,看不到交错的组织和针状α相。

图3 图2中1区焊缝金相组织

Fig.3 Metallographs of welding joint in zone 1 in Fig.2

图4 图2中2区焊缝金相组织

Fig.4 Metallographs of welding joint in zone 2 in Fig.2

图5 图2中3区焊缝金相组织

Fig.5 Metallographs of welding joint in zone 3 in Fig.2

图6 常规TIG焊接焊缝金相组织

Fig.6 Metallographs of TIG welding joint

在进行1区焊接时,焊接过程中的收缩变形较大,焊接收缩变形和焊接热处理的协同作用造成焊缝区的组织交错。而冲击过程是瞬时的动态载荷,在恒定的载荷下,试样将主要发生弹性变形、塑性变形和裂纹的快速扩展,其中塑性变形和裂纹扩展对冲击断裂韧度影响较大[8]。相互交错的组织在冲击试验裂纹扩展过程中对其形成了阻力,从而提高焊缝区的冲击韧性。进行2区和3区焊接时,已焊焊缝的刚性较大,焊接收缩变形量较小,焊接应力、焊接热处理和部分的焊接变形,也在一定程度上促进了组织的交错化。而普通TIG焊接,焊接层道少,焊接过程在开放的坡口中进行,焊接收缩和变形都能够随意进行。同时,普通TIG焊接过程中焊缝冷却速度较慢,这也在一定程度上限制针状α相的形成,所以在普通TIG焊接焊缝中心的金相组织中仅存在锯齿状α相,同样普通TIG焊接接头的冲击韧性大约为800 kJ/m2,与Ⅰ区、Ⅲ区的冲击韧性差别不大。

自焊缝下表面中心至焊缝上表面中心进行显微维氏硬度检验,检验结果如图7所示。由图7可以看出,焊缝不同厚度区域硬度的差别基本在30HV以内。

图7 焊缝维氏硬度的分布

Fig.7 Vickers hardness distribution of welding joint

2.4 扫描电镜分析

采用Quanta600扫描电子显微镜对焊缝全厚度冲击韧性试样断口分析,其断口形貌如图8~10所示。由图8和10可以看出,Ⅰ区和Ⅲ区断口形貌基本一致,断裂方式主要为沿晶断裂,断口面较平整,韧窝较浅,而且分布均匀。由图9(a)可以看出,Ⅱ区断口粗糙不平,韧窝分布不均匀,存在较深的韧窝,说明在冲击断裂过程中受到的阻力更大。图9(b)则呈现出部分较深的韧窝。

图8 Ⅰ区断口形貌

Fig.8 Fractographs of welding joint in zone Ⅰ

图9 Ⅱ区断口形貌

Fig.9 Fractographs of welding joint in zone Ⅱ

图10 Ⅲ区断口形貌

Fig.10 Fractographs of welding joint in zone Ⅲ

3 讨论

采用窄间隙TIG焊接实现了40 mm TA2对接焊接,焊缝表面宽度小于10 mm,焊缝经X射线无损检测符合JB/T4730 Ⅰ级焊缝要求。对焊接接头进行全厚度力学性能检验,焊接接头拉伸试验均断在母材,即采用窄间隙焊接的接头强度较高,焊接系数大于1。对焊缝截面进行全厚度显微维氏硬度检验,发现焊缝全厚度方向上显微维氏硬度差别基本在30HV以内,符合标准要求;对焊接接头进行冲击性能试验时,焊缝中部的冲击韧性明显高于焊缝边部的。对冲击断口进行SEM分析,发现焊缝截面中部的冲击断口,韧窝较深,裂纹扩展的阻力更大。

在40 mm TA2窄间隙焊接过程中,焊缝对称收缩量约为4 mm,而且焊接过程的收缩量主要集中在焊接厚度为0~20 mm的范围内;当焊接厚度超过20 mm后,焊接收缩变形由于已焊部分刚性过大而基本停止。除此之外,在全焊缝厚度焊接过程中,焊接热输入量差别不大,所以焊接过程的收缩变形和窄间隙TIG焊接的特殊过程便构成了焊缝截面中部区域冲击韧性提高的主要因素,具体分析如下。

窄间隙焊接构件规格较大,散热较快,同时窄间隙过程坡口宽度较小(<10 mm),钨极的部分能量会被侧壁吸收,从而窄间隙TIG焊接较一般的TIG焊接需要更多的输入热,从而形成了深而窄的熔池,这就促使了窄间隙焊接后道焊缝对前道焊缝的热处理更充分,甚至对前两道、前三道焊缝都会构成热影响,多次的热处理促进了钛合金焊缝晶粒的细化,增大冲击试验过程中裂纹扩展的阻力,提高焊缝的冲击韧性。在0~20 mm的厚度范围内焊接时,焊接过程的收缩变形较大,已焊接区域由于焊接过程的收缩和后道焊缝对前道焊缝的热处理,加剧了晶粒细化的程度,同时焊缝组织也因此变得错综复杂,从而提高了焊缝的冲击韧性。

4 结论

1) 采用窄间隙焊接方法焊接40 mm TA2材料,可以获得无缺陷焊缝,焊接接头力学性能良好。

2) 先焊区域由于受到焊接变形应力和层道之间焊接热处理的协同作用,使焊缝晶粒细化、组织交错,提高了接头的强度和冲击韧性。

REFERENCES

[1] 张富巨, 罗传红. 窄间隙焊及其新进展[J]. 焊接技术, 2000, 29(6): 33-36.

ZHANG Fu-ju, LUO Chuan-hong. Narrow-gap welding and new research progress[J]. Welding Technology, 2000, 29(6): 33-36.

[2] 郑喜刚, 赵 勇. 钛合金窄间隙TIG焊接工艺研究[J]. 钛工业进展, 2006, 23(5): 40-43.

ZHENG Xi-gang, ZHAO Yong. The research on narrow-gap TIG welding of titanium alloys[J]. Titanium Industry Progress, 2006, 23(5): 40-43.

[3] 胡存银, 张富巨. 窄间隙焊接工艺及经济性分析[J]. 焊接技术, 2001, 30(2): 47-48.

HU Cun-yin, ZHANG Fu-ju. The narrow-gap welding technology and economical efficiency analyzing[J]. Welding Technology, 2001, 30(2): 47-48.

[4] 周方明, 王江超, 周涌明, 张 军. 窄间隙焊接的应用现状及发展趋势[J]. 焊接技术, 2007, 36(4): 4-7.

ZHOU Fang-ming, WANG Jiang-chao, ZHOU Yong-ming, ZHANG Jun. The actuality and develop direction of narrow gap welding[J]. Welding Technology, 2007, 36(4): 4-7.

[5] 王 朋, 张富巨. 窄间隙焊接技术及其新进展[J]. 电力建设, 1999(8): 12-14.

WANG Peng, ZHANG Fu-ju. Narrow gap welding technology and its new development[J]. Electric Power Construction, 1999(8): 12-14.

[6] 刘希林, 高佩钦, 王 岗, 张建欣. 钛合金厚板自动窄间隙TIG焊接工艺研究[J]. 稀有金属材料与工程, 2008, 27(增刊3): 177-180.

LIU Xi-lin, GAO Pei-qin, WANG Gang, ZHANG Jian-xin. Research on narrow-gap automatic TIG welding technology of titanium alloys thick plate[J]. Rare Metal Materials and Engineering, 2008, 27(S3): 177-180.

[7] 张建欣, 刘希林, 崔永杰, 卢 海. 大厚度钛合金大规格环材环缝的焊接[J]. 稀有金属材料与工程, 2008, 27(增刊3): 224-226.

ZHANG Jian-xin, LIU Xi-lin, CUI Yong-jie, LU Hai. The welding ring welding seam of heavy section titanium alloys ring section material[J]. Rare Metal Materials and Engineering, 2008, 27(S3): 224-226.

[8] 郑修麟. 材料力学性能[M]. 西安: 西北工业大学出版社, 1996.

ZHENG Xun-lin. The tensile properties of materials[M]. Xi’an: Northwestern Polytechnical University Press, 1996.

(编辑 杨 华)

通信作者:胡伟民,高级工程师;电话:0379-67256058;E-mail: XILIN.L@126.com