DOI:10.19476/j.ysxb.1004.0609.2019.03.08

搅拌摩擦焊焊缝缺陷形态对超声相控阵检测的影响

胡博文1,黄春平1,夏 春1,刘 钺2,柯黎明1

(1. 南昌航空大学 轻合金加工科学与技术国防重点学科实验室,南昌 330063;

2. 江西省锅炉压力容器检验检测研究院,南昌 330063)

摘 要:搅拌摩擦焊缺陷界面紧贴、细微、取向复杂,常用的检测方法在角度选择及缺陷判别上存在难点,超声相控阵可在单一探头上实现多角度聚焦扫查。以不同形态未焊透(LOP)和隧道孔作为研究对象,采用超声相控阵扇扫,研究了界面取向和曲率对检测的影响。结果表明:超声相控阵扇扫可不移动探头对未焊透和隧道孔进行精确识别;平直未焊透界面检测受界面取向及入射角的共同影响,信号强度与声束和界面偏离垂直的程度呈反比,弯曲未焊透界面检测受界面曲率影响,信号强度与曲率成反比,综合多角度检测得到的角度-幅值曲线可以判断未焊透界面是否弯曲。

关键词:搅拌摩擦焊;超声相控阵扇扫;未焊透;隧道孔;界面形态

文章编号:1004-0609(2019)-03-0491-07 中图分类号:TG441.7 文献标志码:A

铝合金具有高比强度、良好的加工成形性,广泛应用于航空、海运和铁路行业[1],搅拌摩擦焊作为一种新型的铝合金固相焊接技术,具有接头性能好、焊接过程不需气体保护、无烟尘及飞溅等优点[2-6],但焊缝中易产生紧贴、细微和取向复杂的缺陷[7],超声波检测技术对此类缺陷应用最为普遍,但当前相关的超声方法研究主要集中在入射面规则的缺陷检测,对于未焊透缺陷通常采用斜入射方式检测,波形只有一个较高的波峰[8-10],对于变曲率、变取向的缺陷界面,由于超声波在曲面上的聚焦、散射特性相比平面上显著增强[11-13],导致缺陷检出困难,取向的不确定性又导致检测角度难以选择,刘松平等[14]以机械方式实现入射角的变换,分析了超声入射方向、缺陷取向对铝合金FSW焊缝超声检测的影响,但是设备复杂、操作繁琐,检测灵敏不高,LAFONTAINE等[15]将相控阵与传统超声进行对比,并对其探测潜力进行了预测。

相控阵技术通过控制晶片激励的时间差,能实现声束聚焦、偏转[16-17],超声能量集中且可使用单一探头在位置不变的情况下进行多角度扫查[18]。基于此,许多研究者将超声相控阵检测方法用于FSW缺陷的检测,发现相控阵对于取向复杂的缺陷有很好的检出率和精确的定位能力[19],对体积型、贴合型缺陷及曲面结构的相控阵检测均有尝试的先例[20-22],但是超声相控阵扇扫图像本质上还是由声束在材料为各点的反射信号转换而来,仅从图像上依然无法准确的判断缺陷形态。

本文针对铝合金FSW焊缝中不同形态的未焊透及隧道孔,采用超声相控阵扇形扫查方式,重点研究了界面曲率及取向对相控阵检测的影响,并以不同方向的相控阵扇形扫查图像分析得到了未焊透和隧道孔信号识别及分离的方法。

1 实验

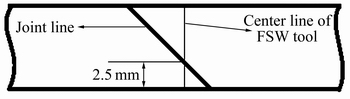

试验材料采用2A14铝合金,试件尺寸为200 mm×100 mm×8 mm。试验使用的搅拌头轴肩直径d 26 mm,搅拌针长度5.5 mm,通过改变对接面倾斜角以及焊接时塑性流动程度(使用两种不同搅拌头,即左旋螺纹搅拌头和同样尺寸无螺纹搅拌头),对2A14铝合金板材进行对接焊,制备隧道孔以及不同形态未焊透缺陷,保证搅拌针轴线与对接面交点距试板底面2.5 mm,如图1所示,避免界面结合程度不同对检测造成影响。

图1 搅拌头插入位置示意图

Fig. 1 Schematic diagram of insert position of FSW tool

采用进口的OmniScan MX2超声相控阵探伤仪进行检测,选用5 MHz横波相控阵探头,耦合剂为机油,图像显示模式为A型显示+S型显示,扫查角度45°~70°,基于搅拌摩擦焊焊缝方向各区域缺陷稳定的特点,对带缺陷试样取横截面进行金相法验证。

2 结果与分析

2.1 搅拌摩擦焊缺陷特征

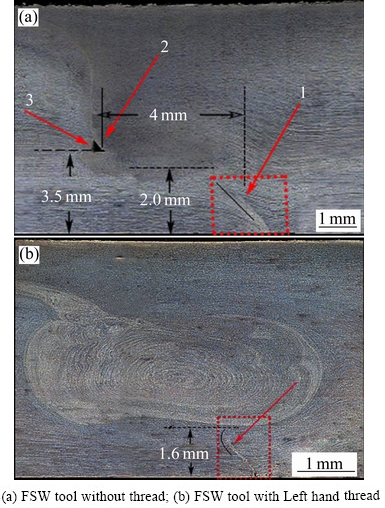

图2所示为两种不同搅拌头制备的缺陷宏观形貌,红色虚线框为未焊透位置,黑色实线标识出缺陷界面的大致形态,当试板的对接面倾斜角度改变时,框内未焊透形态会有变化,红色箭头代表3种不同的声束入射方向。图2(a)由无螺纹搅拌头得到,未焊透界面平直,垂直方向尺寸2.0 mm,前进侧(焊接方向与搅拌头旋转方向相同的一侧)出现距底部3.5 mm的隧道孔,焊核不明显,图2(b)由左旋螺纹搅拌头得到,未焊透界面向后退侧弯曲,垂直方向尺寸1.6 mm,焊核出现明显洋葱瓣花纹。

图2 两种不同搅拌头制备的缺陷形貌

Fig. 2 Morphologies of defects made by two different FSW tool

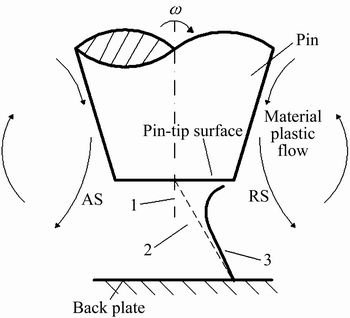

根据抽吸挤压理论[23]建立模型(如图3所示),AS代表前进侧,RS代表后退侧,使用左旋螺纹搅拌头时,搅拌针周围金属沿螺纹在厚度方向产生剧烈的螺旋流动,在螺纹端部脱离搅拌针并向周围挤压,形成环形挤压区,表现为洋葱瓣花纹。当搅拌针长度较短时,金属塑性流动范围减小,根部产生未焊透缺陷,在搅拌头前进过程中,未焊透界面形态主要受端面的摩擦力及搅拌头前沿挤压力作用,同一横截面先受到端面前部作用,塑性金属在摩擦力作用下由前进侧向后推侧迁移。在前沿挤压力作用下,以轴线为分水岭,AS和RS侧塑形金属分别向本侧迁移,然后受到端面后部的作用,仅在摩擦力作用下导致塑性金属由后退侧向前进侧迁移;而1、2、3区域受到的作用程度逐渐降低,1区域迁移程度最大,由于倾斜界面(虚线表示)在靠RS侧,搅拌头运动过程中,前部挤压力和摩擦力的综合作用大于后部摩擦力的作用,因此未焊透形态表现为上部向后退侧弯曲(实线表示)。使用无螺纹搅拌头时,焊缝金属在横截面上以平移为主,不产生洋葱瓣花纹,且由于无螺纹作用时塑性金属流动较弱,对未焊透的弯曲作用可忽略,前进侧金属流动仅分布在前进侧,后退侧金属流动一直延伸到前进侧,后退侧塑形金属流动程度不足以填满前进侧的瞬时空腔时,会导致在前进侧产生隧道孔缺陷。

图3 抽吸-挤压理论模型

Fig. 3 Suction-extrusion theory model

2.2 界面取向对检测的影响

图4所示为两种不同取向的平直界面金相图及沿图2(a)的1方向检测图像,从图4(a)和(b)可以看出,A、B界面取向为50°和65°,图4(c)和(d)中左侧为A型显示,右侧为S型显示图像(45°~70°的扇扫图像),以颜色深浅表示信号强弱,红色虚线框内为缺陷图像,穿过缺陷图像的蓝线为虚拟探头发出声束的路径,45°~70°每个角度对应一个虚拟探头,A、B界面检测信号幅值为全屏的84.9%和66.5%,距焊缝边缘11 mm,A界面幅值高于B界面,波形为单束波峰状,根部干净无杂波,S型显示图像为中部深色,两侧逐渐变浅的长色带。

由于检测位置界面没有弯曲,从理论上认为,反射强度只受角度关系影响,而未焊透是面积型缺陷,在虚拟探头角度垂直于界面时(即检测声束角度与界面取向角度相等时),反射波最强,虚拟探头角度与界面偏离垂直时,反射强度随偏离程度增大而逐渐降低,在同样51°检测角度时,A界面基本可以认为是垂直反射,B界面与检测声束明显偏离垂直,A界面对声波的反射强度明显高于B界面,与理论分析一致。

图4 A、B界面金相图及其相控阵检测图像

Fig. 4 Metallographs of flat interfaces of A((a), (c)) and B((b), (d)) and phase array testing images

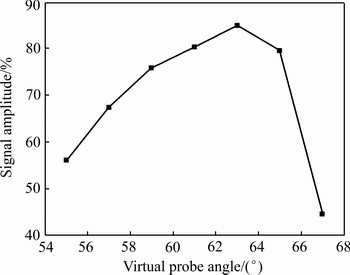

图5所示为不同角度虚拟探头对B界面的检测幅值曲线。从图5中可以看出,55°~67°虚拟探头以2°为间隔扫查时,信号幅值分别为全屏的56%、67.3%、75.8%、80.2%、84.9%、79.5%、44.6%,63°虚拟探头时反射强度最高,以63°为基准,角度增大减小反射强度均降低,角度增大时急剧降低,角度减小时降低速度较为缓慢,波幅曲线表现为长程缓慢上升-峰值-短程缓慢降低-急剧降低。

图5 不同角度虚拟探头对B界面的检测信号幅值

Fig. 5 Signal amplitude of virtual probe on B interface at different angles

通过多角度检测特征分析:超声波声束以向外扩散的曲面形式在介质中传播,不是以绝对单一角度进行反射,而是以中部能量高向两侧逐渐降低的小范围角度群方式进行反射,且随传播距离增加,声束扩散面增大,能量衰减,55°与67°虚拟探头的声束传播距离为37.01 mm和57.1 mm,传播距离增大会导致声束能量衰减增大,小范围角度群对检测角度的补充作用降低,所以使用小角度虚拟探头时,随偏离垂直反射的程度增加,反射强度降低速率明显低于大角度虚拟探头时,接近垂直反射的63°虚拟探头检测时,作用于反射界面的是小范围角度群中能量最高的声束中部,反射强度最大。

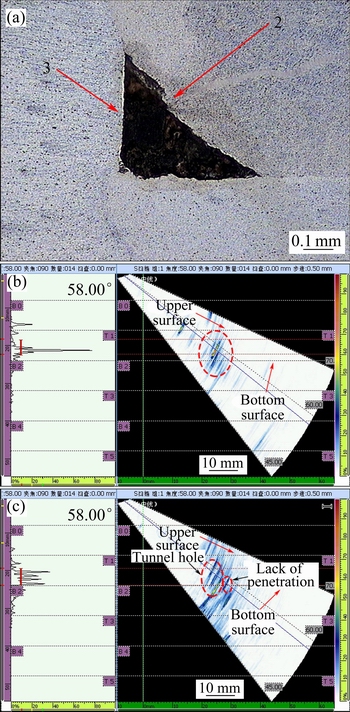

图6所示为隧道孔形貌图及沿图2(a)的2、3方向检测图像.从图6中看出,隧道孔存在两种不同形态的界面,主要表现为取向杂乱的锯齿状界面和取向平稳的界面,图6(b)从S型显示图像上看,缺陷部分存在多种色带,有一个长度较短的类似未焊透的色带,其他色带颜色较淡且分布杂乱,从A型显示波形上看,信号曲线由多个波峰组成,波宽范围内含有一个主峰和数个次峰,主峰次峰峰值为全屏的78%和23%。图6(c)可以从S型显示图像中观察到4个色带,其中3个均在距前进侧焊缝边缘11 mm处,与另一个相隔4 mm左右,A型显示图像中为4个峰值达到全屏28%左右的波峰。

图6 隧道孔形貌及其2、3方向相控阵检测图像

Fig. 6 Morphology of tunnel hole(a) and phased array testing images along directions of 2(b) and 3(c)

沿2方向的反射界面取向复杂突变无规律,声波漫反射现象较强,会产生多个较弱的反射回波,但其声阻抗近似空气,声波反射率会很大,因此最强回波会明显高于漫反射产生的杂乱回波,检测结果与分析相符。沿3方向的反射界面平滑,取向规则,由于焊缝宽度为26 mm,通过检测数据发现,距前进侧焊缝边缘15 mm的单个信号正好匹配距离后退侧焊缝边缘11 mm的未焊透缺陷信号,隧道孔界面垂直尺寸为0.3 mm左右,当障碍物尺寸小于波长时,衍射增强反射减弱,一般超声检测的灵敏度约为λ/2 (λ为波长),检测频率为5 MHz,铝合金中横波声速为3100 m/s,可以根据公式(1)计算得到波长为0.628 mm,λ/2为0.314 mm,大于缺陷界面尺寸,上下端点处会产生衍射信号,形成3个水平位置相同的信号,检测结果与理论分析相符,3个水平位置相同的信号与单个信号距离4 mm与图2(a)的尺寸关系也相符。所以可以断定3个一列的信号为隧道孔,单个信号为未焊透。

(1)

(1)

式中:v为声速;f为频率。

2.3 界面曲率对检测的影响

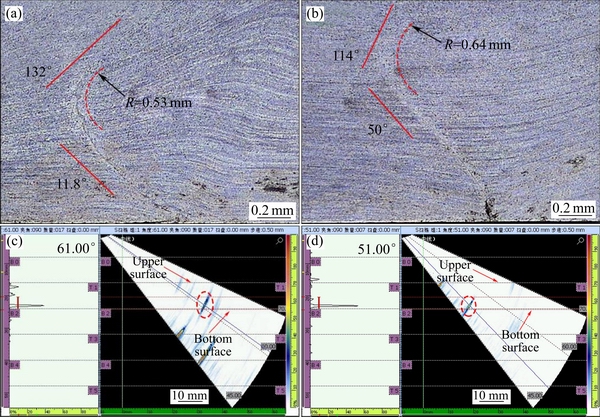

图7所示为两种不同形态的弯曲界面金相图及其检测图像。从图7中可以看出,C界面形态为41.8°~132°的弓形,弯曲明显从缺陷的中部开始出现,D界面形态为50°~114°的弯曲界面,弯曲程度降低,弯曲起始位置上移,检测结果表明,C界面和D界面检测信号幅值为满屏的39.1%和52.1%,波形曲线整体形状均为单束波峰状,根部干净没有杂波。

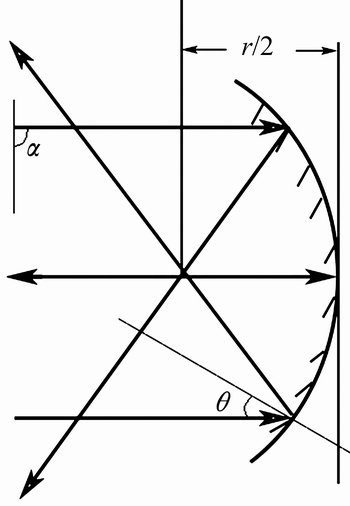

根据曲界面反射理论模型(如图8所示)可以得知,弯曲界面对声束的反射会受界面曲率和声束扩散角的影响,介质相同时,声束扩散角α以及界面曲率1/r为界面反射的主要影响因素。当声束指向性相同(α相同)时,界面曲率增大(半径减小)会导致反射波焦点距离(r/2)变短,且θ增大,在超过焦点距离时,发散性增强;当声束指向性减小时(α由90°增大),声束能量发散,且反射面增大,在超过焦点距离时,发散性增强。

C界面和D界面上用红色虚线表示出了近似的曲率圆弧,曲率半径分别为0.53 mm和0.64 mm,反射波焦点距离反射面为0.265 mm和0.32 mm,由于板厚为8 mm,显然超过了焦点距离,声束呈发散性反射,C界面的曲率1/r大于D界面,发散性大于D界面,因此反射波强度要小于D界面,理论分析与实际检测结果相符。

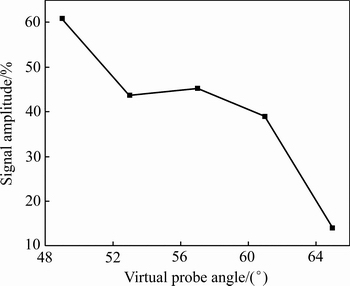

图9所示为不同角度虚拟探头对C界面的检测幅值曲线。从图9中可以看出,49°~65°虚拟探头以4°为间隔扫查时,信号幅值分别为全屏的60.7%、43.6%、41.5%、39.1%、14%,虚拟探头角度由53°至61°时反射强度变化不明显,49°时明显增强,65°时明显降低,波幅曲线表现为降低-平台-降低。

图7 C、D界面金相图及其相控阵检测图像

Fig. 7 Metallographs and phased array testing image of C((a), (c)) and D((b), (d)) interfaces

图8 曲界面反射理论模型

Fig. 8 Theoretical model of curve interface reflection

图9 不同角度虚拟探头对C界面的检测信号幅值

Fig. 9 Signal amplitude of virtual probe on C interface at different angles

结合曲界面反射模型及C界面形貌,分析认为,由于C界面弯曲部位曲率不断变化,检测角度在一定范围内改变时都能找到最佳反射界面,且传播距离变化不大,可认为扩散衰减的影响较小,检测信号主要受到曲界面散射的影响,信号幅值基本相同,与实际53°~61°的检测结果相符。从C界面形貌可以看到,在中部区域有一个取向角从锐角向钝角转变的过程,若入射声束检测位置在转变处,会产生声束一部分朝上反射,一部分朝下反射的现象,反射强度将会急剧降低,65°虚拟探头检测信号幅值明显降低。弯曲下部曲率降低,逐渐趋于平直界面,取向角变小,49°虚拟探头与此处的界面较为接近垂直,且由于小角度传播距离的降低,小范围角度群的补充作用增大,扩散衰减效果也降低,理论分析认为信号幅值会有明显增大,与实际检测结果相符。

3 结论

1) 隧道孔界面分为取向杂乱和稳定两种。前者A型显示波形为一主峰和多个次峰,与未焊透的单束波峰状区别明显;后者易衍射,S型显示图像为同一水平位置的3个色带,通过S型显示色带的位置可区分隧道孔和未焊透。

2) 平直未焊透界面的检测主要受界面取向及入射角的影响,信号强度与声束和界面偏离垂直的程度呈反比,以最佳角度为基准,入射角越大,偏离垂直程度的影响越强。

3) 弯曲未焊透界面检测主要受界面曲率影响,信号强度与曲率成反比;相控阵扇扫可以判断未焊透界面是否弯曲,检测信号在中部弯曲部位保持平稳,在下部较平直部位急剧升高,上部取向角由锐角向钝角转变部位由于声束分为上下两个方向反射,信号急剧降低。

REFERENCES

[1] ADAMUS K, ADAMUS J, LACKI J. Ultrasonic testing of thin walled components made of aluminum based laminates[J]. Composite Structures, 2017, 12(7): 1-7.

[2] KINCHEN D G, ALDAHIR E. NDE of friction stir welds in aerospace applications[R]. New Orleans: Lockheed Martin Michoud Space Systems, 2002: 1-7.

[3] 徐国富, 段雨露, 钱 健, 唐 磊, 邓 英, 尹志民. Al-Mg-Mn-Sc-Zr合金搅拌摩擦焊接头显微组织、力学性能及腐蚀性能[J]. 中国有色金属学报, 2017, 27(2): 225-233.

XU Guo-fu, DUAN Yu-lu, QIAN Jian, TANG Lei, DENG Ying, YIN Zhi-min. Microstructure, Mechanical properties and corrosion behaviors of Al-Mg-Mn-Sc-Zr alloy friction stir welded joints[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(2): 225-233.

[4] 刘会杰, 李金全, 段卫军. 静止轴肩搅拌摩擦焊的研究进[J]. 焊接学报, 2012, 33(5) : 18-22.

LIU Hui-jie, LI Jin-quan, DUAN Wei-jun. Progress in the stationary shoulder friction stir welding[J]. Transactions of the China Welding Institution, 2012, 33( 5): 18-22.

[5] 赵雪梅. 铝合金搅拌摩擦焊接头超声信号特征与质量评价方法[D]. 哈尔滨: 哈尔滨工业大学, 2010.

ZHAO Xue-mei. Ultrasonic signal features and quality evaluation method of friction stir welded joint of aluminum alloy[D]. Harbin: Harbin Institute of Technology, 2010.

[6] KHAN N Z, KHAN Z A, SIDDIQUEE A N, AL-AHMARI A M, ABIDI M H. Analysis of defects in clean fabrication process of friction stir welding[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(7): 1507-1516.

[7] BIRD C. Quality control of friction stir welds by the application of non-destructive testing[C]// 4th International Symposium on Friction Stir Welding. Part City, Utah, USA, 2003.

[8] VUGRIN T, STANIEK G, HILLIGER W, DONNEL C. Nondestructive detection of flaws in FSW and their metallographic characterization[C]// 5th International Friction Stir Welding Conference. Metz France, 2004: 1-14.

[9] TABATABAEIPOUR M, HETTLER J, DELRUE S, van den ABEELE K. Nondestructive ultrasonic inspection of friction stir welds[J]. Physics Procedia, 2015, 8(71): 660-663.

[10] 孟永乐. 搅拌摩擦焊缺陷的无损检测技术研究[D]. 南昌: 南昌航空大学, 2011.

MENG Yong-le. Research on non-destructive testing technology of friction stir welding defects[D]. Nanchang: Nanchang Hangkong University, 2011.

[11] LEE J R, TAKATSUBO J, TOYAMA N, KANG D H. Health monitoring of complex curved structures using an ultrasonic wave field propagation imaging system[J]. Measurement Science and Technology, 2007, 18(12): 3816-3825.

[12] 胡宏伟, 彭凌兴, 周正干, 李雄兵, 孙广开. 曲面构件水浸超声检测缺陷定量研究[J]. 航空学报, 2014, 35(11): 3166-3173.

HU Hong-wei, PENG Ling-xing, ZHOU Zheng-gan, LI Xiong-bing, SUN Guang-kai. Quantitative research on defect of curved components with immersion ultrasonic testing[J]. Acta Aeronautica et Astronautica Sinica, 2014, 35(11): 3166-3173.

[13] 杨 岳, 戴万林, 李雄兵, 倪培君, 乔日东. 镁合金壳体内部缺陷的精确超声定量方法[J]. 中国有色金属学报, 2015, 25(10): 2666-2671.

YANG Yue, DAI Wan-lin, LI Xiong-bin, NI Pei-jun, QIAO Ri-dong. Accurate ultrasonic quantitative method for internal defects of magnesium alloy shell[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(10): 2666-2671.

[14] 刘松平, 刘菲菲, 李乐刚, 郭恩明, 王瑞川. 搅拌摩擦焊缝变入射角超声检测方法研究[J]. 无损检测, 2006, 28(5): 225-228.

LIU Song-ping, LIU Fei-fei, LI Le-gang, GUO En-ming, WANG Rui-chuan. Ultrasonic detection method of variable angle of incidence in friction stir welding [J]. Nondestructive Testing, 2006, 28(5): 225-228.

[15] LAFONTAINE G, CANCRE F. Potential of ultrasonic phased arrays for faster, better and cheaper inspections [EB/OL]. [2014-03-10]. http://www.ndt.net/article/v05n10/ lafont2/lafont2.htm.

[16] 苗玲玉, 李 衍. 钢结构件焊接接头超声相控阵实际探伤条件的研讨[J]. 无损检测, 2011, 35(3): 2-6.

MIAO Ling-yu, LI Yan. Research on the actual test conditions of ultrasonic phased array for welded joints of steel structures[J]. Nondestructive Testing, 2011, 35 (3): 2-6.

[17] 王伏喜, 周晓峰, 鄂 楠, 李 斌. 超声波相控阵检测技术在钛合金厚板焊缝中的应用[J]. 中国有色金属学报, 2010, 20(S1): 964-966.

WANG Fu-xi, ZHOU Xiao-feng, E Nan, LI Bin. Application of ultrasonic phased array technology in titanium alloy thick plate welds[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s964-s966.

[18] POPOVYCH O V, KARPASH O M, KARPASH M O. Procedure of choosing of phased array transducers for the determination of the sizes and shapes of defects[J]. Materials Science, 2016, 52(3): 438-445.

[19] LAMARRE A, DUPUISO O, MOLES M. Complete inspection of friction stir welds in aluminum using ultrasonic and eddy current arrays[J]. CINDE Journal, 2006, 27(4): 14-16.

[20] 余 亮, 陈玉华, 黄春平, 柯黎明. 搅拌摩擦焊焊缝缺陷的超声相控阵检测技术[J]. 焊接学报, 2014, 35(1): 21-24.

YU Liang, CHEN Yu-hua, HUANG Chun-ping, KE Li-ming. Ultrasonic phased array detection of friction stir welding defects[J]. Transactions of the China Welding Institution, 2014, 35 (1): 21-24.

[21] GAO X R, JIANG Q Y, PENG C Y, Li JY. Application of water immersion ultrasonic phased array technology in wheel rim inspection[J]. Advanced Materials Research, 2012, 468: 733-737.

[22] 王常玺, 刚 铁, 于 朋, 冯 伟, 王 龙. 一种铝合金薄板搅拌摩擦焊焊缝的超声快速检测方法[J]. 机械工程学报, 2015, 51(2): 7-13.

WANG Chang-xi, YU Peng, FENG Wei, WANG Long. An ultrasonic rapid detection method for the friction stir welding of aluminum alloy sheet [J]. Journal of Mechanical Engineering, 2015, 51(2): 7-13.

[23] 柯黎明, 潘际銮, 邢 丽, 王善林. 搅拌摩擦焊焊缝金属塑性流动的抽吸-挤压理论[J]. 机械工程学报, 2009, 45(4): 89-94.

KE Li-ming, PAN Ji-luan, XING Li, WANG Shan-lin. Sucking-extruding theory for the material flow in friction stir welding[J]. Journal of Mechanical Engineering, 2009, 45(4): 89-94.

Effect of friction stir welding defects morphology on phased array ultrasonic testing

HU Bo-wen1, HUANG Chun-ping1, XIA Chun1, LIU Yue2, KE Li-ming1

(1. National Defense Key Discipline Laboratory of Light Alloy Processing Science and Technology, Nanchang Hangkong University, Nanchang 330063, China;

2. Jiangxi Province Boiler Pressure Vessel Inspection and Testing Institute, Nanchang 330063, China)

Abstract: The defects of friction stir welding(FSW) are close and usually have complicated orientations, the commonly used methods have some difficulties in the selection of the angle and the identifying of defects, phased array ultrasonic testing can realize multi-angle focusing scanning by a single probe. Different morphologies of lack of penetration(LOP) and tunnel holes are taken as the research object, ultrasonic phased array S-scan was used to study the effects of interface orientation and curvature on the detection. The results show that the ultrasonic phased array S-scan can accurately identify LOP and tunnel holes without moving the probe. The detection of the flat LOP interface is affected by the interface orientation and the incident angle, the signal intensity is inversely proportional to the degree of deviation of the vertical reflection of the ultrasonic beam. The signal intensity is inversely proportional to the curvature of the interface when the LOP interface is curving. The angle-amplitude curve obtained by multi-angle detection can determine whether the interface can be used to determine whether the interface is curved or not.

Keywords: friction stir welding; ultrasonic phased array S-scan; lack of penetration; tunnel hole; interface morphology

Foundation item: Project(51465044) supported by the National Natural Science Foundation of China; Project(20111156004) supported by the Aviation Science Foundation, China; Project supported by Jiangxi Bureau of Quality and Technical Supervision, China

Received date: 2018-02-08; Accepted date: 2018-07-10

Corresponding author: HUANG Chun-ping; Tel: +86-13576030335; E-mail: hcp98106@163.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51465044);航空科学基金资助项目(20111156004);江西省质检局科技计划项目

收稿日期:2018-02-08;修订日期:2018-07-10

通信作者:黄春平,副教授;电话:13576030335;E-mail:hcp98106@163.com