DOI: 10.11817/j.issn.1672-7207.2017.04.007

滚压对碳钢微动磨损性能的影响

屈盛官1,和锐亮1,王光宏1,付志强2,李小强1

(1. 华南理工大学 机械与汽车工程学院,广东 广州,510640;

2. 中国地质大学(北京) 工程技术学院,北京,100083)

摘要:为了提高碳钢的微动磨损特性,采用不同参数的滚压工艺对45号钢试样进行表面处理,通过表面形貌测量仪、维氏显微硬度计和扫描电镜(SEM)考察在不同参数下,滚压工艺对钢的表面粗糙度、显微硬度、硬化层的厚度等的影响,然后在SRV IV摩擦磨损试验机上对比研究各工艺处理试样的微动磨损特性。研究结果表明:滚压工艺使试样表面形成一定厚度的硬化层,可以降低试样表面的粗糙度,提高表层显微硬度;滚压工艺使试样的磨损量和摩擦因数显著减小;未处理试样的磨损形式主要为黏着磨损和疲劳磨损,滚压后试样以磨粒磨损为主,并伴随轻微的疲劳剥落;不同的滚压参数对45号钢表面性能和微动性能影响较大,滚压工艺使45号钢试样的抗微动磨损性能更加优异。

关键词:滚压;微动磨损;碳钢;磨损机理

中图分类号:TG176;TG506.2 文献标志码:A 文章编号:1672-7207(2017)04-0896-07

Effect of burnishing on fretting wear behaviors of carbon steel

QU Shengguan1, HE Ruiliang1, WANG Guanghong1, FU Zhiqiang2, LI Xiaoqiang1

(1. School of Mechanical and Automotive Engineering,

South China University of Technology, Guangzhou 510640, China;

2. School of Engineering and Technology, China university of Geosciences (Beijing), Beijing 100083, China)

Abstract: In order to improve fretting wear properties of the carbon steel, the burnishing processes with different parameters were introduced to the surface treatment of 1045 steel specimens. The surface roughness, microhardness and the thickness of hardening layer treated by different burnishing processes were evaluated using surface topography device, vickers microhardness tester and scanning electronic microscopy (SEM). In addition, the fretting wear characteristics of samples with different burnishing parameters were investigated using SRV IV tester. The results show that thick hardening layer is generated on the surface of the steel samples by burnishing process. The surface roughness reduces and the microhardness increases significantly. The friction coefficient and wear loss are decreased obviously after burnishing process. Moreover, the wear mechanisms of untreated specimens are mainly adhesive wear and fatigue wear, whereas the treated specimens are mainly damaged by abrasive wear accompanied with slight fatigue spalling. The burnishing parameters have an obvious effect on steel surface properties and fretting wear characteristics. And the burnished 1045 steel specimens have better wear resistance.

Key words: burnishing; fretting wear; carbon steel; wear mechanism

微动是指发生在接触表面间,位移幅度在微米量级的往复运动[1]。而微动磨损是一种在微动过程中材料退化的形式,广泛存在于3个不同微动运行区:部分滑移区、混合区、滑移区[2-3],是涉及到摩擦、弹性变形、氧化、裂纹等的复杂过程[4]。微动磨损会引起结合件、螺栓连接件、紧缩离合器等[5-8]的松动、咬合,尽管微动磨损量较小,但是会造成接触区表层裂纹的扩展,严重影响零部件的使用性能[9]。微动磨损现象在工业领域中普遍存在,已经成为造成很多关键零部件失效的主要原因。表面滚压技术是重要的表面光整技术,通过机械手段在金属表面产生压缩变形,使金属表层发生晶体扭曲、晶粒细化,形成高强度的致密性组织,提高了金属表层硬度;同时由于滚压后外围弹性区的回复作用,使表层材料产生残余压应力。而滚压工艺产生的加工硬化和残余压应力对提高零件的抗微动磨损性能和疲劳强度具有重要作用[10]。WANGER[11]研究了钛合金、铝合金、镁合金在滚压后的疲劳性能,指出疲劳强度主要取决于加工形成的残余压应力的大小和分布;MAJZOOBI等[12]研究了滚压后的7075铝合金的微动疲劳,指出滚压可以将7075铝合金的抗微动疲劳性能大幅度提高;李宁等[13]研究了滚压诱导梯度超细晶铜在油润滑下的微动磨损特性,指出了梯度铜抗微动磨损性能比粗铜提高10倍以上。碳钢作为一种在工业中常用的零部件材料,其微动磨损性能受到极大的关注,但是目前关于滚压后碳钢微动磨损性能的研究却鲜有报道。本文作者以不同的滚压参数对45号钢进行滚压处理,然后通过对试验对象的微动磨损试验,系统地分析了滚压工艺对碳钢微动磨损性能的影响,为其他工艺对碳钢的作用提供了重要的参考。

1 试验

1.1 试验材料

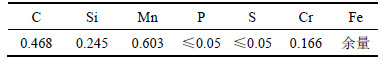

为了充分探究滚压工艺对该45号钢微动磨损性能的影响,特别使用未经热处理的圆棒材料,该碳钢包含F(铁素体)+P(珠光体)相,其化学成分如表1所示。

1.2 试验方法

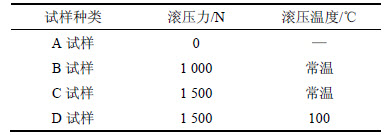

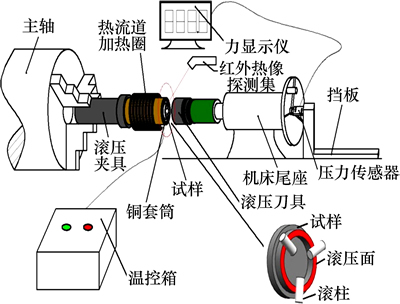

采用一种三滚柱的滚压工具在车床上对碳钢试样进行端面滚压处理,滚压示意图如图1所示,滚柱直径×长度为5 mm×12 mm,材料为YG6硬质合金,硬度(HRA)为90.5,抗弯强度高,抗冲击性能好。车床主轴转速为360 r/min,通过装有滚压工具的机床尾座对试样表面施加滚压力,采用压力传感器测量滚压力,装置示意图见文献[13]。通过设置滚压参数(滚压力和滚压温度)将试样分为4类,如表2所示,进行试验处理,滚压时间为60 s。

表1 碳钢的化学成分(质量分数)

Table 1 Chemical composition of carbon steel %

表2 滚压参数分类

Table 2 Classification on burnishing parameters

利用BMT Expert3D表面形貌仪测量滚压前后试样的表面粗糙度,并利用SEM(扫描电镜)观察试样的表面特征。将滚压试样的截面抛光后用体积分数为4%的硝酸酒精溶液进行腐蚀,在SEM上观察腐蚀后的显微组织结构。采用HVS-1000显微硬度仪测量不同滚压参数处理后的试样在深度方向上的硬度变化,加载力为0.98 N,保持时间为15 s。

采用Optimal SRV IV摩擦磨损试验机进行试样的微动磨损试验,摩擦副的接触形式为球-盘接触,在微动磨损试验前后,使用超声波清洗机在无水乙醇中清洗试样并保存于干燥器中避免污染。微动磨损试验条件为:室温,干摩擦,对偶球为GCr15轴承钢球,直径为10 mm,硬度(HRC)为62~63,微动试验的行程为200 μm,法向载荷为20 N,频率为5 Hz,试验时间为1 800 s。试验结束后,采用BMT Expert3D表面形貌仪测量磨痕的几何形貌,根据文献[14]中的公式可以计算出试样的平均磨损体积,然后利用扫描电镜观察磨斑的表面形貌。

图1 滚压示意图

Fig. 1 Schematic diagram of burnishing

2 结果与讨论

2.1 试样的表面性能

2.1.1 表面粗糙度

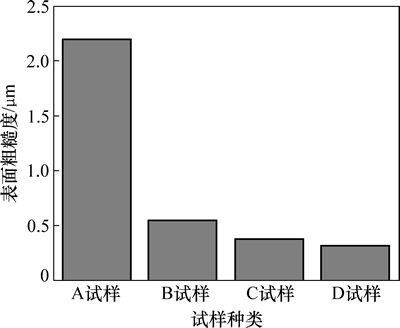

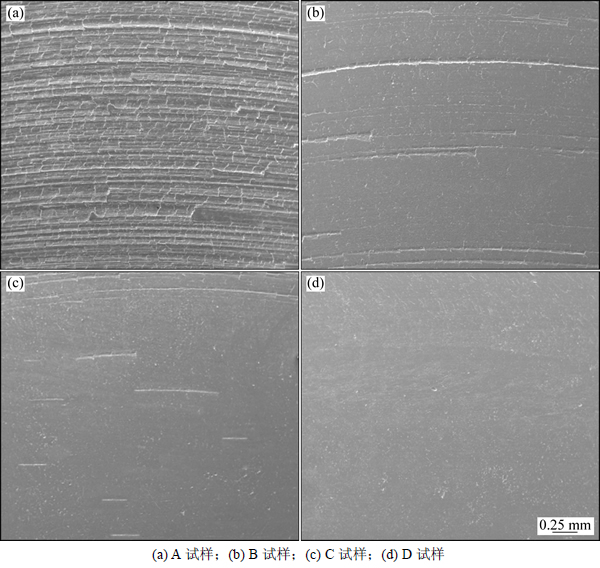

各试样的表面粗糙度如图2所示,A,B,C和D试样的表面粗糙度分别为2.20,0.55,0.38和0.32 μm,从A试样到D试样具有明显的下降趋势。其中D试样表面粗糙度较A试样下降了85.5%,4类试样在SEM下观察的表面形貌如图3所示。从图3可知:A试样表面含有很多车削形成的沟槽和凹坑,表面粗糙度较大;B和C试样由于不同的滚压作用,表面的沟槽和凹坑明显的减少;D试样由于滚压温度的提升,其表面发生强烈的塑性变形,车削产生的沟槽和凹坑被金属填平,试样表面更加光整,表面粗糙度明显下降。

2.1.2 显微硬度分布

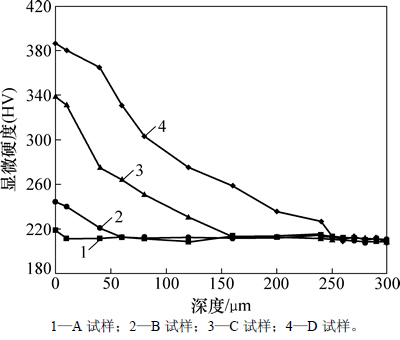

各试样的显微硬度随深度的变化如图4所示,试样的显微硬度在深度方向上呈梯度变化。各试样表层硬度最高,随着深度的增加,硬度逐渐降低到基体的

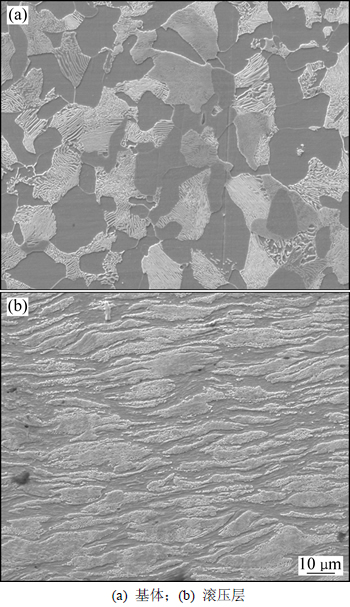

硬度。其中由于试验前切削形成轻微的加工硬化层, A试样的表面显微硬度(HV)为 218.82,比基体硬度略高,D试样的表面最大显微硬度为386.46,比基体硬度提高近82.7%,这是因为滚压作用使试样表面发生塑性变形,如图5所示,在滚压后试样的晶体结构发生扭曲,晶粒发生伸长、细化,并向变形方向延伸,排列紧密有序,形成了比基体具有更高强度的紧密层组织-滚压硬化层。同时,滚压硬化层的厚度随滚压参数的变化而变化,由于实验前切削参数较小,切削产生的加工硬化层忽略不计,由各试样的显微硬度在深度方向的变化可知:B,C和D试样的硬化层厚度分别约为60,160和250 μm。在一定范围内,硬化层厚度随着滚压力增大而增大,并且由于滚压温度的提高,塑性变形更加强烈[15],在相同滚压力作用下,硬化层厚度更大。

图2 各试样的表面粗糙度

Fig. 2 Surface roughness of each specimen

图3 不同试样的表面形貌

Fig. 3 Surface topography of different specimens

图4 各试样沿深度方向的硬度分布

Fig. 4 Vickers hardness variation with depth for each specimen

图5 试样不同深度组织对比

Fig. 5 Microstructure comparison of specimens with different depths

2.2 摩擦磨损性能

2.2.1 摩擦性能

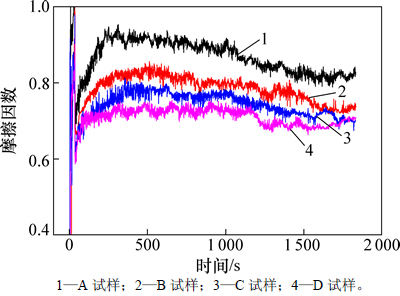

各试样的动态摩擦因数如图6所示,在摩擦初期,由于试样粗糙峰直接接触,形成局部点焊,使表面粗糙度增大,摩擦因数较高;随着磨屑的形成,并成为“第三体”保护层[16],参与承载作用,形成两个摩擦界面,使得摩擦因数下降;在摩擦的稳定期,由于在摩擦过程中磨屑的不断产生和排出,形成动态平衡,摩擦因数逐渐稳定。所以摩擦因数表现为先上升后下降,逐渐趋于稳定的趋势。图6中各试样之间摩擦因数的差异与试样表面性能有关,由摩擦学原理公式可知:

式中:μ为摩擦因数;S为剪切应力;A为接触面积;W为施加载荷。试样D表面硬度最大,承载力较大,摩擦副间的接触面积最小,因此摩擦因数最小。

图6 各试样的动态摩擦因数

Fig. 6 Dynamic friction coefficient of each specimen

2.2.2 磨损性能

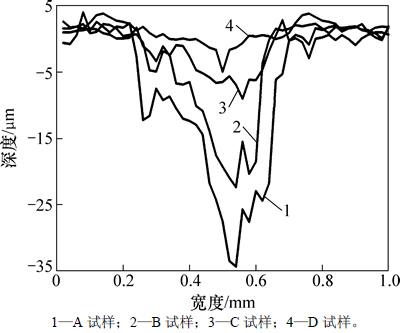

各试样在微动磨损方向上的截面轮廓如图7所示。从图7可知:A试样的磨痕深度最大,达到34.3 μm,这是因为A试样由于车削形成的加工硬化层非常薄,很容易遭到破坏,较软的基体直接暴露出来,使得试样磨损严重,B,C和D试样的最大磨痕深度分别为22.4,9.0和4.9 μm,D试样的磨痕深度较A试样减少了85.7%。

图7 磨斑截面轮廓

Fig. 7 Section profiles of wear scars

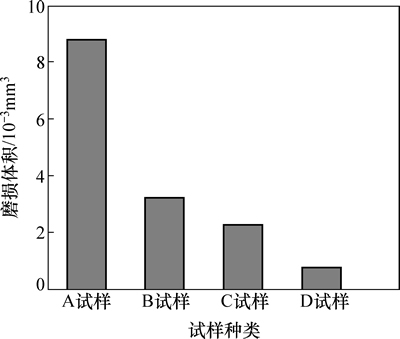

各试样的微动磨损体积如图8所示。由图8可以看出:从A试样依次到D试样,磨损量逐渐减少。试样B,C和D的磨损量分别比试样A的磨损量减少了63.4%,74.1%和91.2%。说明在一定范围内滚压工艺提高了试样的耐磨性,并且随着滚压参数(滚压力和滚压温度)的不同,试样耐磨性的提高程度也发生变化。这是因为滚压使试样表层发生剧烈的塑性变形,形成了具有较高硬度和残余压应力的硬化层,促进了试样耐磨性的提高[17]。

图8 各试样的微动磨损体积

Fig. 8 Fretting wear volume of each specimen

2.3 磨损机理分析

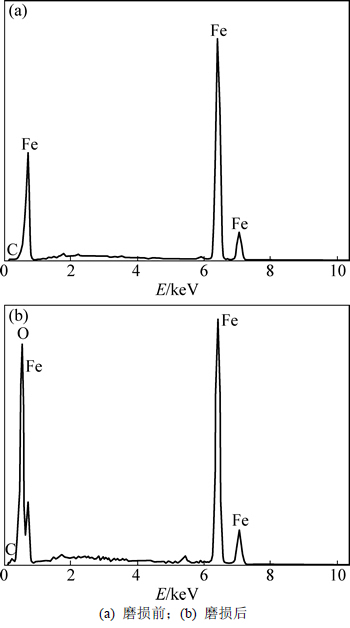

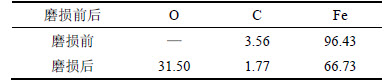

试样经过微动磨损试验后,表面产生了棕红色粉末状磨屑,张绪寿等[18]指出磨屑的主要成分为Fe2O3和单质铁。其形成机理为:随着微动磨损的进行,较大的金属磨损颗粒被碾压、粉碎,发生进一步的的塑性变形,氧化作用更加充分,试样产生氧化磨损,从而形成氧化物磨屑[19]。试样D磨损前后表面的能谱(EDS)分析对比结果如图9和表2所示(试样A,B和C具有类似结果),其中试样磨损后表面的氧元素质量分数为31.50%,表明在磨损过程中发生剧烈的氧化作用,发生氧化磨损,与磨屑分析结果相符合。

图9 磨损前后表面能谱分析图

Fig. 9 EDS spectra of worn and unworn surface

表2 磨损前后表面能谱分析结果(质量分数)

Table 2 EDS results of worn and unworn surface %

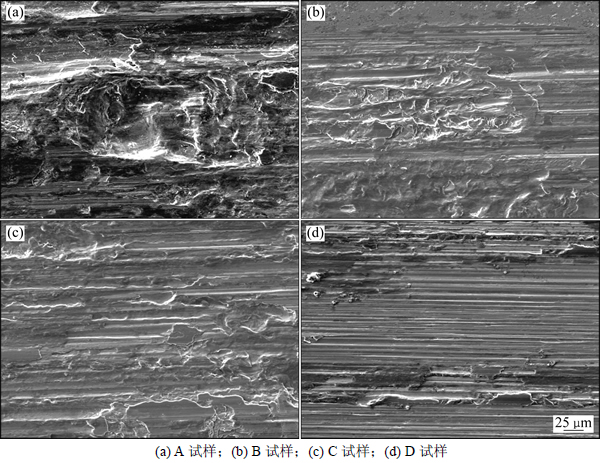

为进一步探究滚压对试样微动磨损的影响,对微动试验后不同试样的磨损表面形貌进行分析,如图10所示。由图10可知:试样表面都出现了平行于微动方向的犁沟,这是磨粒磨损的重要特征。由于未处理的试样A表面硬度较低,抗黏着磨损能力较差;并且表面粗糙度较大,相互作用表面的粗糙峰彼此嵌入,产生很高的局部应力。因此试样A表面由于黏着磨损产生了很多黏着坑,并且在表面摩擦力和循环应力的共同作用下,表面开裂,形成垂直于微动方向的疲劳裂纹,导致材料脱落,形成凹坑。从试样A到试样B,C和D磨损程度依次得到明显改善,试样B,C和D表面的疲劳剥落和黏着坑明显减少,尤其试样D的磨损表面只有轻微的犁沟现象,这是因为一方面滚压使得表面光整,减小了接触表面的应力集中,并且具有高硬度的硬化层提高了试样的抗黏着磨损的能力[20];另一方面,滚压产生的残余压应力抑制了裂纹尖端的扩展,降低了材料对缺口的敏感,提高了试样的抗疲劳能力。

图10 不同试样的表面磨损形貌

Fig. 10 Surface wear micrographs of different specimens

3 结论

1) 滚压工艺对提高45号钢表面性能具有显著作用, 不同滚压参数(滚压力和滚压温度)对提高试样表面质量、表面显微硬度、硬化层厚度程度明显不同。在一定范围内,随着滚压力和滚压温度的增大,试样表面质量、表面显微硬度逐渐提高,硬化层厚度逐渐加大。经过温滚压(滚压力为1 500 N,滚压温度为100 ℃)处理后的试样表面粗糙度为0.32 μm,比未处理试样减少了85.5%;表面显微硬度(HV)为386.46,比未处理样提高了近82.7%;硬化层厚度约为250 μm。

2) 滚压工艺对提高45号钢的抗微动磨损性能具有显著作用,其影响因素主要是硬度的提高和残余压应力的增大。不同滚压参数对碳钢的抗微动磨损性能提高幅度不同,温滚压(滚压力为1500 N,滚压温度为100 ℃)作用最佳。

3) 试样在微动磨损过程中发生强烈的氧化作用,未处理试样的磨损形式主要为黏着磨损和疲劳剥落;滚压后试样的磨损形式以磨粒磨损为主,伴随轻微的疲劳剥落。

参考文献:

[1] 周仲荣. 微动摩擦学的发展现状与趋势[J]. 摩擦学学报, 1997, 17(3): 272-280.

ZHOU Zhongrong. Recent development in fretting research[J]. Tribology, 1997, 17(3): 272-280.

[2] LEMM J D, WARMUTH A R, PEARSON S R, et al. The influence of surface hardness on the fretting wear of steel pairs-Its role in debris retention in the contact[J]. Tribology International, 2015, 81(8): 258-266.

[3] REN Pingdi, CHEN Guangxiong, ZHU Minhao, et al. Influence of oil and water mediums on fretting behavior of AISI 52100 steel rubbing against AISI 1045 steel[J]. Trans Nonferrous Met Soc China, 2004, 14(S2): 364-369.

[4] LI Jie, LU Yonghao, ZHANG Haoyang, et al. Effect of grain size and hardness on fretting wear behavior of Inconel 600 alloys[J]. Tribology International, 2015, 81: 215-222.

[5] PERRETA J, BOEHM-COURJAULT E, CANTONI M, et al. EBSD,SEM and FIB characterization of subsurface deformation during tribocorrosion of stainless steel in sulphuric acid[J]. Wear, 2010, 269(5/6): 383-393.

[6] PAPE J A, NEU R W. Subsurface damage development during fretting fatigue of high strength steel[J]. Tribology International, 2007, 40(7): 1111-1119.

[7] RYBIAK R, FOUVRY S, BONNET B. Fretting wear of stainless steels under variable temperature conditions: introduction of a ‘composite’ wear law[J]. Wear, 2010, 268(3/4): 413-423.

[8] FOUVRY S, FRIDRICI V, LANGLADE C, et al. Palliatives in fretting: a dynamical approach[J]. Tribology International, 2006, 39(10): 1005-1015.

[9] VARENBERG M, HALPERIN G, ETSION I. Difference aspects of the role of wear debris in fretting wear[J]. Wear, 2002, 252(11/12): 902-910.

[10] 李风雷, 夏伟, 周照耀. 滚柱滚压表面光整机理的解析分析和实验验证[J]. 华南理工大学学报(自然科学版), 2008, 36(8): 98-103.

LI Fenglei, XIA Wei, ZHOU Zhaoyao. Analytical investigation and experimental verification of surface smoothing mechanism of roller burnishing[J]. Journal of South China Uiversity of Technology (Natural Science Edition), 2008, 36(8): 98-103.

[11] WAGNER L. Mechanical surface treatments on titanium, aluminum and magnesium alloys[J]. Materials Science and Engineering A, 1999, 263(2): 210-216.

[12] MAJZOOBI G H, AZADIKHAH K, NEMATI J. The effects of deep rolling and shot peening on fretting fatigue resistance of Aluminum-7075-T6[J]. Materials Science and Engineering A, 2009, 516(1/2): 235-247.

[13] 李宁, 夏伟, 赵婧, 等. 滚压诱导梯度超细晶铜的润滑微动磨损特性研究[J]. 摩擦学学报, 2014, 34(1): 20-27.

LI Ning, XIA Wei, ZHAO Jing, et al. Lubrication fretting wear of gradient ultrafine-grained copper induced by burnishing[J]. Tribology, 2014, 34(1): 20-27.

[14] 阎逢元, 周惠娣, 张泽抚. 球盘微动摩擦件磨损体积的测量和计算[J]. 摩擦学学报, 1995, 15(2): 145-151.

YAN Fengyuan, ZHOU Huidi, ZHANG Zefu. The measurement and caculation of the wear volume of the pairs for fretting test[J]. Tribology, 1995, 15(2): 145-151.

[15] TIAN Y G, SHIN Y C. Laser-assisted burnishing of metals[J]. International Journal of Machine Tools and Manufacture, 2007, 47(1): 14-22.

[16] DIOMIDIS N, MISCHLER S. Third body effects on friction and wear during fretting of steel contacts[J]. Tribology International, 2011, 44(11): 1452-1460.

[17] 易丹青, 黄亮, 李荐, 等. WC-Ni/SiC 摩擦副滑动摩擦性能[J]. 中南大学学报(自然科学版), 2009, 40(1): 99-105.

YI Danqing, HUANG Liang, LI Jian, et al. Sliding friction properties of WC-Ni/SiC friction couple[J]. Journal of Central South University (Science and Technology), 2009, 40(1): 99-105.

[18] 张绪寿, 刘洪, 王秀娥. 硬度对碳钢微动磨损行为和磨屑组分的影响[J]. 摩擦学学报, 1995, 15(4): 300-305.

ZHANG Xushou, LIU Hong, WANG Xiue. Effect of the hardness on fretting wear behaviour and wear debris composition of carbon steel[J]. Tribology, 1995, 15(4): 300-305.

[19] 张孟恩, 王振生, 郭源君, 等. NiAl-2.5Ta-7.5Cr合金的室温摩擦磨损性能[J]. 中南大学学报(自然科学版), 2015, 46(1): 88-93.

ZHANG Mengen, WANG Zhensheng, GUO Yuanjun, et al. Friction and wear behavior of NiAl-2.5Ta-7.5Cr alloy at room temperature[J]. Journal of Central South University (Science and Technology), 2015, 46(1): 88-93.

[20] 屈盛官, 王光宏, 李文龙, 等. 高性能渗氮钢微动磨损性能研究[J]. 摩擦学学报, 2012, 32(5): 486-492.

QU Shengguan, WANG Guanghong, LI Wenlong, et al. Fretting wear of a high-performance plasma nitride steel[J]. Tribology, 2012, 32(5): 486-492.

(编辑 杨幼平)

收稿日期:2016-03-07;修回日期:2016-05-28

基金项目(Foundation item):国家自然科学基金资助项目(41572362,51375466,51275494)(Projects (41572362, 51375466, 51275494) supported by the National Natural Science Foundation of China)

通信作者:屈盛官,博士,教授,博士生导师,从事高性能金属材料的制备、精密成形及机械零部件的摩擦磨损研究;E-mail:qusg@scut.edu.cn