文章编号:1004-0609(2009)10-1848-06

SiO2含量对铜基摩擦材料摩擦行为的影响

韩晓明,符 蓉,高 飞,宋宝韫,农万华

(大连交通大学 轨道交通关键材料实验室,大连 116028)

摘 要:采用粉末冶金技术制备铜-石墨-SiO2烧结材料,利用销盘式摩擦试验机,在摩擦速度为7.8~47.1 m/s的范围内,研究SiO2在不同摩擦速度条件下的损伤机理及其与材料性能的关系。结果表明:SiO2对材料摩擦磨损性能的影响与摩擦速度密切相关;低摩擦速度条件下,SiO2含量的变化对提高摩擦因数的作用明显,原因在于摩擦力的静载荷性质有利于发挥SiO2粒子的犁沟作用而增加摩擦力;材料的磨损率对SiO2含量不敏感;高摩擦速度条件下,具有冲击作用的摩擦载荷导致SiO2粒子粉碎性破碎,破碎的SiO2粒子弥散嵌入高温软化的基体中而弱化了犁沟作用,导致摩擦因数对SiO2含量的变化不敏感;弥散分布的SiO2粒子强化基体表面强度,导致其磨损率随SiO2含量的增加而降低。

关键词:铜基摩擦材料;SiO2;摩擦行为;第三体

中图分类号:TF 125; TH 117.3 文献标识码: A

Effects of content of SiO2 particles on tribological behavior of

Cu-matrix friction materials

HAN Xiao-ming, FU Rong, GAO Fei, SONG Bao-yun, NONG Wan-hua

(Key Materials Laboratory for Railway, Dalian Jiaotong University, Dalian 116028, China)

Abstract: To investigate the relationship between dandification mechanism of SiO2 particles and materials performance under different friction speeds, Cu-graphite-SiO2 sintered materials were prepared through powder metallurgy. The tests were conducted on a pin-on-disk tester in speed range of 7.8-47.1 m/s. The results demonstrate that the effects of SiO2 on the friction and wear performance of the materials are closely related to the friction speed. At low friction speed, the friction coefficient increases with increasing content of SiO2 particles, this is attributed to the effect of SiO2 scratch, which can improve the friction force remarkably under static load. However, the wear rate is not sensitive to the content of SiO2 particles. At high friction speed, the SiO2 particles are broken by impact action and embedded in the matrix softened at high temperature, which results in reduction of scratch influence, and makes the friction coefficient insensitive to SiO2 content. The increase of surface hardness causes the wear rate to fall with increasing content of SiO2 particles.

Key words: Cu-matrix friction material; SiO2; tribological behavior; third body

铜基摩擦材料以其优良的摩擦性能在高速列车制动方面取得广泛应用[1-2]。摩擦材料中的组分根据其在材料中的作用,分为基体组元、摩擦组元和润滑组元。摩擦组元用以调整摩擦因数,起到增摩、抗磨和抗粘结的作用。摩擦组元一般为SiO2、Al2O3、SiC和一些金属氧化物和氮化物等,利用其高硬度和高粗糙度的硬质点犁削对偶而增加摩擦力[3-7],其含量和粒度的变化在很大程度上影响着材料的摩擦磨损性能[8]。摩擦组元含量增加,有利于摩擦因数增加[3, 6-8],但过量硬质颗粒容易降低基体夹持能力[9-10],对提高材料的整体强度是不利的。可见,摩擦组元对材料摩擦性能的影响是多方面的。另一方面,这类硬质颗粒强化摩擦材料通常应用在干摩擦条件下。干摩擦条件的特点在于摩擦面上存留大量磨损颗粒,这部分组织被称为第三体。第三体的行为及其对材料摩擦磨损性能的影响同样引起人们的注意[11-13]。然而,在材料中含有SiO2颗粒的情况下,随摩擦速度的不同,SiO2颗粒对材料的摩擦磨损性能的影响程度也不同,目前人们对SiO2颗粒在不同速度条件下的摩擦学行为及其对摩擦磨损性能的影响理解有限。因此,研究材料中SiO2与第三体的关系及在不同摩擦速度条件下表现出的摩擦学行为对制备高性能的铜基摩擦材料具有重要意义。

本文作者针对铜基粉末冶金材料,在定速摩擦条件下,试验研究多种摩擦速度条件下SiO2的摩擦学特征及其与摩擦摩擦磨损性能的关系,并考虑第三体与SiO2颗粒的相互作用。

1 实验

采用粉末冶金工艺制备Cu-graphite-SiO2烧结材料,试验材料由电解铜粉(300 μm)、石墨和SiO2(颗粒粒度300~600 μm)构成,3种组分的配比(质量分数)为:石墨10.0%,SiO2 3.0%~12.0%,余量Cu。粉末经均匀混合,在压制压力为600 MPa条件下压制成型,在钟罩式烧结炉中加压烧结,烧结压力为1.77 MPa,烧结温度为820 ℃,保温时间为1.5 h。制备的试样尺寸为d17 mm×15 mm。

摩擦磨损试验在销盘式摩擦机上进行(见图1),对偶盘为H13,摩擦半径为150 mm,摩擦压力为0.5 MPa,转动速度为200~3 000 r/min(摩擦线速度为7.8~47.1 m/s),每种速度条件下的摩擦时间为30~60 s。

图1 销盘式摩擦机示意图

Fig.1 Schematic diagram of pin-on-disk tester

温度测量方式为在试样中心钻d 3 mm孔,将热电偶插入孔中,热电偶距摩擦接触表面3~4 mm。表面形貌观察采用OLYMPUS数码成像显微镜和JSM-6360LV型扫描电子显微镜。

2 结果与分析

2.1 SiO2颗粒对摩擦因数的影响

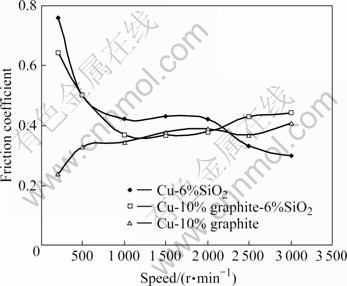

为考察摩擦过程中SiO2粒子在表面的作用,将所研究材料与Cu-graphite材料[14]和Cu-SiO2材料[3]摩擦磨损性能进行比较。3种材料成分及组成如表1所列3种材料摩擦磨损性能试验条件相同。 061991,图2所示为摩擦速度对摩擦因数的影响。由图2可知,从总体趋势上看,Cu-SiO2和Cu-graphite-SiO2材料摩擦因数都随着摩擦速度的提高而下降,Cu-graphite材料的摩擦因数随摩擦速度提高变化不大。在摩擦速度超过1000 r/min时,3种材料的摩擦因数趋于稳定。对于加入SiO2的两种铜基摩擦材料来说,其摩擦因数在低速阶段要比在高速阶段高很多,且远远高于Cu-graphite材料。而Cu-SiO2材料与Cu-graphite-SiO2材料相比,其摩擦因数要略高。由此可见,在高速条件下,无论是石墨还是SiO2对材料的摩擦因数的影响程度都是有限的。同时,在低速条件下,SiO2体现出增加摩擦因数的特性,而石墨起到降低摩擦因数的作用。

表1 材料组成

Table 1 Compositions of materials (mass fraction, %)

图2 摩擦速度对摩擦因数影响

Fig.2 Effect of friction speed on friction coefficient

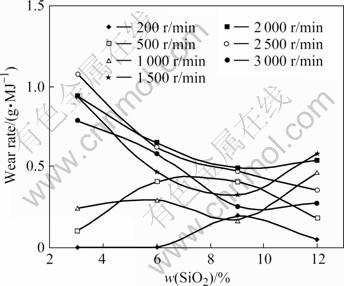

图3所示为Cu-graphite-SiO2材料中SiO2含量对摩擦因数的影响。由图3可见,随SiO2含量增加,摩擦因数总体表现出升高趋势。同时,SiO2含量对材料摩擦因数的影响与摩擦速度有关。当摩擦速度较低时,SiO2含量增加,摩擦因数增加明显;随着摩擦速度提高,SiO2含量增加,摩擦因数变化范围减小。当摩擦速度达到3 000 r/min时,随SiO2含量增加,摩擦因数变化不明显。

图3 SiO2含量对摩擦因数影响

Fig.3 Effect of SiO2 content on friction coefficient

从理论上来说,摩擦力源自摩擦副表面接触点上机械啮合作用和分子吸引作用所产生的剪切阻力的总和。SiO2为高硬度质点,对摩擦因数的影响在于产生犁削作用而增加机械啮合力。SiO2含量增加,有利于增加机械啮合力而提高摩擦因数,然而由图2可知,SiO2这部分的作用主要体现在低摩擦速度条件下。这说明SiO2在摩擦表面的力学行为随摩擦速度不同而有所不同。

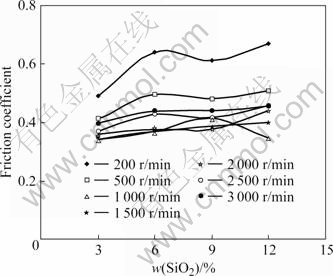

图4所示分别为摩擦速度为200和3 000 r/min条件下摩擦表面SiO2颗粒的形貌特征。由图4可见,在摩擦速度为200 r/min时,SiO2颗粒破裂程度小,容易观察到在SiO2颗粒周围富集大量微细粉末(第三体)(见图4(a)),这表明SiO2颗粒的损耗呈现较大程度的逐渐磨损过程;在摩擦速度为3 000 r/min情况下,SiO2颗粒呈完全破碎状,破碎后的颗粒再次嵌入基体中(见图4(b)),这表明SiO2主要处于一种粉碎性的损伤过程。比较这两种摩擦速度条件下SiO2颗粒破裂程度可知,摩擦速度不同时摩擦表面SiO2颗粒的损伤方式是有区别的,因此,材料会表现出不同的摩擦学行为。在低速摩擦条件下,摩擦对偶间的作用力近似静载荷,力的作用点往往是高硬度的SiO2颗粒构成的微凸体,因此,摩擦力很大程度取决于与SiO2颗粒微凸体啮合的面积和强度。SiO2含量增加,硬质点微凸体数量增加,犁沟力增大,从而表现出较高的摩擦因数。同时,在犁削的过程中,SiO2颗粒经历了一个逐渐损伤过程。在高速摩擦条件下,摩擦面微凸体间的作用力具有较强的冲击载荷性质,导致摩擦表面SiO2粒子成粉碎性破裂,破碎的SiO2颗粒容易嵌入铜基体中,并在表面弥散分布,相当于增加了表面SiO2颗粒数量,使得低SiO2含量材料由于摩擦表面嵌入较多的SiO2颗粒而同样表现出高的摩擦因数。而高速条件下SiO2含量的改变对摩擦因数的影响程度减弱。由图3可见,随着摩擦速度的提高,摩擦因数降低,这可从SiO2颗粒在表面的行为来解释,即破碎的SiO2颗粒嵌入基体的过程存在一个SiO2颗粒型面与摩擦面的平顺过程,使SiO2颗粒型面与摩擦面处于同一个平面而起到降低SiO2颗粒锐度的作用,同时,基体金属的高温软化降低了对SiO2颗粒的夹持能力,这两种因素均降低了SiO2颗粒的犁沟效果,削弱了SiO2含量增加引起摩擦因数增高的作用,因此,在高速条件下SiO2含量的改变对摩擦因数的影响程度减弱。

图4 在摩擦速度200 r/min和3 000 r/min条件下SiO2颗粒的形貌

Fig.4 Morphologies of SiO2 particles at friction speeds of 200 r/min (a) and 3 000 r/min (b)

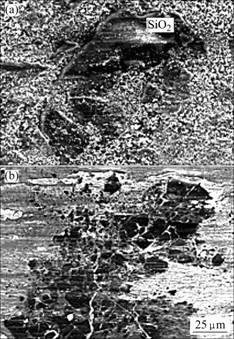

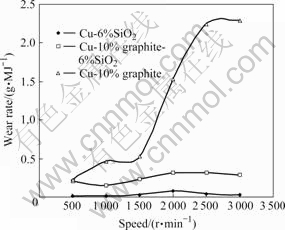

2.2 SiO2颗粒对材料耐磨损性的影响

图5所示为不同摩擦速度条件下,摩擦速度对材料磨损率的影响。从图5中可以看出,加入SiO2的两种铜基摩擦材料在各个摩擦速度条件下的磨损率都很低,并且Cu-SiO2材料与Cu-graphite-SiO2材料相比,前者磨损率要更低;而不加SiO2的Cu-graphite材料在较低摩擦速度时的磨损率较小,随着摩擦速度增加,磨损率明显增加。由此可知,摩擦材料的磨损率的变化受材料成分的影响。

图5 摩擦速度对磨损率的影响

Fig.5 Effect of friction speed on wear rate

图6所示为摩擦速度3 000 r/min时,两种材料的表面形貌。由图6可见,在材料中不含SiO2的情况下,摩擦表面粗糙,容易形成大量深且宽的犁沟(见图6(a));当材料中含SiO2时,摩擦表面相对平滑,一层连续致密的第三体覆盖在表面(见图6(b))。因此,材料组分的不同对表面状态产生明显的影响,从而导致磨损量的不同。SiO2颗粒的存在起到硬质点的强化作用,一方面提高了摩擦表面强度,另一方面有利于磨损粒子存留在摩擦表面,使摩擦表面形成一层较致密的第三体保护层,这两方面的因素均有助于提高材料在高速摩擦条件下的耐磨性。

图6 摩擦速度为3 000 r/min时两种材料的摩擦表面形貌

Fig.6 Morphologies of worn surfaces of two kinds of materials at friction speed of 3 000 r/min: (a) Cu-10% graphite; (b) Cu-6%SiO2-10% graphite

图7所示为在摩擦速度200 r/min条件下摩擦时间对摩擦表面的SiO2颗粒的影响。由图7可见,随摩擦时间的增加,摩擦表面SiO2颗粒的形状和周围的状态均发生一定程度的变化。在摩擦初期,SiO2颗粒周围形成深色斑带,当摩擦超过一定时间,SiO2颗粒颜色变化不明显,而周围组织的颜色趋向一致。这表明,在摩擦过程中SiO2颗粒起到硬质点的承载作用。在摩擦初期,SiO2颗粒与基体铜具有相同的接触啮合几率,然而,SiO2颗粒的硬度和强度远高于铜,因此,在摩擦力的作用下,铜微凸体容易发生剪切变形而损伤,而高硬度的SiO2颗粒微凸体与对偶钢盘相作用产生犁削现象,对偶盘被损伤而形成磨屑;被犁削下的钢盘磨屑转移到SiO2颗粒周围,使SiO2颗粒附近形成富铁区,从而表现出深色的斑带。随SiO2颗粒承载面积的增加,当犁削力达到破碎强度时,SiO2颗粒发生局部碎裂而使SiO2颗粒形状发生变化。同时,随摩擦时间的增加,大量的磨屑充分混合,各区域的表面成分趋于均匀,从而在颜色上不再存在差别。

图7 摩擦时间对摩擦表面SiO2颗粒的影响

Fig.7 Effects of friction time on morphology of SiO2 particles of worn surface (6%SiO2): (a) 2 s ; (b) 124 s

摩擦表面SiO2颗粒随着摩擦时间的这种变化情况表明,SiO2颗粒在摩擦过程中起到了提高承载力和耐磨性的作用,因此,有利于降低磨损率。

图8所示为Cu-graphite-SiO2材料中,SiO2含量对磨损率影响。由图8可知,从总体趋势看,材料的磨损率随着SiO2含量增加而降低,同时,SiO2含量对材料磨损率影响与摩擦速度有关。当摩擦速度较低时,SiO2含量增加,磨损率无明显变化,随着摩擦速度提高,SiO2含量增加,磨损率下降幅度明显。

图8 不同摩擦速度时SiO2含量对磨损率影响

Fig.8 Effects of SiO2 contents on wear rate of Cu-graphite- SiO2 material at different friction speeds

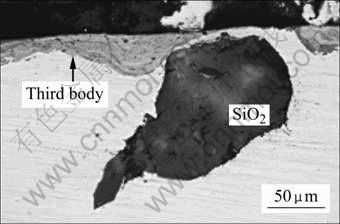

由摩擦表面组织状态的变化情况可知(见图7),在低速摩擦条件下,磨损程度取决SiO2颗粒的破损和参与啮合的SiO2的数量。低速摩擦条件下摩擦力的静载荷性质容易产生SiO2颗粒的渐进性损耗(见图4(a)),SiO2含量的增加可以增加表面SiO2的数量,但处于啮合状态的SiO2的损伤程度不一定随表面SiO2数量的增加而减少,因此,磨损量并没表现出随SiO2的提高而降低。在高摩擦速度条件下,SiO2颗粒的增加有利于降低磨损率,其原因有两方面:一是高速摩擦形成的冲击载荷作用使表面SiO2产生粉碎性破坏,破碎的SiO2颗粒弥散分布在摩擦表面,起到了增强摩擦面强度和提高材料抗犁削能力的作用(见图4(b));二是SiO2颗粒起到钉扎第三体的作用,有利于高速摩擦形成的大量第三体存留在表面(图9),形成一层连续致密的第三体层[3, 9](图6(b)),起到对摩擦表面的保护作用。同时,在高速摩擦造成金属基体软化的条件下,SiO2颗粒对表面的强化作用可降低材料的磨损率,因此,随着SiO2含量增加,磨损率降低(图8)。

图9 SiO2对第三体的钉扎

Fig.9 Third bodies hindered by SiO2 particle

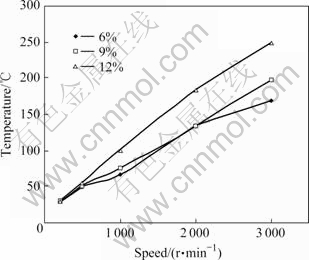

2.3 SiO2对摩擦面温度的影响

图10所示为不同摩擦速度条件下,SiO2含量对材料摩擦表面温度的影响。由图10可见,随着SiO2含量增加,摩擦表面温度升高,且温度升高的速度随SiO2含量增加而增加。

图10 不同摩擦速度时SiO2含量对摩擦表面温度影响

Fig.10 Effects of SiO2 contents on temperature of friction surface at different friction speeds

材料摩擦表面温度随SiO2含量增加而升高的原因有:一方面SiO2为非金属材料,其导热性能低,其含量增加,材料导热性能下降,导致温度升高[15];另一方面SiO2含量增加造成摩擦功率增加而导致热量增加。这两方面的因素均随摩擦速度的提高而表现明显。

3 结论

1) 摩擦材料中SiO2提高摩擦因数的作用与摩擦速度有关,在低摩擦速度条件下,SiO2提高摩擦因数的作用明显。原因在于摩擦力的静载荷性质使SiO2颗粒主要通过犁沟作用增加摩擦阻力;在高摩擦速度条件下,冲击性载荷造成SiO2颗粒粉碎性破坏,使表面SiO2含量增加而降低了摩擦因数的变化程度。

2) SiO2可改善材料的耐磨性,低摩擦速度条件,SiO2含量增加,磨损率变化不明显,原因在于静载荷性质的摩擦力对SiO2质点的损伤程度与SiO2的含量相关性不强;高速摩擦条件下,SiO2颗粒弥散分布在表面而有利于强化摩擦面和减少第三体的流失,起到了降低材料磨损率的作用。

REFERENCES

[1] RAISON J. Les materiaux de freinage[J]. Revue Generale des Chemins de Fer, 1991, 110(7/8): 27-36. (in Franch)

[2] COPIN R. Braking tests on a reduced-scale test bench with a disc-pad couple used on the TGV-PBKA[C]// Proceedings of JEF 1998. Lille, 1998: 141-150.

[3] 符 蓉, 宋宝韫, 高 飞, 徐振越. Cu-SiO2烧结材料的摩擦磨损性能研究[J]. 摩擦学学报, 2007, 27(4): 377-381.

FU Rong, SONG Bao-yun, GAO Fei, XU Zhen-yue. Study on the friction and wear properties of sintered Cu-SiO2 composites [J]. Tribology, 2007, 27(4): 377-381.

[4] SINGH M, MONDAL D P. Effect of sillimanite particle reinforcement on dry sliding wear behaviour of aluminium alloy composite[J]. Materials Science and Technology, 2003, 19: 303-312.

[5] KORKUT M H. Effect of particulate reinforcement on wear behaviour of aluminium matrix composites[J]. Materials Science and Technology, 2004, 20: 73-8.

[6] 李月英, 刘勇兵, 曹占义, 杨 杰. A12O3·SiO2颗粒增强铝基复合材料的摩擦磨损特性[J]. 材料科学与工艺, 2003, 11(2): 140-143.

LI Yue-ying, LIU Yong-bing, CAO Zhan-yi, YANG Jie. Friction and wear behavior of Al203·SiO2 particle reinforced Al matrix composites[J]. Materials Science and Technology, 2003, 11(2): 140-143.

[7] 刘德宝, 崔春翔. 氮化物陶瓷颗粒增强铜基复合材料的干摩擦磨损性能研究[J]. 摩擦学学报, 2006, 26(1): 54-59.

LIU De-bao, CUI Chun-xiang. Study on dry friction and wear properties of copper-matrix composites reinforced with nitrides ceramics particles[J]. Tribology, 2006, 26(1): 54-59.

[8] 戈晓岚, 许晓静, 蔡 兰, 陈康敏, 居志兰. SiCp含量和尺寸对Al基复合材料摩擦学特性的影响[J]. 中国有色金属学报, 2005, 15(3): 458-462.

GE Xiao-lan, XU Xiao-jing, CAI Lan, CHEN Kang-min, JU Zhi-lan. Effect of grain size and content of SiCp on tribology characterization of SiCp/Al composites[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(3): 458-462.

[9] 姚萍屏, 熊 翔, 李世鹏. Fe及SiO2 对铜基刹车材料摩擦磨损性能的影响机制[J]. 摩擦学学报, 2006, 26(5): 478-483.

YAO Ping-ping, XIONG Xiang, LI Shi-peng. Friction and wear behavior and mechanism of Fe and SiO2 in Cu-based P/M friction material[J]. Tribology, 2006, 26(5): 478-483.

[10] 白同庆, 佟林松, 李东生. SiO2和莫来石对铜基摩擦材料性能的影响[J]. 粉末冶金技术, 2006, 24(2): 114-117.

BAI Tong-qing, TONG Lin-song, LI Dong-sheng. The effects of SiO2 and mullite on the properties of copper-based friction materials[J]. Powder Metallurgy Technology, 2006, 24(2): 114-117.

[11] ERIKSSON M. Tribological surface of organic brake pads[J]. Tribology International, 2000, 33: 817-827.

[12] SINGER I L, DAVID S, KATHRYN D. Investigation of third body progress by in vivo Raman tribology[C]// Conference Proceeding of Nord Trib, Porvo, Finlan. 2000: 1-12.

[13] BERTHIER Y, DESCARTES S. The role and effects of the third body in the wheel-rail interaction[J]. Fatigue Fract Eng Mater Struct, 2004, 27: 423-436.

[14] 高 飞, 杜素强, 符 蓉, 宋宝韫. 不同速度下石墨含量对铜基摩擦材料性能的影响[J]. 矿冶工程, 2005, 25(4): 80-82.

GAO Fei, DU Su-qiang, FU Rong, SONG Bao-yun. Effects of graphite content on performance of copper-based friction materials[J]. Mining Metallurgical Engineering, 2005, 25(4): 80-82.

[15] 樊 毅, 张金生, 高 游, 吴 芳, 刘伯威. 石墨粒度对Cu-Fe基摩擦材料性能的影响[J]. 摩擦学学报, 2000, 20(6): 475-477.

FAN Yi, ZHANG Jin-sheng, GAO You, WU Fang, LIU Bo-wei. The influence of graphite particle size on friction and wear properties of copper-ferrous matrix friction materials[J]. Tribology, 2000, 20(6): 475-477.

基金项目:国家高技术研究发展计划资助项目(2006AA03Z515);国家自然科学基金资助项目(50375025)

收稿日期:2008-08-23;修订日期:2008-12-25

通信作者:高 飞,教授;电话:0411-84109429;E-mail: gaofei@djtu.edu.cn

(编辑 何学锋)