DOI: 10.11817/j.ysxb.1004.0609.2021-36517

废石-风砂高浓度料浆管道输送数值模拟及管输阻力新模型

杨天雨1,乔登攀1,王 俊1,张 希2,陈 印3

(1. 昆明理工大学 国土资源工程学院,昆明 650093;

2. 玉溪矿业有限公司 技术管理部,玉溪 653100;

3. 昆明有色冶金设计研究院股份公司 矿山工程设计院,昆明 650051)

摘 要:为研究废石-风砂高浓度充填料浆自流输送管道输送特性,将矿山实际充填管路进行还原,应用FLUENT软件进行输送模拟研究。结果表明:充填料浆在管道的管径方向有明显的速度梯度;随料浆流速的增大,料浆的输送沿程阻力损失基本呈线性增大;质量浓度对管输阻力的影响非常大,在充填料浆质量浓度相差2%左右时,管道单位长度的阻力损失会相差20%~30%。通过对不同骨料比的充填料浆进行数值模拟,可知废石风砂质量比为6:4的浆体稳定性和流动性相对较好,更有利于管道输送。建立了管输阻力新模型,并通过工业试验对模型进行检验,验证了新的管输阻力模型的可靠性,研究结果为该矿选取充填系统的运行参数提供了重要依据。

关键词:自流输送;高浓度料浆;阻力损失;数值模拟;阻力模型

文章编号:1004-0609(2021)-01-0234-11 中图分类号:TD 853.34 文献标志码:A

引文格式:杨天雨, 乔登攀, 王 俊, 等. 废石-风砂高浓度料浆管道输送数值模拟及管输阻力新模型[J]. 中国有色金属学报, 2021, 31(1): 234-244. DOI: 10.11817/j.ysxb.1004.0609.2021-36517

YANG Tian-yu, QIAO Deng-pan, WANG Jun, et al. Numerical simulation and new model of pipeline transportation resistance of waste rock-aeolian sand high concentration slurry[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(1): 234-244. DOI: 10.11817/j.ysxb.1004.0609.2021-36517

高浓度充填料浆具有不离析,不分层,充填质量好,充填效率高等优点已被国内外广泛应用,高浓度充填料浆理论上属于均质结构流,结构流理论意义上的“高浓度”是指充填料浆浓度接近或大于临界流态浓度而小于极限可输送浓度[1-3]。管道输送技术是目前绝大多数矿山所采用的充填料浆输送方法,合理的输送浓度影响着管道输送充填倍线的设计,直接关系到管道输送堵管与否,影响着矿山的生产活动。自流输送依靠浆体自身质量克服管道阻力进行输送,其工艺简单,经济性好,特别是针对当前深井开采,自流输送的研究显得尤为重要。计算机模拟作为现代研究的一种重要手段,在此方面已被广泛应用。目前国内外专业用于流体分析的软件为FLUENT [4];李国栋[5]利用FLUENT软件模拟了4种管道中料浆的输送情况,揭示了充填料浆的速度和压力分布规律。侯俊等[6]基于FLUENT数值模拟对磷石膏膏体充填料浆管道输送进行研究。温震江等[7]利用FLUENT对鞍钢张家湾铁矿全尾砂充填料浆输送特性进行了模拟和研究。杨志强等[8]对戈壁砂和棒磨砂骨料充填料浆管输特性进行了试验研究与分析。王少勇等[9]通过环管试验对膏体料浆管道输送压力损失的影响因素进行了研究分析。林天埜[10]研究了矸石似膏体的流变特性及管流特征,针对非稳态流动,特别是竖直管段的不满管流进行了计算机建模。高德真等[11]基于FLUENT对气固两相流进行了数值模拟与分析。

在管道输送阻力方面,甘德清等[12]和石宏伟 等[13]探讨了不同管径,不同流速对管道输送阻力的影响规律。熊有为等[14]研究了大流量膏体管道输送阻力特性并结合环管试验推导出了适合于某矿山充填料浆管道输送阻力的理论公式。CHENG等[15]研究了时-温效应对充填料浆的流变特性和流动性能的影响规律。

目前,国内外研究成果存在以下不足:其一是很少考虑级配因素对管输沿程阻力损失的影响;其二是很少以矿山实际充填管路为模板建模,不能真实地反映矿山充填实际情况,所得结果往往差强人意。因此,针对以上不足,本文作者以金川公司二矿区实际充填管路建模,模拟实际充填料浆管输情况,研究废石-风砂充填料浆在不同级配的情况下管道输送的特性分析管道输送过程中的流速和压力规律,为废石-风砂高浓度料浆自流充填技术的发展提供研究依据。

1 充填材料

1) 实验中所用的废石风砂均来自金川公司二矿区,实验测得废石破碎集料的密度为2.625 g/cm3,破碎废石集料的最大粒径Dmax为12 mm,Tabol级配递减系数为0.651,其粒径的粒径分布呈“粗粒偏多细粒偏少”的特征。废石粒度4.75 mm以上达到50%左右,粒度2.36 mm以上达70%以上,粗粒级含量大,细料含量偏少,从而较粗的颗粒无法“被悬浮”,不利于管道输送,需要辅以细颗粒来改善管输条件。

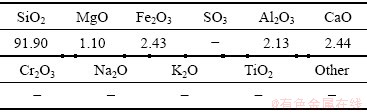

2) 风砂是自然采集到的天然集料,金川矿区地处沙漠戈壁地区,是一种理想的充填材料。风砂颗粒呈圆球状,成分90%为石英砂,密度为2.570 g/cm3,最大粒径Dmax为1.18 mm,Tabol级配递减系数为0.517;其粒径分布呈“粗粒偏少中间偏多细粒偏少”的特征,化学成分如表1所示。由表1可见,风砂以SiO2为主,且四种材料中SiO2含量较高,属于良性的惰性材料。

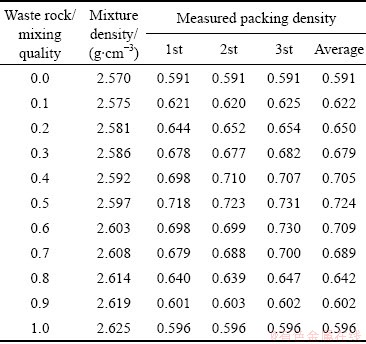

3) 堆积密实度是固体颗粒混合物体系的一个重要性质,其定义为单位体积中固体颗粒所占的体积,骨料的堆积密实度能全面反映骨料填隙效应,是孔隙率、颗粒粒径、形状、级配关系的综合反映,是描述骨料散体体系的重要特征参数。实验测得废石-风砂两种骨料的堆积密实度实验结果如表2所示。

表1 金川镍矿风砂的化学成分

Table 1 Chemical composition of aeolian sand in Jinchuan Nickel Mine

表2 废石破碎集料+风砂的堆积密实度实验结果

Table 2 Test results of packing density of waste rock crushed aggregate+aeolian sand

堆积密实度的大小只能反映骨料填隙效应的优劣,并不能说骨料堆积密实度越大越适合管道输送,所以本文选取废石风砂质量比为5:5、6:4和7:3的三种混合料比的骨料来进行数值模拟分析。

2 数值建模

2.1 几何模型的建立

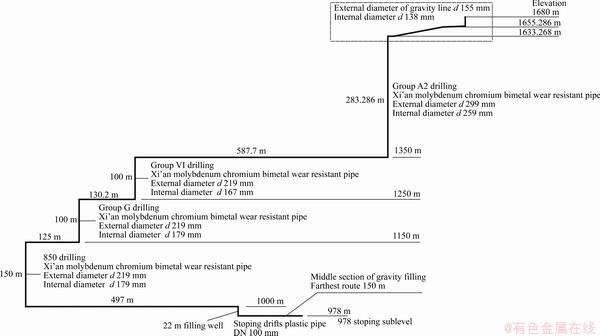

根据金川公司二矿区实际充填管路的布置情况,结合FLUENT软件的特性,利用前处理建模软件Gambit建立了与实际管道一样的管道输送的几何模型。该模型主要包括管道在1680 m水平的二期充填小井到井下978回采中段充填工作面,主要有13个弯管部分和10个变径管部分,管道总长约2378 m,垂直高差约为703 m,理论充填倍线为3.38。主要几何模型示意图如图1所示。

2.2 数值模拟方案

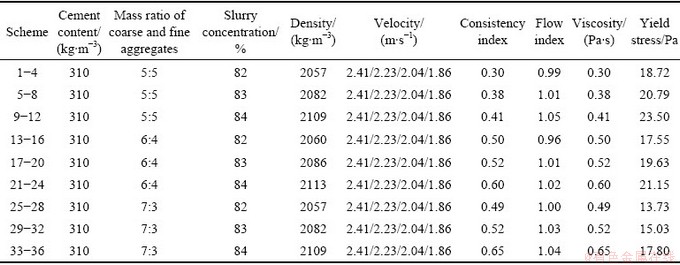

本次进行的数值模拟中充填浆体采用废石与风砂质量比分别为5:5、6:4和7:3,水泥添加量为310 kg/m3,充填料浆质量浓度分别为82%、83%和84%;流速分别为2.41、2.23、2.04和1.86 m/s,共计模拟方案36组,浆体基本参数如表3所示。

通过数值模拟分析,可以得到不同配比、不同级配和不同流速条件下的管输阻力规律以及充填料浆在管输过程中的流速及压力的分布规律。

2.3 模型参数设置

根据数值模拟的试验方案的设计,在管道模型中设置入口边界条件为速度入口(Velocity-Inlet),管道壁定义为管壁边界(Wall),出口边界条件为出口流动(Outflow)。因金川集团二矿区采用重力自流输送,设置边界条件时,需附上竖直方向的重力加速度(9.8 m/s2)。

图1 充填管线几何模型示意图

Fig. 1 Geometric model of filling pipeline

表3 模拟方案和流变参数表

Table 3 Simulation scheme and rheological parameter table

2.4 管道输送边界层效应

边界层位于管道壁面和浆体主流区之间,其黏度远低于浆体主流区的黏度。当充填料浆受到剪切作用时,在边界层内产生极高的速度梯度。边界层厚度相对于管道直径极小,料浆流动过程中的速度分布在壁面上表现出跃迁,形成所谓的表观滑移流动。该边界层对充填料浆管道输送起到减租的作用。考虑到这一点,本次模拟建立了边界层网格,为了合理体现边界层,边界层网格数设置为5层,使模拟结果更加接近实际情况。边界层网格如图2所示。

图2 管道入口边界层网格

Fig. 2 Grid of boundary layer at pipeline entrance

3 数值模拟结果分析

3.1 管输速度对沿程阻力损失的影响

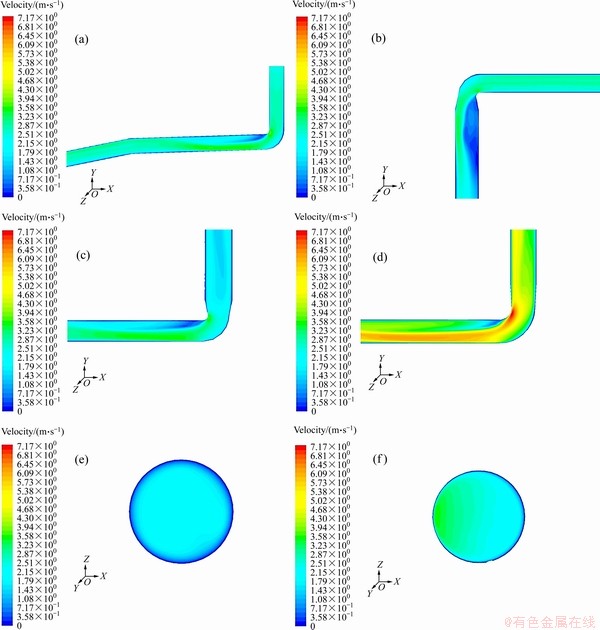

经过FLUENT的计算结果和模拟的速度云图(见图3)可以发现,36个方案中的速度规律基本都一致的,只是在速度的大小上有所差别,为避免重复,现仅附上方案3(即废石风砂质量比为5:5、料浆浓度为82%、浆体流速为2.04 m/s)的各种管道处的速度云图,如图3所示。从图3中可以看出,因边界层表面效应(也叫“伯努利效应”),充填管道的整个管道壁面处的速度接近0或为0;在管道的半径方向,在管道圆心附近的速度较大,接近管道的管壁附近的速度比较小,在管道的管径方向有明显的速度梯度。从图3中的不同弯管及变径管的速度云图可观察到,在弯管处的速度有剧烈的波动,其主要原因是在弯管处浆体的流速和方向发生了变化。在弯管靠近圆心处其速度相对较小,而在弯管离圆心较远处其速度就相对较大。特别是由图3(c)和(d)可明显看出,90°的弯管比其他角度的弯管的变化更为明显。浆体的流速在弯管处的波动较大,但不是一过弯管料浆流速就趋于稳定,而是要过一段过渡阶段才能趋于稳定,然后呈管道圆心靠下处的速度大、管径方向往管壁处速度逐渐减小的梯度分布。特别是管道的拐弯越大,其速度云图中的过渡阶段越明显。从图3(b)和(c)可以看出,变径管对充填料浆具有加速或减速的作用。从图3(e)和(f)中可以看出,变径管的入口速度明显小于出口速度,这是由于管径由大变小,导致流速增大,而流速增大导致管道输送动压增大,阻力损失增大。由于增大流速可以减轻料浆沉降的情况,在实际应用中,可以根据具体情况,选择对应的变径管。

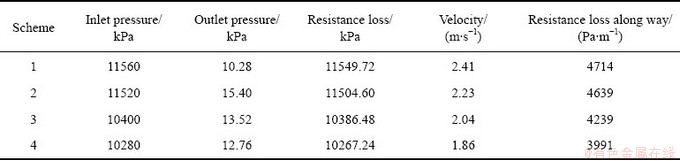

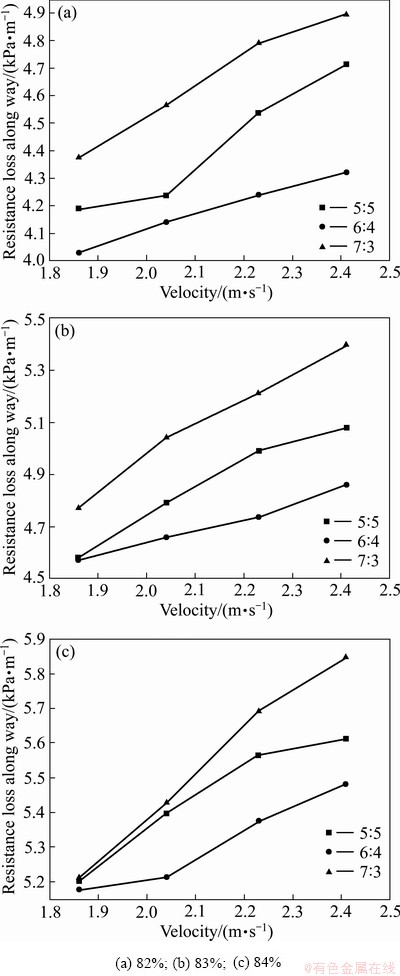

以废石风砂质量比为5:5、水泥添加量为310 kg/m3、料浆浓度为82%为例,管输流速从1.86 m/s增大到2.41 m/s时,管道沿程阻力损失统计结果如表4所示,各个配比下料浆管输沿程阻力损失随流速的变化情况如图4所示。从图4可以看出,当废石-风砂充填料浆的骨料比、水泥添加量和料浆浓度一定时,随料浆流速的增大,料浆的输送沿程阻力损失基本呈线性增大。

3.2 管输浓度对沿程阻力损失的影响

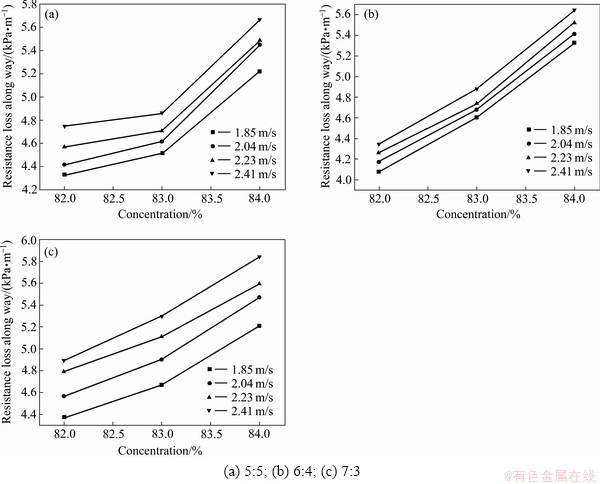

图5所示为料浆浓度与沿程阻力损失的关系。从图5中可已看出,在废石-风砂充填料浆的管输中,当骨料比和流速相同时,料浆浓度对管输阻力的影响非常大。当充填料浆的料浆浓度有较小的变化时,管道沿程阻力损失迅速变大,通常在充填料浆浓度相差2%左右时,管道单位长度的阻力损失可能会相差20%~30%。因此,在实际输送时通常通过降低充填料浆的浓度来输送充填料浆至采场,这样可以防止充填料浆在管输阻力过大,导致充填料浆不能够流动而造成堵管。

从图5中可知,随着料浆浓度的增大,管道的沿程阻力损失变得越来越大。料浆浓度在82%~83%时,沿程阻力损失增加缓慢,而料浆浓度在83%~ 84%时,沿程阻力损失增加较快,尤其当废石风砂质量比为5:5时,这种趋势尤为明显。

根据金川公司二矿区的具体条件和管输阻力综合考虑,比较适合管道输送的废石-风砂充填料浆的质量浓度为82%~83%。

图3 方案3的速度云图

Fig. 3 Velocity cloud of scheme 3

表4 水泥添加量为310 kg/m3、料浆浓度为82%时不同流速下的沿程阻力损失

Table 4 Resistance loss along way under slurry concentration of 82% and cement of 310 kg/m3 at different velocities

图4 料浆流速与沿程阻力损失的关系

Fig. 4 Relationship between slurry velocity and resistance loss along way

图5 料浆浓度与沿程阻力损失的关系

Fig. 5 Relationship between slurry concentration and resistance loss along way

3.3 级配与沿程阻力损失的关系

图6所示为不同级配的料浆流速与沿程阻力损失的关系。级配是影响着充填料浆管道输送阻力的重要因素。由图6可知,在相同的料浆浓度和流速下,废石风砂质量比为5:5和7:3的浆体的沿程阻力损失要明显大于废石风砂质量比为6:4的浆体的沿程阻力损失。其原因是:当浆体的废石风砂比过小时,由于浆体中细粒级含量过多,浆体的黏度增大,在浆体流动时浆体的管道阻力比较大,从而使沿程阻力损失增大。而当废石风砂比较大时,浆体中粗颗粒(废石)的含量过多,导致浆体的固体颗粒级配较差,浆体的稳定性也就相对较差,从而导致浆体的管道阻力变大,沿程阻力损失增大。从沿程阻力损失的关系中可知,废石风砂质量比为5:5、6:4和7:3充填料浆中,废石风砂质量比为6:4的废石-风砂浆体的稳定性和流动性要相对较好,相对更有利于管道输送。

在实际的矿山高浓度充填中,要使高浓度的废石-分级尾砂料浆的浓度提高1%~2%是比较困难的,因此选择合理的配合比就非常重要。根据金川公司二矿区的管输实验和数值模拟结果,废石风砂质量比为6:4应是比较合理的配比。在矿山的实际充填中还可以充分利用井下的废石,使充填成本尽量降到最低又可以取得较好的充填效果。

图6 不同级配的料浆流速与沿程阻力损失的关系

Fig. 6 Relationship between slurry velocity of different gradations and resistance loss along way

4 管道输送阻力新模型

金川公司二矿区高浓度充填料浆的管道输送阻力计算新模型,主要采用金川公司二矿区充填料浆的流变实验获得的参数,与进行FLUENT数值模拟统计的沿程阻力为基础,结合常用的经验-半经验的阻力计算公式,基于量纲分析法来建立新的阻力计算模型,运用统计回归分析法来回归得出具体公式。

根据高浓度充填料浆管道输送阻力的影响因素和管道阻力损失的关系,建立了新的管道阻力计算模型如式(1)所示:

(1)

(1)

式中:v为料浆流速,m/s; 为充填料浆的体积浓度;

为充填料浆的体积浓度; 为料浆的密度;

为料浆的密度; 为清水密度;

为清水密度; 为料浆黏度;

为料浆黏度; 为清水黏度,常温下取0.01;Cx为沉积阻力系数;D为管道直径;g为重力加速度,取9.81 m/s2;

为清水黏度,常温下取0.01;Cx为沉积阻力系数;D为管道直径;g为重力加速度,取9.81 m/s2; 为料浆的级配系数;k为修正系数;a、b、c、d为待定系数。

为料浆的级配系数;k为修正系数;a、b、c、d为待定系数。

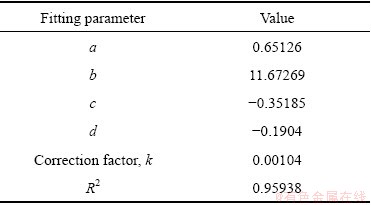

根据数值模拟得出的充填料浆管道输送沿程阻力损失值,运用Origin对表中的数值进行回归分析,拟合结果见表5。从表5可以看出,数据和拟合曲线的相关性R2为0.95938,因此金川公司二矿区废石-风砂高浓度充填料浆的水平管道中的阻力计算新模型表示为

(2)

(2)

式中:△i的单位为mwater/m。

表5 管道阻力计算模型拟合结果表

Table 5 Fitting results of pipe resistance calculation model

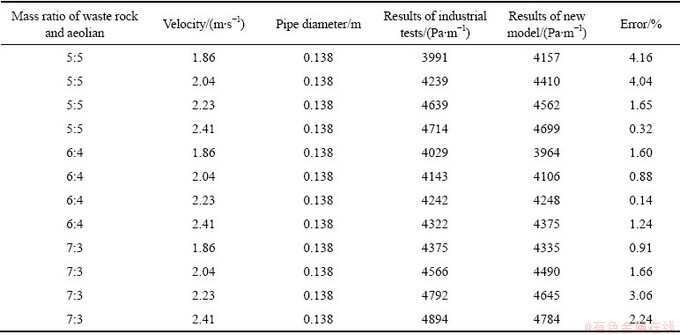

5 工业验证

为了能准确地了解新的沿程阻力损失模型的适用性以及实际管输时的阻力情况,在金川二矿的二期制备站进行管输工业试验,并于1350中段安装了压力检测设备,根据压力检测设备的读数计算出实际的沿程阻力损失。工业试验沿程阻力损失结果与新的沿程阻力损失模型的计算结果对比如表6所示。通过表6中的结果对比可知,新模型的结果与工业试验的误差在5%以内。

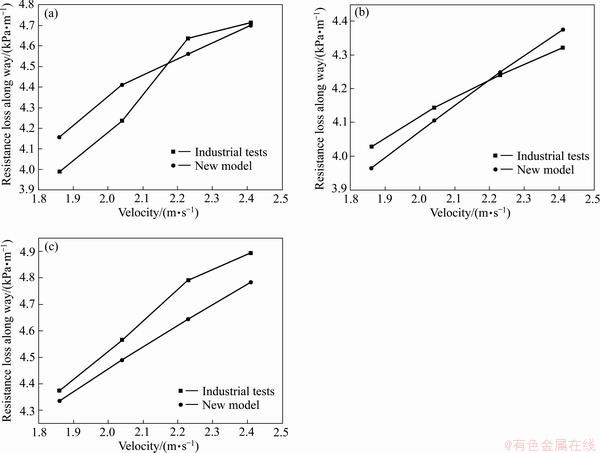

从表6和图7可以看出,金川公司二矿区的工业试验结果与模型计算的阻力值最大误差为4.16%,最小误差为0.32%。结果表明,用新模型来计算管道输送的沿程阻力损失是可行的,新模型有良好的普遍适用性。

6 结论

表6 新模型计算结果与工业试验结果比照表(以浓度82%为例)

Table 6 Comparison between calculation results of new model and industrial test results (taking 82% concentration as example)

图7 新模型计算结果与工业试验结果比照图

Fig. 7 Comparison between calculation results of new model and industrial test results (taking slurry concentration of 82% as an example)

1) 充填管道的整个管道壁面处的速度接近0或为0;在管道的管径方向,在管道圆心附近的速度较大,接近管道的管壁附近的速度比较小,在管道的管径方向有明显的速度梯度,料浆的输送沿程阻力损失随料浆流速的增大而呈线性增大。

2) 料浆浓度对管输阻力的影响非常大,当料浆浓度有较小的变化时,管道沿程阻力损失迅速变大。

3) 对不同骨料比的充填料浆的数值模拟结果表明,废石风砂质量比为6:4的废石-风砂浆体的稳定性和流动性相对较好,有利于管道输送,在矿山的实际充填中还可以充分利用井下的废石,使充填成本尽量降到最低又可以取得较好的充填效果。

4) 以FLUENT数值模拟统计的沿程阻力为基础,结合常用的经验-半经验的阻力计算公式,基于量纲分析法来建立新的阻力计算模型,并进行工业验证,验证结果误差小于5%,表明用新模型来计算管道输送的沿程阻力损失是合理可行的。

REFERENCES

[1] 吴爱祥, 王 勇, 王洪江. 膏体充填技术现状及趋势[J]. 金属矿山,2016(7): 1-9.

WU Ai-xiang, WANG Yong, WANG Hong-jiang. Status and prospects of the paste backfill technology[J]. Metal Mine,2016(7): 1-9.

[2] 张修香. 矿山废石-尾砂高浓度充填料浆的流变特性及多因素影响规律研究[D]. 昆明: 昆明理工大学, 2016.

ZHANG Xiu-xiang. Study on the rheological characteristics and multi factor influence law of high concentration filling slurry of mine waste rock tailings[D]. Kunming University of Science and Technology, 2016.

[3] 邱晓伟. 膏体管道输送现状分析与技术研究[J]. 中国矿山工程, 2019, 48(1): 51-53.

QIU Xiao-wei. Current situation analysis and technical research of paste pipeline transportation[J]. China Mining Engineering, 2019, 48(1): 51-53.

[4] 韩占忠, 王 敬, 兰小平. FLUENT-流体工程仿真计算机实例与应用[M]. 北京: 北京理工大学出版社, 2010.

HANG Zhan-zhong, WANG Jing, LAN Xiao-ping. FLUENT-Example and application of fluid engineering simulation calculation[M]. Beijing: Beijing Institute Technology Press, 2010.

[5] 李国栋. 金川镍矿新型胶凝材料开发及管道输送特性的研究[D]. 包头: 内蒙古科技大学, 2015.

LI Guo-dong. Development of new cementitious materials and research on pipeline transportation characteristics of Jinchuan nickel mine[D]. Baotou: Inner Mongolia University of Science and Technology, 2015.

[6] 侯 俊, 程文文, 张小瑞, 等. 基于FLUENT的磷石膏膏体充填料浆管道输送模拟[J]. 现代矿业, 2018, 34(4): 148-152.

HOU Jun, CHENG Wen-wen, ZHANG Xiao-rui, et al. Pipeline transportation simulation of phosphogypsum paste filling slurry based on fluent[J]. Modern Mining, 2018, 34(4): 148-152.

[7] 温震江, 高 谦, 王忠红, 等. 基于FLUENT的全尾砂充填料浆输送特性模拟与分析[J]. 化工矿物与加工, 2017, 46(9): 54-58.

WEN Zhen-jiang, GAO Qian, WANG Zhong-hong, et al. Simulation and analysis of transportation characteristics of full tailings filling slurry based on fluent[J]. Chemical Minerals and Processing, 2017, 46(9): 54-58.

[8] 杨志强, 高 谦, 姚维信, 等. 戈壁砂和棒磨砂骨料充填料浆管输特性试验[J]. 山东科技大学学报(自然科学版), 2017, 36(1): 38-45, 53.

YANG Zhi-qiang, GAO Qian, YAO Wei-xin, et al. Test on the pipeline transportation characteristics of Gobi sand and rod ground aggregate filling slurry[J]. Journal of Shandong University of Science and Technology (Natural Science Edition), 2017, 36(1): 38-45, 53.

[9] 王少勇, 吴爱祥, 尹升华, 等. 膏体料浆管道输送压力损失的影响因素[J]. 工程科学学报, 2015, 37(1): 7-12.

WANG Shao-yong, WU Ai-xiang, YIN Sheng-hua, et al. Influencing factors of pressure loss in paste slurry pipeline transportation[J]. Journal of Engineering Science, 2015, 37(1): 7-12.

[10] 林天埜. 矸石似膏体充填料浆流动性能研究[D]. 北京: 中国矿业大学, 2016.

LIN Tian-ye. Study on flow performance of paste like gangue filling slurry[D]. Beijing: China University of Mining and Technology, 2016.

[11] 高德真, 李佳璐, 李德臣, 等. 基于FLUENT气固两相流数值模拟与分析[J]. 辽宁石油化工大学学报, 2015, 35(4): 5-8, 15.

GAO De-zhen, LI Jia-lu, LI De-chen, et al. Numerical simulation and analysis of gas-solid two-phase flow based on fluent[J]. Journal of Liaoning University of Petroleum and Chemical Technology, 2015, 35(4): 5-8, 15.

[12] 甘德清, 薛 娜, 刘志义, 等. 全尾砂充填料浆管道阻力损失探究及优化[J]. 金属矿山, 2019(7): 32-40.

GAN De-qing, XUE Na, LIU Zhi-yi, et al. Research and optimization of resistance loss of full tailings filling slurry pipeline[J]. Metal Mine, 2019(7): 32-40.

[13] 石宏伟, 黄吉荣, 滕高礼, 等. 高浓度分级尾砂充填料浆管输阻力影响因素研究与分析[J]. 有色金属(矿山部分), 2019, 71(6): 89-94.

SHI Hong-wei, HUANG Ji-rong, TENG Gao-li, et al. Study and analysis on the factors influencing the resistance of slurry pipe transportation with high concentration graded tailings filling[J]. Non Ferrous Metals (Mine Part), 2019, 71(6): 89-94.

[14] 熊有为, 刘福春, 刘恩彦, 等. 大流量膏体管道输送阻力特性研究[J]. 矿业研究与开发, 2019, 39(9): 100-104.

XIONG You-wei, LIU Fu-chun, LIU En-yan, et al. Study on the resistance characteristics of large flow paste pipeline transportation[J]. Mining Research and Development, 2019, 39(9): 100-104.

[15] CHENG Hai-yong, WU Shun-chuan, LI Hong, et al. Influence of time and temperature on rheology and flow performance of cemented paste backfill[J]. Construction and Building Materials, 2019, 231: 1-10.

Numerical simulation and new model of pipeline transportation resistance of waste rock-aeolian sand high concentration slurry

YANG Tian-yu1, QIAO Deng-pan1, WANG Jun1, ZHANG Xi2, CHEN Yin3

(1. School of Land and Resources Engineering, Kunming University of Science and Technology, Kunming 650093, China;

2. Technical Management Division, Yuxi Mining Co., Ltd., Yuxi 653100, China;

3. Mine Engineering Design Institute, Kunming Nonferrous Metallurgy Design and Research Institute Co., Ltd., Kunming 650051, China)

Abstract: In order to investigate the transportation characteristics of waste rock-aeolian sand high concentration slurry for self flow pipeline filling, the actual filling pipeline in the mine was reduced, and the transportation simulation research was carried out with FLUENT software. The results show that there is an obvious velocity gradient in the direction of pipe diameter. With the increase of slurry velocity, the resistance loss of slurry transportation increases linearly. The slurry concentration has a great influence on the resistance of pipeline transportation. When the concentration difference of filling slurry is about 2%, the resistance loss per unit length of pipeline will vary by 20%-30%. Through the numerical simulation of the filling slurry with different aggregate ratio, the results show that the stability and fluidity of the slurry with waste rock-aeolian sand mass ratio of 6:4 are relatively better, which is more conducive to pipeline transportation. A new model of pipeline resistance was established, and the reliability of the new model was verified by industrial test. The results provide an important basis for selecting the operation parameters of the filling system.

Key words: gravity conveying; high concentration slurry; resistance loss; numerical simulation; resistance model

Foundation item: Project(1203GKDC003) supported by the Major Special Science and Technology Plan of Gansu Province, China; Project(IRTSTYN) supported by the Program for Innovative Research Team (in Science and Technology) in University of Yunnan Province, China; Project(2019M663576) supported by the China Postdoctoral Science Foundation

Received date: 2020-02-19; Accepted date: 2020-07-29

Corresponding author: QIAO Deng-pan; Tel: +86-13888129512; E-mail: mvpkobe248@126.com

(编辑 李艳红)

基金项目:甘肃省科技重大专项计划资助项目(1203GKDC003);云南省高校科技创新团队支持计划资助项目(IRTSTYN);中国博士后科学基金资助项目(2019M663576)

收稿日期:2020-02-19;修订日期:2020-07-29

通信作者:乔登攀,教授,博士;电话:13888129512;E-mail:mvpkobe248@126.com