文章编号:1004-0609(2015)-01-0258-09

粗骨料高浓度充填料浆的管道输送模拟及试验

张修香,乔登攀

(昆明理工大学 国土资源工程学院,昆明 650093)

摘 要:为了研究粗骨料高浓度充填料浆管道自流输送问题,根据金川矿区的实际充填管路利用Gambit建立三维管道模型,依据料浆自身的特点以及结构流理论,在Fluent(3D)求解器中进行数值模拟。通过对不同浓度及不同流量情况下管道阻力损失的分析以及对弯管处压力的分析,获得在满足强度和高浓度的前提下的最佳料浆输送浓度为78 %~79 %,最佳流速为90 m3/h。同时,通过坍落度试验以及工业试验对数值模拟的结果进行验证。结果表明,粗骨料高浓度料浆管道输送模拟是可行的,研究结果为矿山应用粗骨料高浓度充填提供了理论依据。

关键字:废石-尾砂;Fluent数值模拟;自流输送;管道阻力损失

中图分类号:TD 853.34 文献标志码:A

Simulation and experiment of pipeline transportation of high density filling slurry with coarse aggregates

ZHANG Xiu-xiang, QIAO Deng-pan

(Faculty of Land and Resources Engineering, Kunming University of Science and Technology, Kunming 650093, China)

Abstract: In order to study the pipeline gravity transport of high-density filling slurry with coarse aggregates, the Gambit was used to establish 3D pipeline models according to the actual filling line in Jinchuan and numerical simulations were performed in the solver of Fluent (3D) based on the slurry characteristics and the structure flow theory. Through analyzing the resistance loss of the pipeline and force condition of the elbow under different concentrations and volume fluxs, the best transportation concentration of slurry is 78%-79%, and the optimal flux is 90 m3/h on the premise of meeting the requirement of strength and high-density. At the same time, the results of numerical simulation through the slump test and industrial experiment were verified, the pipeline simulation of high-density slurry with coarse aggregates is feasible, the result provides a theoretical basis for applying high density filling with coarse aggregates in mine.

Key words: waste rock-tailing; Fluent numerical simulation; gravity transportation; pipeline resistance loss

高浓度充填是近几十年来充填研究的主要方向,高浓度料浆具备不离析、不沉淀、充填质量好、效率高、采场脱水量少等优点[1-3]。在充填倍线确定的前提下,料浆以自流或泵送方式输送到井下采空区,是实现充填的先决条件之一。金川集团股份有限公司采用盘区机械化下向水平分层进路式充填法,目前金川公司主要的充填物料—棒磨砂的供应量无法满足超大充填的需求,急需既廉价又充足的材料来补充。金川周边有丰富的采掘废石、选矿尾砂,因此,研究废石-尾砂高浓度充填料浆管道自流输送对指导此矿山的充填采矿具有重要意义。

充填料浆管道输送的主要研究方法是利用环管实验测沿程阻力损失,但其实验强度大、费用高、有一定的局限性。随着计算机技术的不断发展,料浆管道输送仿真模拟成为一种趋势。专业用于流体分析的软件主要是Fluent[4],它是基于有限体积法[5]的计算工具,邓代强等[6]基于此软件研究了充填料浆L型管道自流输送模拟实验,但L管过于简单不能全面反映矿山实际情况,同时还针对冬瓜山铜矿长距离管道输送问题,应用Fluent软件分析不同浓度的充填料浆对弯管处的磨损情况,但此项研究并未对流量的影响进行分析[7]。黄玉诚等[8]应用此软件针对弯管处的压力场、速度场的分布特征进行了分析,但未对整个管道的状况进行分析;WANG 等[9]使用 Fluent 软件对深井煤矿自流输送充填系统中料浆的流动速度进行了研究,但是并未涉及管道系统的受力分析;张钦礼等[10]针对孙村煤矿的煤矸石似膏体充填料浆的特点,只是对料浆的管道输送过程进行了研究;吴迪等[11]使用Fluent软件对料浆管道输送的阻力损失和弯管部分的受力情况进行了分析,但其研究内容为固液两相流的料浆,对于高浓度(结构流)料浆并未研究。而国外主要应用泵送方式进行管道输送,对自流输送系统的研究报道较少。

基于以上分析,本文作者利用金川矿区材料配制高浓度料浆,应用Fluent软件模拟金川矿区东部充填站的实际情况,分析不同浓度、不同流速下管道输送情况以及弯管处压力变化情况,确定适合管道输送的浓度及流速,并与坍落度试验和现场工业试验的结果进行对比验证,研究结果为矿山充填提供了保证。

1 高浓度料浆及实验方案

20世纪80年代后,充填技术向高浓度方向发展。但对于浆体“高浓度”的定义仍然众说纷纭,适用于结构流 (区别于两相流) 理论意义上的“高浓度”是指大于临界流态浓度而小于极限可输送浓度的固-液混合流体的浓度,其流态是指当浆体的浓度达到某临界浓度(临界流态浓度)值时,浆体中的固体颗粒在横断面上呈均匀分布状态,各点速度迹线大体平行于管道轴线,使流体速度图近于平行分布,浆体中固体颗粒基本不发生相对沉降,没有浓度梯度或者浓度梯度很小[12-14]。由此可以认为,管输充填料浆的高浓度判定条件的理论依据是:高浓度为在静置一段时间后还能保持不分层的料浆浓度。在静止过程中,料浆中颗粒只压缩不存在自由沉降,特点为在体积收缩时不存在粗颗粒分选沉降,仅有少量水析出,在管道输送工程中不存在速度梯度。

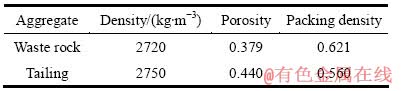

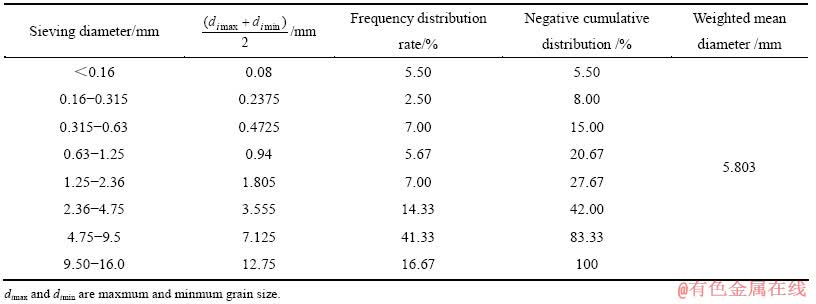

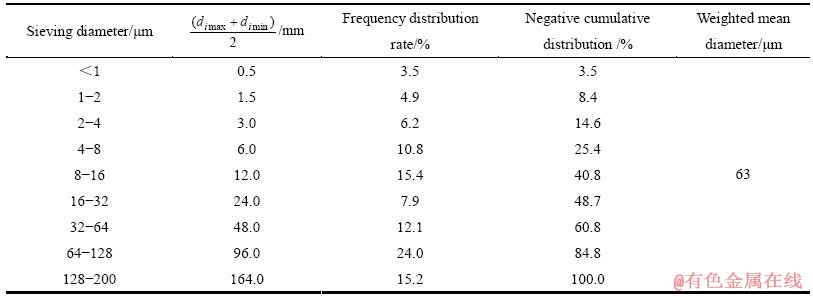

在此次模拟中,选用金川矿区的废石与尾砂作为材料,两种骨料的物理参数及粒径组成如表1~3所列。

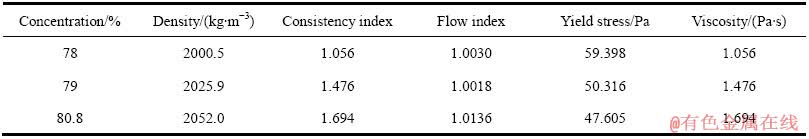

参考混凝土级配设计的有关经验:日本建筑学会制定的《泵送混凝土施工规程》中规定,用于配制泵送混凝土的细集料,通过0.3 mm筛孔颗粒的含量为10 %~30 %,此值过低易造成堵管;我国的规程规定,通过0.315 mm筛孔的砂含量不应少于15 %[15-16],从表2和3可知,破碎废石中粒径小于0.3 mm的颗粒含量不到15 %,而尾砂的粒度很细,采用废石配尾砂的形式来改善级配,增大填隙效应和骨料密实度。根据金川二矿区工业试验的结果,满足高浓度条件以及强度要求的充填浆体采用废石与尾砂质量比(废尾比)为6:4,水泥用量为260 kg/m3,质量浓度大于77 %,具体方案以及浆体参数如表4所列。

表1 废石集料-尾砂的物理参数

Table 1 Physical parameters of waste rock and tailing

表2 废石集料的粒度分布

Table 2 Size distributions of waste rock

表3 尾砂的粒度分布

Table 3 Size distributions of tailing

表4 方案设计与料浆参数

Table 4 Solution design and rheological parameters of slurry

2 模型

为了便于理论研究将流体的物理实体加以模型化,引入流体质点和连续介质[17-18]的概念。结合充填浆体的特点,对充填浆体做出以下假设:1) 认为充填浆体不论是静置还是在管道中流动时都是连续的,无间隙;2) 各个方向的力学性质是一致的;3) 浆体在流动中是不可压缩的;4) 满足定常稳定流动假设;5) 浆体是无热交换的。

2.1 模型的选择

流体流动的研究方法有两种:欧拉法和拉格朗日法。欧拉法是基于流体经过空间各个固定点的运动情况,把这些固定点的运动流当成流体不同质点在不同时间经过不同位置的流动来考虑的。

拉格朗日法与欧拉法在研究流体时,只是着眼点不同,并没有本质上的区别,对于相同的问题,得到的结果应该是一致的。对于充填浆体,当其不离析(在管道的横截面上没有明显的浓度梯度)时,应该看成是均匀的连续介质来研究,拉格朗日法和欧拉法同样适用。本文作者选用欧拉法来描述流体运动。

2.2 控制方程

1) 浆体的连续性方程为

(1)

(1)

式中: t 为时间;ρ 为浆体的密度;v 为浆体的速度。

由于浆体是不可压缩的均质体,密度为常数,故连续性方程就简化为

(2)

(2)

式中:u、v、w为速度矢量沿 x、y、z 轴的3个速度的分量。

式(2)表明,浆体作为不可压缩流体流动时,流速的空间变化是彼此关联,相互制约的,必须受到连续性方程的约束,否则流动的连续性将被破坏。

2) 动量方程形式为

(3)

(3)

式中:X、Y、Z 分别表示流体微元在 x、y、z 方向的面力;F 表示流体微元受到的面力的合力;ρ 表示流体的密度;μ 表示流体的黏度。

3) 伯努利方程可以写成如下形式:充填浆体在管道中流动时符合能量守恒和转化定理,伯努利方程就是建立在能量守恒的基础上的,取竖直向上为 z 轴。

(4)

(4)

式中:z1和z2表示单位流体的位置;F1和F2表示流体在位置z1、z2处的压力;γ为料浆的容重;v1和v2表示流体在z1、z2处的速度; 表示流体从z1位置运动到z2位置过程中内摩擦力做的功。

表示流体从z1位置运动到z2位置过程中内摩擦力做的功。

2.3 边界条件

竖直管道入口设置为速度入口(Velocity-inlet),管道水平出口设置为自由出流(Outflow),操作条件为标准大气压,在竖直方向存在重力加速度9.8 m/s2(y轴负方向)。

2.4 几何模型

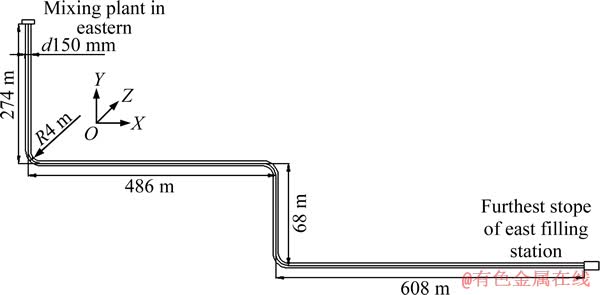

金川矿区东部充填管线目前布置到达的最深位置在1220 m水平,现阶段的充填路线是充填料浆从东部制浆站(钻孔口标高1682 m)通过充填钻孔到达1408 m水平, 然后通过充填管线到 1400~1280 m盲井口,充填范围最远可到18行东,充填管线简图见图1。本研究中采用Fluent的前处理软件 Gambit 进行几何建模,管道的几何模型与实际尺寸及布置方式保持一致,坐标原点在第一个弯管的中心处,如图 1 所示。管道内径为150 mm,弯管处呈直角,弯管半径为4 m,充填倍线为4.2。

图1 充填管道线路

Fig. 1 Route of filling pipeline

3 数值模拟与分析

应用前处理软件Gambit建立物理模型,并进行网格的划分,然后导入Fluent进行计算,最后输出计算结果。通过在室内实验室配置表4中的高浓度料浆进行流变实验,得到流变曲线为一条在剪切应力轴上有截距的下弯曲线。浆体开始流动后,剪切率与剪切应力之呈非线性递减关系,曲线凸向剪切应力轴,属于屈服-假塑性体,符合H-B模型,所以,本次模拟选用H-B模型[19-22]进行分析。

3.1 浓度分析

金川矿区的实际输送能力为90~105 m3/h,为了考察适合管道自流的输送浓度,设定相同的输送流速为105 m3/h,计算不同浓度下的管道输送情况(见表4)。

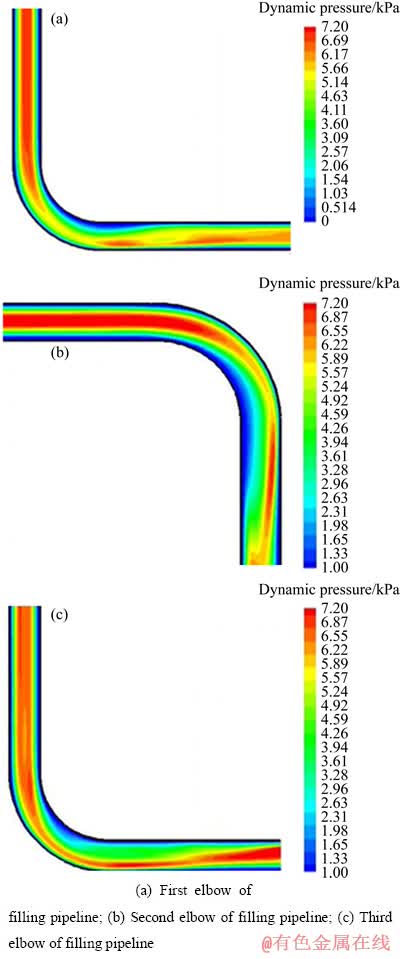

由于篇幅有限只将浓度为78 %,流量为105 m3/h时的压强分布列于图2中,将各个浓度下的管道阻力损失列于表5。

从图2可知,料浆在管道中动压变化情况为在竖直以及水平管道中,最大动压出现在管道中心处,而经过弯管处时最大动压向外侧管壁处偏移,所以,弯管处的管道磨损较为严重。

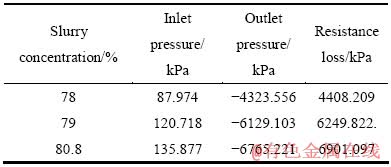

从表5可以看出,随着浓度的增加,管道的阻力损失逐渐变大,且当浓度为80.8 %时,料浆重力势能无法提供足够的能量使料浆自流,料浆不能满足自流输送的条件,会造成堵管,所以建议使用浓度78%~79%进行自流管道输送。

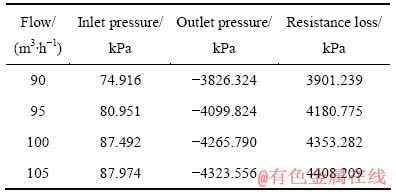

3.2 流速分析

为了分析同一浓度时不同流量下管道阻力损失情况,选用料浆浓度为78 %,流量分别为90、95、100和105 m3/h时对应的管道损失,其数值模拟结果列于表6。从表6中可以看出,随着流量的增加,管道阻力损失逐渐增大,在流量90 m3/h时,损失最小。

3.3 弯管处压力分析

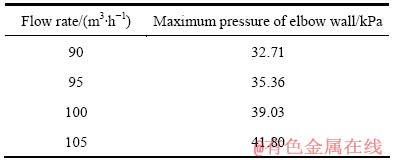

取与坐标原点成45角的斜线测得弯管处的压强变化值,以质量浓度为79 %,流量为90和95 m3/h时管道弯管处的情况为例绘于图3中,各流量下的最大压强值列于表7。

图3显示,在弯管底部受到的压力最大,随着慢慢靠近原点压强值逐渐减少。从表7可知,随着输送流量的增加,最大压力值逐渐增加,在流量为90 m3/h时受力值最小,这与流量分析结果一致。

图2 管道压强变化云图

Fig. 2 Pressure cloud diagram of pipe

表5 料浆流速为105 m3/h时不同浓度料浆管道阻力损失

Table 5 Piping resistance loss of slurry with different concentrations at slurry flow rate of 105 m3/h

表6 料浆浓度为78 %时不同流速下管道阻力损失

Table 6 Piping resistance loss of slurry with different flow rates at slurry concentration of 78 %

图3 弯管处压强变化曲线

Fig. 3 Change curves of pressure in bend at different flow rate

表7 弯管处最大压强值

Table 7 Maximum pressure value in bend at different flow rate

4 实验验证

为了验证管道模拟的准确性,在实验室内进行坍落度试验,以及在金川矿区进行工业试验。

4.1 坍落度试验

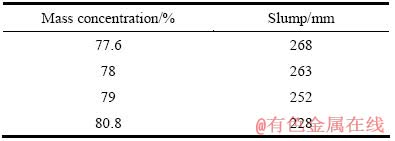

坍落度试验反映料浆在自重作用下克服剪切阻力所产生的变形能力。坍落度是一项综合性的定量指标,料浆的流动性、保水性和粘聚性是料浆的定性表现,可以说坍落度是料浆内在质量的外在表现,坍落度不满足要求会直接影响到泵送甚至影响到充填质量,因此对坍落度的控制就十分重要,邓代强等[23]的研究表明:粗骨料充填料浆当坍落度在230~275 mm范围内,可基本满足自流输送要求,在实验室进行废尾比6:4的料浆坍落度试验(见图4),并将结果列于表8中。

从表8可知 当料浆浓度为80.8 %时,坍落度值刚刚达到230 mm,料浆的流动性差,不适宜进行自流输送,而料浆78 %~79 %满足自流输送的要求,坍落度试验结果验证了数值模拟的正确性。

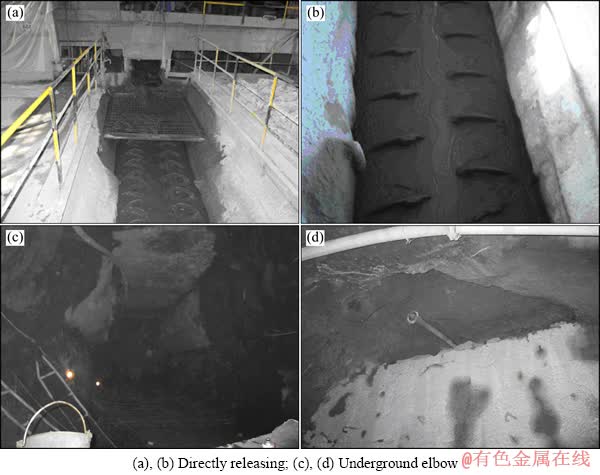

4.2 工业试验

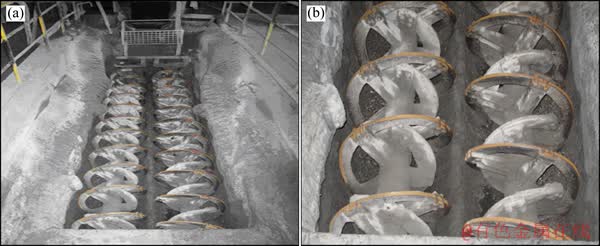

金川充填系统的主搅拌为ATDⅢ-Ф700型双螺旋搅拌输送机(如图5),搅拌轴长达6 m,设计搅拌槽的最大容积为5 m3,设计生产能力为36~90 m3/h,采用两个30 kw电机传动。

由于废石-尾砂充填料浆骨料粒级范围大,充填起始阶段料浆浓度需要迅速提高,以保证工业应用中充填体的整体性和强度稳定。

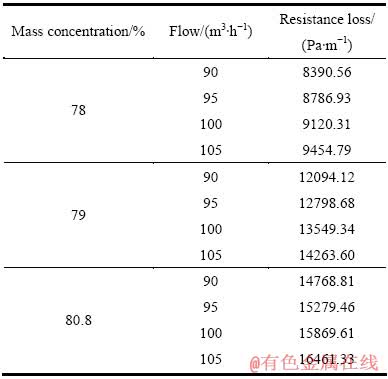

根据工业试验测得不同流量及浓度下充填料浆水平直管沿程阻力损失结果,列于表9中。

从表9可以看出,在同等浓度下, 随着流量的增加,沿程阻力损失也在增加,流量为90 m3/h时阻力损失最小;在同等流量时,浓度越大,阻力损失越大,与模拟结果一致,这也验证了模拟的正确性。

图4 坍落度试验照片

Fig. 4 Photos of slumps at different measurement conditions

表8 废尾比为6:4时废石-尾砂料浆坍落度

Table 8 Slump of waste rock-tailing slurry at mass ratio of waste rock and tailing of 6:4

根据工业试验充填进路揭露情况,试验组测量了进路内废石-尾砂充填体的流动状态(充填系统见图6)。测定方法是先由工区冲洗充填体,给定一条水平线。然后按5 m左右间距布置测条,用锤击、目测来判断充填体的均匀性。根据现场情况,试验组根据试块压裂后骨料分布情况对比设定了均匀层(粗骨料分布均匀)、粗砂层(粗粒废石有较明显富集现象)、细砂层(粗粒废石少)、细浆层(明显的水泥尾砂浆)。现场测定结果表明:废尾比为6:4,料浆浓度为78%~79%时,料浆流动坡面角在0.55°~1.19°之间,料浆流动性较好;当料浆浓度为80.8% 时,料浆在管道中出现滞留的现象,造成堵管,而选用流量越大,弯管处易出现跑浆现象,当控制浓度为78%~79%,流速为90 m3/h时,料浆输送稳定,工业试验的结果进一步证实了数值模拟的合理性。

表9 废尾比为6:4时水平直管沿程阻力损失试验结果

Table 9 Results of frictional resistance loss of straight tube at mass ratio of waste rock and tailing of 6:4

图5 ATDⅢ-Ф700型双螺旋搅拌输送机

Fig. 5 Twin screw conveyor of ATDⅢ-Ф700 type

图6 充填系统的照片

Fig. 6 Photos of backfilling system

5 结论

1) 在料浆流量相同时,随着料浆浓度的增加,管道的阻力损失逐渐增加,且当浓度大于一定值(80.8%)时,就会出现滞留现象,造成堵管。

2) 在料浆浓度相同时,随着料浆流量的增加,管道的阻力损失及弯管处的最大压强值呈增长趋势,弯管底部受到的压力最大,距离原点越近,压力值越小,当流速为90 m3/h时,最适宜管道输送。

3) 通过数值模拟,室内坍落度试验以及工业试验的验证表明在满足强度要求以及高浓度要求下最佳管道输送的料浆浓度为78%~79%,最佳流速值为90 m3/h。

REFERENCES

[1] 乔登攀, 程伟华, 张 磊, 姚维信, 王贤来, 王虎. 现代采矿理念与充填采矿[J]. 有色金属科学与工程, 2011, 2(2): 7-14.

QIAO Deng-pan, CHENG Wei-hua, ZHANG Lei, YAO Wei-xin, WANG Xian-lai, WANG Hu. Modern mining concepts and filling technique[J]. Non-ferrous Metal Science and Engineering, 2011, 2(2): 7-14.

[2] 胡 华, 孙恒虎. 矿山充填工艺技术的发展及似膏体充填新技术[J]. 中国矿业, 2001, 10(6): 47-50.

HU Hua, SUN Heng-hu. Development of backfill technology and the new backfill process using paster-like material[J]. China Mining, 2001, 10(6): 47-50.

[3] 许毓海, 许新启, 李建雄. 高浓度(膏体)充填流变特性及自流输送参数的合理确定[C]//中国有色金属学会第八届国际充填采矿会议论文集. 北京: 矿业研究与开发, 2004: 234-236.

XU Yu-hai, XU Xin-qi, LI Jian-xiong. Rheological behavior of high-density backfill and reasonable determination of the parameters for its gravity-flow transport[C]//Eighth International Filling Mining Conference Proceedings of China Nonferrous Metals Society. Beijing: Mining Research and Development, 2004: 234-236.

[4] 韩占忠, 王 敬, 兰小平. FLUENT-流体工程仿真计算机实例与应用[M]. 北京: 北京理工大学出版社, 2008: 20-27.

HANG Zhan-zhong, WANG Jing, LAN Xiao-ping. FLUENT-simulation computer instances and application[M]. Beijing: Beijing Institute Technology Press, 2008: 20-27.

[5] 李进良, 李承曦, 胡仁喜. 精通FLUENT6.3流场分析[M]. 北京: 化学工业出版社, 2009: 16-38.

LI Jin-liang, LI Cheng-xi, HU Ren-xi. Proficient the analysis of flow field in FLUENT6.3[M]. Beijing: Chemical Industry Press, 2009: 16-38.

[6] 邓代强, 王 莉, 周 喻, 张友轩. 充填料浆L型管道自流输送模拟试验分析[J]. 广西大学学报: 自然科学版, 2012, 37(4): 837-843.

DENG Dai-qiang, WANG Li, ZHOU Yu, ZHANG You-xuan. Experimental analysis on the transportation simulation of filling slurry in L-shape pipeline[J]. Journal of Guangxi University: Nature Science Edition, 2012, 37(4): 837-843.

[7] 邓代强, 朱永建, 王发芝, 王 莉, 余伟健. 充填料浆长距离管道输送数值模拟[J]. 安徽大学学报: 自然科学版, 2012, 36(6): 36-43.

DENG Dai-qiang, ZHU Yong-jian, WANG Fa-zhi, WANG Li, YU Wei-jian. Transportation numerical simulation of filling slurry in long distance pipeline[J]. Journal of Anhui University: Natural Science Edition, 2012, 36(6): 36-43.

[8] 黄玉诚, 董 羽, 许保国, 王子升, 吕艳奎. 似膏体管道输送弯管段浆体流动数值模拟研究[J]. 煤炭工程, 2014, 46(3): 84-86.

HUANG Yu-cheng, DONG Yu, XU Bao-guo, WANG Zi-sheng, LV Yan-kui. Numerical simulation study on paste-like slurry flow at elbow section of paste material transportation pipeline[J]. Coal Engineering, 2014, 46(3): 84-86.

[9] WANG XM,ZHAOJW, XUEJ H, YUG F.Features ofpipe transportation of paste like backfilling in deep mine[J]. Journal of CentralSouth University of Technology, 2011, 18(5): 1413-1417.

[10] 张钦礼, 谢盛青, 郑晶晶, 王新民.充填料浆沉降规律研究及输送可行性分析[J]. 重庆大学学报, 2011, 34(1): 105-109.

ZHANG Qin-li, XIE Sheng-qing, ZHENG Jing-jing, WANG xin-ming. Sedimentation law research and transportation feasibility study of backfilling slurry[J]. Journal of Chongqing University, 2011, 34(1): 105-109.

[11] 吴 迪, 蔡嗣经, 杨 威, 王文潇, 王 章. 基于CFD的充填管道固-液两相流输送模拟及试验[J]. 中国有色金属学报, 2012, 22(7): 2133-2140.

WU Di, CAI Si-jing, YANG Wei, WANG Wen-xiao, WANG Zhang. Simulation and experiment of backfilling pipeline transportation of solid-liquid two-phase flow based on CFD[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(7): 2133-2140.

[12] 赵龙生, 孙恒虎, 孙文标, 刘建庄. 似膏体料浆流变特性及其影响因素分析[J]. 中国矿业, 2005, 14(10): 45-48.

ZHAO Long-sheng, SUN Heng-hu, SUN Wen-biao, LIU Jian-zhuang. Study on the rheological characteristic and effect of paste-like slurry[J]. China Mining, 2005, 14(10): 45-48.

[13] 余 斌, 张绍才, 李 政, 吉兆宁, 刘 坚. 高浓度尾砂充填料浆管道输送性能试验[J]. 河北冶金, 2003, 3: 7-10.

YU Bin, ZHANG Shao-cai, LI Zheng, JI Zhao-ning, LIU Jian. Experiment of pipe transportation performance for filling pulp of high-density tailings-sand[J]. Hebei Metallurgy, 2003, 3: 7-10.

[14] 翟永刚, 吴爱祥, 王洪江, 陈琴瑞, 李航空, 严佳龙. 全尾砂膏体料浆的流变特性研究[J]. 金属矿山, 2010, 12: 30-32.

ZHAI Yong-gang, WU Ai-xiang, WANG Hong-jiang, CHEN Qin-rui, LI Hang-kong, YAN Jia-long. Study on rheological properties of the unclassified-tailings paste[J]. Metal Mine, 2010, 12: 30-32.

[15] 刘小洁, 余志武. 自密实混凝土的研究与应用综述[J]. 铁道科学与工程学, 2006, 3(2): 6-10.

LIU Xiao-jie, YU Zhi-wu. Research and application of self-compacting concrete[J]. Railway Science and Engineering, 2006, 3(2): 6-10.

[16] 陈建奎, 王栋民. 高性能混凝土(HPC)配合比设计新法—全计算法[J]. 硅酸盐学报, 2000, 28(2): 194-198.

CHEN Jian-kui, WANG Dong-ming. New mix design method for HPC-overall calculation method[J]. Journal of the Chinese Ceramic Society, 2000, 28(2): 194-198.

[17] 谢振华, 宋存义. 工程流体力学[M]. 北京: 冶金工业出版社, 2007: 2-5.

XIE Zhen-hua, SONG Cun-yi. Engineering fluid mechanics[M]. Beijing: Metallurgical Industry Press, 2007: 2-5.

[18] 王新民, 丁德强, 吴亚斌, 张钦礼, 卢央泽. 膏体充填管道输送数值模拟与分析[J]. 中国矿业,2006, 15(7): 58-59.

WANG Xin min,DING De qiang,WU Ya bin, ZHANG Qin-li, LU Yang-zhe. Numericalsimulationand analysis of paste backfilling with piping transport[J]. China Mining Magazine,2006, 15(7): 58-59.

[19] JAU W C, YANG C T. Development of a modified concrete rheometer to measure the rheological behavior of conventional and self-consolidating concretes[J]. Cement & Concrete Composites, 2010, 32: 450-460.

[20] CLAVER A I, JAVIERRE C, PONZ L. Method for generation of rheological model to characterize non-conventional injection molding by means of spiral mold[J]. Journal of Materials Processing Technology, 2005, 162/163: 477-483.

A I, JAVIERRE C, PONZ L. Method for generation of rheological model to characterize non-conventional injection molding by means of spiral mold[J]. Journal of Materials Processing Technology, 2005, 162/163: 477-483.

[21] 张强胜. H-B 模型在似膏体管道输送数值模拟中的应用[J]. 山西焦煤科技, 2013, 12: 22-25.

ZHANG Qiang-sheng. Application of H-B model in like paste pipeline numerical simulation[J]. Shanxi Coking Coal Science &Technology, 2013, 12: 22-25.

[22] BOGER D V. Rheology and the resource industries[J]. Chemical Engineering Science, 2009, 64: 4525-4536.

[23] 邓代强, 高永涛, 吴顺川. 基于坍落度测试的粗骨料充填料浆流动性检验[J]. 北京建筑工程学院学报, 2009, 25(1): 30-33.

DENG Dai-qiang, GAO Yong-tao, WU Shun-chuan. Liquidity detection based on the slump testing of coarse aggregate filling material[J]. Journal of Beijing University of Civil Engineering and Architecture, 2009, 25(1): 30-33.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51164016);甘肃省科技重大专项计划项目(1203GKDC003)

收稿日期:2014-07-13;修订日期:2014-10-12

通信作者:乔登攀,教授,博士;电话:13888129512;E-mail:1215550723@qq.com