文章编号:1004-0609(2017)-02-0423-07

高铁锌焙砂还原焙烧-碱浸工艺

彭 兵1, 2,林冬红1,刘 恢1, 2,彭 宁1,陈 栋1,李燕春1,袁莹珍1

(1. 中南大学 冶金与环境学院,长沙 410083;

2. 中南大学 国家重金属污染防治工程技术研究中心,长沙 410083)

摘 要:利用还原焙烧-碱性浸出工艺处理高铁锌焙砂以解决现有炼锌工艺锌铁分离的难题,通过还原焙烧将高铁锌焙砂中铁酸锌分解为氧化锌和铁氧化物,氧化锌在碱性体系被选择性浸出,铁氧化物赋存于浸出渣中实现锌铁分离。以锌、铁浸出率为评价指标,考察还原焙烧及碱性浸出条件对锌铁分离效果的影响,并对焙烧产物及浸出渣进行XRD、SEM-EDS分析。结果表明:最佳还原焙烧条件如下,焙烧时间45 min,焙烧温度800 ℃,CO浓度4%(体积分数);最佳浸出条件如下,NaOH浓度240 g/L,液固比12:1,浸出温度80 ℃,浸出时间60 min。在最佳条件下总锌浸出率约为90%,总铁浸出率约为0.25%,SEM分析显示:浸出渣中锌铁氧化物镶嵌现象严重,这是锌浸出率不能进一步提高的原因。

关键词:铁酸锌;高铁锌焙砂;还原焙烧;碱性浸出

中图分类号:TF813 文献标志码:A

锌是一种重要的有色金属,广泛应用于冶金、化工及纺织等领域[1]。每年产生的大量炼锌废渣是一种重要的含锌二次资源,除了锌以外,还含有多种伴生金属,如Pb、Ga、Ge、In、Ag等。炼锌废渣的不当处置不仅造成资源浪费,还对环境造成潜在危险[2],因此,从含锌废渣中回收锌不仅具有经济效益,还可以减少对环境的危害。

硫化锌矿是最重要的炼锌原料,但由于铁的伴生,在其氧化焙烧过程中不可避免地产生铁酸锌,铁酸锌由于其特殊的尖晶石结构,不溶于弱酸弱碱而存留在浸出渣中,因此,破坏铁酸锌尖晶结构是回收锌的关键。从含锌废渣中回收锌的研究已经有很多[3-11],传统火法、热酸浸锌工艺,虽能得到较好的锌回收率,但存在能耗高或劳动强度大等缺点,特别是酸浸后锌铁分离困难,需要沉铁处理,且铁渣成分复杂难处理,易产生二次污染。面对锌铁分离难的问题,YAN等[12]提出一种选择性还原-酸浸工艺回收锌浸渣中锌和铁,在弱酸条件下锌被选择性浸出进入浸出液,铁通过磁选分离回收,但该工艺中铁的浸出率仍在10%以上;侯栋科等[13]在以上基础上再次优化条件,将铁浸出率下降至7%;彭兵等[14]提出硫酸盐焙烧-两段浸出工艺,该工艺能将铁的浸出率降低至2.04%,但两段焙烧总耗时长达2 h以上,能耗大,回收工艺长。由于铁无法溶解于碱性体系,碱浸工艺日益受到重视[11, 15-19]。韦岩松等[20]碱浸回收铅锑冶炼水淬渣中锌,结果表明在常规浸出条件下锌的浸出率只能达到50%,渣中的其他形式锌(ZnS、ZnFe2O4、Zn2SiO4)在碱性环境下稳定,不易浸出;ORHAN[17]采用碱浸回收电炉粉尘中的重金属,在最佳条件下Zn、Pb浸出率分别达到85%和90%,浸出渣检测表明氧化锌基本被浸出,而铁化合物残留在浸出渣中,实现锌铁有效分离,但存在铁酸锌溶解率不高,造成锌回收率不高,其他碱浸研究也得到相同结论[18-19, 21]。为了有效回收铁酸锌中锌,XIA等[9]进行铁酸锌碱浸研究,结果表明只有9%左右锌被浸出;在此基础上,采用微波加热-碱浸工艺研究铁酸锌碱浸效果,与传统碱浸相比,微波加热可以提高锌浸出率5%~10%左右,虽能溶解部分铁酸锌,但浸出率还是很低[22];DUTRA等[10]对样品进行微波预热以及超声波搅拌处理,效果也不理想;ZHANG等[5]对样品进行机械活化处理,结果表明机械活化处理可以引起铁酸锌晶格缺陷从而增加锌浸出率,但最高浸出率也只有45.32%。此外,YOUCAI等[23]采用氢氧化钠与铁酸锌熔融的方法从铁酸锌中回收锌,结果表明锌的浸出率很低直到温度达到NaOH的熔融点318 ℃,锌的回收率才达到70%左右,该方法不仅能耗高对设备损伤也大,不适用于工业应用,因此,采用碱浸直接从铁酸锌中回收锌是不合理的,需要对铁酸锌进行预处理破坏铁酸锌结构。

为了有效回收锌和实现锌铁分离,本文作者提出了铁酸锌还原焙烧-碱法浸锌的工艺研究,在CO还原分解铁酸锌工艺[7, 24-25]的基础上利用氢氧化钠体系选择性浸出锌,铁氧化物进入渣中留待后续回收。主要研究了还原焙烧条件以及碱浸条件对锌回收率以及锌铁分离效果的影响,并采用XRD对焙烧产物以及浸出渣物相进行检测,采用SED-EDS检测分析浸出渣成分分布情况。

1 实验

1.1 实验原料

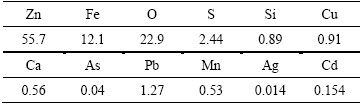

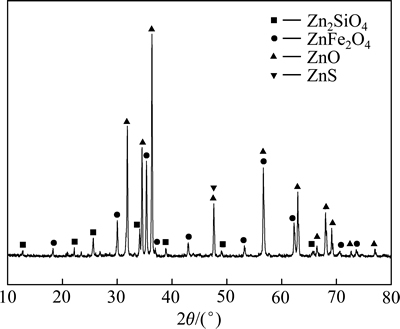

本实验中所用高铁锌焙砂取自内蒙古某湿法炼锌厂,为褐色粉末状样品,易受潮结块。取样品置于105 ℃烘箱烘干至恒量,磨碎过孔径74 μm的标准筛,取适量筛下样品进行XRF分析,分析结果如表1所示,其中锌品位为55.7%、铁品位为12.1%。结合样品XRD谱(见图1)及化学组成分析(见表2)可知:锌主要以氧化锌和铁酸锌形式存在,二者锌含量占总锌含量96%以上。提高铁酸锌中锌组分的浸出,实现浸出过程锌铁高效分离是本工艺的关键。

1.2 实验方法

1.2.1 焙烧实验

称取50 g样品于300 mL陶瓷坩埚中,将坩埚放入管式气氛炉中。样品在氮气流中以10 ℃/min的加热速率升温至预定温度,然后按设定的浓度通入还原气体CO与氮气组成的混合气体,反应结束后停止通入CO并停止加热,快速取出样品水淬冷却,105 ℃下烘干至恒量得到还原焙砂。

表1 锌焙砂的化学成分

Table 1 Chemical composition of zinc calcine (mass fraction, %)

图1 锌焙砂的XRD谱

Fig. 1 XRD pattern of zinc calcine

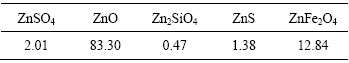

表2 锌焙砂中锌的物相分布

Table 2 Phase distributions of zinc presented in zinc calcine (mass fraction, %)

1.2.2 浸出实验

称取10 g还原焙砂(经研磨过孔径74 μm的标准筛)与一定固体氢氧化钠混合均匀倒入250 mL锥形瓶中,按一定的液固比加入去离子水,摇匀,盖上保鲜膜,在一定温度以及转速的振荡水浴箱中进行浸出,一定时间后取出趁热过滤,用去离子水洗渣三次并在105 ℃下烘干至恒量,取2 mL浸出液用EDTA滴定法分析锌含量,计算浸出率;将浸出液稀释50倍后进行ICP-AES分析,测定铁的浸出率。并对浸出渣进行XRD以及SED-EDS检测,分析浸出渣的物相组成以及颗粒层成分分布。

2 结果与讨论

2.1 还原焙烧工艺

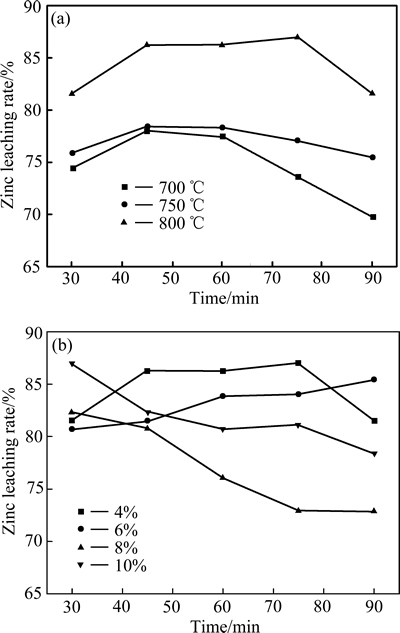

用CO气体对高铁锌焙砂进行还原焙烧,得到的还原焙砂在相同条件下浸出:浸出温度80 ℃、浸出时间30 min、液固比10:1、初始碱度5 mol/L,考察不同焙烧条件下锌的浸出率变化。准确称取50 g锌焙砂于坩埚中,分别在不同CO浓度(体积分数,下同)以及温度下进行焙烧实验,实验结果如图2所示。

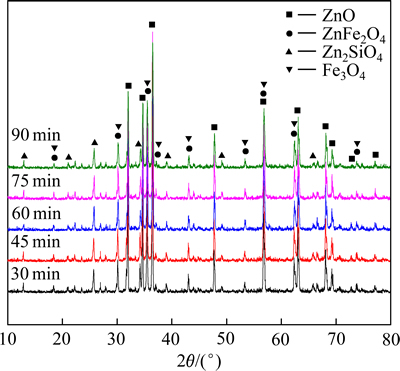

由图2(a)可知,固定CO的浓度,焙烧温度对还原焙烧效果影响较大。CO浓度为4%时,锌浸出率随焙烧温度的升高而增大,尤其是温度达到800℃时,锌浸出率显著提高,比750 ℃升高10%左右达到87%,说明升高温度有利于铁酸锌的还原,增加可溶锌的含量,但各温度下锌浸出率随焙烧时间的变化不大,时间过久反而有所下降,这是由于随着焙烧时间的延长,产物层不断变厚,使得产物内部部分与还原气体接触不充分从而形成铁锌固溶体。图3所示为700 ℃不同焙烧时间后的XRD谱。由图3可以看出,随着焙烧时间延长,氧化锌特征峰强度有所下降(见图3衍射角68°附近),说明随时间延长,氧化锌晶型变差。因此,当CO浓度为4%时,较优焙烧温度为800 ℃,焙烧时间以40~75 min范围内为宜。

由图2(b)可知,当焙烧温度800 ℃时,CO浓度的增加可加快还原反应的速度,提高锌浸出率,尤其当CO浓度超过8%,但该现象仅限于反应初始阶段 (30 min以内),时间超过40 min以后,基本上CO浓度4%的焙烧效果最好,且随着CO浓度的增加呈先下降后上升的趋势,这是由于焙烧时间延长,使得快速生成的还原产物固溶成铁锌固溶体造成锌浸出率下 降[26],后续对碱浸渣分析也证明,锌铁固溶体的生成。综合能源消耗经济因素,在800 ℃下,选择CO浓度4%,焙烧时间45 min;在该条件下浸出率比原样浸出率提高11.4%,说明还原焙烧可以有效分解铁酸锌,提高锌的回收率。

图2 不同焙烧时间下焙烧温度以及CO浓度对锌浸出率的影响

Fig. 2 Effects of roasting temperature(a) and CO concentration(b) on zinc leaching rate at different roasting time

图3 700 ℃焙烧不同焙烧时间还原焙砂的XRD谱

Fig. 3 XRD patterns of reduction roasted zinc at 700 ℃ for various time

2.2 碱性浸出工艺

2.2.1 还原焙砂碱性浸出

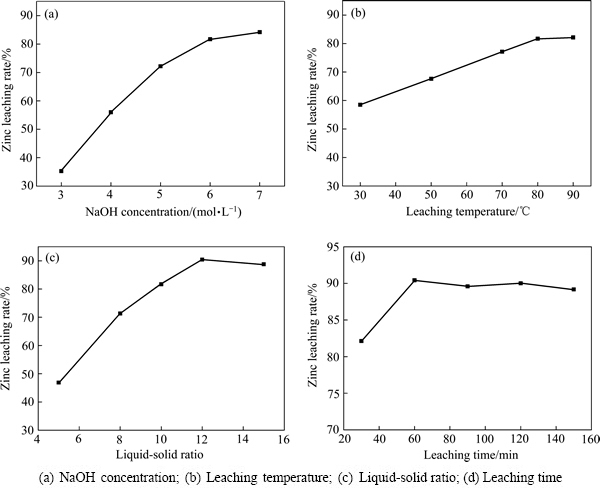

为进一步提高锌浸出率,对最佳焙烧条件下获得的还原焙烧产物在不同NaOH浓度、温度、液固比以及浸出时间下进行浸出实验,各实验条件对锌浸出率的影响如图4所示。

由图4(a)可知,氢氧化钠浓度对锌浸出效果影响大,在温度80 ℃,液固比10:1,浸出时间60 min条件下,锌浸出率随着浓度的增加而增加,当氢氧化钠浓度由3 mol/L增加到7 mol/L时,锌浸出率由35.3%上升到84.2%,且前期增加较快,当达到6 mol/L时,上升速度变缓,说明该浓度已经足够反应的需要。由图4(b)可知,锌浸出率随温度升高线性增加,当温度超过80 ℃后,锌浸出率增加速度变缓,几乎可忽略不计,因此,选择80 ℃为最佳温度。从图4(c)可看出,液固比对锌浸出率的影响也较大,其变化趋势与浓度对锌浸出率的影响相差不大,在液固比为12:1时达到最大,此时的浸出率有90.4%,再增大反而下降,这可能是由于液体过多,搅拌不充分引起。由图4(d)可知,时间对锌浸出率影响相对较小,当浸出时间超过60 min后,锌浸出率变化不大,因此选择浸出时间60 min。综上所述可知,最佳浸出条件为NaOH浓度6 mol/L,温度80 ℃,液固比12:1,浸出时间60 min。

图4 各实验条件对锌浸出率的影响

Fig. 4 Effect of different experiment conditions on leaching rate of Zn

在上述最佳条件下锌浸出率达到90.4%,由于铁不能碱性浸出,采用ICP-AES分析检测铁的浸出率,其结果见表3,由表3可知,浸出液中含有大量的锌、钠元素,而铁、铝、铅等元素含量很低,可忽略不计,说明铁基本存留在浸出渣中,其他杂质元素的浸出也较低,利于后续沉锌处理,通过计算可得铁浸出率只有0.25%。

表3 碱浸液主要化学组成

Table 3 Chemical component of alkaline leaching solution (mg/L)

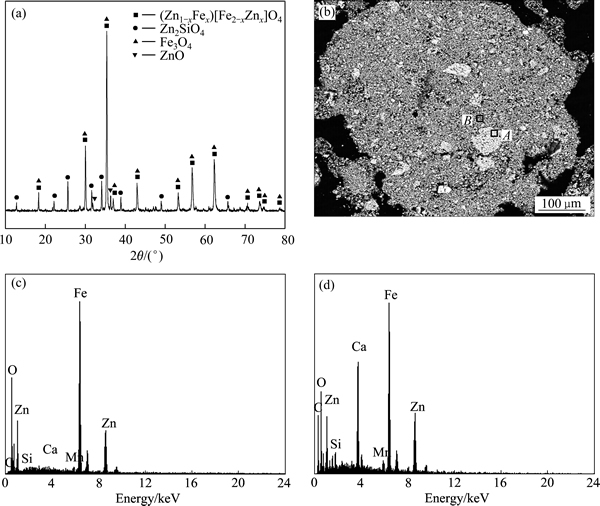

2.2.2 浸出渣XRD及SEM-EDS分析

取2.2.1节最佳浸出条件下的浸出渣进行XRD以及SEM-EDS分析,其结果如图5所示。由图5可以看出,浸出渣中基本无氧化锌特征峰,主要为锌铁氧化物,说明在该条件下,可溶性锌基本被浸出,而铁富集于渣中。由浸出渣的SEM-EDS图可知,浸渣颗粒成分主要为Zn、Fe、O元素,且锌铁氧化物相互镶嵌,该现象是造成锌浸出率不能进一步提高的主要原因;颗粒不同区域不同的亮度是由于不同的铁锌含量引起的,A点铁锌含量高达74.6%,可能为形成的铁锌固溶体[27],而B点铁锌含量只有44.4%。

图5 碱浸渣的XRD谱及SEM像和EDS图

Fig. 5 XRD pattern(a) and SEM image(b) of alkaline leaching residues and EDS spectra of areas A(c) and B(d)

3 结论

1) 高铁锌焙砂经过CO还原焙烧-碱浸工艺处理,可以提高锌的回收率和基本实现锌铁分离,实验结果表明焙烧温度、焙烧时间、氢氧化钠浓度、温度以及液固比对锌浸出效果影响较大,其最佳工艺条件为焙烧温度800 ℃,CO浓度4%(体积分数),焙烧时间45 min,NaOH浓度6 mol/L,浸出温度80 ℃,液固比12:1,浸出时间60 min,此条件下锌浸出率达90.4%,而铁的浸出率只有0.25%。

2) 浸出渣中铁锌氧化物互相镶嵌现象严重,这是锌回收率不能进一步提高的主要原因,有待于进一步研究。

REFERENCES

[1]  ATA O N. Optimization of dissolution of metals from waelz sintering waste (wsw) by hydrochloric acid solutions[J]. Chemical Engineering Journal, 2010, 162(2): 718-722.

ATA O N. Optimization of dissolution of metals from waelz sintering waste (wsw) by hydrochloric acid solutions[J]. Chemical Engineering Journal, 2010, 162(2): 718-722.

[2] 王纪明, 彭 兵, 柴立元, 李 密, 彭宁. 锌浸渣还原焙烧-磁选回收铁[J]. 中国有色金属学报, 2012, 22(5): 1455-1461.

WANG Ji-ming, PENG Bing, CHAI Li-yuan, LI Mi, PENG Ning. Recovery of iron from zinc leaching residues by reduction roasting and magnetic separation process[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(5): 1455-1461.

[3] NAGIB S, INOUE K. Recovery of lead and zinc from fly ash generated from municipal incineration plants by means of acid and/or alkaline leaching[J]. Hydrometallurgy, 2000, 56(3): 269-292.

[4] LECLERC N, MEUX E, LECUIRE J M. Hydrometallurgical extraction of zinc from zinc ferrites[J]. Hydrometallurgy, 2003, 70(1/3): 175-183.

[5] ZHANG Cheng-long, WANG Jing-wei, BAI Jian-feng, ZHAO You-cai. Recovering of zinc from solid waste bearing sphalerite or zinc ferrite by mechano-chemical extraction in alkaline solution[J]. Procedia Environmental Sciences, 2012, 16: 786-790.

[6] ZHANG Ya-li, YU Xian-jin, LI Xiao-bin. Zinc recovery from franklinite by sulphation roasting[J]. Hydrometallurgy, 2011, 109: 211-214.

[7] PENG Ning, PENG Bing, CHAI Li-yuan, LIU Wei, LI Mi, YUAN Yuan, YAN Huan, HOU Dong-kou. Decomposition of zinc ferrite in zinc leaching residue by reduction roasting[J]. Procedia Environmental Sciences, 2012, 16(4): 705-714.

[8] WANG Xin, YANG Da-jin, JU Shao-hua, PENG Jin-hui, DUAN Xin-hui. Thermodynamics and kinetics of carbothermal reduction of zinc ferrite by microwave heating[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3808-3815.

[9] XIA D K, PICKLES C A. Kinetics of zinc ferrite leaching in caustic media in the deceleratory period[J]. Minerals Engineering, 1999, 12(6): 693-700.

[10] DUTRA A J B, PAIVA P R P, TAVARES L M. Alkaline leaching of zinc from electric arc furnace steel dust[J]. Minerals Engineering, 2006, 19(5): 478-485.

[11] ASHTARI P, POURGHAHRAMANI P. Selective mechanochemical alkaline leaching of zinc from zinc plant residue[J]. Hydrometallurgy, 2015, 156: 165-172.

[12] YAN Huan, CHAI Li-yuan, PENG Bing, LI Mi, PENG Ning, HOU Dong-kou. A novel method to recover zinc and iron from zinc leaching residue[J]. Minerals Engineering, 2014, 55: 103-110.

[13] 侯栋科, 彭 兵, 柴立元, 彭 宁, 闫 缓, 胡 明. 锌焙砂的选择性还原焙烧硫酸浸出工艺研究[J]. 有色金属科学与工程, 2014, 5(1): 1-8.

HOU Dong-kou, PENG Bing, CHAI Li-yuan, PENG Ning, YAN Huan, HU Ming. Zinc recovery from zinc calcine by selective reduction roasting and acid leaching[J]. Nonferrous Metals Science and Engineering, 2014, 5(1): 1-8.

[14] 彭 兵, 李燕春, 柴立元, 刘 恢, 闵小波, 胡 明, 袁莹珍, 雷 杰, 彭 宁. 锌浸渣硫酸铵焙烧-选择性浸出回收锌[J]. 中国有色金属学报, 2015, 25(9): 2596-2603.

PENG Bing, LI Yan-chun, CHAI Li-yuan, LIU Hui, MIN Xiao-bo, HU Ming, YUAN Ying-zhen, LEI Jie, PENG Ning. Recovery of zinc from zinc leaching residue by ammonia sulfate roasting-selective leaching[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(9): 2596-2603.

[15] GARGUL K, BORYCZKO B. Removal of zinc from dusts and sludges from basic oxygen furnaces in the process of ammoniacal leaching[J]. Archives of Civil and Mechanical Engineering, 2015, 15(1): 179-187.

[16] JU Shao-hua, ZHANG Yi-fei, ZHANG Yi, XUE Pei-yi, WANG Yi-hui. Clean hydrometallurgical route to recover zinc, silver, lead, copper, cadmium and iron from hazardous jarosite residues produced during zinc hydrometallurgy[J]. Journal of Hazardous Materials, 2011, 192(2): 554-558.

[17] ORHAN G. Leaching and cementation of heavy metals from electric arc furnace dust in alkaline medium[J]. Hydrometallurgy, 2005, 78: 236-245.

[18] NOGUEIRA C A, MARGARIDO F. Selective process of zinc extraction from spent Zn-MnO2 batteries by ammonium chloride leaching[J]. Hydrometallurgy, 2015, 157: 13-21.

[19]  M, ERDEM M. Cleaning of high lead-bearing zinc leaching residue by recovery of lead with alkaline leaching[J]. Hydrometallurgy, 2015, 153: 170-178.

M, ERDEM M. Cleaning of high lead-bearing zinc leaching residue by recovery of lead with alkaline leaching[J]. Hydrometallurgy, 2015, 153: 170-178.

[20] 韦岩松, 潘恒开. 从铅锑冶炼鼓风炉水淬渣中碱浸锌的试验研究[J]. 湿法冶金, 2013, 32(3): 158-160.

WEI Yan-song, PAN Heng-kai. Experimental study on alkaline leaching of zinc from blast furnace water-quenched slag in lead and antimong metallurgical process[J]. Hydrometallurgy of China, 2013, 32(3): 158-160.

[21] ERDEM M, YURTEN M. Kinetics of Pb and Zn leaching from zinc plant residue by sodium hydroxide[J]. Journal of Mining and Metallurgy, Section B: Metallurgy, 2015, 51(1): 89-95.

[22] XIA D K, PICKLESI C A. Microwave caustic leaching of electric arc furnace dust[J]. Minerals Engineering, 2000, 13(1): 79-94.

[23] YOUCAI Z, STANFORTH R. Extraction of zinc from zinc ferrites by fusion with caustic soda[J]. Minerals Engineering, 2000, 13(13): 1417-1421.

[24] YU Gang, PENG Ning, ZHOU Lan, LIANG Yan-jie, ZHOU Xiao-yuan, PENG Bing, CHAI Li-yuan, YANG Zhi-hui. Selective reduction process of zinc ferrite and its application in treatment of zinc leaching residues[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(8): 2744-2752.

[25] 陈 栋, 彭 兵, 柴立元, 彭 宁, 胡 明, 李燕春. 铁酸锌选择性还原方法及其在锌焙砂处理中的应用[J]. 中国有色金属学报, 2015, 25(8): 2284-2292.

CHEN Dong, PENG Bing, CHAI Li-yuan, PENG Ning, HU Ming, LI Yan-chun. Selective reduction reaction process of zinc ferrite and its application in treatment of zinc calcine[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(8): 2284-2292.

[26] 侯栋科, 彭 兵, 柴立元, 彭 宁, 闫 缓. 铁酸锌选择性还原的反应机理[J]. 中国有色金属学报, 2014, 24(10): 2634-2641.

HOU Dong-ke, PENG Bing, CHAI Li-yuan, PENG Ning, YAN Huan. Selective reduction mechanism of zinc ferrite[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(10): 2634-2641.

[27] 李 密. 锌焙砂选择性还原与铁锌分离的基础研究[D]. 长沙: 中南大学, 2013: 76-89.

LI Mi. Fundamental research on selective reduction of zinc calcine and separation of zinc and iron[D]. Changsha: Central South University, 2013: 76-89.

Alkaline leaching zinc from high iron-bearing zinc calcine after reduction roasting

PENG Bing1, 2, LIN Dong-hong1, LIU Hui1, 2, PENG Ning1, CHEN Dong1, LI Yan-chun1, YUAN Ying-zhen1

(1. School of Metallurgy and Environment, Central South University, Changsha 410083, China;

2. Chinese National Engineering Research Center for Control and Treatment of Heavy Metal Pollution, Central South University, Changsha 410083, China)

Abstract: To resolve the problem of zinc-iron separation of zinc ferrite in conventional zinc smelting process, a reduction roasting-alkaline leaching process was proposed. Zinc ferrite in high iron-bearing zinc calcine was decomposed to zinc oxide and iron oxide by reduction roasting, then, zinc oxide was selectively leached in alkaline system, the iron oxide remained in the leaching residues. The effects of roasting conditions and leaching conditions on the separation of zinc-iron were evaluated by the leaching rate of zinc and iron. The roasted products and leaching residues were analyzed by XRD and SEM-EDS. The results show that the optimal roasting condition as follows: roasting temperature of 800 ℃, CO concentration of 4% (volume fraction), roasting time of 45 min; the optimal leaching condition is leaching temperature of 80 ℃, NaOH concentration of 6 mol/L, liquid-solid ratio of 12:1 and leaching time of 60 min. Under this optimal condition, the leaching rates of zinc and iron are 90.4% and 0.25%, respectively. But the analysis result of SEM-EDS shows that the mosaic phenomenon of zinc oxide and iron oxide in leaching residue is serious, this is the reason why the leaching rate of zinc is hard to be further improved.

Key words: zinc ferrite; high iron-bearing zinc calcine; reduction roasting; alkaline leaching

Foundation item: Project(51574295) supported by the National Natural Science Foundation of China; Project (2014FJ1011) supported by the Major Science and Technology Project of Hunan Province, China

Received date: 2015-12-28; Accepted date: 2016-05-10

Corresponding author: LIU Hui; Tel: +86-731-88830875; E-mail: leolau@csu.edu.cn

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51574295);湖南省科技重大专项资助项目(2014FJ1011)

收稿日期:2015-12-28;修订日期:2016-05-10

通信作者:刘 恢,研究员,博士;电话:0731-88830875;E-mail: leolau@csu.edu.cn