文章编号:1004-0609(2013)S1-s0374-07

TC4薄壁壳体焊缝裂纹分析

柳 军,刘志颖,晏阳阳,王 洋,胡光远

(洛阳船舶材料研究所,洛阳 471039)

摘 要:采用氮氢氧气体分析仪、金相显微镜、扫描电子显微镜及能谱仪、显微硬度计、三维视频显微镜分析壳体焊缝三维裂纹外观、裂纹抛光形态、裂纹低倍形态、裂纹横截面形貌、裂纹附近显微硬度、内壁裂纹形态、裂纹断口形貌。结果表明:薄壁壳体穿透型裂纹为氢脆导致的延迟开裂失效,是典型的氢致裂纹现象,这主要是焊前清理不当、焊后没有及时热处理以及酸洗后没有进行去氢热处理造成的。

关键词:钛合金;焊缝;裂纹;氢脆;热处理

中图分类号:TG146.2 文献标志码:A

Analysis of TC4 thin-walled shell weld crack

LIU Jun, LIU Zhi-ying, YAN Yang-yang, WANG Yang, HU Guang-yuan

(Luoyang Ship Material Research Institute, Luoyang 471039, China)

Abstract: The shell weld appearance, three-dimensional crack morphology, polishing form low times, crack cross section morphology, microhardness, near the crack wall crack, crack fracture surface morphology were analyzed by using nitrogen hydrogen gas analyzer, metallographic microscope, scanning electron microscope and energy spectrum instrument, microhardness tester, three-dimensional video microscopy. The results show that thin-walled shell penetrated crack for hydrogen embrittlement of the delayed cracking failure is typical of the hydrogen induced cracking phenomenon. It is improper cleaned before welding, welding not timely heat treatment and pickling is not caused by heat treatment to hydrogen.

Key words: titanium alloy; weld metal; cracking; hydrogen embrittlement; heat treatment

钛合金经过40多年的研究和开发,已广泛应用于航天、航空、石油化工、造船等各个领域[1-2]。钛合金的使用主要基于以下几个原因:1)可降低工件质量;2)抗腐蚀性好(代替钢和Ni基合金);3)减小体积(代替Al合金);4)适用于高温应用(代替Al,Ni和Fe基合金)[3]。随着钛合金加工技术的发展,钛合金应用已逐渐由性能要求推动逐渐转向如何降低工件的使用成 本[4],薄壁钛合金构件基于上述原因在许多领域逐渐广泛应用。本文作者以TC4薄壁壳体为某滤器用筒体类结构件,产品使用过程中承受较高压力,因此,壳体及其焊缝强度均要求较高。

1 实验

1.1 工件材料及加工过程

该薄壁壳体为TC4合金,发现渗漏,经分析该渗

漏处出现裂纹。壳体加工工艺为:950热成形—焊接管嘴环缝—真空去应力退火(500 ℃,1 h,3次)—整体酸洗2次—1.2 MPa内部气压试验—1.62 MPa内部水压试验—真空退火(720 ℃,3 h)—化学镀镍—除氢(320 ℃,1 h) —3.14 MPa内部油压试验。

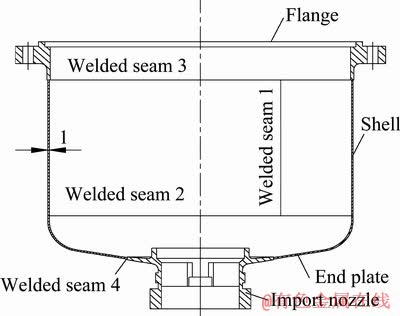

TC4薄壁壳体示意图见图1,底部环焊缝周围附近着色探伤有裂纹显示,除了一条长的裂纹外周围环有一些小的裂纹显示痕迹。

1.2 分析方法

采用线切割方法切取裂纹部分,分别进行化学成分、宏观形貌分析、金相组织分析和断口形貌分析等。

1.3 分析设备

分析裂纹主要采用的设备为TCH600氮氢氧气体分析仪、OLYMPUS GX71金相显微镜、FEI Quanta 600扫描电子显微镜及EDAX Genesis XM2能谱仪、VMH-I04显微硬度计、VHX-600E三维视频显微镜等。

图1 TC4薄壁壳体示意图

Fig.1 Schematic diagram of TC4 thin-walled shell

2 结果与分析

2.1 化学成分

对底部焊缝附近取样进行H、O含量测定,其结果见表1。结果表明:材料中H含量较高,O含量超过标准要求。

表1 底部焊缝成分分析结果

Table 1 Result of composition analysis of welding line at bottom (mass fraction, %)

2.2 裂纹外观分析

对裂纹进行三维视频显微镜分析,壳体内壁裂纹见图2(a),放大形貌见图2(b),下部裂纹(靠近壳体中轴)较深,定义为Ⅰ型裂纹,上部裂纹与下部裂纹呈一定夹角,较浅且钝,定义为Ⅱ型裂纹。对内壁其他区域着色,发现也存在微裂纹,与内壁中的Ⅱ型裂纹相同。壳体外壁只发现一条裂纹,裂纹长约16 mm,裂纹形态见图3(a),放大形貌见图3(b),呈现折线状,与内壁的Ⅰ型裂纹相同,从位置上看,应为贯穿内外壁造成泄漏的裂纹。

图2 内壁裂纹形态

Fig.2 Morphologies of inwall crack

图3 外壁裂纹形态

Fig.3 Morphologies of ectotheca crack

2.3 金相分析

2.3.1 表面裂纹抛光态观察

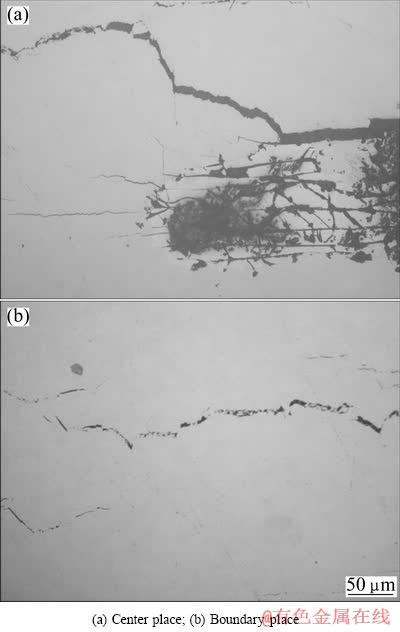

抛光态观察,裂纹形态见图4,裂纹呈现折线状,有很多近似平行的裂纹,放大形貌见图5。

图4 裂纹抛光形貌

Fig.4 Crack shapes by polish

图5 裂纹放大形貌

Fig.5 Enlargement crack shapes by polish

2.3.2 表面浸蚀裂纹形态及金相组织

裂纹低倍形态见图6,在其周围为焊缝组织,放大后见图7。裂纹在焊缝内,为穿晶型,焊缝热影响区有微裂纹。

图6 裂纹低倍形貌

Fig.6 Crack shapes of low power

图7 裂纹放大形貌

Fig.7 Enlargement crack shapes

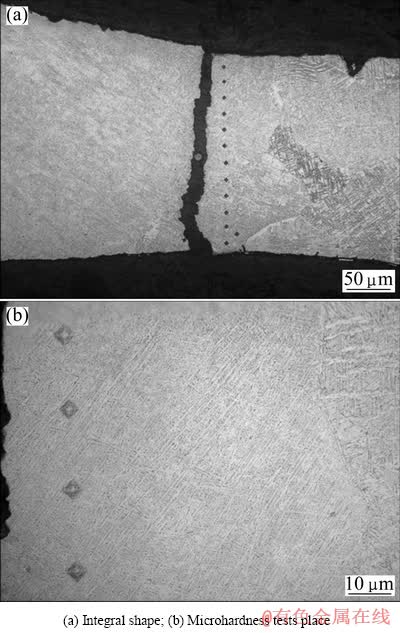

2.3.3 截面裂纹形态

裂纹横截面形貌见图8,裂纹在焊缝中生成和扩展,最终导致薄壁壳体穿透泄漏(图8(a)),裂纹旁边的压痕为显微硬度测试点(图8(b))。从裂纹处焊缝厚度看,焊缝厚度只有0.71 mm,低于TC4板材厚度,焊缝处强度低于母材的强度。

图8 裂纹截面形貌

Fig.8 Morphologies of cross-section crack

2.3.4 裂纹附近显微硬度分析

从上述分析可以看出:Ⅰ型穿透裂纹从外壁开裂,穿透至内壁导致泄漏,在裂纹附近沿壁厚方向从外壁到内壁进行显微硬度分析,结果可以看到裂纹源区硬度最高,心部相对较低,如图9所示。从外表面裂纹尖端附近到基体进行硬度分析,也同样显示裂纹尖端附近硬度明显高于基体硬度,如图10所示。材料裂纹源焊缝处硬度远高于基体硬度,材料脆化导致裂纹产生。

2.4 扫描电镜分析

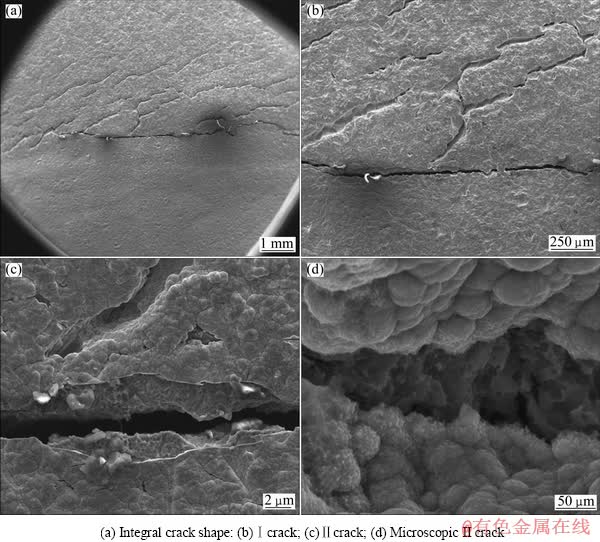

2.4.1 壳体裂纹形态观察

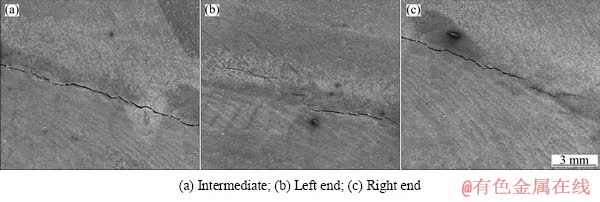

壳体内壁裂纹形态见图11,下部一条裂纹为Ⅰ型裂纹,与下部裂纹呈一定角度有众多Ⅱ型裂纹(图11(a)),放大后可以看到Ⅰ型裂纹很深(图11(b)),Ⅱ型裂纹相对浅且钝(图11(c)),高倍下可以看到Ⅱ型裂纹内的化学镀形成的晶胞(图11(d))。壳体外壁只有一条裂纹,裂纹中部形态见图12(a),裂纹形态两端形貌见图12(b)和图12(c),裂纹呈现折线状。裂纹放大形貌见图13,裂纹为Ⅰ型裂纹。

图9 横截面显微硬度

Fig.9 Microhardness of cross-section

图10 外表面裂纹尖端到基体硬度数据

Fig.10 Hardness data in exterior surface crack tip with basal body

2.4.2 壳体裂纹断口分析

裂纹断口形貌见图14,断口上部有三分之一形态为硬化层,裂纹起源于外硬化层表面,为多源断裂。裂纹源放大形貌见图15(a),可以看到裂纹源附近有很多大小不等的气孔。裂纹扩展区形貌,见图15(b),靠近内壁处有少量剪切特征,见图15(c)。

2.5 分析与讨论

实际上,许多焊接手段均可以用来焊接钛合金。由于在焊接过程中引入的空气中的N2、O2和含碳物质使得钛合金的熔化焊接头变脆[5],因此,待焊区一定要清理干净并使用高纯度惰性气体保护。

图11 内壁裂纹扫描电镜形态

Fig.11 Stereoscan photographs of inwall crack

图12 外壁裂纹形态

Fig.12 Morphologies of ectotheca crack

图13 外壁裂纹放大形态

Fig.13 Morphologies of ectotheca crack of enlargement

图14 裂纹断口形貌

Fig.14 Crack shape of fracture

图15 裂纹源形貌

Fig.15 Crack source shapes

钛合金焊接接头中气孔的产生主要受焊接前的清洁程度和焊接接头的准备以及焊接时间长短的影响,表面不清洁导致的吸氢是弧焊接头气孔产生的主要原因[6-7]。

试验分析中可以看出:板材中H和O含量较高,导致材料变硬、变脆,裂纹源处存在较多的气孔,说明材料焊接工艺存在一定问题,如表面清理不彻底,惰性气体保护不充分等,裂纹源处硬度最高,说明这里H和O等杂质含量最高。

金相分析和扫描电镜分析都表明裂纹形态为折线状,裂纹在焊缝中生成和扩展,裂纹有两种形态,一种为化学镀前已经形成,但未导致薄壁壳体失效,另一种为化学镀后过了一段时间形成,并导致薄壁壳体泄漏。Ⅰ型裂纹为折线状,裂纹较平直、分叉少且裂纹断口断面清晰、整齐,呈脆性断裂,材料裂纹源焊缝处硬度远高于基体,材料明显脆化,具有氢脆裂纹的典型特征[8-10]。Ⅱ型裂纹为化学镀前形成,裂纹呈现比较钝且不深,应为材料表面局部杂质含量如O等较高,造成材料表面局部硬化,塑性变差,在加工过程中形成。

从上述各种特征表明薄壁壳体穿透型裂纹为氢脆导致的延迟开裂失效,是典型的氢致裂纹现象,这主要是焊接工艺以及焊接后没有及时热处理,以及酸洗、化学镀后没有及时去氢热处理造成的;焊缝高度不足,裂纹源处焊缝厚度只有母材的70%左右,焊缝强度较低,是产生裂纹的次要原因;化学镀前形成的浅而钝的裂纹为表面局部硬化,生产过程中形成表面微裂纹。

3 结论

1) 薄壁壳体裂纹是由于氢脆导致的延迟开裂造成的。

2) 氢脆裂纹为穿透裂纹在化学镀镍后产生,另一种较浅的微裂纹在化学镀镍前产生。

3) 焊接工艺不合理是产生裂纹的次要原因。

4) 工件在焊接前应对焊丝和焊接件表面进行充分的预处理,在焊接过程中焊缝要保护充分且氩气纯度要高,焊缝高度要高于母材,工件焊接、酸洗、化学镀后应立即进行去氢处理。

REFERENCES

[1] 张文毓.国外钛合金的研究与发展[J].世界有色金属, 2009(7): 64-66.

ZHANG Wen-yu. Research and development of titanium alloys in foreign countries[J]. World Nonferrous Metals, 2009(7): 64-66.

[2] 赵永庆. 国内外钛合金研究的发展现状及趋势[J]. 中国材料进展, 2010, 29(5): 1-8.

ZHAO Yong-qing. Current situation and development trend of titanium alloys[J]. Materials China, 2010, 29(5): 1-8.

[3] 肖树龙, 陈玉勇, 朱洪艳, 等. 大型复杂薄壁钛合金铸件熔模精密铸造研究现状及发展[J]. 稀有金属材料与工程, 2006, 35(5): 678-681.

XIAO Shu-long, CHEN Yu-yong, ZHU Hong-yan, et al. Recent advances on precision casting of large thin wall complex castings of titanium alloys[J]. Rare Metal Materials and Engineering, 2006, 35(5): 678-681.

[4] 赵永庆, 魏建峰, 高占军, 等. 钛合金的应用和低沉本制造技术[J]. 材料导报, 2003, 17(4): 5-7.

ZHAO Yong-qing, WEI Jian-feng, GAO Zhan-jun, et al. Current status of application and low cost manufacturing technologies[J]. Materials Review, 2003, 17(4): 5-7.

[5] HARWIG D D, FOUNTAIN C, ITTIWATTANA W, CASTNER H. Oxygen equivalent effects on the mechanical properties of titanium welds[J]. Welding Research, 2000(11): 305-316.

[6] 赵敬东. 钛合金焊接的常见缺陷及其预防[J]. 焊接学报, 2000(5): 56-59.

ZHAO Jing-dong. The Welding common flaw and preventive of titanium alloys[J]. Transactions of the China Welding Institution, 2000(5): 56-59.

[7] 樊兆宝. TC4钛合金壳体的手工氩弧焊工艺[J]. 电焊机, 2007, 37(7): 25-27.

FAN Zhao-bao. Manual argon welding technology of TC4 titanium alloy shell[J]. Electic Welding Machine, 2007, 37(7): 25-27.

[8] 刘彦章, 黄新泉, 丘绍宇, 等. Ti-Al-Zr合金的氢致脆性研究[J]. 核动力工程, 2005, 26(5): 456-460.

LIU Yan-zhang, HUANG Xin-quan, QIU Shao-yu, et al. Hydrogen embrittlement of Ti-Al-Zr alloy[J]. Nuclear Power Engineering, 2005, 26(5): 456-460.

[9] 杨彦涛, 王禹华, 张永洋. 氢对钛合金的影响[J]. 材料开发与应用, 2009, 24(1): 69-72.

YANG Yan-tao, WANG Yu-hua, ZHANG Yong-yang. Impact of hydrogen on titanium alloys[J]. Development and Application of Materials, 2009, 24(1): 69-72.

[10] 褚武扬. 氢损伤和滞后断裂[M]. 北京: 冶金工业出版社, 1988: 341-352.

CHU Wu-yang. Hydrogen damage and delayed fracture[M]. Beijing: Metallurgical Industry Press, 1988: 341-352.

(编辑 杨幼平)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:柳 军,工程师;电话:0379-67256050;E-mail:ravidy@tom.com