文章编号:1004-0609(2010)S1-s0815-04

BTi62钛合金锻造工艺

杨慧丽1,李晓维2,羊玉兰1,马恩惠1,李冬梅1

(1. 宝钛集团有限公司,宝鸡 721014;

2. 国核宝钛锆业股份公司,宝鸡 721014)

摘 要:研究不同锻造工艺生产的BTi62钛合金棒材对组织、性能的影响。结果表明:BTi62钛合金采用β锻造工艺和α+β两相区锻造工艺生产的棒材,均可获得良好的组织与性能,可以达到设计要求。采用β锻造工艺,由于变形抗力较小,锻造火次少,生产效率高,容易操作,建议生产时采用该工艺。

关键词:BTi62钛合金;棒材;热处理;组织

中图分类号:TG146 文献标志码:A

Forging process of BTi62 titanium alloy

YANG Hui-li1, LI Xiao-wei2, YANG Yu-lan1, MA En-hui1, LI Dong-mei1

(1. Baoti Group Co., Ltd., Baoji 721014, China;

2. State Nuclear Baoti Zirconium Industry Company, Baoji 721014, China)

Abstract: The effects of different forging processes on microstructure and mechanical properties of BTi62 titanium alloy bars were studied. The results show that the titanium alloy BTi62 bars produced through β forging process and two phase region (α+β) forging process have good microstructure and properties which can meet the design requirements. By β forging process, the production efficiency is high and it is easy to operate due to the small resistance of deformation and less forging times. This process is proposed to be adopted.

Key words: titanium alloy BTi62; bars; heat treatment; microstructure

钛合金具有比强度高、耐腐蚀、高温性能好、无磁性和高韧性等特点,广泛应用于航空、航天、舰船和兵器等领域。国内外针对钛合金的优点展开了许多研究,逐渐用钛合金替代钢。目前,国内外广泛使用的钛合金主要有TC4(Ti-6Al-4V)和Ti-6Al-2Sn-4Zr- 2Mo等。但由于钛合金原料较贵,熔炼和加工困难,致使生产成本很高,通常为钢的8~10倍,大大限制了钛合金的应用。TC4(Ti-6Al-4V)合金属于典型的α+β两相合金,该合金是美国20世纪50年代研制,具有优异的综合性能,良好的工艺塑性和超塑性,适合于各种压力加工成形,在航空、航天工业中获得广泛应用。可用于制作工作温度400 ℃以下的各类零件,占钛合金使用量的一半以上。我国20世纪50年代末和60年代初开始研究和试生产Ti-6Al-4V合金。1970年冶标将其定名为TC4合金。该合金是我国引进、仿制的诸多钛合金中生产和应用最为成熟的合金之一。由于Mo和V在钛合金中均为同晶型β稳定元素,但相对来说,我国钼资源蕴藏比钒资源丰富,钼矿的使用潜力较大。

BTi62钛合金是宝钛集团有限公司新研制的一种Ti-Al-Mo系合金,该合金采用元素Mo代替元素V,属于近α型钛合金,具有近α型钛合金的优点。可用于航空、航天、舰船等场所。

本文作者研究该合金热加工工艺与组织性能的关系,为制定该合金生产工艺提供技术保证基础。

1 实验

1.1 试验材料

试验用材料采用真空自耗电弧炉3次熔炼的BTi62钛合金铸锭。铸锭的β相转变温度为:Tβ为 1 000~1 020 ℃。铸锭在2500T快锻机、3150T水压机及SXP精锻机进行锻造,得到d 27.5 mm的成品棒材。

1.2 试验方法

试验采用β锻造和α+β两相区两种锻造工艺生产d 27.5 mm的成品棒材[1]。棒材采用退火处理[2]。β锻造工艺简称工艺1,α+β两相区锻造工艺简称工艺2,具体锻造工艺如下。

工艺1:铸锭→1 200 ℃开坯锻造→中间坯料→相变点以上30~50 ℃多火次中间锻造→d 80中间坯料→相变点以下30~50 ℃→d 27.5 mm成品棒材

工艺2:铸锭→1 200 ℃开坯锻造→中间坯料→相变点以下30~50 ℃多火次中间锻造→d 80中间坯料→相变点以下30~50 ℃→d 27.5 mm成品棒材

在以上两种锻造工艺所得的d 27.5 mm的棒材上切取高倍试样和性能试样若干。试样热处理工艺为870 ℃,保温1.5 h,空冷。然后用光学显微镜观察该合金的组织形态,用拉伸试验机测试室温、高温拉伸性能,分析锻造工艺对显微组织、拉伸性能的影响。

2 结果与讨论

2.1 不同锻造工艺对应的锻态组织

图1所示为BTi62钛合金棒材不同锻造工艺的锻态组织。由图1可见,工艺1在d 80 mm中间坯料前所有锻造均在相变点以上进行,在d 80 mm中间坯料后成品锻造在相变点以下进行,变形量较大(为88%)。粗大的魏氏组织已经细化且均匀,组织为β基体上分布的片状α组织及等轴α组织;工艺2由于中间锻造和成品锻造均在相变点以下进行,锻后组织为典型的两相区加工组织,为β基体上分布的等轴α组织[3]。工艺1与工艺2高倍组织差异不大。但工艺1与工艺2相比,工艺1生产时变形温度较高,变形抗力较小,锻造火次较少,生产时容易操作。

2.2 不同锻造工艺热处理后的组织形态

图2所示为BTi62钛合金棒材相同热处理不同锻造工艺后的显微组织[4-5]。图2(a)对应工艺1组织;图

图1 BTi62经不同锻造工艺的锻态组织

Fig.1 Forging microstructures of BTi62 titanium alloy after different forging processes: (a) Process 1; (b) Process 2

图2 BTi62经相同热处理不同锻造工艺的显微组织

Fig.2 Microstructure of BTi62 titanium alloy after heat treatment and different forging processes: (a) Process 1; (b) Process 2

2(b)对应工艺2组织。由图2可见,图2(a)与图2(b)所得的显微组织差异不大,都为β转+等轴α组织。这是因为BTi62钛合金为近α型钛合金,这种合金对热处理制度不敏感。

2.3 不同锻造工艺对应的室温和高温拉伸性能

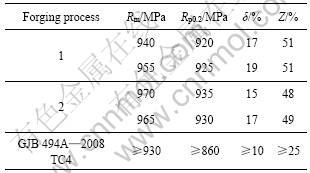

表1所列为不同锻造工艺生产的d 27.5 mm棒材热处理后的室温拉伸性能[6-7]。从表1可见,两种锻造工艺所得的d 27.5 mm棒材的室温拉伸性能强度与塑性匹配均较好,且在该温度处理后,屈服强度(Rp0.2)均不小于920 MPa。两种工艺生产的棒材室温拉伸均高于同规格TC4棒材。工艺1抗拉强度(Rm)比工艺2约低15 MPa,屈服强度约低5 MPa;伸长率(δ)和断面收缩率(Z)约高2%。

表1 退火后室温拉伸性能

Table 1 Room tensile properties of anneal for BTi62 titanium alloy

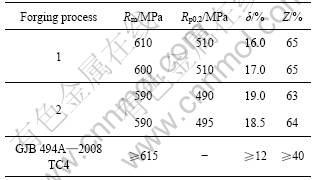

TC4(Ti-6Al-4V)合金主要用于450 ℃以下的工作温度,设计BTi62钛合金的目的是用元素Mo代替元素V得到性能与TC4(Ti-6Al-4V)相当的合金。目前,国标、国军标中TC4合金的高温拉伸指标均为400 ℃。所以研究BTi62时直接测定400 ℃高温拉伸性能与TC4同规格棒材进行对比。表2所列为热处理后d 27.5 mm棒材400 ℃时的高温拉伸性能。由表2可见,两种工艺生产的BTi62棒材实测高温性能,强度均比TC4的低,塑性均比TC4的高。工艺1和工艺2在400 ℃时的高温拉伸性能较好。屈服强度均在490 MPa以上,伸长率也保持在15%以上。工艺1的抗拉强度和屈服强度比工艺2的约高10 MPa;伸长率约低2%,断面收缩率约高1%[8-9]。

通过以上室温拉伸性能与高温拉伸性能的分析对比,工艺1与工艺2热处理后的室温拉伸性能和高温拉伸性能均达到设计要求。但工艺1高温拉伸性能比

表2 退火后高温拉伸性能

Table 2 High tensile properties of BTi62 titanium alloy after annealing

工艺2的稍好。且工艺1锻造火次较少,减少了中间修磨量,提高生产效率,且变形容易操作。所以建议实际生产时采用β锻造工艺。

3 结论

1) BTi62钛合金采用β锻造和α+β两相区锻造两种锻造工艺,均可获得强度与塑性匹配较好的组织。其室温屈服强度均不小于920 MPa,满足设计要求。

2) 在实际生产时,采用β锻造工艺,由于变形抗力较小,锻造火次少,生产效率高,经济效益好,容易操作,便于生产时采用。

REFERENCES

[1] 郭 强, 严红革, 陈振华, 张 辉. 多向锻造工艺对AZ80镁合金显微组织和力学性能的影响[J]. 金属学报, 2006, 42(7): 739-744.

GUO Qiang, YAN Hong-ge, CHEN Zhen-hua, ZHANG Hui. Effect of multiple forging process on micro structure and mechanical properties of magnesium alloy AZ80[J]. Acta Metallurgica Sinica, 2006, 42(7): 739-744.

[2] 储俊鹏, 张庆玲, 李兴无, 沙爱学, 贾栓孝, 刘惠芳, 王 俭, 魏寿庸. 普通退火对TA15合金拉伸性能的影响[J]. 金属学报, 2002, 38(z1): 81-83.

CHU Jun-peng. ZHANG Qing-ling, LI Xing-wu, SHA Ai-xue, JIA Shuan-xiao, LIU Hui-fang, WANG Jian, WEI Shou-yong. Effect of common annealing on tensile property of TA15 alloy[J]. Acta Metallurgica Sinica, 2002, 38(z1): 81-83.

[3] 李惠曲, 王淑云, 东赟鹏, 姜 涛. TC6钛合金棒材热处理组织与性能[J]. 稀有金属材料与工程, 2008, 37(Suppl 3): 464-466.

LI Hui-qu, WANG Shu-yun, DONG Yun-peng, JIANG Tiao. Microstructures and room temperature tensile properties of TC6 titanium alloy bars after different heat treatment[J]. Rare Metal Materials and Engineering, 2008, 37(Suppl 3): 464-466.

[4] 陈春和, 高灵清, 严中令. Ti-31合金微观结构的TEM研究[J]. 材料开发与应用, 1997, 12(5): 2-5.

CHEN Chun-he, GAO Ling-qing, YAN Zhong-ling. Study on microstructure of Ti-31 alloy by TEM[J]. Development and Application of Materials, 1997, 12(5): 2-5.

[5] 刘 勇, 刘瑞堂. 魏氏组织BT14合金应力松弛行为及微观机理[J]. 宇航材料工艺, 2008(1): 71-73.

LIU Yong, LIU Rui-tang. Stress relaxation behavior and micro-mechanism of BT14 alloy with Widmanstaten microstructure[J]. Space Navigation Materials Technology, 2008(1): 71-73.

[6] 李士凯, 惠松晓, 熊柏青. Ti-6Al-2Zr-1Mo-1V合金冲击韧性研究[J]. 稀有金属材料与工程, 2008, 37(Suppl 3): 590-593.

LI Shi-kai, HUI Song-xiao, XIONG Bai-qing. Study on the impact toughness of Ti-6Al-2Zr-1Mo-1V alloy[J]. Rare Metal Materials and Engineering, 2008, 37(Suppl 3): 590-593.

[7] 郑修麟. 材料力学性能[M]. 西安: 西北工业大学出版社, 1996.

ZHENG Xiu-lin. The tensile properties of materials[M]. Xi’an: Northwestern Polytechnical University Press, 1996.

[8] 许永光, 王 晶. TC4钛合金环形件的锻造工艺[J]. 稀有金属材料与工程, 2008, 37(Suppl 3): 68-70.

XU Yong-guang, WANG Jing. The forging process of TC4 titanium alloy ring[J]. Rare Metal Materials and Engineering, 2008, 37(Suppl 3): 68-70.

[9] 王惠光, 田 竞, 卢玉红, 齐秀梅, 罗文茜, 李 丰, 陈玉勇. 钛合金用氧化物陶瓷型壳的研究[J]. 材料科学与工艺, 1999(Suppl): 128-131.

WANG Hui-guang, TIAN Jing, LU Yu-hong, QI Xiu-mei, LUO Wen-qian, LI Feng, CHEN Yu-yong. Study on structure and property of ceramic shells for titanium alloy[J]. Material Science and Technology, 1999(Suppl): 128-131.

(编辑 杨幼平)

通信作者:杨慧丽;电话:13619277690;E-mail: kjb@baoti.com