DOI:10.19476/j.ysxb.1004.0609.2019.11.20

含钒钢渣选择性预处理及提钒工艺

高明磊1, 2,周 欣2,王海旭2,杨 合1,李兰杰2,薛向欣1

(1. 东北大学 冶金学院,沈阳 110004;

2. 河钢股份有限公司承德分公司 钒钛技术研究所,承德 067102)

摘 要:针对含钒钢渣存在的钙和铁含量高、钒含量低等难以利用的问题,本文研究了含钒钢渣选择性预处理工艺,通过降低含钒钢渣的钙钒比(CaO/V2O5 比),获得可利用的钒原料。通过分析含钒钢渣在盐酸体系下的分解行为,考察了酸度、反应温度、粒度及液固比等因素对溶出过程的影响,并探讨了反应机理。结果表明:含钒钢渣最优预处理工艺条件为初始酸度2 mol/L、反应温度40 ℃、液固比8:1、含钒钢渣粒度74~124 μm、反应时间10 min。在此最优条件下,CaO含量(质量分数)由41.09%降至14.28%,CaO/V2O5 比由16降至3,MnO2、MgO、FeO、SiO2的溶出率分别达到39%、47%、39% 和55%。随着反应的进行,游离氧化钙、氧化铁、铁酸钙等矿相破坏,富集钒的硅酸二钙和硅酸三钙等矿相无变化。经碳酸钠浸出后,钒的提取率由80%提高到85%以上。

关键词:含钒钢渣;预处理;浸出;盐酸

文章编号:1004-0609(2019)-11-2635-10 中图分类号:TF11.31 文献标志码:A

钒是一种极为重要的稀有金属,同时也是一种重要的战略物资,在不同的领域具有广泛的用途。约有85%~90% 的钒用于钢铁生产中[1-2]。钒在钢中的应用主要是通过添加钒来提高强度和韧性[3]。约5%的钒与钛生成重要的合金Ti6Al4V和Ti8AlMoV,用作飞机、火箭、宇航等的高温结构材料[4-6]。其余的钒用于化工行业的催化剂[7]、光学电子工业[8-9]、钒液流电池[10]、环保领域的脱硝催化剂[11]、医药等领域[12]。钒主要赋存于钒钛磁铁矿中,约占钒资源总量的46%[13],储量最大。目前,世界上大多数国家多采用间接法从钒钛磁铁矿中提钒,即先将钒钛磁铁矿冶炼成含钒铁水,再氧化吹炼得到钒渣(w(V2O5 )≥12%)作为生产钒产品的原料[14-15]。含钒钢渣产生于钒钛磁铁矿的炼钢过程,在冶炼过程中,有两种途径使钒进入钢渣形成含钒钢渣[16-17]:一种是钒作为一种杂质吹入钢渣,在对含钒铁水进行吹炼钒渣时,大约5%~10%的钒渣残钒进入半钢,并最终形成品位较低(0.8%~3%)的含钒钢渣;另一种是将含钒铁水直接吹炼成钢,未经过吹炼钒渣的过程[18],生成含钒钢渣。含钒钢渣具有如下特点:1) CaO和铁含量高,结晶完善,质地密实,解离度差;2) 成分复杂,且波动较大;3) 钒含量较低,钒弥散分布于多种矿相中,赋存状态复杂[19-21]。

目前,从含钒钢渣中提钒主要有以下几种方法:一是火法提钒,将低钒钢渣添加在烧结矿中作为熔剂进入高炉冶炼[22-23],钒在铁水中得以富集,使铁水含钒2%~3%,再吹炼得到高品位(w(V2O5 )为30%~40%)的钒渣,以此制取V2O5或钒铁合金。目前,俄罗斯下塔吉尔钢铁联合公司对该法进行了有益探索,但未见成功报道。攀枝花钢铁公司在20世纪80年代开展了矿热炉熔炼含钒钢渣试验,取得了成功,但要打通该工艺流程,还需做大量工作[24];另一种是湿法提钒,一般将含钒钢渣作为原料经过湿法冶金化学选矿的过程直接提钒[25]。湿法提钒在20世纪后半叶发展较快。传统的湿法提钒多为钠盐焙烧-水浸-沉钒的工艺流程[26],但该工艺不适合含钙高的原料,钒的总回收率低。伊朗德黑兰大学RASHCHI团队[27]针对Esfahan钢铁公司生产的LD转炉含钒钢渣进行一系列研究,提出了钠化焙烧-碱浸、钠化焙烧-酸浸的钢渣提钒工艺,通过碱浸或酸浸的方法强化钢渣的分解。钠化焙烧-碱浸是在钢渣中添加20%的碳酸钠,在1000 ℃下焙烧2 h得到焙烧熟料,钢渣中的CaV2O7转化为水溶性的NaVO3,在NaOH溶液中浸出得到NaVO3浸出液。NaOH碱溶液有助于提高了钢渣的分解率,从而实现钒的高效提取,钒的提取率可达94%[27],虽然该方法的钒提取率很高,但钠盐消耗量较大,不仅在焙烧过程中添加了渣量20%的碳酸钠,而且浸出过程中使用了100~200 g/L的NaOH溶液,这势必导致钒浸出液中钠含量增高。过高的钠盐含量造成生产成本的升高,导致后续酸法沉钒困难,钒产品钠含量高,难以获得合格的钒产品。该方法目前仅进行了实验研究,工业可行性有待考证。RASHCHI团队[28]提出的钠化焙烧-酸浸工艺,是在同样的焙烧条件下得到焙烧熟料,在硫酸溶液中浸出得到硫酸氧钒浸出液,钒的提取率可达95%,他们还采用RSM(Response surface methodology)研究方法对工艺参数进一步优化,获得了更优的浸出条件,钒的提取率提高到96%。钠化焙烧-酸浸方法虽然钒的转化率较高,但由于钢渣钒品位低,单位钒产品的钠盐和硫酸的消耗量较大。叶国华等[29]未对浸出液的成分进行深入分析,但酸浸液通常杂质含量较高,钒的分离提取复杂,工艺的可行性有待验证。直接酸浸是指未经焙烧工序,完全湿法提钒。但由于酸浸过程需在强酸溶液中进行,得到的浸出液杂质较多,难以进行后续分离。基于上述方法存在的问题,高明磊等[30]提出碳酸钠直接浸出工艺,该方法是将含钒钢渣在20%~30%(质量分数)的碳酸钠浓度下,温度在180 ℃,通过高压,碳酸化浸出含钒钢渣中的钒,钒的浸出率可达80%以上。但是,由于含钒钢渣中含有大量的CaO,在浸出过程中会有大量的碳酸钙生成,碳酸钙附着在反应釜内壁及管道上,使得难以工业化应用。另外,浸出过程中需通入二氧化碳气体将反应生成的NaOH转化为Na2CO3,造成成本较高且提高工艺化难度。至今,含钒钢渣提钒仍然是科学难题。我国每年排放的含钒钢渣近百万吨,不仅污染环境,同时还造成有价元素钒的损失。

本文作者采用低浓度盐酸选择性提取含钒钢渣中的CaO,并去除部分硅、锰、铁等杂质元素,对钒进行富集,降低含钒钢渣的CaO/V2O5比(w(CaO)/w(V2O5)),以获得高品质、可利用的钒原料,为含钒钢渣利用开辟了一条新的途径。

1 实验

1.1 实验材料与试剂

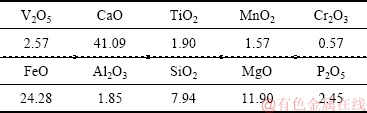

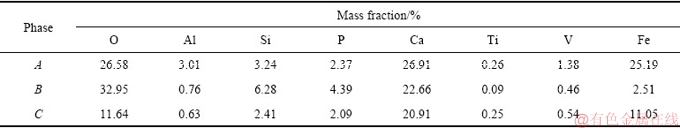

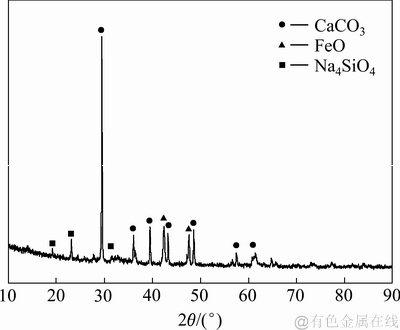

含钒钢渣为河钢股份有限公司承德分公司的转炉钢渣,其主要化学成分和物相组成见表1和图1。从图1可以看出,含钒钢渣具有一般钢渣的特性,主要物相由硅酸二钙(2CaO×SiO2,C2S)、硅酸三钙(3CaO×SiO2,C3S)、铁酸钙、氧化物及游离CaO等组成。含钒钢渣与普通钢渣不同之处在于硅酸二钙、硅酸三钙、自由氧化物和铁酸钙等物相固溶了钒元素。图2给出了提钒尾渣的背散射电子衍射图及对应的能谱分析结果,可以看出,色度偏白的物相(A)主要为含铁、钙相,即主要为铁酸钙相,稍微发暗的物相(B)为含硅、钙相,即主要为硅酸钙相。发黑的物相(C)为含铁、钙相,即主要铁酸钙相,并掺杂一些氧化铁相。

实验所用HCl和Na2CO3为分析纯(北京化工厂),实验用水为去离子水(电阻高于18.2 MW×cm,密理博中国有限公司)。

表1 含钒钢渣化学组成表

Table 1 Composition of vanadium-bearing steel slag (mass fraction, %)

图1 含钒钢渣的XRD谱

Fig. 1 XRD pattern of vanadium-bearing steel slag

图2 含钒钢渣SEM像

Fig. 2 SEM image of vanadium-bearing steel slag

表2 含钒钢渣能谱分析结果表

Table 2 EDS analysis results of vanadium-bearing steel slag

1.2 实验装置与分析仪器

预处理反应在烧杯中完成。采用恒温水浴锅加热,镍铬-镍硅热电偶测温,控温精度为±2 ℃。搅拌桨为磁力搅拌,搅拌转速采用D-8401-WZ型数控显速搅拌机控制(额定电压220 V,额定功率80 W,额定转速1400 r/min,搅拌桨桨径5 cm)。碳酸钠浸出在高压反应釜中完成。反应釜体积500 mL,材质为316L,配有搅拌及控制系统、加热及温控系统,温度控制精度为±2 ℃。分析仪器为电感耦合等离子体-原子发射光谱仪(美国Thermo Scientific公司),D/Max-RC型固定铜靶X射线衍射仪(日本RIGAKU公司),FEI SIRION 200场发射扫描电镜(美国FEI公司)。

1.3 实验方法

盐酸预处理实验:量取一定体积的浓盐酸试剂放入烧杯中,按设定好的盐酸浓度加入去离子水,在搅拌作用下配置成HCl溶液;量取一定体积的盐酸溶液加入到烧杯中,将烧杯放入水浴锅中,按设定的反应温度进行加热,加热至预定温度后,向烧杯中加入预定量的含钒钢渣进行反应;在反应结束后,将取出的样品经过滤、洗涤、干燥后得到分析用渣。

碳酸钠浸出实验:称取一定量的Na2CO3和去离子水,经充分混合后,加入到高压反应釜中,同时称取一定量的含钒钢渣加入到反应釜中。封闭后开通搅拌和加热,反应预订的时间后取出浆料经液固分离、洗涤、烘干后得到尾渣。

将渣称重,从其中称取一定量的样品进行溶解,溶解后的样品移入容量瓶中定容,用ICP-AES测定渣中钒、铬、硅、铁、铝、锰、钛、钠等元素的含量。由于反应过程中钛不会浸出,且原含钒钢渣中钛的含量最高,故以含钒钢渣中钛含量为基准计算元素的浸出率。某一元素n浸出率的计算公式如下:

(1)

(1)

式中:m为原含钒钢渣中元素n的质量分数,%; 为尾渣中某元素n的质量分数,%;mTi为原含钒钢渣中钛的含量,%;

为尾渣中某元素n的质量分数,%;mTi为原含钒钢渣中钛的含量,%; 为尾渣中钛的含量,%。

为尾渣中钛的含量,%。

2 结果与讨论

2.1 酸度对含钒钢渣元素浸出行为的影响

酸度主要影响的是热力学条件。为了研究含钒钢渣的不同初始酸度条件对CaO/V2O5比及其他元素溶出行为的影响,实验固定浸出温度40 ℃,液固比6:1,原料粒度74~124 μm,在此条件下固定搅拌速度800 r/min,以消除动力学传质的影响。考察了盐酸酸度分别在0.5、1、2、3和4 mol/L浓度下元素的溶出行为及对钙钒比的影响,如图3~5所示。由图3~5可以看出,随着盐酸浓度的增加,CaO/V2O5比逐渐降低。在盐酸浓度<2 mol/L时,钒几乎不被浸出,CaO、FeO、MgO、MnO、SiO2等组分有部分溶出,其中CaO的溶出最为明显,可达到近70%。随盐酸浓度的增加,当盐酸浓度>2 mol/L时,V2O5开始溶出,FeO、MgO、MnO、SiO2等组分溶出率得到了迅速提高,CaO的溶出率增加速度缓慢。因此,为了充分溶出CaO及其他杂质,而不溶出V2O5,使得V2O5在含钒钢渣中富集,降低钙钒比,选择溶出酸度为2 mol/L。

图3 盐酸浓度对CaO/V2O5比的影响

Fig. 3 Effect of HCl initial concentration on CaO/V2O5 ratio

图4 盐酸浓度对V2O5浸出行为的影响

Fig. 4 Effect of HCl initial concentration on leaching rate of V2O5

图5 盐酸浓度对其他元素浸出行为的影响

Fig. 5 Effect of HCl initial concentration on leaching rate of other elements

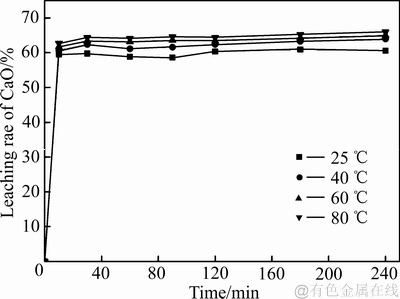

2.2 反应温度的影响

温度是影响反应动力学的重要因素,因此实验研究了不同温度对CaO/V2O5比及其他元素溶出行为的影响。在盐酸浓度2 mol/L、液固比6:1、含钒钢渣粒度74~124 μm、搅拌速度800 r/min的条件下,考察了反应温度分别在25、40、60和80 ℃条件下对含钒钢渣CaO溶出率及CaO/V2O5比的影响,结果如图6和7所示。从图6和7可以看出,CaO的溶出率随温度升高变化不大,呈缓慢上升趋势。当反应温度从25 ℃上升到40 ℃,CaO的溶出率有3%左右的升高,CaO/V2O5由原渣的15.6%迅速降至5%左右。继续升高温度,当反应温度由40 ℃升高至80 ℃时,CaO的溶出率随温度升高变化不大,其主要原因是40 ℃是CaO浸出反应的非常理想的热力学条件,温度的升高对CaO溶出率的影响不及动力学过程对其的影响。综合考虑,确定反应温度为40 ℃。

图6 反应温度对CaO溶出率的影响

Fig. 6 Effect of reaction temperature on leaching rate of CaO

图7 反应温度对CaO/V2O5比的影响

Fig. 7 Effect of reaction temperature on CaO/V2O5 ratio

2.3 液固比的影响

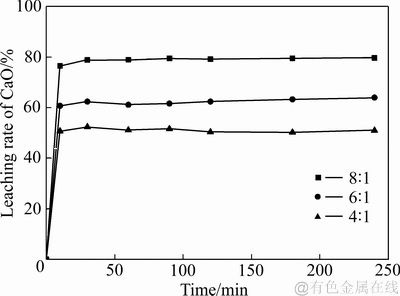

通常情况下,高液固比有利于降低反应浆液的黏度,提高传质速率,因此实验中研究了液固比为4:1、6:1和8:1的条件下对含钒钢渣CaO溶出率及CaO/V2O5比的影响。反应条件如下:含钒钢渣粒度74~124 μm,盐酸浓度2 mol/L,反应温度40 ℃,搅拌速度800 r/min,实验结果如图8和9所示。液固比对CaO的溶出率影响非常大,当液固比为4:1时,CaO的溶出率只有50%左右,当液固比增加到8:1时,CaO的溶出率可达78%左右。钙钒比由液固比4:1时的8%降至8:1时的3%。主要原因是液固比的增大,保证了盐酸浓度在反应过程中变化很小。综合考虑,选择液固比为8:1。

2.4 粒度的影响

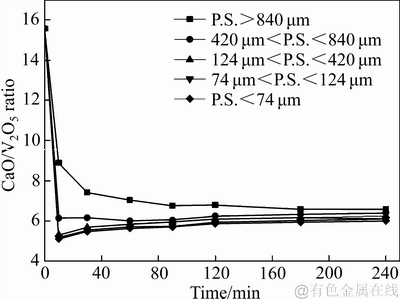

浸出反应中,浸出速率与液固接触的表面积成正比。减小原料粒度可以增大液固反应面积,降低内扩散阻力,有利于提高浸出速率。但是,原料粒度过小, 会使矿浆的黏度增大,外扩散速率降低,从而降低浸出速率,同时给固液分离造成困难。因此,实验研究了含钒钢渣不同粒度对CaO的溶出率及CaO/V2O5比的影响,在液固比8:1、初始酸度2 mol/L、反应温度40 ℃、搅拌速度800 r/min时,考察了含钒钢渣的粒度分别在>840 μm、420~840 μm、124~420 μm、74~ 124 μm和<74 μm时CaO的溶出率及钙钒比与时间的关系,结果如图10和11所示。当粒度>124 μm时,对反应前期CaO的溶出率影响较大,并随着粒度的减小,CaO的溶出率呈缓慢增长趋势。当粒度小于124 μm时,对反应前期、后期CaO的溶出率影响较小。并在20 min内达到平衡。另外,由图11还可以看出,在反应10 min时,CaO/V2O5比降至最小,并随反应时间的增长出现缓慢增长。主要原因在2.5节进行分析。因此综合考虑,确定最佳粒度为74~124 μm。

图8 液固比对CaO溶出率的影响

Fig. 8 Effect of liquid-solid ratio on leaching rate of CaO

图9 液固比对CaO/V2O5比的影响

Fig. 9 Effect of liquid-solid ratio on CaO/V2O5 ratio

图10 含钒钢渣粒度(P.S.)对CaO溶出率的影响

Fig. 10 Effect of particle size(P.S.) on leaching rate of CaO

图11 含钒钢渣粒度对CaO/V2O5比的影响

Fig. 11 Effect of particle size on CaO/V2O5 ratio

2.5 其他元素的溶出行为

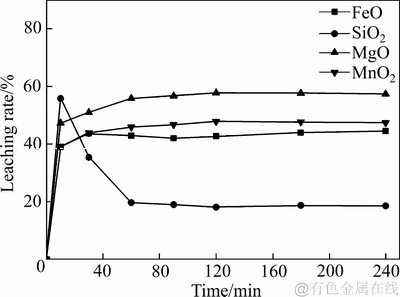

通过以上因素实验结果,确定以下适宜工艺条件如下:盐酸初始浓度2 mol/L,反应温度40 ℃,液固比8:1,含钒钢渣粒度74~124 μm。并在此条件下,固定搅拌速度800 r/min,考察了含钒钢渣中其他元素的溶出行为,结果如图12所示。由图12可以看出,随着反应时间的增加,铁、镁、锰的溶出率逐渐增加,并在反应前10 min内增长最快,其中MnO2的溶出率可达39%,MgO的溶出率可达47%,FeO的溶出率可达到39%。另外,由图12还可以看出,SiO2的溶出率在反应10 min有个明显的增长,可达55%,随着反应时间的延长,SiO2的溶出率逐渐减小至20%左右,这也是第2.2、2.3、2.4节的讨论中,CaO/V2O5比随时间变化的曲线在10 min有个低谷的原因。其主要原因是,在反应10 min内,含钒钢渣中的SiO2与盐酸反应生成硅酸溶解于液相,随着时间的延长,浆液酸度逐渐降低,硅酸不稳定生成沉淀进入渣相。同时,这也说明实验的最佳反应时间为10 min。

图12 含钒钢渣中其他元素的溶出行为

Fig. 12 Dissolution behavior of other elements in vanadium bearing steel slag

3 机理分析

本研究的目的是对含钒钢渣进行选择性预处理,主要目的是去除影响提钒的钙元素,降低CaO/V2O5 比,同时,在处理过程中降低杂质元素含量,以获得高品质的钒原料。由表3可以看出,经过盐酸预处理后,CaO品位由41.09%降至14.28%,钙钒比由16降至3,FeO的品位由24.28%降至21.65%,溶出率可达39%,MgO的品位由11.9%降至7.71%,溶出率可达47%,钒的品位由2.57%提高至4.85%。

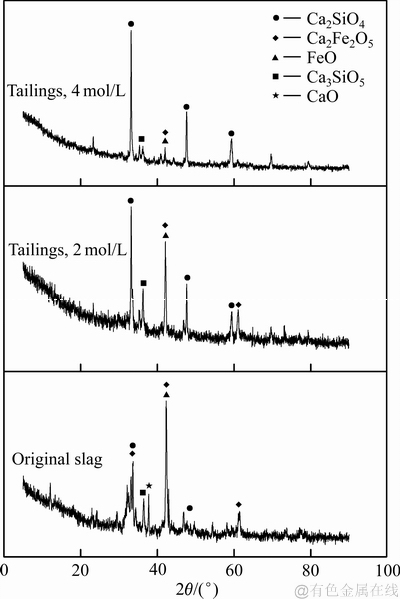

含钒钒钢渣作为一种“人造矿”,矿物组成要比常规钒矿复杂得多。根据含钒钢渣矿物学分析,钒在含钒钢渣中分布较为分散,钒以固溶体的形式赋存于硅酸二钙、硅酸三钙、铁酸钙中。图13所示分别为含钒钢渣,2 mol/L盐酸预处理的尾渣和4 mol/L盐酸预处理的尾渣的XRD谱。由图13可以看出,在小于2 mol/L时,浸出的只有游离氧化钙、氧化铁、部分铁酸钙等矿相。在4 mol/L时,硅酸二钙和硅酸三钙的峰明显减弱,说明矿物晶体结构得到破坏。可见,只有当钢渣中主要载体矿物晶体结构溶解破坏后,其中的钒才会暴露在介质中,才能被浸取出来。钒浸出率大小与含钒矿物晶体结构在浸出过程中破坏程度是紧密相关的,晶体结构破坏程度越大,钒浸出率越高。因此,盐酸浓度不能超过2 mol/L。

图13 含钒钢渣原矿及不同盐酸浓度浸出尾渣的XRD谱

Fig. 13 XRD patterns of vanadium steel slag and tailings leached by different acid concentrations

表3 含钒钢渣和预处理后尾渣化学组成表

Table 3 Composition of vanadium-bearing steel slag and pretreated tailings

表4 预处理后尾渣能谱分析

Table 4 EDS analysis results of tailing after pretreatment

图14和表4给出了提钒尾渣的背散射电子衍射图及对应的能谱分析结果,可以看出,色度偏白的物相(A)主要为含铁、铝、钛和钒,且钒的含量达到17.97%,主要为预处理后裸露出来的RO相,稍微发暗的物相(B)为含硅、钙、铁相,即主要为硅酸钙和钛铁矿。发黑的物相(C)为含硅、钙、钛相,即主要硅酸钙相。

图14 预处理后尾渣SEM像

Fig. 14 SEM image of tailing after pretreatment

4 碳酸钠浸出

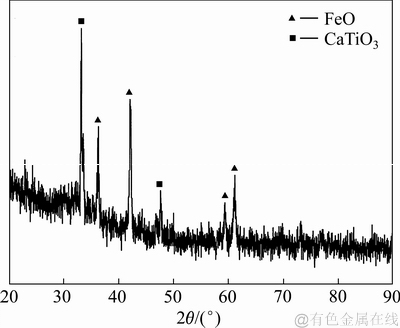

将预处理后的尾渣进行碳酸钠浸出处理,根据已有的研究结果[29],碳酸钠浸出的最佳反应条件如下:浸出温度200 ℃,Na2CO3初始含量20%,液固比4:1,搅拌速度600 r/min。同时,实验与未经预处理的含钒钢渣进行了对比。不经过盐酸预处理和经过盐酸预处理后的含钒钢渣经碳酸钠浸出后,得到的尾渣成分如表5所示。由表5可以看出,经盐酸预处理后的含钒钢渣通过碳酸钠浸出后得到的尾渣CaO、FeO、MgO明显低于未经预处理的尾渣,且钒的提取率分别为80.3%和85.9%,大大提高了钒的浸出率。另外,图15和16分别给出了未经预处理的含钒钢渣碳酸钠浸出后尾渣XRD谱和经预处理的含钒钢渣碳酸钠浸出后尾渣XRD谱,由两种尾渣的XRD谱可以看出,未经预处理的含钒钢渣得到的尾渣物相主要为CaCO3,而经预处理得到的尾渣主要物相为FeO和CaTiO3。说明通过预处理,避免了碳酸钠浸出过程产生碳酸钙结垢,提高了工艺的可行性。另外,在碳酸钠浸出过程中不必通入CO2,大大降低了工艺实施的难度。

图15 未经预处理的含钒钢渣碳酸钠浸出后尾渣XRD谱

Fig. 15 XRD pattern of tailings leached by sodium carbonate from vanadium bearing steel slag without pretreatment

图16 经预处理的含钒钢渣碳酸钠浸出后尾渣XRD谱

Fig. 16 XRD pattern of tailings leached by sodium carbonate from vanadium bearing steel slag by pretreatment

表5 预处理和未经预处理的含钒钢渣经碳酸钠浸出后尾渣成分

Table 5 Tailings components of vanadium bearing steel slag with pretreatment and un-pretreatment leached by sodium carbonate

5 结论

1) 采用盐酸选择性浸出含钒钢渣中的CaO,并去除硅、锰、铁等杂质元素,对钒进行富集,降低含钒钢渣的CaO/V2O5比,以获得高品质、可利用的钒原料。含钒钢渣最适宜的预处理工艺条件如下:初始酸度2 mol/L,反应温度40 ℃,液固比8:1,含钒钢渣粒度74~124 μm,反应时间10 min。CaO含量由原来的41.09%降至14.28%,钙钒比由16降至3,MnO2、MgO、FeO、SiO2的溶出率分别达到39%、47%、39% 和55%。

2) 随着反应的进行,游离氧化钙、氧化铁、部分铁酸钙等矿相破坏溶出,富集钒的硅酸二钙和硅酸三钙矿相等矿相无变化。通过碳酸钠浸出后,经盐酸预处理后的含钒钢渣、得到的尾渣CaO、FeO、MgO明显降低。

3) 预处理后的尾渣进行碳酸钠浸出,钒的提取率由80.3%提高至85.9%。避免了含钒钢渣在碳酸钠浸出过程中产生碳酸钙结垢,提高了含钒钢渣碳酸钠浸出工艺的可行性,大大降低了工艺实施的难度。

REFERENCES

[1] 刘世友. 钒的应用与展望[J]. 稀有金属与硬质合金, 2000, 9(5): 58-61.

LIU Shi-you. Applications and outlook of vanadium[J]. Rare Metals and Cemented Carbides, 2000, 9(5): 58-61.

[2] MOSKALYK R R, ALFANTAZI A M. Processing of vanadium: A review[J]. MineralsEngineering, 2003, 16(8): 793-805.

[3] 云正宽. 冶金工程设计[M]. 北京: 冶金工业出版社, 2006: 36-45.

YUN Zheng-kuan. Metallurgical engineering design[M]. Beijing: Metallurgical Industry Press, 2006: 36-45.

[4] 孙诗淋. 航空航天级钒铝中间合金制备工艺研究[D]. 大连: 大连理工大学, 2015: 14-16.

SUN Shi-lin. Research of fabricating technology of vanadium aluminium master alloy for aerospace[D]. Dalian: Dalian University of Technology, 2015: 14-16.

[5] 冯军宁, 胡志杰, 马忠贤, 李献军, 杨 蓉. 钛合金用中间合金及其标准化[J]. 世界有色金属, 2016(2): 49-52.

FENG Jun-ning, HU Zhi-jie, MA Zhong-xian, LI Xian-jun, YANG Rong. Master alloy for titanium alloy and its standardization[J]. World Nonferrous Metals, 2016(2): 49-52.

[6] 刘志光. 航空航天钛合金用中间合金-钒铝65合金[J]. 钛工业进展, 2014(1): 12-14.

LIU Zhi-guang. The master alloy of VAl65:35 used for aerospace[J]. Titanium Industry Progress, 2014(1): 12-14.

[7] OLSEN J C, MAISNER H. Vanadium catalysts[J]. Indengchem, 2002, 29(3): 254-267.

[8] KUCHARCZYK D, NIKLEWSKI T. Accurate X-ray determination of the lattice parameters and the thermal expansion coefficients of VO2 near the transition temperature[J]. Journal of Applied Crystallography, 2010, 12(4): 370-373.

[9] ISRAELSSON M, KIHLBORG L. The phase relations in the VO2|WO2 system[J]. Materials Research Bulletin, 1970, 5(1): 19-29.

[10] CHOI C, KIM S, KIM R, CHOI Y, KIM S, JUNG H, YANG J H, KIM H. A review of vanadium electrolytes for vanadium redox flow batteries[J]. Renewable & Sustainable Energy Reviews, 2017, 69: 263-274.

[11] ZHAO Z, WANG X, BAO L I. Formation and emission control of nitrogen oxides during coal combustion [J]. Yantai Teachers College Journal, 2000, 16(3): 212-216.

[12] 段 炼, 田庆华, 郭学益. 我国钒资源的生产及应用研究进展[J]. 湖南有色金属, 2006, 22(6): 17-20.

DUAN Lian, TIAN Qing-hua, GUO Xue-yi. Review on production and utilization of vanadium resources in china[J]. Hunan Nonferrous Metals, 2006, 22(6): 17-20.

[13] 冯其明, 何东升, 张国范, 欧乐明, 卢毅屏. 石煤提钒过程中钒氧化和转化对钒浸出的影响[J]. 中国有色金属学报, 2007, 17(8): 1348-1352.

FENG Qi-ming, HE Dong-sheng, ZHANG Guo-fan, OU Le-ming, LU Yi-ping. Effect of vanadium oxidation and conversion on vanadium leaching in extraction process of vanadium from stone coal[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(8): 1348-1352.

[14] 赵海燕. 钒资源利用概况及我国钒市场需求分析[J]. 矿产保护与利用, 2014(2): 54-58.

ZHAO Hai-yan. Analysis of vanadium resources utilization and demand for vanadium in China[J]. Conservation and Utilization of Mineral Resources, 2014(2): 54-58.

[15] 席增宏, 覃向民, 赵景福. 钠化焙烧提钒工艺中焙烧温度的控制[J]. 铁合金, 2005, 183(4): 19-20.

XI Zeng-hong, TAN Xiang-min, ZHAO Jing-fu. The temperature control in the technology of roasting vanadium slag with sodium carbonate[J]. Ferro-Alloys, 2005, 183(4): 19-20.

[16] 杨素波, 罗泽中, 文永才, 何 为, 王 建, 陈 渝. 含钒转炉钢渣中钒的提取与回收[J]. 钢铁, 2005, 40(4): 72-75.

YANG Su-bo, LUO Ze-zhong, WEN Yong-cai, HE Wei, WANG Jian, CHEN Yu. Vanadium recovery from BOF slag containing vanadium oxide[J]. Iron & Steel, 2005, 40(4): 72-75.

[17] PREBLINGER H. Vanadium in converter slags[J]. Steel Research, 2002, 73(12): 522-525.

[18] 余 亮, 董元篪. 含钒钢渣添加SiO2后的钒富集相与钒富集行为[J]. 材料与冶金学报, 2007, 6(2): 94-98.

YU Liang, DONG Yuan-hu. Vanadium rich phases and vanadium concentration of vanadium bering steel slag by addition of SiO2[J]. Journal of Materials and Metallurgy, 2007, 6(2): 94-98.

[19] 朱桂林, 孙树杉, 赵 群, 王建华. 冶金渣资源化利用的现状与发展趋势[J]. 中国资源综合利用, 2002, 3(6): 29-32.

ZHU Gui-lin, SUN Shu-shan, ZHAO Qun, WANG Jian-hua. Status and development trend of resource utilization of metallurgical slag[J]. China Resources Comprehensive Utilization, 2002, 3(6): 29-32.

[20] 古隆建. 我国火法提钒技术的进展及现状[J]. 钒钛, 1992, 13(6): 29-36.

GU Long-jian. Progress and status of vanadium extraction technology in China[J]. Vanadium & Titanium, 1992, 13(6): 29-36.

[21] 田茂明, 唐大均, 张 奇. 含钒钢渣提钒工艺及其主要技术[J]. 重庆科技学院学报(自然科学版), 2009, 11(2): 59-60.

TIAN Mao-ming, TANG Da-jun, ZHANG Qi. The technique of extracting the vandium from vanadium slag and its main technology[J]. Journal of Chongqing University of Science and Technology(Natural Sciences Edition), 2009, 11(2): 59-60.

[22] 钱 强. 低品位钢渣磁选粉在烧结工艺中的应用[J]. 烧结球团, 2018, 43(3): 43-46.

QIAN Qiang. Application of low grade steel slag magnetic separation powder in sintering process[J]. Sintering and Pelletizing, 2018, 43(3): 43-46.

[23] 刘长波, 彭 犇, 夏 春, 岳昌盛, 吴 龙. 钢渣利用及稳定化技术研究进展[J]. 矿产保护与利用, 2018(6): 145-150.

LIU Chang-bo, PENG Ben, XIA Chun, YUE Chang-sheng, WU Long. The research progress of steel slag utilization and stabilization technology[J]. Conservation and Utilization of Mineral Resources, 2018(6): 145-150.

[24] 戈文荪, 张玉东, 黎 建. 攀钢转炉提钒工艺的技术变革与展望[J]. 钢铁钒钛, 2001, 22(3): 11-14.

GE Wen-sun, ZHANG Yu-dong, LI Jian. Development and prospect of technology for vanadium recovery from hot metal in converter at PZH steel[J]. Iron Steel Vanadium Titanium, 2001, 22(3): 11-14.

[25] 刘安华, 李辽沙, 余 亮. 含钒固废提钒技术及展望[J]. 金属矿山, 2003, 10: 61-64.

LIU An-hua, LI Liao-sha, YU Liang. Technology of vanadium extraction from V-bearing solid wastes and its prospect[J]. Metal Mine, 2003, 10: 61-64.

[26] SHAHNAZI A, RASHCHI F, VAHIDI E. A kinetics study on the hydrometallurgical recovery of vanadium from LD converter slag in alkaline media[M]. New York: John Wiley & Sons, Inc., 2012: 18-22.

[27] MIRAZIMI S M J, RASHCHI F, VAHIDI E, MOSTOUFI N. Optimization and dissolution kinetics of vanadium recovery from LD converter slag in alkaline media[J]. Russian Journal of Non-Ferrous Metals, 2016, 57(5): 395-404.

[28] AARABI-KARASGANI M, RASHCHI F, MOSTOUFI N, VAHIDI E. Leaching of vanadium from LD converter slag using sulfuric acid[J]. Hydrometallurgy, 2010, 102(1/4): 14-21.

[29] 叶国华, 童 雄, 路 璐. 含钒钢渣的选矿预处理及其对后续浸出的影响[J]. 中国有色金属学报, 2010, 20(11): 2233-2238.

YE Guo-hua, TONG Xiong, LU Lu. Pretreatment for V-bearing steelmaking slag by beneficiation methods and its effect on followed leaching procedure[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(11): 2233-2238.

[30] GAO Ming-lei, XUE Xiang-xin, LI Lan-jie, YANG He, BAI Rui-guo, WANG Hai-xu. A novel method to extract vanadium from vanadium-bearing steel slag using sodium carbonate solution[J]. Physicochemical Problems of Mineral Processing, 2018, 54(3): 911-921.

Selective pretreatment and vanadium extraction of vanadium-bearing steel slag

GAO Ming-lei1, 2, ZHOU Xin1, WANG Hai-xu2, YANG He2, LI Lan-jie2, XUE Xiang-xin1

(1. School of Metallurgy, Northeastern University, Shenyang 110004, China;

2. Institute of Vanadium Titanium Technology, HBIS Group Cheng Steel, Chengde 067102, China)

Abstract: Because of high Ca and Fe contents and low vanadium content, the vanadium-bearing steel slag cannot be utilized synthetically. Available vanadium materials are obtained by selective pretreatment method. The dissolution behaviors of Ca and other impurity elements from vanadium-bearing steel slag in hydrochloric acid system were studied. The effects of the hydrochloric acid concentration, the leaching temperature, the particle size and the liquid-to-solid ratio on the dissolution rate were investigated. And the dissolution mechanism of the process was also investigated. The experimental results show that the optimal pretreatment conditions is as follows: the initial HCl concentration of 2 mol/L, reaction temperature of 40 ℃, liquid-to-solid ratio of 8:1, reaction time of 10 min, and particle size of 74-124 μm. The content of CaO decreases from 41.09% to 14.28%, the CaO/V2O5 ratio decreases from 16 to 3, and the dissolution rates of MnO2, MgO, FeO and SiO2 are 39%, 47%, 39% and 55% respectively. With the reaction process, the mineral phases of free calcium oxide, iron oxide and calcium ferrite are destroyed, while the mineral phases of dicalcium silicate and tricalcium silicate are unchanged. After leaching with sodium carbonate, the extraction rate of vanadium increases from 80% to 85%.

Key words: vanadium-bearing steel slag; pretreatment; leaching; hydrochloric acid

Foundation item: Project(E2017318007) supported by the Natural Science Foundation of Hebei Province, China

Received date: 2018-12-10; Accepted date: 2019-05-06

Corresponding author: XUE Xiang-xin; Tel: +86-13909813905; E-mail: xuexx@mail.neu.edu.cn

(编辑 何学锋)

基金项目:河北省自然科学基金资助项目(E2017318007)

收稿日期:2018-12-10;修订日期:2019-05-06

通信作者:薛向欣,教授,博士;电话:13909813905;E-mail:xuexx@mail.neu.edu.cn