DOI: 10.11817/j.issn.1672-7207.2018.05.004

含钒钢渣在熔融NaOH体系中的焙烧过程

蔡永红1, 2,赵昌明1,宁哲1,王一雍1,张崇民1

(1. 辽宁科技大学 材料与冶金学院,辽宁 鞍山,114051;

2. 攀钢集团成都钢钒有限公司,四川 攀枝花,617000)

摘要:研究含钒钢渣在熔融NaOH体系中的焙烧过程,考察焙烧温度、碱矿比(NaOH与含钒钢渣的质量比)、焙烧时间对含钒钢渣中钒提取率的影响;获得最佳反应条件,并对反应机理进行解析,建立反应动力学模型。研究结果表明:含钒钢渣在熔融NaOH体系中的焙烧过程最佳反应条件为焙烧温度450 ℃,碱矿比5:1,焙烧时间60 min,在此条件下,钒提取率稳定在90%以上。对钒提取率影响最大的为碱矿比,其次是焙烧温度和焙烧时间;含钒钢渣在熔融NaOH体系中焙烧过程受固体产物层扩散控制,表观活化能为39.4 kJ/mol,动力学方程为 。

。

关键词:含钒钢渣;熔融;动力学;焙烧

中图分类号:TF09 文献标志码:A 文章编号:1672-7207(2018)05-1047-07

Roasting process of vanadium-bearing steel slag in molten NaOH system

CAI Yonghong1, 2, ZHAO Changming1, NING Zhe1, WANG Yiyong1, ZHANG Chongmin1

(1. School of Materials and Metallurgy, University of Science and Technology Liaoning, Anshan 114051, China;

2. Pangang Group Chengdu Iron & Steel Co. Ltd., Panzhihua 617000, China)

Abstract: The process of vanadium bearing steel slag roasting in molten NaOH system was studied and the influences of factors, such as roasting temperature, mass ratio of NaOH to vanadium-bearing steel slag (alkali-to-ore) and roasting duration, on extraction rate of vanadium were investigated. The optimum reaction conditions were obtained. The reaction mechanism of roasting process was analyzed and the reaction kinetics model was established. The results show that the optimum conditions are as follows: roasting temperature is 450 ℃, mass ratio of alkali-to-ore is 5:1, roasting duration is 60 min. Extraction rate of vanadium stabilizes at 90% or more under the optimum conditions. The most influential factor on extraction rate of vanadium is mass ratio of alkaline-ore, which is then followed by roasting temperature and roasting duration. Roasting process of vanadium-bearing steel slag in molten NaOH system is controlled by solid product layer diffusion. Activation energy of this process is 39.4 kJ/mol. The kinetic equation for the course of roasting is  .

.

Key words: vanadium-bearing steel slag; melting; kinetic; roasting

钒是一种重要的战略金属,由于其具有优良的物理化学性质,被广泛应用在冶金、化工等领域[1-4]。目前,钢铁行业通常利用冶炼钒钛磁铁矿所产生的含钒钢渣来作为提取钒的主要原料。与正常钒渣相比,含钒钢渣赋存物相复杂,渣中钒化合物被以硅酸盐为主的辉石相包裹,若采用传统工艺处理会出现焙烧易结块、钒提取率低等问题[5-8]。我国钢铁工业每年有数百万t含钒钢渣排放,这些钒渣不仅危害环境,而且造成渣中V,Fe,Mn,Ti,Cr和Al元素的损失。因此,如何高效处理含钒钢渣,实现渣中有价金属资源化利用,已成为当前需要解决的重要问题。传统处理含钒钢渣主要以钠化焙烧工艺为主,该工艺以Na2CO3为添加剂,利用高温焙烧(750~900 ℃)将钒转化为五价钒酸盐,经水浸、加铵盐步骤制得多钒酸铵沉淀,再通过还原焙烧获得V2O5产品。该工艺能耗高,钒回收率低,对渣中V和Ca品位有严格要求,而且焙烧过程中会产生HCl和Cl2有害气体,污染环境[9-10]。针对钠化焙烧工艺的不足,研究者开展了很多优化和改进实验。邱士星等[11]采用不同质量配比添加剂(Na2CO3,NaCl)与含钒钢渣焙烧,考察焙烧温度、沉钒温度和pH等对钒回收率的影响,钒回收率可达85.4%;李京等[12]采用钙化焙烧-碳酸钠浸出处理含钒钢渣,考察CaO/V2O5、焙烧温度、焙烧时间对钒回收率的影响。与钠化焙烧工艺相比,上述工艺虽然钒提取率略有提高,但仍存在高能耗、生产成本偏高的缺点,而且对物料成分要求严格,不适合扩大生产。因此,开发短流程、低能耗处理含钒钢渣工艺是钒冶金的研究热点。本文作者基于现有钠化焙烧钒渣提钒工艺的研究现状,结合含钒钢渣结构特点,对其在熔融NaOH体系中的焙烧机理进行探讨,并解析焙烧过程的动力学模型,以期为含钒钢渣提钒技术的生产实践提供参考依据。

1 实验

1.1 实验原料与试剂

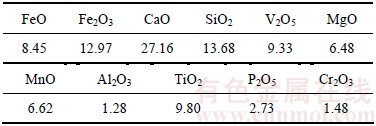

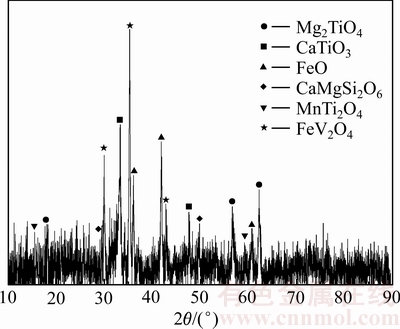

实验所用含钒钢渣由攀枝花某钒金属加工企业提供,经干燥、研磨、过筛后得到实验样品,其化学成分如表1所示。样品中主要含有 V,Fe,Ti,Si,Ca和Mg等元素。样品X线衍射(XRD)图谱以及扫描电镜(SEM)图谱分别如图1和图2所示。由图1~2可知:钒渣表面成不规则块状形体,质地坚硬,主要赋存物相由尖晶石相(FeV2O4)、钛晶石相((Mg2TiO4),(MnTi2O4)和(CaTiO3))和辉石相(CaMgSi2O6)组成。

实验以NaOH(分析纯,沈阳化工试剂厂生产)为添加剂,水为自制去离子水。

表1 含钒钢渣的成分(质量分数)

Table 1 Chemical composition of vanadium bearing steel Slags %

图1 含钒钢渣的XRD图谱

Fig. 1 XRD pattern of vanadium bearing steel slag

图2 含钒钢渣的SEM图谱

Fig. 2 SEM image of vanadium bearing steel slag

1.2 实验和检测设备

实验设备:SHZ-D(Ⅲ) 循环水式真空泵,SX2-5-12型马弗炉,DHG-9070A型烘箱,ACS-1AL电子天平。

检测设备:采用Rigaku Ultima IV射线衍射仪分析含钒钢渣和焙烧产物的物相,Cu靶Kα辐射(波长为1.540 6 nm),工作电压为40 kV,扫描范围2θ=5°~90°;采用JSM-6390A型扫面电镜分析含钒钢渣和焙烧产物的形貌;釆用Optima 4300DV型电感耦合等离子体发射光谱仪分析含钒钢渣成分;采用SDT Q600型热分析仪分析钒渣和NaOH混合物的热重曲线,以10℃/min升温速率由室温升温至设定温度,气流量为100 mL/min。

1.3 实验步骤

按一定碱矿比准确称取NaOH与含钒钢渣,用研钵将其均匀混合,装入镍坩埚内,置于马弗炉内加热至设定温度并开始计时。焙烧过程中马弗炉半开门以保证样品在氧化性气氛中。反应结束后,待温度降到室温,将镍坩埚取出放入盛有温水的烧杯中进行浸 出,通过固液分离得到含钒溶液和浸出渣。将得到的渣保存,之后进行XRD和SEM结构表征分析,浸出液中的钒含量采用高锰酸钾氧化-硫酸亚铁铵进行滴定[13]。计算公式如下:

(1)

(1)

式中: 为V2O5的提取率;m1为滤液中V2O5的质量;m2为钒渣中所含V2O5的质量。

为V2O5的提取率;m1为滤液中V2O5的质量;m2为钒渣中所含V2O5的质量。

1.4 实验原理

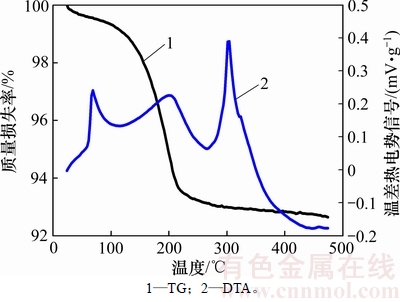

图3所示为含钒钢渣与NaOH的混合物焙烧过程的差热-热重(TG-DTA)曲线。由图3可知混合物在焙烧过程中主要在2段温度范围内发生质量变化:第1段放热过程(58~120 ℃)是由物料中FeV2O4氧化过程引起的,第2段吸热过程(200~320 ℃)是由于物料中主要赋存物相FeV2O4,Mg2TiO4,MnTi2O4,CaTiO3和CaMgSi2O6在NaOH作用下发生分解引起的。FeV2O4在NaOH作用下生成钒酸盐和水;钛晶石相在NaOH作用下生成钛酸盐和相应的金属氧化物;辉石相在在NaOH作用下分解成镁、钙橄榄石相,镁、钙橄榄石相继续与NaOH反应生产相应的金属氢氧化物。由TG曲线可知随焙烧温度升高混合物的质量逐渐减少。为保证焙烧反应过程中钒提取率达到最大,结合NaOH的性质,将反应温度选为450~500 ℃。

图3 NaOH与含钒钢渣焙烧过程的TG-DTA曲线图

Fig. 3 TG-DTA curves of roasting reaction of vanadium bearing steel slag with NaOH

将钒渣与NaOH混合,焙烧过程中发生如下反应:

2NaOH+V2O5=2NaVO3+H2O (2)

2FeV2O4+5O2+4NaOH=4NaVO3+Fe2O3+2H2O (3)

6FeV2O4+7O2=2Fe3O4+6V2O5 (4)

CaTiO3+2NaOH=Na2TiO3+CaO+H2O (5)

MnTi2O4+2NaOH=Na2TiO3+MnO+H2O (6)

Mg2TiO4+2NaOH=Na2TiO3+2MgO+H2O (7)

CaMgSi2O6+4NaOH=Na2MgSiO4+Na2CaSiO4+2H2O (8)

Na2CaSiO4+2NaOH=Ca(OH)2+Na4SiO4 (9)

Na2MgSiO4+2NaOH=Mg(OH)2+Na4SiO4 (10)

Mg(OH)2=MgO+H2O (11)

2 结果与讨论

2.1 单因素实验

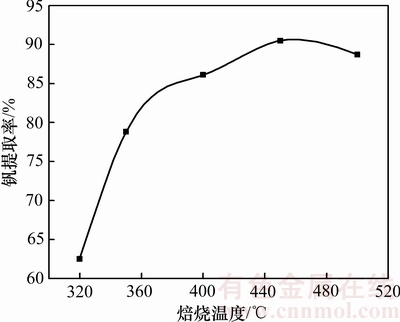

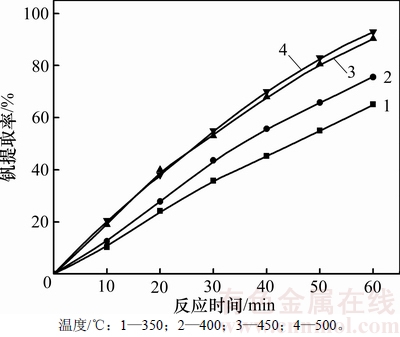

2.1.1 焙烧温度的影响

在碱矿比为5:1和焙烧时间为60 min条件下,考察焙烧温度对含钒钢渣中钒提取率的影响,实验结果如图4所示。由图4可知:焙烧温度对钒提取率影响较大;在320~450 ℃范围内钒提取率随焙烧温度升高而增加,并在450 ℃时达到最大,这是因为在此焙烧温度范围内,分子运动速度加快,有利于体系中钒尖晶石中钒氧化成五价钒并在熔融NaOH作用下生成钒酸钠;当焙烧温度升高至450 ℃以上时,钒提取率略有降低,这是由于含钒钢渣成分复杂,在浸出过程中钒酸盐易被水解产生的胶体硅酸盐包裹,形成“裹络”现象,导致钒提取率降低。

图4 焙烧温度对钒提取率的影响

Fig. 4 Effect of roasting temperature on extraction rate of V2O5

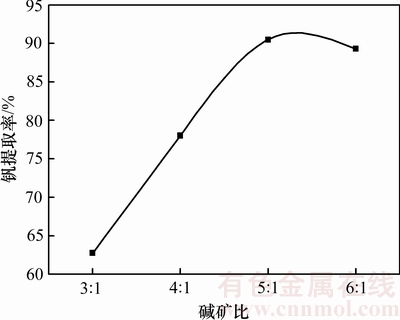

2.1.2 碱矿比的影响

在焙烧时间为60 min和焙烧温度为450 ℃条件下,考察碱矿比对含钒钢渣中钒提取率的影响,实验结果如图5所示。由图5可知:当碱矿比为3:1时,钒提取率为62.74%;当碱矿比增至5:1时,钒提取率达到90.47%;而当碱矿比继续增加时,钒提取率有下降趋势。由此推测,当体系中加入的NaOH质量过多时,容易造成体系黏度增加、流动性较差、传质困难,不利于反应进行。

图5 碱矿比对钒提取率的影响

Fig. 5 Effect of mass ratios of alkali-to-ore on extraction rate of V2O5

2.1.3 焙烧时间的影响

在焙烧温度为450 ℃和碱矿比为5:1条件下,考察焙烧时间对含钒钢渣中钒提取率的影响,实验结果如图6所示。由图6可知:当焙烧时间从15 min延长至 60 min 时,钒提取率逐渐升高;而焙烧时间超过 60 min 后,钒提取率略有降低。这是由于焙烧时间过长,物料在高温下滞留的时间增加,更易导致烧结的发生,从而影响钒提取率。

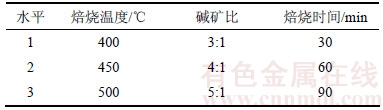

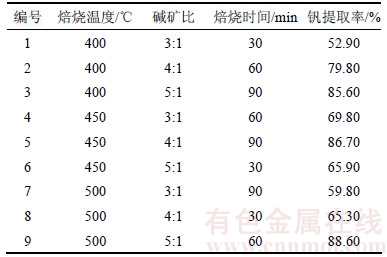

2.2 正交实验

为了考察各因素对含钒钢渣在熔融NaOH体系中焙烧过程的影响程度,在单因素实验的基础上设计正交实验。以钒提取率为指标,取焙烧温度、碱矿比、焙烧时间为3个正交因素,选择L9(34)正交实验设计,以确定各影响因素同时作用时的影响主次顺序和最佳反应条件。各因素和水平如表2所示。

图6 焙烧时间对钒提取率的影响

Fig. 6 Effect of roasting time on extraction rate of V2O5

正交实验方案及结果如表3所示。正交实验结果极差分析如表4所示。其中:K1,K2和K3分别表示1个因素各水平相应的实验结果之和,K1/3,K2/3和K3/3分别表示1个因素相应水平的平均值,并以此来判断实验的最佳反应条件;R为极差。通过极差分析结果可知:1) 根据R,各因素对钒提取率影响程度从大到小依次为碱矿比、焙烧温度和焙烧时间;2) 最佳反应条件为焙烧温度450 ℃,碱矿比5:1,焙烧时间60 min;在最佳反应条件下进行多次重复实验,钒提取率稳定在90%以上。

表2 因素水平表

Table 2 Factors and levels

表3 正交实验方案及结果

Table 3 Scheme and results of orthogonal test

表4 正交实验结果极差分析

Table 4 Extreme value of analysis of orthogonal test results

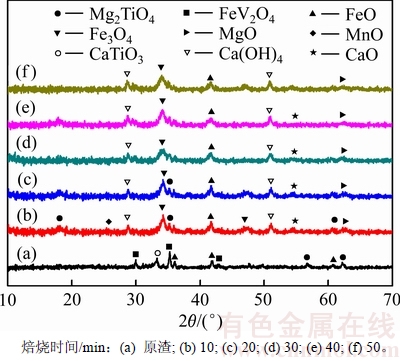

2.3 浸出渣的分析

在焙烧温度为450 ℃,碱矿比为5:1,焙烧时间为60 min条件下,对焙烧不同时间所得渣进行XRD和SEM分析,结果分别如图 7和图8 所示。由图7可知:随焙烧时间的延长,含钒钢渣中主要赋存物相衍射峰逐渐减弱,部分衍射峰也逐渐消失。FeV2O4在NaOH作用下生成NaVO3,Fe2O3和Fe3O4;Mg2TiO4,MnTi2O4和CaTiO3在NaOH作用下生成Na2TiO3,CaO,MnO和MgO;CaMgSi2O6在NaOH作用下发生分解生成镁、钙橄榄石相;镁、钙橄榄石相与NaOH继续反应生成Mg(OH)2,Ca(OH)2和Na4SiO4,而Mg(OH)2在380 ℃发生分解生成MgO。由于渣经过过滤、洗涤等步骤,反应生成的NaVO3,Na2TiO3和Na4SiO4易溶于水而进入液相。因此,渣的XRD 谱中不存在NaVO3,Na2TiO3和Na4SiO4衍射峰。

由图8可知:反应前含钒钢渣表面光滑、质地坚硬、表面空隙较少,随着焙烧时间延长,含钒钢渣表面逐渐被NaOH侵蚀变得疏松,粒度逐渐变小。产生上述现象的原因在于体系中存在较高浓度OH-,对含钒钢渣中主要赋存物相有较强的分解作用,生成的可溶性NaVO3,Na2TiO3和Na4SiO4 进入溶液,而生成的Fe2O3,Fe3O4,Ca(OH)2和MgO等物质附着在颗粒表面形成固体产物层。

图7 不同焙烧时间浸出渣的XRD谱

Fig. 7 XRD patterns of leaching residues after roasting for different time

图8 不同焙烧时间浸出渣的SEM像

Fig. 8 SEM images of leaching residues after roasting for different time

2.4 含钒钒渣在熔融NaOH体系中的焙烧过程动力学

2.4.1 动力学模型的建立

含钒钒渣在熔融NaOH体系中焙烧过程属于液-固两相反应,结合不同焙烧时间所得渣的形貌分析结果可知:焙烧过程中会生成固体产物层,因此,可选择收缩未反应核模型来描述。收缩未反应核模型控制步骤主要有固体产物层扩散控制、化学反应控制、二者混合控制。焙烧过程的控制步骤符合哪种类型,还需实验进一步验证[14]。

2.4.2 焙烧温度的影响

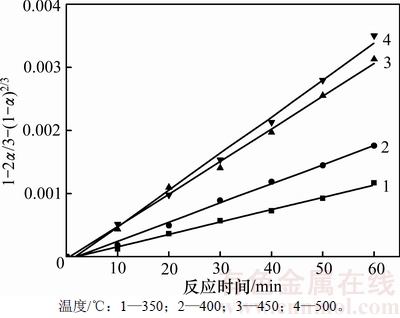

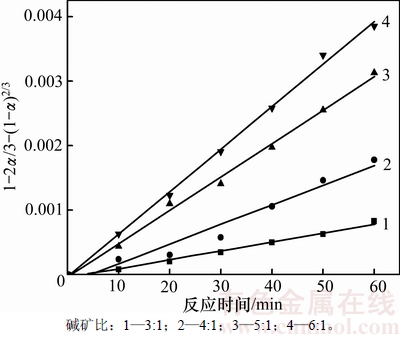

在最佳反应条件下,考察不同焙烧温度随时间变化对反应速率的影响,其结果如图9所示。将实验数据分别代入化学反应控制方程式和固体产物层扩散控制方程式拟合,拟合结果如图10所示。由图10可知:通过固体产物层扩散控制方程计算,结果与焙烧时间t呈较好的直线关系,其方程为 (其中,k为反应速率常数),说明含钒钢渣在碱熔NaOH体系焙烧过程符合固体产物层扩散控制。

(其中,k为反应速率常数),说明含钒钢渣在碱熔NaOH体系焙烧过程符合固体产物层扩散控制。

图9 温度对钒提取率的影响

Fig. 9 Effect of temperature on extraction rate of V2O5

图10 不同焙烧温度下钒的焙烧过程动力学曲线

Fig. 10 Kinetic curves of vanadium bearing steel slag roasting process at different roasting temperatures

根据Arrhenius方程[15-17]

(12)

(12)

式中:A为频率因子,min-1;E为活化能,J/mol;R为气体常数,取8.314 J/(K·mol)。

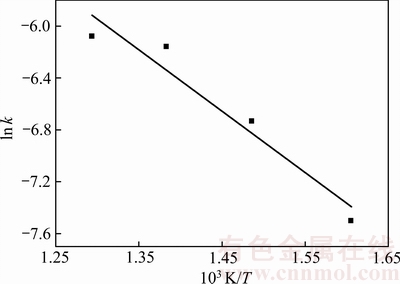

用线性回归可以得到不同焙烧温度时的反应速率常数k,将ln k对1/T作图,结果如图11所示。计算得频率因子A=1.239 s-1,反应表观活化能E=39.4 kJ/mol,此活化能包括本征化学反应活化能以及物质传递过程的综合结果。故在350~500 ℃焙烧温度范围内,钒渣在熔融NaOH体系中焙烧过程受固体产物层扩散控制,动力学方程可描述为

(13)

(13)

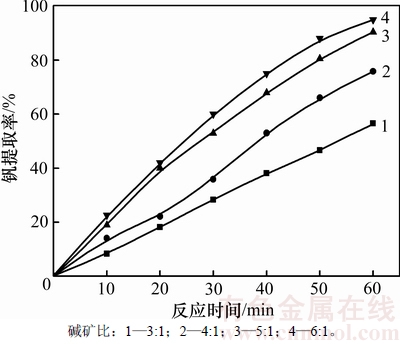

2.4.3 碱矿比的影响

在最佳反应条件下,考察不同碱矿比对钒提取率的影响,其结果如图12所示。将实验数据分别代入化学反应控制方程式和固体产物层扩散控制方程式拟合,拟合结果如图13所示。由图13可知:通过固体产物层扩散控制方程计算,结果与焙烧时间t呈直线关系,其方程为 ,进一步证明含钒钢渣在碱熔NaOH体系焙烧过程符合固体产物层扩散控制。

,进一步证明含钒钢渣在碱熔NaOH体系焙烧过程符合固体产物层扩散控制。

图11 ln k与T-1的关系

Fig. 11 Relationship between ln k and T-1

图12 碱矿比对钒提取率的影响

Fig. 12 Effect of mass ratio of alkali-to-ores on roasting extraction rate of V2O5

图13 不同碱矿比下钒的焙烧过程动力学曲线

Fig. 13 Kinetic curves of vanadium bearing steel slag process with different mass ratios of alkali-to-ore

3 结论

1) 含钒钢渣在熔融NaOH体系中焙烧过程最佳反应条件如下:焙烧温度为450 ℃,碱矿比为5:1,焙烧时间为60 min,在此条件下进行多次重复实验,钒提取率稳定在90%以上。

2) 含钒钢渣在熔融NaOH体系中焙烧动力学符合固体产物层扩散控制方程,反应表观活化能E=39.4 kJ/mol,动力学方程为

。

。

参考文献:

[1] 刘挥彬, 杜浩, 刘彪, 等. KOH 亚熔盐中钒渣的溶出行为[J]. 中国有色金属学报, 2013,23(4): 1129-1139.

LIU Huibin, DU Hao, LIU Biao, et al. Dissolution behavior of vanadium slag in KOH sub-molten salt[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 1129-1139.

[2] 叶国华, 童雄, 路璐. 含钒钢渣资源特性及其提钒的研究进展[J]. 稀有金属, 2010,34(5): 769-775.

YE Guohua, TONG Xiong, LU Lu. Resource characteristics of vanadium-bearing steel slag and progress in extracting vanadium from it[J]. Chinese Journal of Rare Metals, 2010, 34(5): 769-775.

[3] MONSKALYK R R, ALFANTAZI A M. Processing of vanadium: a review[J]. Minerals Engineering, 2003, 16(8): 793-805.

[4] MONAKHOV L N, KHROMOV S V, CHERMOUSOV P I. The Flow of vanadium bearing-materials in industry[J]. Metallurgist, 2004, 48(7): 381-385.

[5] 李延芬, 刘叶凤, 罗浩, 等. 提钒技术研究进展[J]. 化工进展, 2016,35(S1): 223-229.

LI Yanfen, LIU Yefeng, LUO Hao, et al. Progress of vanadium extraction technology[J]. Chemical Industry and Engineering Progress, 2016,35(S1): 223-229.

[6] VPGLAUER B, GRAUSAM A, JORGL H P. Reaction kinetics of the vanadium roasting process using steel slag as a secondary raw material[J]. Miner Eng, 2004, 17(2): 317-321.

[7] LI Xinsheng, XIE Bing, WANG Guangen, et al. Oxidation process of low-grade vanadium slag in presence of Na2CO3[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(8): 1860-1867.

[8] 宋文臣, 李宏, 李昆, 等. 熔融钒渣直接提钒新工艺[J]. 有色金属(冶炼部分), 2013(7): 35-37, 41.

SONG Wenchen, LI Hong, LI Kun, et al. New process of vanadium extraction from molten vanadium slag[J]. Nonferrous Metals(Extractive Metallurgy), 2013(7): 35-37, 41.

[9] 张新霞. 高硅高钙钒渣钠化焙烧工艺的优化研究[J]. 铁合金, 2013, 44(1): 22-24, 29.

ZHANG Xinxia. Optical research on vanadium slag with high Si Ca sodium roasting process[J]. Ferro-Alloys, 2013, 44(1): 22-24, 29.

[10] XIAO Qinggui, CHEN Yin, GAO Yiying, et al. Leaching of silica from vanadium-bearing steel slag in sodium hydroxide solution[J]. Hydrometallurgy, 2010,104(2): 216-221.

[11] 邱士星, 刘先松, 周丹, 等. 钒渣提取五氧化二钒的研究[J]. 无机盐工业, 2010,42(4): 46-48.

QIU Shixing, LIU Xiansong, ZHOU Dan, et al. Study on extracting vanadium pentoxide in vanadium slag[J]. Inorganic Chemicals Industry, 2010,42(4): 46-48.

[12] 李京, 施哲, 梁晨, 等. 低钙化焙烧-碳酸钠浸出提钒试验[J]. 矿冶,2015,24(5): 52-56.

LI Jing, SHI Zhe, LIANG Chen, et al. Experiment on extracting vanadium by the method of low calcium roasting-sodium carbonate leaching[J]. Mining & Metallurgy, 2015,24(5): 52-56.

[13] 李传启. 硫酸亚铁铵滴定法快速测定钢铁中钒[J]. 冶金分析, 2008, 28(6): 79-80.

LI Chuanqi. Rapid determination of vanadium in steel by ammonium ferrous sulfate titration method[J]. Metallurgical Analysis, 2008, 28(6): 79-80.

[14] 华一新. 冶金过程动力学导论[M]. 北京: 冶金工业出版社, 2004: 188-193.

HUA Yixin. Introduction to kinetics of metallurgy progress[M]. Beijing: Metallurgical Industry Press, 2004: 188-193.

[15] WANG Ruochao, ZHAI Yuchun, NING Zhiqiang, et al. Kinetics of SiO2 leaching from Al2O3 extracted slag of fly ash with sodium hydroxide solution[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(6): 1928-1936.

[16] 赵昌明, 翟玉春, 刘岩, 等. 红土镍矿在NaOH亚熔盐体系中的预脱硅[J]. 中国有色金属学报, 2009, 19(5): 949-954.

ZHAO Changming, ZHAI Yuchun, LIU Yan, et al. Pre- desilication of laterite in NaOH sub-molten salt system[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(5): 949-954.

[17] 杨显万, 邱定蕃. 湿法冶金[M]. 北京: 冶金工业出版社, 1998: 164-211.

YANG Xianwan, QIU Dingfan. Hydrometallurgy[M]. Beijing: Metallurgical Industry Press, 1998: 164-211.

(编辑 伍锦花)

收稿日期:2017-05-15;修回日期:2017-06-29

基金项目(Foundation item):国家自然科学基金资助项目(51674141,51174111);辽宁省教育厅项目(2016TSPY02);辽宁科技大学青年科学基金资助项目(2015QN01);辽宁省化学冶金工程重点实验室开放课题基金资助项目(USTLKFSY201502) (Projects(51674141, 51174111) supported by the National Natural Science Foundation of China; Project(2016TSPY02) supported by the Educational Commission of Liaoning Province; Project(2015QN01) supported by the Youth Science Fund of University of Science and Technology Liaoning; Project(USTLKFSY201502) supported by the Key Laboratory of Chemical Metallurgy Engineering of Liaoning Province)

通信作者:赵昌明,博士,副教授,从事矿产综合利用研究;E-mail: lnzhaochangming@163.com