Trans. Nonferrous Met. Soc. China 25(2015) 1901-1910

Surface quality, microstructure and mechanical properties of Cu-Sn alloy plate prepared by two-phase zone continuous casting

Xue-feng LIU1,2,3, Ji-hui LUO2, Xiao-chen WANG2

1. State Key Laboratory for Advanced Metals and Materials, University of Science and Technology Beijing, Beijing 100083, China;

2. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China;

3. Beijing Laboratory of Metallic Materials and Processing for Modern Transportation, University of Science and Technology Beijing, Beijing 100083, China

Received 12 July 2014; accepted 17 December 2014

Abstract: Cu-4.7%Sn (mass fraction) alloy plate was prepared by the self-developed two-phase zone continuous casting (TZCC) process. The relationship between process parameters of TZCC and surface quality of the alloy plate was investigated. The microstructure and mechanical properties of the TZCC alloy plate were analyzed. The results show that Cu-4.7%Sn alloy plate with smooth surface can be obtained by means of reasonable matching the entrance temperature of two-phase zone mold and the continuous casting speed. The microstructure of the TZCC alloy is composed of grains-covered grains, small grains with self-closed grain boundaries, columnar grains and equiaxed grains. Compared with cold mold continuous casting Cu-4.7%Sn alloy plate, the room temperature tensile strength and ductility of the TZCC alloy plate are greatly improved.

Key words: Cu–Sn alloy plate; two-phase zone continuous casting; surface quality; grains-covered grains microstructure; mechanical property

1 Introduction

With the development of high-tech industry, Cu–Sn alloys have attracted more interests because of their excellent performances in elasticity, thermal conductivity, wear resistance and corrosion resistance [1-5]. Cu-Sn alloys prepared by conventional cold mold continuous casting have serious casting defects due to their wide temperature range of two-phase (solid and liquid) zone, such as poor surface quality, inverse segregation and microporosity. These defects easily cause fracture during the cold processing. LIU et al [6] investigated the fracture which was caused by intergranular segregation of tin. MUTHIAH et al [7] developed a model for crack growth of tin-induced in Cu–Sn alloy. Therefore, the alloys need long time for homogenizing annealing before cold processing [8], which leads to low productivity. It has been found that the smooth surface alloys with columnar or single grain, which have been successfully prepared by heated mold continuous casting [9-13], have excellent mechanical properties, corrosion resistance, conductivity and plastic formability. OKAYASU et al [14] investigated the mechanical properties of Al-Cu alloy prepared by heated mold continuous casting. Compared with gravity cast sample, the tensile strength and elongation of the sample prepared by heated mold continuous casting increase. However, the productivity of heated mold continuous casting is relatively low, and it does not fit for alloys with wide two-phase zone. Therefore, heated mold continuous casting technology is not suitable for preparing Cu-Sn alloys with wide two-phase zone.

In order to resolve the problem of continuous casting of alloys with wide two-phase zone, two-phase zone continuous casting (TZCC), a new continuous casting technology, was invented by LIU [15]. TZCC technology can achieve compact processing, save energy and reduce cost. Meanwhile, the microstructure of the TZCC alloys is composed of grains-covered grains (GCGs), small grain with self-closed grain boundaries, columnar grains and equiaxed grains. The TZCC alloys show excellent properties in plasticity, strength, conductivity and corrosion resistance.

However, the experimental evidence of strengthening mechanism of the TZCC alloys is inadequate, and the effects of TZCC parameters on the surface quality of the TZCC alloys are still not clear. In the present work, the Cu-4.7%Sn alloy plate with wide two-phase zone was prepared by TZCC technology. The relationship between the process parameters of TZCC and the surface quality, microstructure and mechanical properties of the TZCC Cu-4.7%Sn alloy plate was investigated. The formation mechanism of GCGs and the mechanism of mechanical properties improvement were preliminarily discussed.

2 Experimental

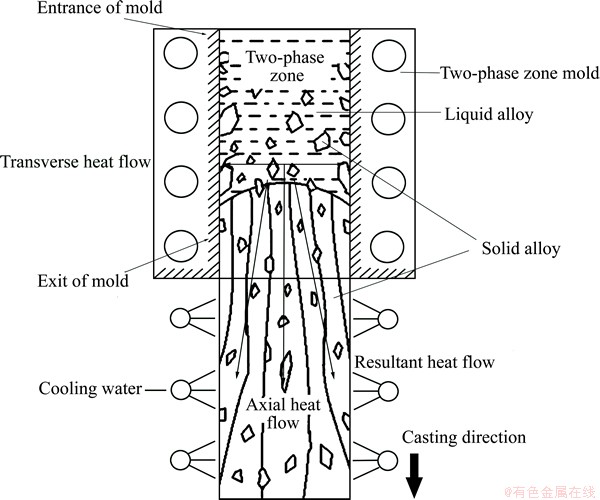

2.1 Fundamental principle of TZCC

Figure 1 shows the fundamental principle of TZCC. The two-phase zone mold was heated to control the temperature range of the mold between the liquidus and solidus during the continuous casting of alloy with wide two-phase zone. The solidified alloy was forced to cool near the exit of the mold. Continuous casting would be achieved while the alloy finished solidification before leaving the exit of two-phase zone mold.

2.2 Alloy and casting

At present, the Cu-4.7%Sn alloy with wide two-phase zone was used as the raw material. The alloy was melted under an Ar atmosphere in a graphite crucible at 1200 °C, and then kept for 20 min for homogenizing. The entrance temperature of the mold was controlled at 1020-1040 °C, and the exit temperature of the mold was controlled at 920 °C. With the liquid Cu-Sn alloy in the crucible continuously feeding into the mold, the solidified alloy was forced to be cooled by the cooling water at the exit of the mold. The flow rate of cooling water is 400 L/h with the temperature of 18 °C. Then, the Cu-Sn alloy plate was continuously prepared by traction wheels at speed of 10-40 mm/min.

2.3 Microstructure analysis

Samples for microstructure observation were cut from the TZCC Cu-4.7%Sn alloy plate. After polishing, the samples were etched by corrosion solution of FeCl3 (5 g) and alcohol (80 mL). The microstructure observation was performed by using Nikon Coolpix 995 optical microscope (OM) and scanning electron microscope (SEM).

The orientation-imaging-microscopic (OIM) was measured by electron back-scattered diffraction (EBSD) system. Chemical composition of the TZCC Cu-4.7%Sn alloy plate was analyzed by the energy dispersive spectrometry (EDS). Phase composition of the TZCC Cu-4.7%Sn alloy plate was determined by X-ray diffractometer (XRD).

Fig. 1 Schematic diagram of TZCC

2.4 Tensile test

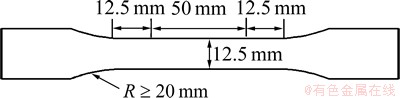

The mechanical properties tests of the Cu-4.7%Sn alloy plate, which were prepared by TZCC and conventional cold mold continuous casting, respectively, were carried out by tensile testing machine. The tensile direction was parallel to the direction of continuous casting, and the tensile samples were obtained from TZCC Cu-4.7%Sn alloy plate with smooth surface. Figure 2 shows the specific dimension parameters of the tensile sample. After the tensile test, the tensile fracture morphology and deformed tensile sample of the TZCC Cu-4.7%Sn alloy plate was characterized by SEM and EBSD, respectively.

Fig. 2 Schematic diagram of tensile sample

3 Results and discussion

3.1 Effects of TZCC process on surface quality of Cu-4.7%Sn alloy plate

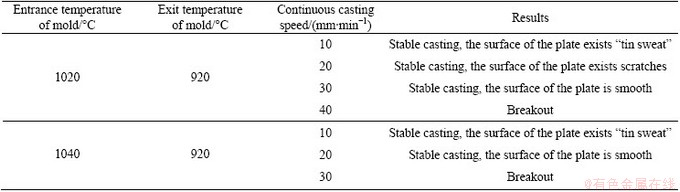

Table 1 shows the effect of process parameters on the casting process of the TZCC Cu-4.7%Sn alloy plate. Figure 3 shows the TZCC Cu-4.7%Sn alloy plate. While the entrance temperature of the mold is 1020 °C and the exit temperature of the mold is 920 °C, the surface of the TZCC Cu-4.7%Sn alloy plate has many obvious scratches at the continuous casting speed of 20 mm/min, as shown in Fig. 3(a). The melt feeding rate into the mold is low because of slow continuous casting speed, which induces the solid–liquid interface of cast alloy to move upward, so the contact distance between the solidified alloy plate and the mold wall becomes longer. Such behavior increases friction between the surface of the alloy and the mold wall. Therefore, scratches on the plate surface easily occur. The solid–liquid interface of cast alloy moves downward when the continuous casting speed is improved to 30 mm/min. The contact distance between the solidified alloy plate and the mold wall becomes shorter. Such behavior decreases the friction between the surface of the alloy and the mold wall. Therefore, the surface prepared at the continuous casting speed of 30 mm/min is smooth. With increasing the entrance temperature of the mold at the continuous casting speed of 20 mm/min, the surface can also keep smooth, which is ascribe to that improving the entrance temperature of the mold contributes to the solid–liquid interface of cast alloy moving downward.

Table 1 Effects of process parameters on casting process of TZCC Cu–4.7%Sn alloy plate

Fig. 3 TZCC Cu-4.7%Sn alloy plate (20 mm×5 mm) with surface defects

While the entrance temperature of the mold is 1040 °C, the exit temperature of the mold is 920 °C and the continuous casting speed is 10 mm/min, “tin sweat” exists on surface of the alloy plate as shown in Fig. 3(b). With high temperature of the alloy melt, solidification speed of alloy is low at the slow continuous casting speed, and the tin with low melting point gathers on the surface. Meanwhile, scratches emerge on the surface because of the slow continuous casting speed. When the continuous casting speed is increased to 20 mm/min, “tin sweat” disappears from the surface. After the continuous casting speed is increased, the solid–liquid interface moves downward and distance to the cooling water is decreased, which accelerates the solidification speed of cast alloy. Consequently, the tin with low melting point cannot gather on the surface, and the “tin sweat” is suppressed.

While the entrance temperature of the mold is 1040 °C, the exit temperature of the mold is 920 °C, the flow rate of cooling water is 400 L/h with the temperature of 18 °C and the continuous casting speed is 20 mm/min, the TZCC Cu-4.7%Sn alloy plate has smooth surface without scratches, “tin sweat” and other surface defects, as shown in Fig. 4.

Fig. 4 TZCC Cu–4.7%Sn alloy plate (20 mm×5 mm) with smooth surface

3.2 Microstructure formation of TZCC Cu-4.7%Sn alloy plate

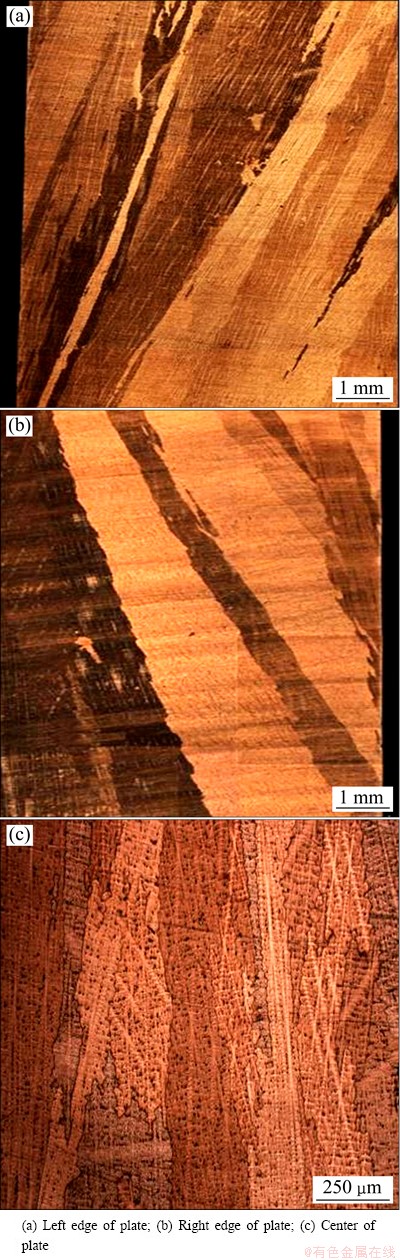

At low magnification observation, the microstructure of the TZCC Cu-4.7%Sn alloy plate is composed of mainly columnar gains, as shown in Fig. 5. From Figs. 5(a) and (b), it can be seen that the “Λ” shape inclined columnar grains, which have a certain angle along casting direction, form at the edges of the plate. From Fig. 5(c), straight columnar grains basically parallel to the casting direction are formed in the center of the plate.

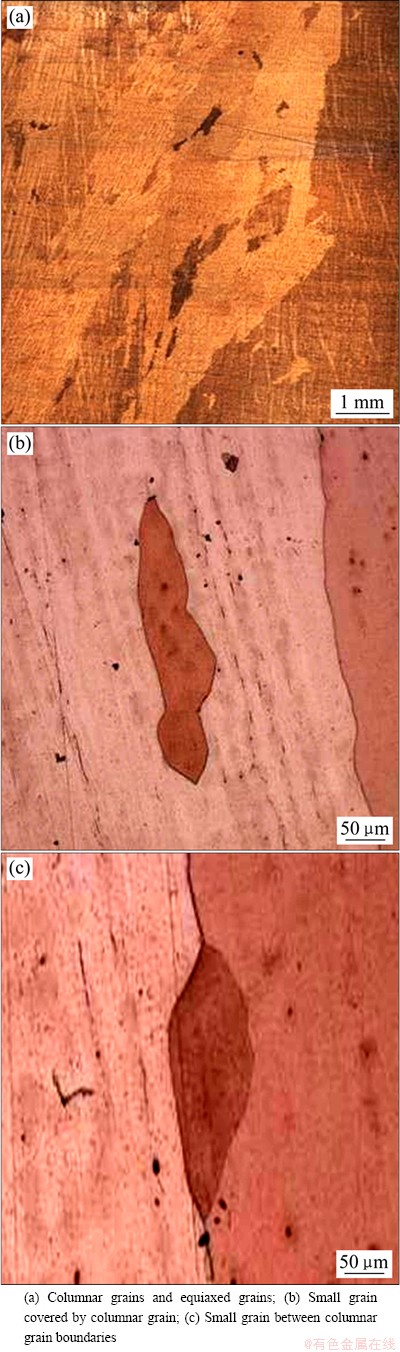

Some equiaxed grains form besides columnar grains in the TZCC Cu–4.7%Sn alloy plate, as shown in Fig. 6(a). Furthermore, many small grains are covered by some continuous columnar grains and some small grains are embedded into the boundaries of continuous columnar grains. For example, from Fig. 6(b), it can be seen that a small grain is covered by a continuous columnar grain, and a small grain is embedded into the boundaries of two continuous columnar grains, as shown in Fig. 6(c).

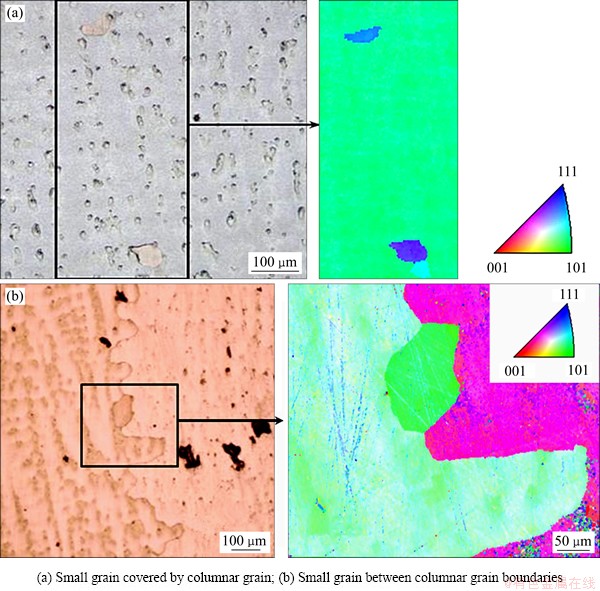

Figure 7 shows the OM and OIM of GCGs. From Fig. 7(a), it can be seen that the orientation of columnar grain tends to be <101> direction, which has different orientations with small grains covered by columnar grain. Figure 7(b) shows the OM and OIM of small grain between columnar grain boundaries. The orientations of two columnar grains approximately tend to <101> and <001> directions, respectively, which also have different orientations with small grain embedded into the columnar grain boundaries.

Fig. 5 Columnar grains of TZCC Cu-4.7%Sn alloy plate

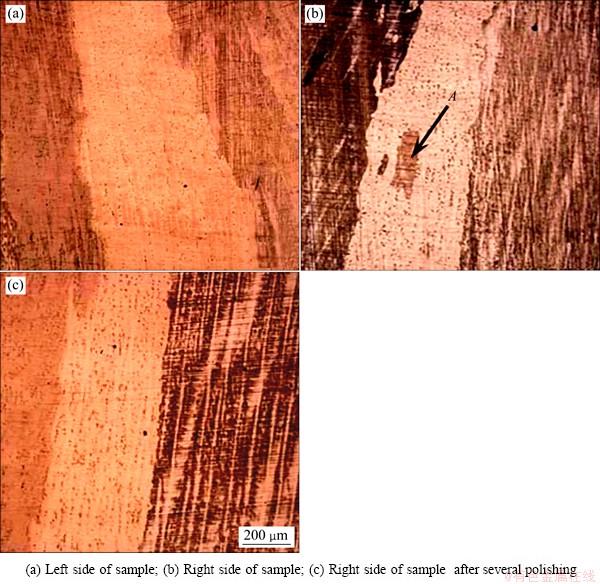

In order to confirm the GCGs microstructure, a plate sample was cut into two sides using wire cutting. Figure 8(a) shows the microstructure of the left side, and only columnar grains can be seen. Figure 8(b) shows the microstructure of the right side. It can be seen that a small grain A is covered by a continuous columnar grain. The right side of the sample was further ground, polished and etched, and the microstructure was observed layer by layer. When the right side of the sample was polished off a thickness of 50 μm, it can be found that the covered small grain by columnar grain completely disappears, but the same continuous columnar grain that covered the small grain is still visible, as shown in Fig. 8(c). This implies that the TZCC Cu-4.7%Sn alloy plate possesses GCGs, in which the small grains are entirely covered by the continuous columnar grains.

Fig. 6 Microstructures of TZCC Cu-4.7%Sn alloy plate

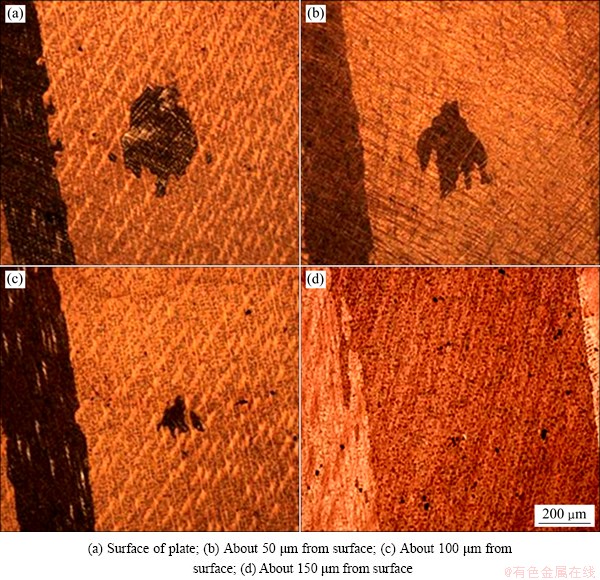

The microstructure of GCGs also can be observed on the surface of the TZCC Cu-4.7%Sn alloy plate, as shown in Fig. 9(a). The surface of the TZCC Cu-4.7%Sn alloy plate sample was further ground, polished and etched, and the microstructure was observed from the surface to interior as shown in Figs. 9(b)–(d), respectively. It can be seen that the size of small grain covered by continuous columnar grain gradually decreases, and finally disappears. However, the continuous columnar grain which covered the small grain still exists. It is suggested that the surface microstructure is GCGs.

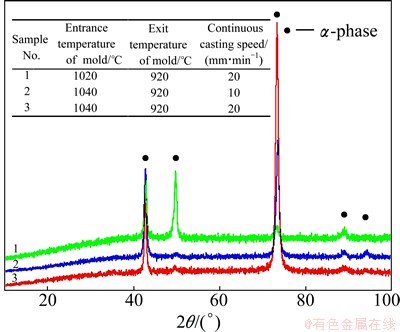

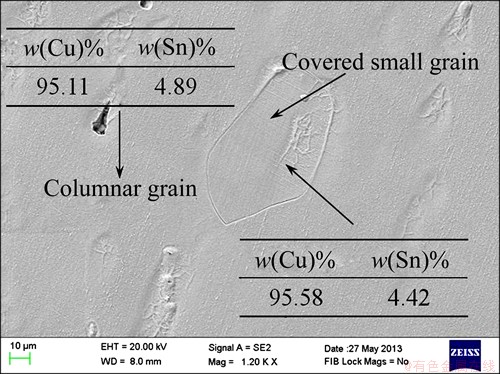

The results of the X-ray diffraction show that only α-phase (Cu-Sn continuous solid solution phase) exists in the TZCC Cu-4.7%Sn alloy plate without any other phases, as shown in Fig. 10. The facts suggest that the covered small grains and continuous columnar grains of the TZCC Cu-4.7%Sn alloy plate are both composed of α-phase, which means that continuous columnar grains cover small grains with the same phase. Figure 11 shows the SEM image of GCGs. The chemical composition of small grain and columnar grain was analysed by EDS. The results of EDS show that both grains have almost the same chemical composition with Sn content of 4.42% in covered small grain and 4.89% (mass fraction) in continuous columnar grain. It can be concluded that the formation of GCGs microstructure is not ascribed to phase transformation or peritectic reaction.

The heat flow directions of the TZCC Cu-4.7%Sn alloy plate in two-phase zone mold are shown in Fig. 1. On one hand, because of the role of intense cooling near the exit of the mold, a high temperature gradient between melt and solidified cast alloy is established during TZCC process, which induces the heat flow of melt to transfer along the casting direction, and there exists a strong axial heat flow parallel to the casting direction. Therefore, continuous columnar grains can form in the center of the alloy plate. On the other hand, the temperature of the two-phase zone mold, controlled in the range of solid–liquid of the alloy, is lower than liquidus, which induces the heat flow of melt to transfer from the mold wall to the outside, and there exists a transverse heat flow perpendicular to the casting direction. Therefore, grains nucleate on the sidewall of the mold and grow up, and drop into the melt induced by thermal convection [9]. Part of these falling small grain grow to equiaxed grains after solidification of the alloy. Some small grains are swallowed by continuous columnar grains which grow to liquid. Therefore, the microstructure of continuous columnar grains-covered small grains with self-closed grain boundaries is formed. The other falling small grains are embedded into the boundaries of continuous columnar grains, and the microstructure of equiaxed grains in boundaries of continuous columnar grains is formed. In addition, because of existing transverse and axial heat flow, the heat flow of the plate edge is actually transferred according to resultant heat flow of “Λ” shape. For this reason, the microstructure of “Λ” shape inclined columnar grains at the edge of the plate is formed.

Fig. 7 OM and OIM of GCGs

Fig. 8 Interior GCGs of TZCC Cu-4.7%Sn alloy plate

Fig. 9 Surface GCGs of TZCC Cu-4.7%Sn alloy plate

Fig. 10 XRD patterns of TZCC Cu-4.7%Sn alloy plate

Fig. 11 SEM image and chemical composition of GCGs

3.3 Mechanical properties of TZCC Cu-4.7%Sn alloy plate

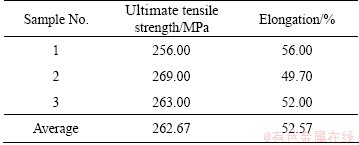

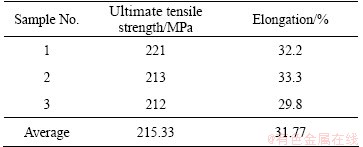

The average ultimate tensile strength of the TZCC Cu-4.7%Sn alloy plate is 262.67 MPa, and the average elongation is 52.57% (Table 2). The average ultimate tensile strength of the cold mold continuous casting Cu-4.7%Sn alloy plate is 215.33 MPa, and the average elongation is 31.77% (Table 3). From Tables 2 and 3, it can be seen that the ultimate tensile strength and elongation of the TZCC Cu-4.7%Sn alloy plate are higher than those of the cold mold continuous casting ones. The ultimate tensile strength and elongation are improved by 21.98% and 65.47%, respectively.

Table 2 Mechanical properties of TZCC Cu-4.7%Sn alloy plate

Table 3 Mechanical properties of cold mold continuous casting Cu-4.7%Sn alloy plate

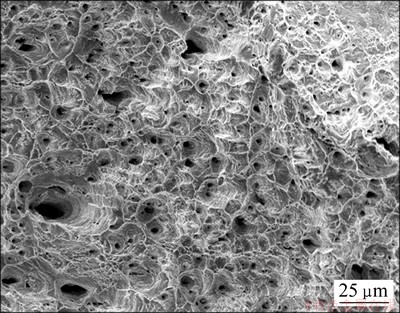

Figure 12 shows the fracture morphology of the TZCC Cu-4.7%Sn alloy plate. The morphology displays the fracture features of the dimple, which is a typical ductile fracture. This means that the TZCC Cu-4.7%Sn alloy plate has excellent ductility.

Fig. 12 Tensile fracture morphology

Because columnar grains parallel to the axial direction are main characteristics of the microstructure, interconnected equiaxed grain boundaries and transverse grain boundaries perpendicular to axial direction are decreased. Coordinate deformation between columnar grains contributes to improving ductility during tensile deformation along the axial direction [16]. Furthermore, less transverse grain boundaries contribute to restraining the intergranular fracture. Therefore, the elongation of the TZCC alloy plate significantly increases.

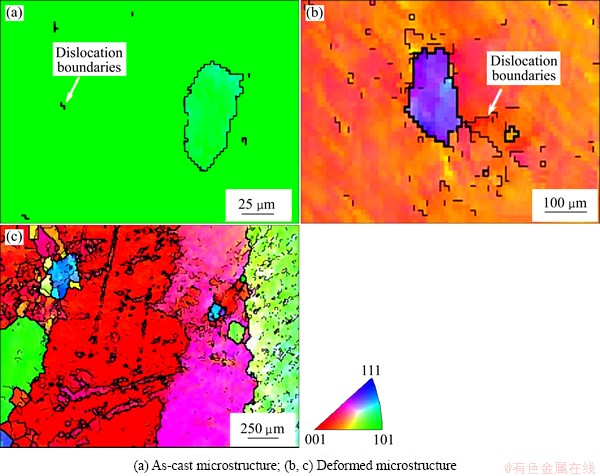

The EBSD measurements have the statistical information of both small angle dislocation boundaries and large angle boundaries [16,17]. Figures 13(a) and (b) show the OIM of small grain, which represent as-cast and deformed tensile sample, respectively. Misorientation angles with a range of more than 5° were counted (the range of less than 5° is not represent in distribution feature of dislocation boundaries). It can be seen that dislocation boundaries mainly concentrate around the small grain in deformed sample (Fig. 13(b)). However, only little boundaries exist in as-cast sample (Fig. 13(a)).

Fig. 13 OIM of GCGs

Small angle dislocation boundaries also concentrate in equiaxed and columnar grains as shown in Fig. 13(c).

On one hand, dislocations concentrate in the grain boundaries of the continuous columnar grains during tensile deformation, which form dislocation bands. On the other hand, because many small grains with self-closed grain boundaries exist in columnar grains, more and more dislocations concentrate at the self-closed grain boundaries during tensile deformation, which form “dislocation islands”. Moreover, some equiaxed grains also exist at the TZCC alloy plate, and dislocations concentrate in the grain boundaries of equiaxed grains during tensile deformation, which form dislocation groups. Because dislocation bands, “dislocation islands” and dislocation groups which emerge during the tensile deformation play a strongly pinning effect for dislocation slip, the tensile strength of the TZCC alloy plate significantly increases.

4 Conclusions

1) In this experiment, the exit temperature of two-phase zone mold is set at 920 °C, and the flow rate of cooling water is 400 L/h with the temperature of 18 °C. The TZCC Cu-4.7%Sn alloy plate with smooth surface can be obtained, and the reasonable process parameters are the entrance temperature of two-phase zone mold of 1040 °C, the continuous casting speed of 20 mm/min, or the entrance temperature of two-phase zone mold of 1020 °C, the continuous casting speed of 30 mm/min.

2) The microstructure of the TZCC Cu–4.7%Sn alloy plate is composed of continuous columnar grains-covered small grains in the center of the plate, small grains with self-closed grain boundaries in GCGs, “Λ” shape inclined columnar grains at the edge of the plate, equiaxed grains and continuous columnar grains in the center of the plate. The main reason that microstructure formation of the Cu-4.7%Sn alloy plate prepared by TZCC is that there simultaneity exist transverse, axial and resultant heat flow in two-phase zone mold.

3) Compared with the cold mold continuous casting counterpart, the TZCC Cu-4.7%Sn alloy plate has excellent mechanical properties. The ultimate tensile strength is 262.67 MPa, and the elongation is 52.57%, which are improved by 21.98% and 65.47%, respectively. Coordinate deformation between columnar grains, which is parallel to the tensile direction and less transverse grain boundaries which suppress the grain boundary fracture are the main reasons for the elongation improvement of the TZCC Cu-4.7%Sn alloy plate. The dislocation bands, “dislocation islands” and dislocation groups which emerge during the axial tensile deformation can increase the ultimate tensile strength of the TZCC Cu-4.7%Sn alloy plate significantly.

References

[1] LIAO Xiao-ning, CAO Fa-he, CHEN An-na, LIU Wen-juan, ZHANG Jian-qing, CAO Chu-nan. In-situ investigation of atmospheric corrosion behavior of bronze under thin electrolyte layers using electrochemical technique [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 1239-1249.

[2] KATO H, TAKAMA M, IWAI Y, WASHIDA K, SASAKI Y. Wear and mechanical properties of sintered copper–tin composites containing graphite or molybdenum disulfide [J]. Wear, 2003, 255: 573-578.

[3] DENG X, CHAWLA N, CHAWLA K K, KOOPMAN M. Deformation behavior of (Cu,Ag)-Sn intermetallics by nanoindentation [J]. Acta Materialia, 2004, 52: 4291-4303.

[4]  MARTINEZ S. Corrosion evaluation and surface characterization of the corrosion product layer formed on Cu-6Sn bronze in aqueous Na2SO4 solution [J]. Corrosion Science, 2009, 51: 1596-1603.

MARTINEZ S. Corrosion evaluation and surface characterization of the corrosion product layer formed on Cu-6Sn bronze in aqueous Na2SO4 solution [J]. Corrosion Science, 2009, 51: 1596-1603.

[5] KOHLER F, CAMPANELLA T, NAKANISHI S, RAPPAZ M. Application of single pan thermal analysis to Cu-Sn peritectic alloys [J]. Acta Materialia, 2008, 56: 1519-1528.

[6] LIU X, THAM D, YATES D, McMAHON C J Jr. Evidence for the intergranular segregation of tin to grain boundaries of a Cu–Sn alloy and its consequences for dynamic embrittlement [J]. Materials Science and Engineering A, 2007, 458: 123-125.

[7] MUTHIAH R C, PFAENDTNER J A, McMAHON C J Jr, XU Y, BASSANI J L. A study of dynamic embrittlement in bicrystals of Cu-7%Sn [J]. Materials Science and Engineering A, 1997, 234-236: 1033-1036.

[8] HUANG J S, ZHANG J, CUEVAS A, TU K N. Recrystallization and grain growth in bulk Cu and Cu(Sn) alloy [J]. Materials Chemistry and Physics, 1997, 49: 33-41.

[9] OHNO A. Continuous casting of single crystal ingots by the O. C. C. process [J]. Journal of Metals, 1986, 38(1): 14-16.

[10] ZHANG Xiao-wei, HUANG Jin-feng, DENG Kang, REN Zhong-ming. Solidification of horizontally continuous casting of super-thin slab in stable magnetic field and alternating current [J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 196-201.

[11] SODA H, McLEAN A, WANG Z, MOTOYASU G. Pilot-scale casting of single-crystal copper wires by the Ohno continuous casting process [J]. Journal of Materials Science, 1995, 30: 5438-5448.

[12] OKAYASU M, YOSHIE S. Mechanical properties of Al-Si13-Ni1.4-Mg1.4-Cu1 alloys produced by the Ohno continuous casting process [J]. Materials Science and Engineering A, 2010, 527: 3120-3126.

[13] MOTOYASU G, KANEKO M, SODA H, McLEAN A. Continuously cast Cu-Al-Ni shape memory wires with a unidirectional morphology [J]. Metallurgical and Materials Transactions A, 2001, 32: 585-593.

[14] OKAYASU M, TAKASU S, YOSHIE S. Microstructure and material properties of an Al-Cu alloy provided by the Ohno continuous casting technique [J]. Journal of Materials Processing Technology, 2010, 210: 1529-1535.

[15] LIU X. Casting equipment and method using solid–liquid two-phase region temperature as casting mold temperature: China Patent, CN201010148612 [P]. 2010-04-14.

[16] WANG Y, HUANG H, XIE J. Texture evolution and flow stress of columnar-grained polycrystalline copper during intense plastic deformation process at room temperature [J]. Materials Science and Engineering A, 2011, 530: 418-425.

[17] IFERGANE S, BARKAY Z, BEERI O, ELIAZ N. Study of fracture evolution in copper sheets by in situ tensile test and EBSD analysis [J]. Journal of Materials Science, 2010, 45: 6345-6352.

两相区连铸Cu–Sn合金板材的表面质量和组织性能

刘雪峰1,2,3,罗继辉2,王晓晨2

1. 北京科技大学 新金属材料国家重点实验室,北京100083;

2. 北京科技大学 材料科学与工程学院,北京100083;

3. 北京科技大学 现代交通金属材料与加工技术北京实验室,北京100083

摘 要:采用自主研发的两相区连铸技术制备Cu-4.7%Sn合金板材,研究两相区连铸工艺参数与Cu-4.7%Sn合金板材表面质量的关系,分析合金板材的微观组织及力学性能。结果表明,通过合理匹配两相区铸型入口温度和拉铸速度,可以制备得到表面光滑的Cu-4.7%Sn合金板材,其微观组织由晶包晶组织、具有自封闭晶界的小晶粒、柱状晶及等轴晶构成。与冷型连铸Cu-4.7%Sn合金板材相比,两相区连铸合金板材的室温抗拉强度和伸长率显著提高。

关键词:Cu-Sn合金板材;两相区连铸;表面质量;晶包晶组织;力学性能

(Edited by Yun-bin HE)

Foundation item: Project (51374025) supported by the National Natural Science Foundation of China; Project (2014Z-05) supported by the State Key Laboratory for Advanced Metals and Materials, University of Science and Technology Beijing, China; Project (2152020) supported by the Beijing Natural Science Foundation, China

Corresponding author: Xue-feng LIU; Tel/Fax: +86-10-62333627; E-mail: liuxuefengbj@163.com

DOI: 10.1016/S1003-6326(15)63797-9