文章编号:1004-0609(2010)10-1955-07

粉末冶金15%SiCp/2009Al复合材料的高周疲劳性能

邹利华,樊建中,左 涛,马自力,魏少华

(北京有色金属研究总院 国家有色金属复合材料工程技术研究中心,北京 100088)

摘 要:采用粉末冶金法制备15%SiCp/2009Al(体积分数)复合材料,并测试其旋转弯曲疲劳和轴向疲劳性能,采用扫描电镜观察其疲劳断口。结果表明:15%SiCp/2009Al复合材料具有良好的高周疲劳性能,疲劳裂纹萌生于试样表面中较大的SiC颗粒、金属间化合物颗粒以及一些“无特殊微观组织特征”区域;疲劳裂纹扩展以形成微孔与韧窝、形成撕裂脊、增强颗粒SiC开裂、增强颗粒-基体界面脱粘为主要形式;控制SiC颗粒粒度、优化SiC颗粒均匀分布于2009Al基体、保证SiC颗粒与基体具有良好的界面结合,这样的微观组织对 15%SiCp/2009Al复合材料的疲劳性能至关重要。

关键词:SiCp/Al复合材料;疲劳;微观组织;疲劳断口

中图分类号:TG146.2 文献标志码:A

High-cycle fatigue behavior of 15%SiCp/2009Al composite prepared by powder metallurgy process

ZOU Li-hua, FAN Jian-zhong, ZUO Tao, MA Zi-li, WEI Shao-hua

(National Engineering and Technology Research Center for Nonferrous Metal Composites,

General Research Institute for Nonferrous Metals, Beijing 100088, China)

Abstract: The fatigue behavior of naturally aged powder metallurgy 15%SiCp/2009Al (volume fraction) composite was investigated. The fatigue lives were determined using load-controlled rotary bending and axial fatigue testing ,the fracture surfaces of samples were examined by scanning electron microscopy. The results show that the high-cycle fatigue properties of 15%SiCp/2009Al composite are superior, the fatigue cracks initiate from several different microstructural defects known as some fractured SiC particles with relatively bigger size at sample surface, intermetallics and so called no specific microstructural feather area. The voids and dimples, tear ridges, SiC particle fracture and SiCp-Al interface decohesion are the main mechanisms during fatigue crack propagation. The microstructure consists of the large size reinforcement, homogeneous distribution of reinforcement and well combination of reinforcement-matrix interface and plays a significant role for fatigue properties of 15%SiCp/2009Al composite.

Key words: SiCp/Al composite; fatigue; microstructure; fracture surface

颗粒增强金属基复合材料(PMMC)具有比强度和比刚度高、弹性模量高、耐疲劳、耐磨损及热膨胀系数低等一系列优点,可以实现工业化生产,有利于生产过程的控制和成本的降低,特别是还可以通过组分及工艺条件的设计来灵活调节其性能,满足不同应用场合的要求,因此,在军事、航空航天和汽车等领域内都具有诱人的应用前景[1-2]。随着PMMC在这些领域内作为承力构件逐渐应用,对其疲劳性能的研究也得到重视。目前,国内外学者从增强颗粒特性、基体特性、增强颗粒与基体的交互影响以及试验条件等方面广泛研究PMMC的疲劳性能[3-9],研究结果表明,与未增强金属相比,加入增强颗粒有利于获得较长的疲劳寿命,但是增强体(颗粒种类、形貌、大小、体积分数等)、基体(成分、微观组织)及其界面结合等因素的共同作用会对PMMC疲劳性能产生复杂的影响。因此,研究这些因素对复合材料疲劳性能的影响及其作用大小对提高复合材料的疲劳性能具有重要意义。

本文作者通过粉末冶金法制备了15%SiCp/ 2009Al(体积分数)复合材料,测试其常规力学性能和疲劳性能,观察了复合材料的微观组织和疲劳断口,并结合SiC增强颗粒在15%SiCp/2009Al复合材料疲劳裂纹萌生和扩展各阶段所起的作用,探讨有利于PMMC获得良好疲劳性能的条件,可为颗粒增强金属基复合材料未来的工程应用提供有益参考。

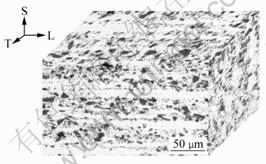

1 实验

实验用15%SiCp/2009Al复合材料的基体选用2009Al,其合金成分如表1所列。增强颗粒选用α-SiC,其体积分数为15%。复合材料制备工艺采用粉末冶金法,其工艺流程如下:首先采用气雾化法制备2009铝合金粉末;然后将SiC粉末和2009Al粉末机械混合、粉末混合物冷压、真空热压;随后热压坯锭在3 600 t挤压机上进行热挤压,挤压比为10:1;挤压棒材在 3 000 t等温模锻设备上进行径向锻造,获得厚度为30 mm的锻坯。挤压棒材及其锻坯的热处理工艺为500 ℃下保温1 h,水淬,室温96 h自然时效。制备的15%SiCp/2009Al复合材料的微观组织及力学性能分别如图1和表2所示。

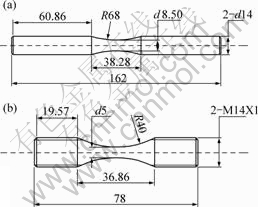

疲劳试验试样如图2所示,试验于室温下进行。旋转弯曲疲劳的加载频率为83.3Hz,应力比R=-1,轴向疲劳的加载波形为三角波,频率为120 Hz,应力比R=0.1;疲劳断口用日立S-4800型冷场发射扫描电镜观察,并进行能谱分析(EDS)。

2024Al是2×××系列铝中的常用铝合金,与2009Al的成分也较为相近,因此,试验还采用商用2024Al(T4)合金与15%SiCp/2009Al复合材料进行常规力学性能及旋转弯曲疲劳性能对比研究,2024Al合金成分及力学性能结果分别列于表1和2。其疲劳试验

图1 15%SiCp/2009Al复合材料金相照片

Fig.1 Optical micrographs of 15%SiCp/2009Al composite

图2 旋转弯曲疲劳试样及轴向疲劳试样

Fig.2 Specimens designed for fatigue test (mm): (a) Specimen for rotary bending fatigue tset; (b) Specimen for axial fatigue test

表1 2009Al粉末及2024Al的化学成分

Table 1 Chemical compositions of 2009Al powder and 2024Al alloy for experiments

表2 15%SiCp/2009Al复合材料及2024Al合金的力学性能

Table 2 General mechanical properties of 15%SiCp/ 2009Al composite and 2024Al alloy

方法与复合材料相同。

2 结果与讨论

2.1 复合材料的疲劳性能

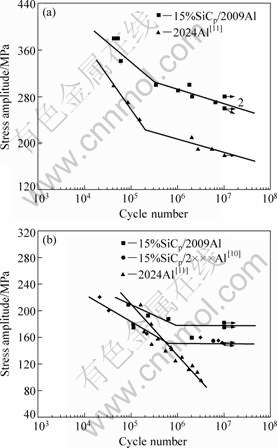

15%SiCp/2009Al复合材料的疲劳试验S—N曲线如图3所示。从图3中可以看出,复合材料具有良好的疲劳性能。在107周次疲劳寿命下,其旋转弯曲疲劳强度为260 MPa,轴向疲劳(R=0.1)强度为182 MPa。

图3 15%SiCp/2009Al复合材料疲劳试验S—N曲线

Fig.3 Fatigue test results of 15%SiCp/2009Al composite: (a) S—N curve of rotary bending fatigue; (b) S—N curve of axial fatigue

值得注意的是,铝合金的疲劳S—N曲线一般随着疲劳寿命的延长而持续下降,因此,铝合金不存在确定的疲劳极限。在铝合金中加入SiC颗粒制备得到SiCp/Al复合材料却有可能改变这一规律(见图3(a)),SiCp/Al复合材料旋转弯曲疲劳S—N曲线的变化规律与铝合金类似,在104~107周次疲劳寿命之间,随着疲劳寿命增长其疲劳强度持续下降,而在轴向疲劳(R=0.1)中,这一规律截然不同(见图3(b)),复合材料在疲劳寿命106~107周次区间存在一个较为明显的平台区,这意味着当低于某一应力水平时,疲劳寿命似乎可以无限延长,BONNEN等[10]对15%SiCp/ (Al-3.57Cu-1.83Mg)复合材料轴向疲劳(R=0.1)的疲劳研究也得到了同样的规律(见图3(b))。目前,关于SiCp/Al复合材料是否存在确定的疲劳极限尚无定论,本研究结果也显示出两种不同的规律,因此要得到较为确切的结论,还需要更加丰富的试验数据及更长的疲劳寿命范围内对SiCp/Al复合材料疲劳进行研究。

2.2 疲劳断口

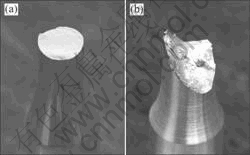

15%SiCp/2009Al复合材料与2024Al旋转弯曲疲劳断口的实物照片如图4所示。由图4可看出,SiCp/Al复合材料与铝合金疲劳断裂的宏观断口有很大不同。由图4(a)可以看出,复合材料断口平整,表面略有起伏,但基本位于垂直于试样轴线的平面上,断口呈暗灰色的纤维状,韧窝特征明显。图4(b)所示的2024Al疲劳断口则凹凸不平,断口有一半以上呈现出大平面状,断口呈锋利的楔形,该断口平面的法线方向与加载方向成约45?角,在该断口平面上可以观察到滑移带,根据铝合金的断裂特征,可以断定断裂面为{111}面。

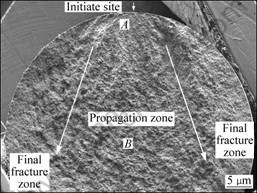

采用扫描电镜(SEM)对15%SiCp/2009Al复合材料的疲劳断口进行了全面观察。低倍下复合材料的疲劳断口如图5所示,疲劳断口可以分为如下3个区域:疲劳裂纹源(Initiation site)、疲劳裂纹扩展区(Propagation zone)及最终断裂区(Final fracture zone)。疲劳裂纹源通常位于试样表面。疲劳裂纹扩展区又可以细分为疲劳核心区(标记A)和粗颗粒区(标记为B),疲劳核心区位于疲劳源周围,以疲劳源为焦点,由于疲劳裂纹在该区域内扩展很慢及裂纹反复张开闭合造成断面磨光,因此该区域较为光滑细洁。粗颗粒区断面则相对粗糙。最终断裂区位于断口最外缘,通常与

图4 疲劳试样断裂后实物图

Fig.4 Photographs of fractured specimens: (a) 15%SiCp/ 2009Al; (b) 2024Al

图5 15%SiCp/2009Al复合材料宏观疲劳断口形貌

Fig.5 Macroscopic appearance of fracture surface of 15%SiCp/2009Al composite

疲劳裂纹扩展区位于不同平面内。在较低的循环载荷下加载时,试样上一般只会产生一个疲劳裂纹源,疲劳核心区面积较大而最终断裂区面积较小。提高循环载荷,则试样上可能出现多个疲劳裂纹源,并且疲劳核心区面积变小、最终断裂区面积增大。

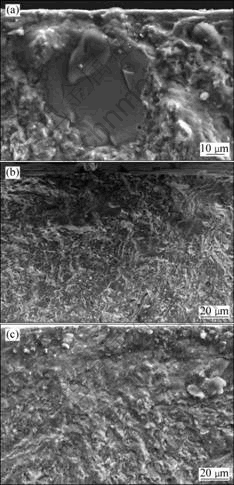

15%SiCp/2009Al复合材料中典型的疲劳裂纹源如图6所示。图6(a)和(b)所示分别为增强颗粒开裂、金属间化合物萌生疲劳裂纹。观察发现,因开裂而萌生裂纹的SiC颗粒其粒径大大超过平均颗粒粒径。文献[2]对PMMC疲劳裂纹萌生规律进行总结发现,当颗粒大于50 μm时,PMMC易于萌生疲劳裂纹,引起疲劳寿命大幅度降低。本试验中,在15%SiCp/ 2009Al复合材料的金相、疲劳断口上较少观察到粒径大于50 μm的SiC颗粒,因此SiC颗粒开裂萌生疲劳裂纹的几率也较低。本研究还对图6(b)所示的金属间化合物进行能谱(EDX)分析,结果显示该金属间化合物中含有Al、Cu、Mg、Si和Fe,这些元素都属于2×××系列铝合金中的常见元素。在材料制备过程中,形成少量金属间化合物几乎是难以避免的[6,12]。由于复合材料中含有占15%(体积分数)的SiC颗粒,SiC颗粒的强度和硬度均远远大于金属间化合物的,材料在制备过程中经历了热挤压和热模锻的大变形过程,SiC颗粒在变形中可以通过挤压、磨削等方式破碎脆性的金属间化合物,使其尺寸变小、分布变得分散,最终只有少量较大的金属间化合物可以萌生疲劳裂纹。总的来说,增强颗粒开裂和金属间化合物造成的疲劳裂纹萌生的试样仅占所有试样的一小部分,大部分试样的疲劳裂纹源如图6(c)所示,该裂纹源无增强颗粒开裂现象、化学成分与周围基体一致、断口形貌与临近区域无明显差别,通常将复合材料中这一现象称为“无特殊微观组织特征”区域萌生疲劳裂纹[10, 13]。

图6 15%SiCp/2009Al复合材料中的疲劳裂纹源

Fig.6 Fatigue initiation of 15%CiCp/2009Al composite: (a) Fractured SiC particle; (b) Intermetallic inclusion; (c) No specific microstructural feature

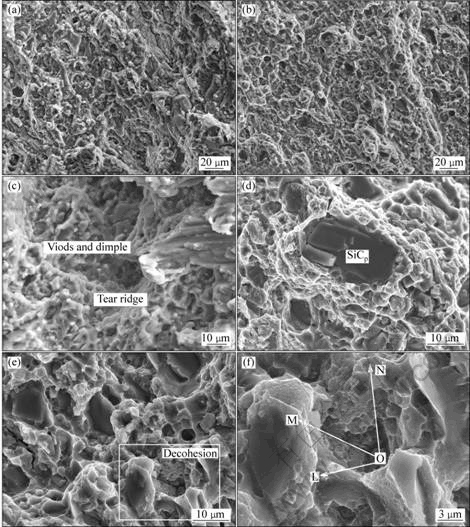

图7所示为15%SiCp/2009Al复合材料疲劳裂纹扩展区形貌。由图7可以看出,复合材料疲劳断裂的主要方式为:载荷循环过程中基体内产生的微孔长大或者聚合形成韧窝、韧窝与韧窝相遇或者通过撕裂脊将韧窝连接,从而实现裂纹生长(见图7(c)),断口中还可以观察到增强颗粒开裂(见图7(d))和增强颗粒-基体界面脱粘(图7(e)和(f))。图7(a)所示为疲劳核心区,断口形貌主要由微孔、韧窝和撕裂脊组成,难以观察到开裂的SiC颗粒;图7(b)所示为粗颗粒区,断口形貌依然以微孔、韧窝和撕裂脊为主,但随着疲劳裂纹长度增长,增强颗粒开裂现象逐渐明显。在疲劳裂纹扩展中后期,才逐渐可以观察到增强颗粒-基体界面脱粘现象。如图7(e)所示,脱粘发生后,原增强颗粒-基体界面处留下一系列紧密排列的浅小韧窝,图7(f)所示为对脱粘部分细节的观察,可推测出该部位原来存在一多面体形SiC颗粒,该颗粒以OL、OM和ON为棱

图7 疲劳裂纹扩展区的形貌

Fig.7 Morphologies of fatigue crack propagation zone: (a) A in Fig.5; (b) B in Fig.5; (c) Voids and dimples, tear ridges; (d) SiC particle fracture; (e) SiCp-Al interface decohesion; (f) Detail of Fig.7(e)

边,“多面体棱边”上的韧窝较大而“面”上的韧窝较小,说明SiC颗粒棱边与基体的连接部位首先发生脱粘,形成韧窝,之后才发生其余部位的脱粘,因此“棱边”部位的韧窝萌生及长大的时间大于“面”上的韧窝,最终“棱边”上韧窝的平均尺寸也较大。在界面脱粘后留下了密排韧窝,这是增强颗粒-基体界面结合良好的特征之一[14],这一形貌反映本试验制备15%SiCp/ 2009Al复合材料具有良好的SiCp-Al界面结合。

2.3 结果分析

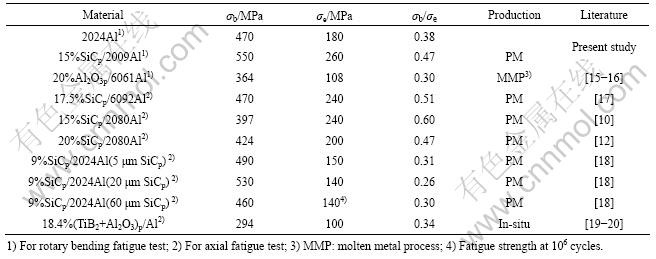

疲劳研究得到的经验规律表明,疲劳极限(σ-1)(或者是在107周次疲劳寿命下的疲劳强度(σe))与抗拉强度(σm)的比值往往为一常数,通常在铝合金中σe/σm值约为0.3,但是这一经验规律却并不适用于PMMC。如表3所列,其中本研究制备的15%SiCp/ 2009Al复合材料σe/σm=0.47,大大超过了2024Al中σe/σm比值。从现有的文献来看,复合材料中σe/σm分布于0.2~0.6之间,并且这一比值可能与复合材料的制备方法有一定联系,综合文献报导来看,粉末冶金法(PM)制备复合材料的σe/σm往往较大,其它方法制备复合材料的σe/σm较小。

实际上,复合材料疲劳强度和σe/σm比值的差异并非完全来源于制备方法的不同,而与增强颗粒对疲劳性能贡献的大小却有很大关系。由复合材料的增强机理可知,在具有良好界面结合的复合材料中,载荷可以由基体有效地传递至增强体,增强体承担更大的载荷而起到了强化材料的作用。在复合材料的疲劳过程中,增强体由于具有较高的强度而难以被破坏,可以在疲劳过程中承担载荷、阻止疲劳裂纹扩展,有利于复合材料获得较高的疲劳性能。相应地,如果存在某些因素降低了颗粒的增强效果,则复合材料的疲劳性能降低,这些因素包括增强颗粒过大、增强颗粒分布不均以及增强颗粒-基体界面结合不良等。一般来说,铸造PMMC中增强颗粒易于团聚,在团聚区域内应力集中较大,且界面结合不良的可能性提高,是疲劳裂纹萌生与扩展的有利区域,因此,在表3所列的颗粒增强铝基复合材料中,铸造法(MMP)制备得到复合材料的疲劳强度和σe/σm值较小[15-16],粉末冶金法制备得到复合材料的疲劳强度和σe/σm值则较大[10, 12, 17]。当然这一结论也并非绝对,UEMATSU等[18]采用粉末冶金法制备不同粒径(5、20、60 μm)SiC颗粒增强的9%SiCp/2024Al复合材料,但由于复合材料中增强颗粒分布不均和SiCp-Al界面结合强度不高,疲劳裂纹主要萌生于颗粒团聚区域(5、20 μm SiC颗粒增强复合材料)或者增强颗粒-基体界面脱粘处(60 μm SiC颗粒增强复合材料),其疲劳强度和σe/σm值也较小。另外,如果存在特别有利于疲劳裂纹萌生扩展的因素,增强颗粒对疲劳性能的贡献也会降低,TJONG等[19-20]用原位反应法制备22%(TiB2+Al2O3)p/ Al复合材料,但反应后生成约4.3%(体积分数)Al3Ti粗大脆性金属间化合物,而TiB2和Al2O3增强颗粒粒径较小(比Al3Ti的小一个数量级),在变形过程中未能有效破碎Al3Ti,粗大的脆性Al3Ti成为该复合材料中疲劳裂纹的萌生与扩展的有利条件,所以该复合材料疲劳强度和σe/σm比值也较小;上述复合材料[15-16, 18-20]中增强颗粒均未能起到有效阻碍疲劳裂纹萌生和扩展的作用,因此它们的疲劳强度和σe/σm值均相对较低。在15%SiCp/2009Al复合材料制备过程中,通过筛分工艺控制SiC颗粒粒度;通过粉末混合、热挤压、锻造等工艺使得增强颗粒在基体中的分布趋于均匀,同时热挤压、锻造还可以破碎基体中产生的金属间化合物;通过合理的工艺参数使得复合材料获得良好的增强体-基体界面结合;以上因素的综合作用使得15%SiCp/ 2009Al复合材料具有良好的疲劳性能和较高的σe/σm比。

若将图3所示的S—N曲线反向延长,不论旋转弯曲疲劳还是轴向疲劳试验中,在较低疲劳寿命处铝合金与复合材料的S—N曲线会相交,此时再提高循环应力,铝合金的疲劳寿命反而会高于复合材料的,因此在较高的循环应力下,SiC颗粒对15%SiCp/ 2009Al复合材料疲劳性能的提高效果减弱。

上述现象需要结合线弹性断裂力学予以分析。疲劳裂纹的萌生和扩展始于试样表面首先萌生的短裂纹(或称小裂纹),这些短裂纹数量众多,由于显微组织的不均匀性,开始时这些短裂纹以一种无规律的方式扩展,其中大部分短裂纹最终停止扩展,最终只有一根短裂纹单独发展或者数根短裂纹汇合形成主裂纹,主裂纹继续发展,依次经历近门槛区扩展、Paris区扩展等阶段,造成试样疲劳失效。根据线弹性断裂力学原理分析可知,在较低的循环载荷下,疲劳裂纹尖端的应力强度因子较小,其尖端塑性区较小,裂纹尖端与前方障碍的交互作用会改变裂纹扩展路径、降低裂纹扩展速率。在金属及合金中,裂纹扩展的障碍主要是晶界,而在复合材料中,裂纹扩展的障碍则包括晶界和增强颗粒,所以复合材料中疲劳裂纹扩展的阻碍因素增多、疲劳裂纹被捕获的几率增大[2, 13]。因此,在较低载荷下的疲劳循环中,裂纹不能造成15%SiCp/ 2009Al复合材料中SiC颗粒开裂或者SiCp-Al界面脱

表3 颗粒增强铝基复合材料中抗拉强度和疲劳强度关系

Table 3 Relationship between ultimate tensile strength and fatigue strength in particle reinforced aluminium composites

粘,反而极有可能出现SiC颗粒捕获疲劳裂纹、裂纹停止扩展的现象;在较高的循环载荷下,裂纹尖端应力强度因子增大,其尖端塑性区也增大。即使SiC颗粒强度较大并且SiCp-Al界面结合良好,疲劳裂纹也可以破坏前端遇到的SiC颗粒和界面,此时增强颗粒开裂和界面脱粘加速了裂纹扩展。因此,增强颗粒对15%SiCp/2009Al复合材料疲劳性能的提高主要发生在低应力高寿命的高周疲劳中。

3 结论

1) 在107周次疲劳寿命下,15%SiCp/2009Al复合材料旋转弯曲疲劳强度为260 MPa,轴向(R=0.1)疲劳强度为182 MPa,具有良好的高周疲劳性能。

2)复合材料疲劳性能与微观组织关系密切,良好的疲劳性能得益于严格控制SiC颗粒粒度、优化的颗粒分散性使得SiC颗粒均匀分布于2009Al基体,以及保证SiC颗粒与基体具有良好的界面结合。

3) 15%SiCp/2009Al复合材料的疲劳裂纹萌生机制为表层增强颗粒开裂萌生疲劳裂纹、表层金属间化合物造成疲劳裂纹萌生以及在“无明显微观组织特征区域”萌生疲劳裂纹,其中后者为复合材料疲劳裂纹萌生的主要机制。没有观察到增强颗粒-基体界面脱粘萌生疲劳裂纹的现象。

4) 15%SiCp/2009Al复合材料的疲劳断裂方式为韧性断裂,疲劳裂纹扩展的主要现象有微孔、韧窝、撕裂脊、增强颗粒开裂、增强颗粒-基体界面脱粘。增强颗粒开裂及增强颗粒-基体界面脱粘仅在疲劳裂纹扩展后期发生,随着疲劳裂纹增长,疲劳断口上发生开裂的增强颗粒比例增大。

REFERENCES

[1] SRIVASTAN T S, MESLET AL-HAJRI, VASUDEVAN V K. Cyclic plastic strain response and fracture behavior of 2009 aluminum alloy metal-matrix composite[J]. Int J Fatigue, 2005, 27: 357-371.

[2] LLORCA J. Fatigue of particle-and whisker-reinforced metal-matrix composites[J]. Prog Mater Sci, 2002, 47(3): 283-353.

[3] TOKAJI K. Effect of stress ratio on fatigue behaviour in SiC particulate-reinforced aluminum alloy composite[J]. Fatigue Fract Engng Mater Struct, 2005, 28: 539-545.

[4] HUANG J, SPOWART J E, JONES J W. Fatigue behaviour of SiC-reinforced aluminium composite in the very high cycle regime using ultrasonic fatigue[J]. Fatigue Fract Eng Mater Struct, 2006, 29: 507-517.

[5] AYYAR A, CHAWLA N. Microstructure-based modeling of crack growth in particle reinforced composite[J]. Compos Sci Technol, 2006, 66: 1980-1994.

[6] CHAWLA N, ANDRES C, JONES J W. Cyclic stress-stain behavior of particle reinforced metal matrix composites[J]. Scripta Mater, 1998, 38(10): 1595-1600.

[7] CHEN Z Z, HE P, CHEN L Q. The role of particles in fatigue crack propagation of aluminum matrix composite and casting aluminum alloys[J]. J Mater Sci Technol, 2007, 23(2): 213-216.

[8] PARK B G, CROSKY A G, HELLIER A K. High cycle fatigue behaviour of microsphere Al2O3-Al particulate metal matrix composites[J]. Composite B, 2008, 7/8(11/12): 1257-1269.

[9] KAYNAK C, BOYLU S. Effect of SiC particulates on the fatigue behaviour of an Al-alloy matrix composite[J]. Mater Des, 2006, 27: 776-782.

[10] BONNEN J J, ALLISON J E, JONES J W. Fatigue behavior of a 2xxx series aluminiun alloy reinforced with 15 vol Pct SiCp[J]. Metall Trans A, 1991, 22(5): 1007-1019.

[11] DI S, YANG X, LUAN G, JIAN B. Comparative study on fatigue properties between AA2024-T4 friction stir welds and base materials[J]. Mater Sci Eng A,2006, 435/436: 389-395.

[12] CHAWLA N, WILLIAMS J J, SAHA R. Mechanical behavior and microstructure characterization of sinter-forged SiC particle reinforced aluminum matrix composites[J]. J Light Metal, 2002, 2: 215-227.

[13] HIROYUKI TODA, TOSHIRO KOBAYASHI. Growth behavior of microstructurely short cracks in the 6061 aluminum alloy with and without 22 Vol Pct SiC whiskers[J]. Metal Mater Trans A, 1996, 27: 2013-2021.

[14] CHAWLA N, WILLIAMS J J, SAHA R. Mechanical behavior and microstructure characterization of sinter-forged SiC particle reinforced aluminum matrix composites[J]. J Light Metal, 2002, 2: 215-227.

[15] COSTANZA G, MONTANARI R, QUADRINI F, SILI A. Influence of Ti coatings on the fatigue behaviour of Al-matrix MMCs. Part I: Fatigue tests and materials characterization[J]. Composites B, 2005, 36: 439-445.

[16] CESCHINI L, MINAK G, MORRI A. Tensile and fatigue properties of the AA6061/20vol.% Al3Tip and AA7005/10vol.% Al3Tip composites[J]. Compos Sci Technol, 2006, 66: 333-342.

[17] DWA Aluminum Composites. 2009 and 6092 alloy DRA mechanical property summary [EB/OL]. http:// www.dwa-dra.com/

prpchars/index.html. 2009-04-15.

[18] UEMATSU Y, TOKAJI K, KAWAMURA M. Fatigue behavior of SiC-particulate-reinforced aluminium alloy composites with different particle sizes at elevated temperatures[J]. Compos Sci Technol, 2008, 68(13): 2785-2791.

[19] TJONG S C, WANG G S, MAI Y W. High cycle fatigue response of in-situ Al-based composites containing TiB2 and Al2O3 particles[J]. Compos Sci Technol, 2005, 65: 1537-1546.

[20] TJONG S C, WANG G S. High cycle fatigue properties of Al-based composites reinforced with in situ TiB2 and Al2O3 particulates[J]. Mater Sci Eng A, 2004, 386: 48-53.

(编辑 李艳红)

收稿日期:2009-09-01;修订日期:2010-05-04

通信作者:樊建中,教授,博士;电话:010-82241232;E-mail:Jzfan@grinm.com