文章编号:1004-0609(2011)09-2139-07

Sip/Al复合材料激光钎焊特性与组织形态

李俐群1, 2, 陶 汪1, 汪 彬1

(1. 哈尔滨工业大学 先进焊接与连接国家重点实验室,哈尔滨 150001;

2. 哈尔滨工业大学 金属精密热加工国家重点实验室,哈尔滨 150001)

摘 要:采用激光填丝钎焊方法进行1.5 mm厚65%(体积分数)Sip/4032Al复合材料对接接头的连接,研究不同工艺参数下的钎料润湿铺展行为和焊缝成形特性,以及焊缝中共晶硅的形态变化规律。结果表明:接头开V型坡口非常有利于焊缝的背面成形;光斑直径为20 mm、激光功率高于1 500 W时焊缝成形容易控制;与激光熔焊相比,激光钎焊方法更适合于连接高比分Sip/4032Al复合材料。焊接热输入对Si元素的溶解、扩散行为影响很大,因此,不同激光功率下,焊缝中硅元素可以板状、多角状、瓣状初生硅、板条状共晶硅等多种形态出现。焊缝中心由于冷却速度较慢,还形成了共晶团组织,共晶团内部为均匀分布的短棒状共晶硅。

关键词:Sip/Al复合材料;激光钎焊;硅结晶行为

中图分类号:TG115.28 文献标志码:A

Characteristics and microstructure of laser brazing Sip/Al composites

LI Li-qun1, 2, TAO Wang1, WANG Bin1

(1. State Key Laboratory of Advanced Welding and Joining,

Harbin Institute of Technology, Harbin 150001, China;

2. National Key Laboratory for Precision Hot Processing of Metals,

Harbin Institute of Technology, Harbin 150001, China)

Abstract: Laser brazing method was used to join 1.5 mm thick 65% (volum fraction) Sip/4032Al composite butt joints. The wetting and spreading behavior of brazing filler metal, characteristics of weld shaping, and morphologies of eutectic silicon with different process parameters were investigated. The results show that the V-groove is favorable to the weld back shaping, the weld shaping is easy to be controlled when the spot diameter is up to 20 mm and the laser power is higher than 1 500 W. Compared with laser fusion welding, the laser brazing method is more suitable for joining high fraction Sip/4032Al composite. Weld heat input has great influence on Si dissolution and diffusion, so various silicon morphologies are found in the weld under different laser powers, including strip, polygonal,petal primary silicon and lath-shaped eutectic silicon. The eutectic cells are formed at the centre of weld because of the lower cool rate.

Key words: Sip/Al composite; laser brazing; silicon crystallization behavior

随着航空航天用电子器件向大功率、轻量化和高性能方向的发展,对基片衬底材料、框架、壳体和封装盖板等材料的性能也提出了更高要求。与传统的SiC/Al和Al2O3/Al复合材料相比,环保型Si/Al复合材料具有低膨胀系数、高热导率和低密度等性能优势,成为国内外当前电子封装材料制备领域的研究热 点[1-4]。伴随而来的问题就是如何实现此类高体积分数Sip/Al复合材料的可靠连接。

目前,应用较广的SiC/Al和Al2O3/Al复合材料连接技术包括熔焊、钎焊和固相连接等方法已得到国内外较多的研究,其金属间化合物的控制以及熔焊过程中的气孔和未熔合等缺陷一直是此类铝基复合材料的焊接难点与关注重点[5-8]。由于Al-Si二元合金相图非常简单,铝和硅之间不存在冶金反应,在室温下仅形成α(Al)相和硅相,主要是以共晶形式存在于焊缝中,因此,Sip/Al复合材料的焊接特点有所不同,没有金属间化合物的控制问题。在焊接过程中保证焊缝中硅元素分布的均匀性与共晶硅相形态控制是这一材料焊接质量控制的关键。此外,也要克服气孔、未熔合等工艺缺陷。

能量高度集中的激光焊方法在工艺控制方面有独特优势,一直是复合材料连接的优选方案。对于Sip/Al复合材料,激光熔焊方法很容易在焊缝中形成大量气孔,焊缝中的硅元素结晶后易形成粗大的板条状初晶硅,对焊缝性能影响严重。为此,本文作者提出以激光填丝钎焊工艺作为Sip/Al复合材料的连接方法,选用Al-12Si共晶焊丝作为填充钎料,研究不同工艺条件下Sip/4032Al复合材料的焊缝成形特性,以及焊接热输入对焊缝中硅元素的扩散行为与微观形态的影响规律。

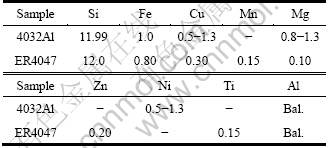

1 实验

实验用Sip/4032Al复合材料由哈尔滨工业大学金属基复合材料研究所提供,采用挤压铸造方法制备而成,基体为4032铝合金,硅颗粒增强相体积分数为65%以上,材料微观组织如图1(a)所示。由图1(a)可以看出,增强相颗粒大小不均匀,最大尺寸达100 μm,最小的不到10 μm,大的硅颗粒连成网格状,将铝基体隔开。选择4047牌号的Al-12Si共晶合金焊丝作为填充钎料,熔化范围575~590 ℃。焊丝为药芯焊丝,中间药芯为Nocolok粉末状钎剂,直径1.2 mm。焊丝微观组织结构如图1(b)所示,主要为枝晶结构的α(Al)和共晶硅相。4032铝基体与4047铝焊丝的化学成分在表1中列出。

图1 母材与填充金属的微观组织

Fig.1 Microstructures of base material and filler material: (a) Sip/4032Al composite; (b) Al-12Si filler metal

表1 4032铝基体与4047铝焊丝的化学成分

Table 1 Chemical compositions of 4032 Al substrate and 4047 Al filler wire (mass fraction, %)

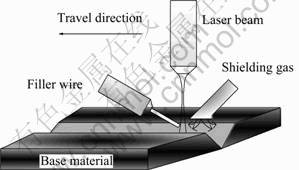

激光钎焊实验原理图如图2所示。实验采用德国Rofin扩散冷却CO2激光器为热源,最大输出功率为 3 000 W, 试件厚度为1.5 mm, 对接形式,考虑到背面成形,试样加工成60°的V型坡口。填充焊丝从激光束前方自动送入,氩气在后方保护。为保证母材温度,提高钎料润湿铺展性能,采用散焦光斑进行加热,光斑直径为20 mm。主要工艺参数包括激光功率P、焊接速度vh和送丝速度vs。

图2 激光钎焊原理图

Fig.2 Schematic diagram of laser brazing

2 结果及讨论

2.1 焊缝成形特性

采用激光填丝钎焊方法连接Sip/4032Al铝基复合材料,比较容易获得成形良好的正面、背面焊缝成形,与SiC/Al复合材料相比,工艺窗口宽很多,焊接过程也稳定。

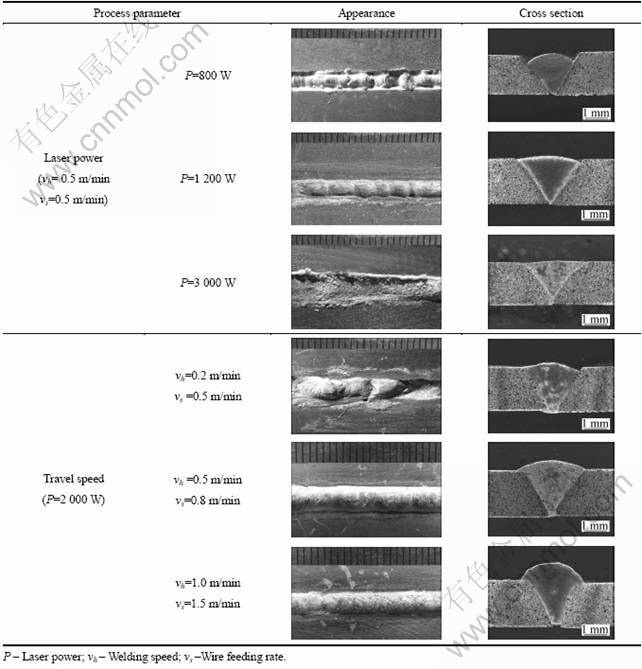

与传统炉中钎焊不同,激光钎焊是一个局部加热过程,液态钎料的高温停留时间很短,钎料是以自动送丝方式加入。因此,焊缝成形质量主要取决于焊丝熔化的稳定性和短时间内液态钎料在母材上的铺展性。通常是固态母材的温度越高,液态钎料的流动性越好,对母材的润湿铺展能力越强,但母材过热或熔化,又容易造成气孔、咬边等工艺缺陷。因此,焊接过程中的热输入控制尤为重要,激光功率、焊接速度、送丝速度是决定焊缝成形的关键参数。本研究在以下实验参数范围内进行了实验:激光功率为800~3 000 W, 焊接速度为0.2~1.5 m/min, 送丝速度为0.5~2.0 m/min。表2中给出了几组典型焊接参数下的焊缝表面与截面形态,以进行对比分析不同参数对焊缝成形的影响。

从激光功率的影响看,当激光功率小于1 000 W时,温度较低,液态在母材表面无法实现很好的润湿铺展,焊缝表面不连续。实验结果表明,只有当激光功率高于1 500 W时,液态钎料才能有较好的流动性,获得良好表面成型。当激光功率达到3 000 W时,由于钎料黏度大大降低,母材温度也很高,液态钎料的流动性很好,焊接过程很容易受到外界干扰因素(保护气、送丝位置等)的影响,形成咬边或不连续缺陷。

表2 不同焊接参数下的焊缝表面成形与截面形态

Table 2 Seam appearances and cross sections with different process parameters

焊接速度与激光功率共同决定了熔池的热输入大小,不过,当焊接速度较低时,熔池的高温停留时间相对更长一些。激光功率为2 000 W时焊接过程比较稳定,因此,选择在此激光功率下比较焊接速度在0.2~1.0 m/min之间变化时的焊缝成形状况,送丝速度随焊接速度变化作相应调整。结果表明,在实验参数范围内,焊接速度在0.5~1.0 m/min之间均可获得成形较好的焊缝,但需根据坡口尺寸确定合适送丝速度。

送丝速度对焊缝成形的影响比较简单,主要是填充量的问题,送丝速度过快,则造成过大的余高,过慢则出现填充不足。

根据实验结果,采用CO2激光器焊接1.5 mm厚的Sip/4032Al复合材料,对接开V型坡口非常有利于背面成形,光斑直径为20 mm时焊缝成形比较容易控制。工艺窗口大致可参考如下:激光功率1 200~2 800 W,焊接速度0.3~1.5 m/min,送丝速度与焊接速度的比在1.5~3.0之间均可,根据焊缝的填充情况而定。总体来看,激光功率对焊缝表面质量的影响较大,功率不合适时,底部未熔透与气孔是常出现的主要缺陷,如图3所示。

图3 底部未熔透与气孔缺陷

Fig.3 Unfilled and porosity defects of seam

2.2 焊缝组织形态

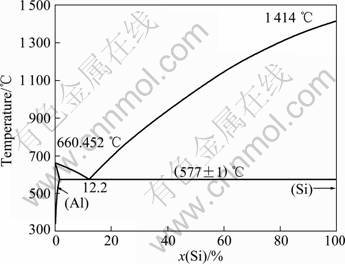

根据图4所示的Al-Si二元相图可以看出,铝与硅主要是以共晶形式存在于焊缝中,因此,熔池中的主要相为共晶硅与α(Al)固溶体。硅可溶于α(Al)固溶体中,而且,硅在液态铝中的溶解度随液态铝温度的升高而逐渐增大,到1 000 ℃时,硅在液态铝中的最大溶解度接近58%。

因此,对于Sip/4032Al复合材料,焊缝组织主要是不同形态的共晶硅。焊接热输入大小对母材中硅元素向焊缝中的溶解与扩散行为有直接影响;溶池中硅含量和冷却速度的不同造成了共晶硅在形态的明显差异。

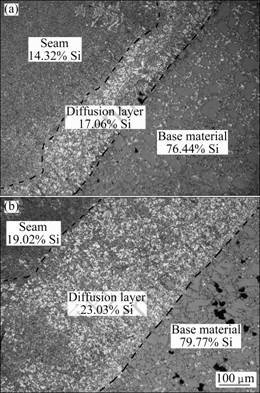

图5所示为不同热输入条件下焊缝界面硅元素的扩散层与不同位置硅元素的含量。由图5可以看出,在2 000和3 000 W两个激光功率下,焊缝都存在一个明显的扩散层,且激光功率为3 000 W时的硅元素扩散层宽度比为2 000 W时的宽1倍以上。

图4 Al-Si二元合金相图

Fig.4 Al-Si binary phase digram

图5 不同激光功率下的焊缝界面扩散层

Fig.5 Diffusion layer with different laser powers (vh=1.0 m/min, vs=1.6 m/min): (a) P=2 000 W; (b) P=3 000 W

EDS的分析结果表明,从母材到焊缝区,硅含量逐渐减少。同区相比,在激光功率较大时(3 000 W),扩散层的硅含量也明显增大。当功率为2 000 W时,扩散层硅含量为17%左右;功率3 000 W时,焊缝扩散层的硅含量则为23%。

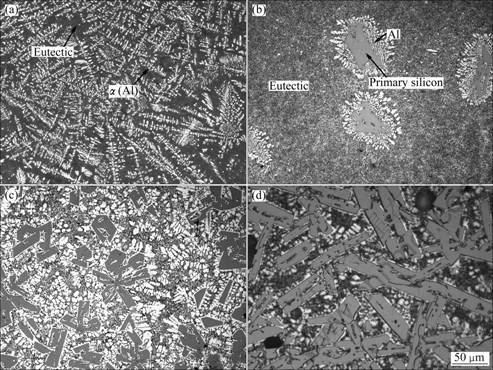

焊接过程中,随着母材中的硅逐渐向液态钎料中的溶解扩散,液态钎料中的硅含量将超过共晶成分,在焊缝冷却过程中,硅逐渐结晶出来。根据硅元素溶解度与熔池冷却速度的不同,焊缝中形成的共晶硅形态也是多样化的。由于激光钎焊过程液态钎料的冷却速度较快,且熔池各部位的冷却速度也不相同,因此,焊缝中很难获得非常均匀一致的组织状态。忽略局部冷却速度较快的区域,总体上来看,在不同的热输入条件下,焊缝主要部位的结晶硅形态呈现出图6所示的几种。

1) 共晶硅组织和树枝晶初生α(Al)如图6(a)所示。当热输入较小时(P=1 000 W),焊缝组织为典型的树枝晶初生α(Al)和共晶组织,这与焊丝直接熔化形成的组织基本一样(见图1(b))。说明热输入过低,母材中的硅几乎没有发生扩散,基本就是焊丝本身的硅发生熔化与结晶。

2) 板状初晶硅如图6(b)所示,当热输入增大(P= 1 200 W)时,液态钎料与母材温度均有所升高,母材中的Si开始向熔池中扩散、溶解,熔池成分达到过共晶成分。在随后的冷却过程中,形成了板状初生相硅颗粒,弥散分布在焊缝中,且颗粒周围包围着铝原子形成的晕圈。对于Al-Si过共晶合金而言,铝为非小平面相,而硅为小平面相,在快速凝固过程中,初晶硅形核后,在过冷的金属中生长,同时向周围外排出铝原子,初晶硅附近液相的成分将随着液相线的降低而不断变化,一旦其成分达到α(Al)液相线相应成分点时就会发生α(Al)的形核与生长,形成α(Al)晕圈。这些铝相以晕圈的形式包围住硅颗粒,限制了硅颗粒的长大。铝晕圈的成长受到自身的生长速度以及液相达到最终共晶温度的时间的影响[9]。α(Al)晕圈的形成 将导致晕圈-液相界面处的液相成分随α(Al)液相线的变化而改变,直到过冷度达到共晶组织生长的要求 为止。

3) 多角状与瓣状初晶硅如图6(c )所示,当激光功率增大到2 000 W时,更多的硅溶解到焊缝中去,冷却时也就结晶出更多的初晶硅。这些初晶硅与图6(b)所示的相比,在形貌上更加多样,有块状、多角状和瓣状,大小不一,分布均匀。硅颗粒周围仍然有铝晕圈包围着,只是更加稀松一些。除了硅颗粒形状和母材不同,从密度上来看,几乎不亚于母材,可以作为焊缝中新的增强相,这是我们希望得到的理想焊缝组织。造成两种不同形态初晶硅(见图6(b)与(c))的主要原因是硅含量与焊接温度的不同。热输入较低时,从母材进入到熔池的硅元素相对较少,硅原子团聚较为集中;在冷却过程中,这些原子团聚成为核心,迅速长成块状。热输入增大之后,扩散到熔池中的硅元素增加,原子团聚相对比较分散,有些原子团会被充分溶解,冷却时以异质形核长大。在高硅铝合金的凝固组织中,初晶硅颗粒主要有以下基本形态:板状初晶硅、五瓣星状初晶硅、八面体型初晶硅。而形成不同形态初晶硅的主要原因是凝固过程受到熔体过热度、冷却速度以及硅含量的影响[10-13]。焊缝中出现的多角状一般是棱锥状或者八面体状的纵剖面以及横剖面,是八面体初晶硅被以任意角度随意的切割而显现出的二维形貌。

图6 不同热输入下的共晶硅形态

Fig.6 Morphologies of eutectic silicon under different heat input (vh= 0.5 m/min): (a) Eutectic silicon and dendrite α(Al), P=1 000 W; (b) Strip primary silicon, P=1 200 W; (c) Polygonal and petal primary silicon, P=2 000 W; (d) Lath-shaped eutectic silicon, P=3 000 W

4) 板条状共晶硅如图6(d)所示,当激光功率高达3 000 W时,母材会发生大量熔化,焊缝中进入了大量的硅,最后凝固成长为粗大的板条状共晶硅,而且焊缝中会出现的缩孔,对焊缝性能影响较大。在焊接过程中要注意避免出现这种母材熔化状态。

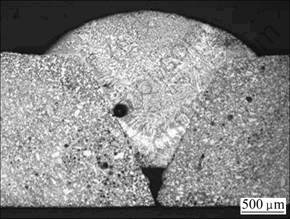

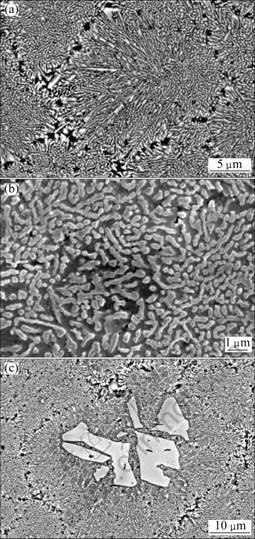

对焊缝中心区域进行深腐蚀之后,发现了大小不一的共晶团,如图7( a)所示,共晶团中为均匀分布的短棒状共晶硅,见图7(b)。从图7(a)可以看出,众多孤立的硅短棒起源于一个共同的核心,径向辐射向外生长,共晶硅是共晶团的领先相,生成位置取决于异质形核,有很大的随机性,因为可以依附形核的质点比较多,各个共晶团同时生长,直到相互接触,互相抑制停止生长,铝、硅两相交互生长的同时向外排出合金元素,合金元素在晶团界面处聚集。在焊缝中心处,由于冷却速度较慢,曲率过冷度的作用变得明 显[14],并有充分的时间进行溶质扩散,使固、液界面前沿的浓度均匀分布,从而增加了界面的稳定性,因此,随着缓慢而均匀的冷却,共晶硅以短棒状形态 生长。

共晶团的存在打破了共晶硅以长条状、网状的生长模式,抵抗裂纹的能力增强,可以提高铸态材料的韧性[15-16]。因此,焊缝中心处出现的短棒状共晶团对焊缝性能也是有帮助的。

共晶团的生长并没有受到初晶硅的影响,如图 7(c)所示,初晶硅存留在共晶团内部。可能因为初晶硅首先结晶,当共晶团开始生长的时候初晶硅已经存在,共晶团里面的共晶硅可以依附于初晶硅形核长大,这样初晶硅就作为形核质点留在共晶团内部。若共晶团不是依附于初晶硅形核时,则可能是共晶团生长的时候,初晶硅作为杂质是应该被排出共晶团的,但是由于初晶硅质量比较大难以排到相界而留在共晶团内部,所以,有些共晶团内部存在初生的硅颗粒。这种共晶团的尺寸往往很大。

图7 共晶团的SEM像

Fig.7 SEM images of eutectic cell: (a) Morphology of eutectic cell; (b) Short rod-like silicon inside eutectic cell; (c) Eutectic cell with primary silicon

3 结论

1) 采用激光填丝钎焊方法连接Sip/4032Al复合材料(Si的体积分数在65%以上),较容易获得正反面均成形良好的焊缝,工艺窗口较宽,焊接过程稳定。对接接头开V型坡口可有效保证焊缝的背面成形。合理控制热输入,可以得到弥散分布的初晶硅作为新的增强相存在于焊缝中。

2) 激光钎焊过程中,母材中的硅元素一直在向焊缝区扩散、溶解。冷却后焊缝界面存在明显的硅元素扩散层,焊接热输入对扩散层宽度与硅含量有明显影响。

3) 焊缝中的硅主要以共晶形式存在。激光钎焊过程钎料的液态形态停留时间很短,熔池冷却后形成的共晶硅的形态对热输入非常敏感,不同的热输入条件下,共晶硅可以板状、瓣状、板条状等多种形态出现。在焊缝中心,出现了共晶团组织,共晶团内部为均匀分布的短棒状共晶硅。

REFERENCES

[1] CHEN Y Y, CHUNG D D L. Silicon-aluminium network composites fabricated by liquid metal infiltration [J]. Journal of Materials Science, 1994, 29: 6069-6075.

[2] 武高辉, 修子杨,孙东立,张 强,宋美慧. 环保型电子封装用Sip/Al复合材料性能研究[J]. 材料科学与工艺, 2006, 14(3): 244-250.

WU Gao-hui, XIU Zi-yang, SUN Dong-li, ZHANG Qiang, SONG Mei-hui. Study on properties of the environmental-friendly Sip/Al composites for electronic packaging applications [J]. Materials Science and Technology, 2006, 14(3): 244-250.

[3] LIM S C, GUPTA M, LENG Y F, LACERNIA E J. Wear of spray-deposited hypereutectic aluminum-silicon alloy [J]. Material Processing Technology, 1997, 63: 865-870.

[4] 陈绍杰. 复合材料技术与大型飞机[J]. 航空学报, 2008, 29(13): 605-610.

CHEN Shao-jie. Composite technology and large aircraft [J]. Acta Aeronautica et Astronautica Sinica, 2008, 29(13): 605-610.

[5] URENA A, GOMEZ de SALAZAR J M, ESCALERA M D. Influence of metal-ceramic interfaces on the behavior of metal matrix composites and their joints[J]. Key Engineering Materials, 1997, 127/131: 687-694.

[6] 陈彦宾, 张德库, 牛济泰, 冀国娟. 激光焊接铝基复合材料钛的原位增强作用[J]. 应用激光, 2002, 2(3): 320-322.

CHEN Yan-bin, ZHANG De-ku, NIU Ji-tai, JI Guo-juan. In-situ reinforcing effect of Ti on aluminum matrix composite during laser beam welding [J]. Applied Laser, 2002, 2(3): 320-322.

[7] CESCHINIA L, BOROMEI I, MINAK G, MORRI A, TARTERINI F. Effect of friction stir welding on microstructure, tensile and fatigue properties of the Al2O3p/Al6061 composite [J]. Composites Science and Technology, 2007, 67: 605-615.

[8] ZHANG X P, YE L, MAI Y W, QUAN G F, WEI W. Investigation on diffusion bonding characteristics of SiC particulate reinforced aluminum metal matrix composites (Al/SiCp-MMC) [J]. Composites: Part A, 1999, 30: 1415-1421.

[9] PEI Y T, de HOSSON TH M. Functionally graded materials produced by laser cladding [J]. Acta Mater, 2000, 48: 2617-2624.

[10] 葛良琦. Al-20%Si中初生硅形态控制技术研究[D]. 南京: 南京理工大学, 2007: 21-31.

GE Liang-qi. Study on the technologies of morphologies modification of primary silicon in Al-20%Si alloys [D]. Nanjing: Nanjing University of Science and Technology, 2007: 21-31.

[11] DAHLBORG U, BESSER M, CALVO-DAHLBORG M, CUELLO G, DEWHURST C D, KRAMER M J, MORRIS J R, SORDELET D J. Structure of molten Al-Si alloys [J]. Non-Crystalline Solids, 2007, 353: 3005-3010.

[12] 张金山, 许春香, 韩富银. 复合变质对过共晶高硅铝合金组织和性能的影响[J]. 中国有色金属学报, 2002, 12(S1): 107-109.

ZHANG Jin-shan, XU Chun-xiang, HAN Fu-yin. Effect of composite modifier on structures and properties of hypereutectic Al-Si alloy [J]. The Chinese Journal of Nonferrous Metals, 2002, 12(S1): 107-109.

[13] HUANG Wan-ru, LIAO Heng-cheng, WU Shen-qing, SUN Guo-xiong. Effect of temperature gradient and solidification rate on eutectic growth of Al-Si alloy during unidirectional solidification [J]. Foundry, 2010, 59(3): 239-246.

[14] 徐长林. 变质对过共晶铝硅合金中初生硅的影响极其作用机制[D]. 长春: 吉林大学, 2007: 27-50.

XU Chang-lin. Effect of modification on primary silicon in hypereutectic Al-Si alloys and modified mechanism [D]. Changchun: Jilin University, 2007: 27-50.

[15] 张 蓉, 沈淑娟, 赵志龙, 刘 林. 熔体过热处理及冷却速度对Al-Si过共晶合金凝固组织的影响[J]. 有色金属, 2002, 54(3): 19-21.

ZHANG Rong, SHEN Shu-juan, ZHAO Zhi-long, LIU Lin. Effect of melt overheating treatment and cooling rate on microstructure of Al-Si hypereutectic alloys [J]. Nonferrous Metals, 2002, 54(3): 19-21.

[16] 吴振平, 廖恒成, 姜云峰, 陈 杰, 孙国雄. Sr对Al-15.5Si合金共晶团大小的影响[J]. 特种铸造及有色合金, 2005(4): 193-195.

WU Zhen-ping, LIAO Heng-cheng, JIANG Yun-feng, CHEN Jie, SUN Guo-xiong. Effect of Sr on the eutectic cells size of Al-15.5Si alloy [J]. Special Casting and Nonferrous Alloys, 2005(4): 193-195.

(编辑 何学锋)

收稿日期:2010-09-13;修订日期:2011-03-18

通信作者:李俐群,副教授,博士;电话:0451-86415506;E-mail: liliqun@hit.edu.cn