文章编号:1004-0609(2010)S1-s0789-03

Ti-6Al-4V合金棒材纵向连轧的温度变化

王 田,陶海林,胡宗式,范 珂

(宝鸡钛业股份有限公司,宝鸡 721014)

摘 要:研究Ti-6Al-4V钛合金在高温高速状态下连续塑性变形过程中各道次变形量、变形速度与轧件温度变化的关系,以及轧制后的微观组织形态。结果表明:在Ti-6Al-4V钛合金线棒材的轧制过程中,不同的轧制阶段,由于轧件单道次变形量、轧制速度的改变,坯料的变形温度有升有降,初轧和中轧阶段变形温度总的变化趋势是降低的,但变化趋势比较缓慢,从预精轧开始,随着轧制速度的提高,坯料变形温度逐渐上升;坯料在相变点温度以上加热开轧时,终轧温度控制在两相区内,轧制组织为细小等轴状α+β两相组织,横、纵向的微观组织相差不大,符合GB/T 13810—2007附录A《两相钛合金金相组织分类评级图》中 A2级标准。

关键词:钛合金;轧制;温度变化;显微组织

中图分类号:TG146.2 文献标志码:A

Temperature shift of Ti-6Al-4V alloy bars in continuous rolling

WANG Tian, TAO Hai-lin, HU Zong-shi, FAN Ke

(Baoji Titanium Industry Co., Ltd., Baoji 721014, China)

Abstract: The relationship among deformation, speed, temperature shift, and the microstructure of Ti-6Al-4V alloy bars after continual rolling were discussed. The results show that during the rolling process, temperature of alloy bars changes continually at different process stages with the change of deformation and speed. The changing tendency is not obvious but slow, generally speaking, the temperature goes down gradually. After preliminary precision rolling, the temperature goes up because of the increasing rolling speed. Bars are heated above the phase transition temperature, and the finishing temperature shall be controlled at α+β phase region. Then the microstructure of the α+β phase of rolled bars is fine and equiaxed. The microstructure at both transverse and longitudinal direction is the same, and can meet with Grade A2 of Chinese standard GB/T 13810—2007.

Key words: titanium alloy; rolled; temperature shift; microstructure

随着国防军工、医疗器械、体育用品等钛材应用领域的进一步发展,钛合金标准件得到更广泛的应用,制造标准件的线棒材其内部组织、表面质量和长度都有一定的要求[1]。目前高端市场所需要的Ti-6Al-4V钛合金线棒材的纵向显微组织接近于横向的,达到A2级以上标准。现所采用的横列式轧机生产很难达要求。为此本文作者在高速纵列式轧机生产线上进行了Ti-6Al-4V钛合金线棒材连轧试验,探索工艺的可能性,为这一新工艺的工程应用提供理论基础。

1 实验

本次试制所用原材料是由宝鸡钛业股份有限公司生产的Ti-6Al-4V钛合金铸锭,相变点为990~1 000 ℃,其化学成分(质量分数,%)如下:Al 6.15,V 3.95,Fe 0.03,O 0.14,N 0.01,H 0.002,C<0.01,Y<0.005,其余为Ti。铸锭经锻造厂在β区开坯锻造,锻后规格为d100 mm×1 000 mm的圆棒。试验设备为纵列式连轧机组,初轧机为立式三辊往复轧机,中轧、预精轧为平立交替的12机架连轧机组。坯料经天然气加热炉加热后,通过12道次连续轧制,加工成尺寸为d12 mm的线材,在轧制过程中利用设置在各机架轧件出口处的高温测温仪来监测轧件在轧制过程中的温度变化情况,随后对成品线材进行金相组织检测。

2 结果与分析

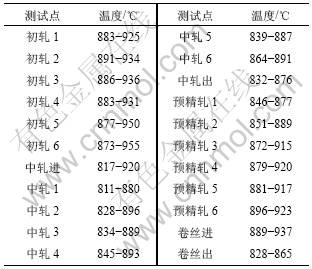

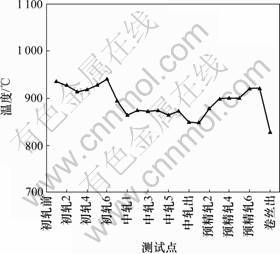

试验过程中测定轧件在各个轧机出口的温度,对原始数据整理后取平均值,结果如表1所列。温度变化曲线图如图1所示。

表1 轧材表面温度

Table 1 Surface temperature of materials

图1 轧制各阶段轧材温度变化曲线

Fig.1 Temperature change of materials in different stages

结合以上数据,分析导致轧件温度变化的因素:一方面在变形过程中,轧件对外散热包括与外界散热和对轧辊的传导传热,还会接触到轧辊冷却水,这些热损失导致轧件的温度降低。另一方面,在加工过程中外力施加的功小部分用于晶格畸变,大部分转换为热能,使轧件温度升高。若引起的温度上升不超过相变点,这种温升对轧制是有利的。

材料塑性变形时,单位体积变形功为 假设塑性变形功热转换效率为η,根据能量转换原理有:

假设塑性变形功热转换效率为η,根据能量转换原理有:

(1)

(1)

其中: 。

。

当 ≥1时,转换效率η=1,这相当于绝热加工过程;当

≥1时,转换效率η=1,这相当于绝热加工过程;当 ≤10-3,η=0则该过程近似可看作等温过程;当10-3<

≤10-3,η=0则该过程近似可看作等温过程;当10-3< <1时,转换效率

<1时,转换效率 ,轧制过程在此范围内,可见变形温升和变形速率关系密切[2]。

,轧制过程在此范围内,可见变形温升和变形速率关系密切[2]。

不同轧制阶段轧件道次变形量见表2,道次变形量曲线见图2。

上述热功转换数学模型和轧制的道次变形量综合分析,轧材从出炉到开轧这一阶段由于强烈的对外散热而使温度迅速下降。初轧前三个道次温度都呈下降趋势,但相对比较缓慢,这是由于轧制过程中,随着每道次变形量的减小,所产生的温升抵不上坯料的热散失。但后面三个轧制道次,每道次的变形量都有所增加,从而温度又呈上升趋势。从初轧6到中轧之间

表2 不同轧制阶段轧件道次变形量

Table 2 Deformation of materials in different stages

图2 轧制各阶段轧材变形量变化曲线

Fig.2 Deformation change of materials in different stages

有剪切头尾的工序,由于轧件与辊道、飞剪等接触的时间较长,增大了传导传热损失的热量,因此此处温度下降较快。中轧1时温度还略有下降,随着后几个道次轧制速度的提高、道次变形量的增大,变形所产生的温升和热散失基本上处于平衡状态,图1中从中轧1至中轧6阶段,温度曲线几乎呈一条水平线。结合图1、2和式(1)可看出,随着轧制速度的提高和道次变形量的增大,轧件温度也是逐渐上升的。轧件在预精轧机组有六道次变形,该轧制阶段虽然轧件与轧辊冷却水接触,且变形量有所减小,理论上温度应该有所降低,但实际上并没有引起温度的下降,这是由于在预精轧阶段轧件的变形速度大幅提升,使得所引起的温升大于坯料的热损失,故该阶段温度变化曲线反而呈上升趋势。

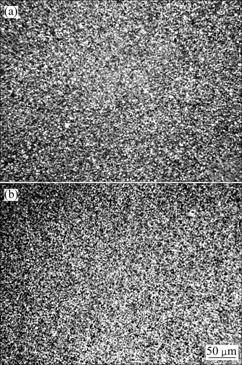

轧棒退火后的纵、横向显微组织如图3所示。可见纵向连轧后获得纵、横向均匀细小的 等轴组织,纵、横向组织差异较横列式轧制明显减小,符合GB/T 13810—2007附录A《两相钛合金金相组织分类评级图》中 A2级标准。

等轴组织,纵、横向组织差异较横列式轧制明显减小,符合GB/T 13810—2007附录A《两相钛合金金相组织分类评级图》中 A2级标准。

3 结论

1) Ti-6Al-4V钛合金棒材在不同的轧制阶段,由于轧制道次变形量、变形速度的改变,轧件的变形温

图3 Ti-6Al-4V钛合金纵列轧制退火态的显微组织

Fig.3 Microstructures of materials after rolled and annealed: (a) Along vertical direction; (b) Along landscape direction

度有升有降,初轧和中轧阶段总的趋势是降低的,但变化趋势相对比较缓慢,从预精轧开始,随着轧制速度的提高和单道次变形量的增大,坯料变形温度逐渐上升。

2) 合理设计变形量和变形速度,可以保证中轧、预精轧全过程在α+β两相区完成。

REFERENCES

[1] 《有色金属及其热处理》编写组. 有色金属及其热处理[M]. 北京: 国防工业出版社, 1981.

Editors of Nonferrous Metals and Treatment. Nonferrous metals and treatment[M]. Beijing: National Defense Industry Publishing House, 1981.

[2] 王少林. TC11钛合金饼材锻造质量控制与数值模拟研究[D]. 北京: 清华大学机械工程系, 1993.

WANG Shao-lin. Research of quality control and numerical value imitation for TC11 alloy[D]. Beijing: Department of Mechanical Engineering, Tsinghua University, 1993.

(编辑 杨幼平)

通信作者:王 田;电话:13571747501;E-mail: wt2002jock@163.com