文章编号:1004-0609(2008)11-1989-06

含铈铝黄铜的显微组织与性能

张 娟,李 周,陈 畅,唐 宁,张德智

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用金相组织分析、显微硬度分析、质量损失分析、电化学测试和扫描电镜等手段研究铈铝黄铜和砷铝黄铜的加工性能、组织结构和耐蚀性能。结果表明:铈铝黄铜最佳热轧温度为700~750 ℃,该合金表现出良好的冷加工性能,退火组织细小均匀,700 ℃退火1 h后再结晶晶粒大小为50 μm左右。在NaCl(3.5%)溶液中腐蚀过程中,铈铝黄铜表面形成一层较均匀致密腐蚀产物膜,较好地阻止了Zn从基体表面向介质中扩散,在一定程度上抑制了脱锌;铈铝黄铜耐腐蚀性能略优于砷铝黄铜,腐蚀速率为6.2×10?3 mm/a。

关键词:铈铝黄铜;砷铝黄铜;耐蚀性能;加工性能

中图分类号:TG 146.11; TG 174.2 文献标识码:A

Microstructure and properties of aluminum brass with Ce

ZHANG Juan, LI Zhou, CHEN Chang, TANG Ning, ZHANG De-zhi

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The processing abilities, structures and corrosion properties of the ceric aluminum brass and the arsenical aluminum brass were studied by means of metallographic analysis, microhardness measurement, mass loss measurement, electrochemical testing and scanning electron microscopy. The results show that the suitable hot-rolling temperature of the alloy with Ce is between 700 and 750 ℃; it has excellent cold-working capability, and the annealed structure is fine and homogeneous after annealing at 700 ℃ for 1 h; the recrystallization grains are about 50 μm. In the process of corrosion in 3.5% NaCl solution, the ceric aluminum brass forms a homogeneous and tight corrosion film on the surface, which can inhibit the diffusion of Zn from the surface of matrix to the solution, and restrain the dezincification to a certain degree. The corrosion resistance of the ceric aluminum brass is slightly better than that of the arsenical aluminum brass, the corrosion rate is 6.2×10?3 mm/a.

Key words: ceric aluminum brass; arsenical aluminum brass; corrosion properties; processing abilities

黄铜以其优良的导热性能、耐蚀性能、力学性能以及低廉的成本而被广泛地用作火电机组冷凝管等热交换材料。但是,黄铜在使用过程中所存在的脱锌腐蚀问题[1?3],为工业生产带来许多隐患。砷能有效抑制黄铜脱锌[4?5],大幅度提高黄铜的耐腐蚀性能,被广泛地添加到多种牌号的黄铜中以提高其耐腐蚀性,如H68A,HSn70-1A和HAl77-2A等。但是砷是剧毒元素,含砷黄铜生产过程中的有毒气体和尘埃会严重污染环境,危害人们的健康[5]。因此,研究者们希望寻找一种环保的元素取代砷。稀土无毒且可以改善铜及铜合金的耐蚀性能,但对其研究远不如物理性能和力学性能的研究那样广泛和深入。国内对含稀土锡黄铜的研究较多,研究[6?7]发现,添加稀土元素的锡黄铜腐蚀表面能形成致密的保护膜,从而提高合金的耐蚀性能。然而在铝黄铜里添加稀土元素是否能产生同样的

效果,国内这方面的研究还很少。陈建奕和李周等[7?8]对稀土铝黄铜的腐蚀过程进行了研究,结果表明,添加稀土元素能改善合金的抗腐蚀性能,并且初步揭示了其耐蚀机制。为了更加详细地了解稀土元素对铝黄铜组织性能的影响,本文作者制备一种添加稀土铈的新型耐腐蚀黄铜,并以一种含砷的铝黄铜为对比,研究铈对铝黄铜组织和性能的影响。

1 实验

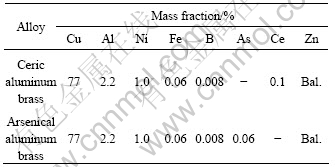

本实验设计制备出两种耐蚀铝黄铜,一种是含砷的HAl77?2铝黄铜[5](以下称砷铝黄铜),另一种是在此基础上以稀土铈取代砷的铝黄铜(以下称铈铝黄铜)。两者合金的成分如表1所列。

表1 所设计合金的化学成分

Table 1 Chemical composition of designed alloy

分别采用电解铜、纯锌、纯铝、纯镍、纯铁、Cu-As中间合金、Cu-B中间合金和Al-Ce中间合金为原料,利用中频感应炉在石墨坩埚中熔炼上述铜合金。不同温度时对合金进行热轧实验:热轧板材冷轧50%,经 690 ℃中间退火30 min后,进行第二次冷轧60%,按上述退火制度退火后经过第三次冷轧,最终在700 ℃退火1 h得到成品,对每一步的样品进行金相观察和硬度测试。轧制实验在小型四辊轧机上进行。金相显微组织观察在Leica DM ILM HC上进行。硬度测量在HVA-10A型小负荷维氏硬度计上进行,载荷为20 N,加载时间为15 s。

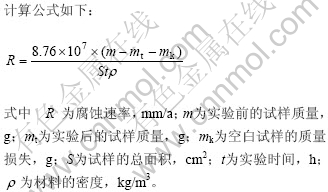

腐蚀实验样品取自最终退火的板材,样品尺寸为50 mm×25 mm×2 mm,将样品浸入腐蚀液中(3.5%NaCl溶液,pH值6.5),静置腐蚀28 d,每隔7 d更换溶液。取出后用1?1 HCl溶液除去表面腐蚀产物,并计算平均腐蚀速率。在清洗腐蚀产物的同时,也将同种材料未经腐蚀的空白试样浸入盐酸中轻轻振荡,而后测量计算其单个表面的质量损失,以对样品在盐酸清洗过程中的腐蚀质量损失进行校正。腐蚀速率的

采用SI1287电化学工作站腐蚀性能测量系统测量合金在3.5%NaCl溶液中的极化曲线。辅助电极为Pt片,参比电极为饱和甘汞电极(SCE),扫描速度为2 mV/s。并采用CorrView Version 2.8d软件对实验所得的极化曲线进行分析。

利用Sirion200场发射扫描电镜观察在腐蚀介质中浸泡30 d后样品的腐蚀表面。

2 结果与分析

2.1 热轧实验

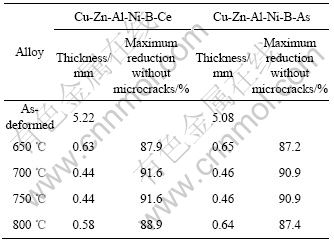

在不同温度下退火后冷轧时实验合金不产生边部裂纹的极限变形,结果如表2所列。由表2可见,铈铝黄铜和砷铝黄铜在700~750 ℃下热轧,均表现出良好的热加工性能,且铈铝黄铜的热加工性能优于砷铝黄铜。

表2 铈铝黄铜和砷铝黄铜合金的热轧性能

Table 2 Rolling properties of ceric aluminum brass and arsenical aluminum brass

2.2 合金的金相显微组织

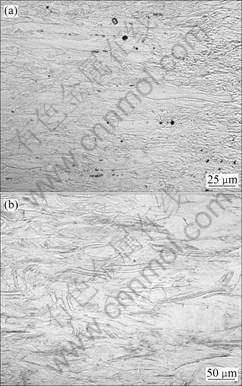

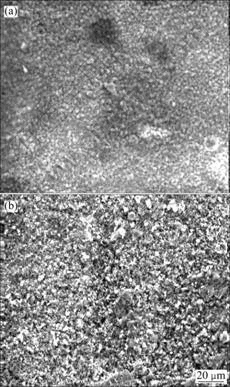

两种合金均显示出良好的冷加工性能,冷轧60%后,边部均未出现裂纹。图1所示为铈铝黄铜和砷铝黄铜热轧板的轧面金相组织。由图1可知,砷铝黄铜经750 ℃热轧后基本形成等轴的再结晶组织,晶粒大小在50 μm左右,而铈铝黄铜再结晶晶粒十分细小,只有20 μm左右。铈铝黄铜和砷铝黄铜冷轧后的侧面金相组织如图2所示。由图2可知,铈铝黄铜和砷铝黄铜的晶粒均被拉长,铈铝黄铜拉长的晶粒细小均匀,而砷铝黄铜的纤维比较粗大。铈铝黄铜和砷铝黄铜经700 ℃退火1 h后最终成品的金相组织分析如图3所示。由图3可知,此时两种合金基本都形成了等轴的再结晶组织,但是铈铝黄铜的晶粒要细小一些。对比分析以上金相组织可知,铈的加入具有明显的细化晶粒作用。

图1 铈铝黄铜和砷铝黄铜750 ℃热轧板的轧面金相分析

Fig.1 Metallographs of 750 ℃ hot-rolled ceric aluminum brass(a) and arsenical aluminum brass(b)

图2 铈铝黄铜和砷铝黄铜冷轧板的侧面金相组织

Fig.2 Metallographs of cold-rolled ceric aluminum brass(a) and arsenical aluminum brass(b)

图3 铈铝黄铜和砷铝黄铜经700 ℃保温1 h后的金相组织

Fig.3 Metallographs of ceric aluminum brass(a) and arsenical aluminum brass(b) after annealing at 700 ℃ for 1 h

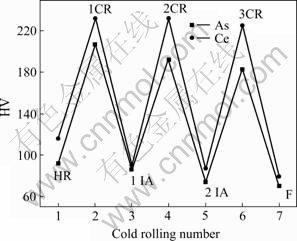

2.3 合金的显微硬度

将铈铝黄铜和砷铝黄铜铸态样进行机加工后在750 ℃下热轧成板材,将热轧板冷轧50%后,再进行690 ℃保温30 min的中间退火,进行第二次冷轧60%,按上述退火制度退火后经过第三次冷轧,最终在700 ℃保温1 h后得到成品,对每一步的样品分别进行显微硬度测试,结果如图4所示。其中HR代表热轧态,1CR,2CR,3CR分别代表第1次冷轧,第2次冷轧和第3次冷轧,1IA和2IA分别代表第1次中间退火和第2次中间退火,F代表最终退火样品。由图4可以看出,同一种状态下,铈铝黄铜的显微硬度都比砷铝黄铜要高,经冷轧后的铈铝黄铜的显微硬度可达HV230,而砷铝黄铜只有HV200左右,最终经700 ℃退火1 h后,铈铝黄铜的显微硬度仍有HV90,比砷铝黄铜高HV10,可见铈的加入细化了晶粒,强化了基体。

图4 不同状态处理后铈铝黄铜和砷铝黄铜的显微硬度

Fig.4 Micro-hardness of ceric aluminum brass and arsenical aluminum brass after treated under different conditions

2.4 合金的腐蚀性能

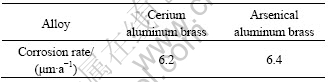

两种合金在NaCl(3.5%)腐蚀介质中的平均腐蚀速率如表3所列。从中可以看出稀土铝黄铜表现出较好的耐腐蚀性能。

表3 两种合金在NaCl(3.5%)溶液中的平均腐蚀速率

Table 3 Average corrosion rate of two alloys in NaCl(3.5%) solution

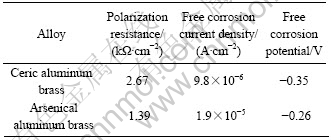

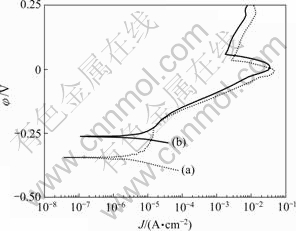

图5和表4所示为两种合金在NaCl(3.5%)溶液中进行电化学测试的结果。可以看出,虽然铈铝黄铜自腐蚀电位较低,但是其极化电阻很大,约为砷铝黄铜的两倍,自腐蚀电流也只有砷铝黄铜的一半左右。

表4 对极化曲线弱极化拟合的结果

Table 4 Weak polarization fit result of polarization curve

图5 两种合金在NaCl(3.5%)溶液中的极化曲线

Fig.5 Polarization curve of two alloys in NaCl(3.5%) solution: (a) Ceric aluminum brass; (b) Arsenical aluminum brass

2..5 合金的腐蚀表面形貌

图6所示为两种合金在NaCl(3.5%)溶液中浸泡腐蚀30 d后的表面腐蚀形貌。由图6可知,两种合金在腐蚀后呈现出完全不同的腐蚀形貌,稀土铝黄铜表面的腐蚀产物完整而致密;而含砷铝黄铜的腐蚀产物疏松多孔。

图6 两种合金在NaCl(3.5%)溶液中腐蚀后的表面形貌

Fig.6 Surface topographies of two alloys after corroded in NaCl(3.5%) solution: (a) Ceric aluminum brass; (b) Arsenical aluminum brass

3 讨论

由于锌的标准电位相对于铜较负,黄铜中的锌容易被优先腐蚀,留下疏松多空的铜,从而降低黄铜的强度,大大缩短黄铜器件的使用寿命[9?11]。国内外对黄铜的脱锌腐蚀机制进行了大量的研究,所提出的脱锌腐蚀机制主要有优先溶解和溶解—再沉积机制、空位机制、渗流机制等[12?13]。对于稀土的研究,马壮 等[14]研究发现,稀土元素La和Ce能净化纯铜的基体、细化晶粒、提高纯铜的电导率等。谢冰等[15]研究认为,稀土添加到铜及铜合金后,能起脱气除杂的作用,改善铜及铜合金的显微结构,提高其强度和硬度及增强热稳定性,还能增强铜合金的耐腐蚀和耐磨性能。在稀土铝黄铜的腐蚀过程中,由于稀土的电极电位较负,化学性质比较活泼,所以稀土的加入致使了铝黄铜的自腐蚀电位降低;而稀土被氧化后,其氧化物与其它腐蚀产物一起在合金表面聚集成膜。这层膜致密、完整,且与基体结合紧密,它一方面有效地将合金基体与腐蚀介质隔离,从而大幅度提高极化电阻,减小腐蚀电流,减缓腐蚀的进行;另一方面,较好地阻止锌从基体表面通过腐蚀产物向介质中扩散,一定程度上抑制脱锌的发生。

由本实验可以看出,稀土铈添加到铝黄铜中后,晶粒得到明显细化,合金具有良好的冷热加工性能。另外,铈铝黄铜的显微硬度比砷铝黄铜的高;腐蚀性能的对比研究发现,铈铝黄铜的抗腐蚀性能比砷铝黄铜的更好,且由于砷有毒,因此,铈铝黄铜可以做为砷铝黄铜的替代材料。

4 结论

1) 在700~750 ℃下热轧,铈铝黄铜和砷铝黄铜均表现出良好的热加工性能,且铈铝黄铜的热加工性能更优于砷铝黄铜的。

2) 铈铝黄铜比砷铝黄铜的组织更加细小均匀,冷轧后铈铝黄铜的显微硬度HV230,而砷铝黄铜只有HV200左右,再结晶后铈铝黄铜的显微硬度仍然比砷铝黄铜的高HV10。

3) 铈铝黄铜在NaCl(3.5%)溶液中腐蚀后形成一层较致密、完整的腐蚀产物膜。

4) 铝黄铜中加入稀土铈后能大幅度提高其极化电阻,减小腐蚀电流,从而减缓腐蚀的进行;而且较好地阻止了锌从基体表面通过腐蚀产物向介质中扩散,一定程度上抑制了脱锌。

REFERENCES

[1] SAYED S M, ASHOUR E A, YOUSSEF G I. Effect of sulfide ions on the stress corrosion behaviour of Al-brass and Cu10Ni alloys in salt water[J]. Journal of Materials Science, 2002, 37: 2267?2272.

[2] RAVICHANDRAN R, RAJENDRAN N. Electrochemical behavior of brass in artificial seawater: effect of organic inhibitors[J]. Applied surface Science, 2005, 241: 449?458.

[3] 王吉会, 姜晓霞, 李诗卓. 黄铜脱锌腐蚀机理的研究进展[J]. 材料研究学报, 1999, 13(1): 1?8.

WANG Ji-hui, JIANG Xiao-xia, LI Shi-zhuo. Advances of researches on the dezincification mechanism of brass[J]. Chinese Journal of Materials Research, 1999, 13(1): 1?8.

[4] 李 勇, 朱应禄. 黄铜脱锌腐蚀的研究进展[J]. 腐蚀与防护, 2006, 27(5): 222?225.

LI Yong, ZHU Ying-lu. Advances in researches of dezincification mechanism of brass[J]. Corrosion & Protection, 2006, 27(5): 222?225.

[5] 王吉会, 姜晓霞, 李诗卓. 硼砷抑制黄铜脱锌的协同作用机制[J]. 科学通报, 1997, 42(6): 669?672.

WANG Ji-hui, JIANG Xiao-xia. Synergetic effect of boron and arsenic on inhibiting dezincification of brass[J]. Chinese Science Bulletin, 1997, 42(6): 669?672.

[6] 邓楚平, 黄伯云, 苏玉长, 刘东华. 微量的砷、硼和稀土Ce对黄铜冷凝管耐蚀行为的影响[J]. 湖南电力, 2007, 27(4): 9?12.

DENG Chu-ping, HUANG Bo-yun, SU Yu-chang, LIU Dong-hua. Influence of trace elements of As, B and rare earth (RE)Ce on the anti-corrosion behavior of yellow copper condenser tube[J]. Hunan Electric Power, 2007, 27(4): 9?12.

[7] 程建奕, 李 周, 唐 宁, 曹建国, 赵学龙. 含稀土HSn70-1 锡黄铜的腐蚀行为研究[J]. 材料热处理学报, 2007, 28(5): 101?104.

CHENG Jian-yi, LI Zhou, TANG Ning, CAO Jian-guo, ZHAO Xue-long. Corrosion behavior of tin brass containing rare earth[J]. Transactions of Materials and Heat Treatment, 2007, 28(5): 101?104.

[8] 程建奕, 李 周, 唐 宁, 汪明朴, 曹建国, 赵学龙, 杨 天. 含稀土HAl77-2 铝黄铜的腐蚀行为[J]. 中国有色金属学报, 2007, 17(8): 1273?1279.

CHENG Jian-yi, LI Zhou, TANG Ning, WANG Min-pu, CAO Jian-guo, ZHAO Xue-long, YANG Tian. Corrosion behavior of aluminum brass contained rare earth[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(8): 1273?1279.

[9] 王吉会, 姜晓霞, 李诗卓. 硼对铜合金组织和性能的影响[J]. 材料研究学报, 1997, 11(4): 381?386.

WANG Ji-hui, JIANG Xiao-xia, LI Shi-zhuo. Synergetic effect of boron on the structure and properties of copper alloys[J]. Chinese Journal of Materials Research, 1997, 42(6): 669?671.

[10] 刘增才, 林乐耘, 刘少峰. 实海暴露黄铜脱锌腐蚀行为及抑制脱锌机理研究[J]. 腐蚀科学与防护技术, 1999, 12(2): 78?83.

LIU Zeng-cai, LIN Le-yun, LIU Shao-fen. Dezincication corrosion behavior and its inhibiting mechanism of brass exposed to seawater[J]. Corrosion Science and Protection Technology, 1999, 12(2): 78?83.

[11] 刘增才, 林乐耘, 刘少峰. 实海暴露黄铜脱锌腐蚀行为及抑制脱锌机理研究[J]. 腐蚀科学与防护技术, 1999, 12(2): 78?83.

LIU Zeng-cai, LIN Le-yun, LIU Shao-fen. Dezincication corrosion behavior and its inhibiting mechanism of brass exposed to seawater[J]. Corrosion Science and Protection Technology, 1999, 12(2): 78?83.

[12] 王吉会, 姜晓霞, 李诗卓. 硼对HAl77-2铝黄铜组织和腐蚀性能的影响[J]. 材料研究学报, 1996, 10(6): 597?601.

WANG Ji-hui, JIANG Xiao-xia, LI Shi-zhuo. Effect of boron on microstructure and corrosion resistance of aluminium brass[J]. Chinese Journal of Materials Research, 1996, 10(6): 597?601.

[13] 王吉会, 姜晓霞, 李诗卓. 硼对HAl77-2铝黄铜组织和耐磨蚀性能的影响[J]. 腐蚀科学与防护技术, 1996, 8(3): 185?189.

WANG Ji-hui, JIANG Xiao-xia, LI Shi-zhuo. Effect of born on corrosive wear and erosion resistance of HAl77-2 brass[J]. Corrosion Science and Protection Technology, 1996, 8(3): 185?189

[14] 马 壮, 狄丽莉, 朱玉军. 稀土元素La 和Ce 对纯铜性能的影响[J]. 铸造技术, 2005, 26(3): 227?229.

MA Zhuang, DI Li-li, ZHU Yu-jun. Effect of rare-earth element La and Ce on pure copper[J]. Foundry Technology, 2005, 26(3): 227?229.

[15] 谢 冰, 章少华, 谢荷茵. 稀土在铜及铜基合金中的作用[J]. 江西有色金属, 2004, 18(3): 31?33.

XIE Bing, ZHANG Shao-hua, XIE He-yin. The effect of rare earth on copper and copper based alloys[J]. Jiangxi Nonferrous Metals, 2004, 18(3): 31?33.

基金项目:国家高技术研究发展计划资助项目(2006AA03Z517);国际铜业协会“耐蚀铜合金”资助项目(MBP3553)

收稿日期:2008-04-08;修订日期:2008-06-24

通讯作者:李 周,副教授,博士;电话:0731-8830264;E-mail: lizhou6931@163.com

(编辑 龙怀中)