文章编号:1004-0609(2012)1-0080-10

基于Murty准则的ZnAl10Cu2合金热变形机制及工艺优化

邬小萍,李德富,郭胜利,许晓庆,胡 捷,贺金宇

(北京有色金属研究总院,北京 100088)

摘 要:在Gleeble-1500D热模拟机上研究了ZnAl10Cu2合金在变形温度为180~330 ℃、应变速率为0.01~10 s-1、最大变形量为0.7条件下的热变形行为,采用动态材料模型的Murty失稳准则绘制了ZnAl10Cu2合金的热加工图,结合微观组织观察研究了该合金在实验条件下的微观变形机制及流动失稳现象,并优化了热变形的工艺参数。结果表明:ZnAl10Cu2合金在高应变速率区域容易发生流变失稳现象,45°剪切开裂、绝热剪切带和局部塑性流动是流动失稳区的主要变形机理,在变形安全区片状α1和α2相均发生了不同程度的球化和扭折,且基体β相发生了动态再结晶,在变形温度为240 ℃、应变速率为0.1 s-1时,能量耗散率达到峰值,约为53%。

关键词:ZnAl10Cu2合金;热加工图;显微组织;绝热剪切带;球化

中图分类号:TB331 文献标志码:A

Hot deformation mechanism and process optimization for ZnAl10Cu2 alloy based on Murty criterion

WU Xiao-ping, LI De-fu, GUO Sheng-li, XU Xiao-qing, HU Jie, HE Jin-yu

(Beijing General Research Institute for Nonferrous Metals, Beijing 100088, China)

Abstract: The hot deformation behavior of ZnAl10Cu2 alloy was studied by compression testing on a Gleeble-1500D simulator in the temperature range from 180 ℃ to 330 ℃ and true strain rate range from 0.01 s-1 to 10 s-1 at the maximum true strain of 0.7. A processing map was developed on the basis of Murty instability criterion of dynamic material model. The micro-deformation mechanism and the flow instability phenomena of ZnAl10Cu2 alloy were studied by the microstructure under the experimental conditions, and the optimum processing parameters were evaluated. The results show that ZnAl10Cu2 alloy exhibits flow instability at high strain rate. The 45° shear cracking, adiabatic shear band and the local plastic flow are the main deformation mechanisms. The globalization and kinking of the laminar α1 and α2 phases are observed in the stable domain, and the dynamic recrystallization of β phase is also observed in the stable domain. At deformation temperature of 240 ℃ and strain rate of 0.1 s-1, the power dissipation rate reaches the peak, which is about 53%.

Key words: ZnAl10Cu2 alloy; processing map; microstructure; adiabatic shear band; globalization

高性能锌铝合金具有密度低、强度适中、硬度高和成本低等特点,作为铜合金的替代材料具有广阔的应用前景。但是,迄今为止,锌合金的研究大多侧重于压铸及超塑性方面,对变形锌合金的关注较少,而对锌合金在各种变形条件下的热变形行为的研究尚少见报道。锌合金具有密排六方的晶体结构,塑性较差,使得其加工变形比较困难,因此,有必要对锌合金的高温变形行为及其组织演变进行系统研究,以提高锌合金的变形能力,并在变形过程中控制其综合力学性能[1-5]。而在热变形的研究中,热加工图作为评价金属和合金的热加工性能被广泛应用,已成功用于分析 铝、镁、铜、钢铁和钛等合金的高温变形特性,利用热加工图与微观组织相结合的方法能够很好地描述材料在高温变形时的组织演变与塑性变形参数之间的关系,在控制热加工后组织和性能方面显示出一定的优势,是控制材料组织演变和优化工艺的一种有效手 段[6-13]。

本文作者以ZnAl10Cu2合金的热模拟压缩实验结果为基础,基于Murty准则绘制ZnAl10Cu2合金热变形时的加工图,并结合组织观察,对该合金的高温变形行为进行研究,为合理制定ZnAl10Cu2合金的热变形工艺、有效控制和提高构件性能和质量提供依据。

1 实验

热压缩实验用ZnAl10Cu2合金由宁波博威集团有限公司提供,铸锭加工成d10 mm×15 mm的圆柱形试样,在Gleeble-1500D热模拟试验机上进行热压缩实验。压缩前,在试样两端与压头接触面上垫石墨片以减少摩擦,避免出现明显的腰鼓、侧翻等不均匀变形现象。实验温度为180、210、240、270、300和330 ℃,应变速率为0.01、0.1、1.0和10.0 s-1,升温速率为5 ℃/s,保温时间为3 min,热压缩完成后立即水冷到室温以保留变形组织。变形过程全部由Gleeble- 1500D热模拟机的计算机控制并自动采集应力、应变、压力、位移、温度及时间等数据,绘制真应力—真应变曲线。

以纵截面为观察面,将取下的试样在Al2O3水砂纸上磨成镜面,然后机械抛光,所用腐蚀剂为铬酐,腐蚀剂的成分及条件如下:三氧化铬20 g、硫酸钠1.5 g、水100 mL、腐蚀时间6 s。金相观察在德国NEOPHOT-21大型金相显微镜上进行,采用带有NORAN-VANTAGE-DI4105型能谱仪的JSM-840型扫描电镜对合金相组成与分布进行二次电子像(SEI)和背散射电子像(BSE)分析。

2 结果与分析

2.1 ZnAl10Cu2合金的铸态显微组织特征及热变形流变行为

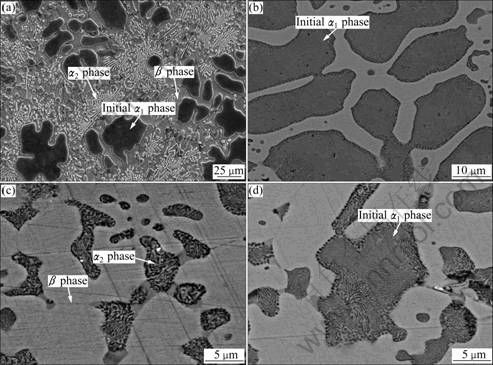

图1所示为ZnAl10Cu2合金的铸态显微组织。图中黑色相为初生α1相,为富Al相,是Zn在Al中形成的固溶体,其晶体结构为面心立方晶格,属于强化相;灰色基体为β-Zn相,为Al在Zn中形成的固溶体,具有密排六方晶格结构;基体上的片状组织为α2相,为富Al相,α2和β组成合金的共晶组织,在放大倍数较高时α1及α2相为片层组织,初生枝晶边缘层 片较中心的大,为粗大的断续层片组织,且晶内各个共析团形成鲜明的界线,在共析组织向内部生长的过程中,层片间距发生变化,同时层片共析组织中出现了粒状组织。

图1 铸态ZnAl10Cu2合金的SEM像

Fig. 1 SEM images of as-cast ZnAl10Cu2 alloy: (a) Primary α1 phase and eutectic structure (α+η); (b)-(c) Primary α1 phase; (d) α2 phase in eutectic structure

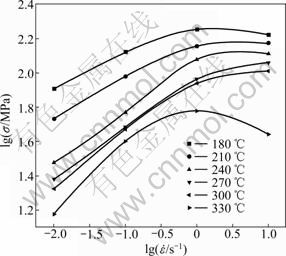

ZnAl10Cu2合金在热压缩变形过程中典型的真应力—真应变曲线如图2所示。从图2可以看出,当应变量较小时,由于加工硬化,流变应力随应变量的增加迅速增加,当出现流变应力峰值后逐渐下降,达到一定真应变时几乎趋于稳态,表现出典型的动态软化及稳态特征。当变形温度为300 ℃时,峰值应力与稳态应力相差不大,而且随应变速率的增大和温度的降低,进入稳态变形时对应的真应变增大。由图2还可以看出,应变速率和变形温度对合金流变应力有明显影 响,在应变速率相同时,流变应力随变形温度的升高而减小,变形温度相同时,流变应力随应变速率的增加而增大,说明ZnAl10Cu2合金是一种正应变速率敏感材料。

2.2 ZnAl10Cu合金的热变形加工图及分析

加工图是变形温度与应变速率空间中的能量耗散图与失稳图的叠加,被视为连接大塑性变形连续介质力学和组织耗散结构的纽带而被广泛应用,它能够很好地反映材料在不同温度和应变速率下变形时内部组织变化机制,并能预测最佳工艺参数[14]。ZnAl10Cu2合金的热加工图是基于动态材料模型的Murty准则[15]绘制的。

根据动态材料模型理论,热变形过程中的材料可以看作一个热力学封闭系统。根据耗散结构理论,在塑性变形过程中工件对单位时间内从系统吸收的总能量进行耗散可分为两部分:耗散量G和耗散协量J。耗散量G是加工件发生塑性变形所引起的能量耗散,其中大部分能量转化为热能,小部分以晶体缺陷能的形式存储;耗散协量J是加工件变形过程中组织演变(如动态回复、动态再结晶、内部裂纹、相变、片状组织的动态球化等)所耗散的能量,工件在变形过程中所吸收的能量可表示为[16-18]

(1)

(1)

式中:σ为流变应力; 为应变速率。

为应变速率。

(2)

(2)

式中: 为等效流变应力;

为等效流变应力; 为等效应变速率;

为等效应变速率; 为等效应变;T为变形温度;m为应变速率敏感指数,它决定输入功率P在G和J之间的分配,当m=1时,材料处于理想线性耗散状态,耗散协量J达到最大值,即Jmax=P/2。

为等效应变;T为变形温度;m为应变速率敏感指数,它决定输入功率P在G和J之间的分配,当m=1时,材料处于理想线性耗散状态,耗散协量J达到最大值,即Jmax=P/2。

图2 锌合金热变形真应力—真应变曲线

Fig. 2 True stress—true strain curves of zinc alloy by hot compression: (a) =0.01 s-1; (b)

=0.01 s-1; (b) =0.1 s-1; (c)

=0.1 s-1; (c) =1.0 s-1; (d)

=1.0 s-1; (d) =10.0 s-1

=10.0 s-1

对于非线性消耗过程,能量耗散效率可表示为[19]

(3)

(3)

η参数反映一定温度和应变速率范围内微观组织的变化机制,η随应变速率和变形温度的变化形成了呈现不同区域的能量耗散图,这些区域和特定的微观组织相关。

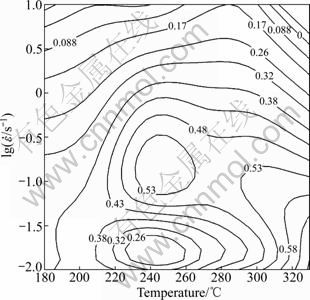

根据压缩实验获得的不同温度及应变速率下的真应力—真应变曲线,在对数坐标中应用3次样条函数可拟合得到180~330 ℃时应变速率敏感指数m的样条曲线,如图3所示,通过式(3)计算可得能量耗散效率η,从而根据不同温度和应变速率下的η值绘制能量耗散图,可以获得与不同显微组织相对应的能量耗散区域,如图4所示。能量耗散图上的等值线表示与材料的微观结构演化相关的相对熵产率,即热变形中微观结构的变化,也称为微观组织轨迹线。一般来说,高η值区域对应着较佳的加工性能区域,η是与m直接相关的参数,其值与工件热加工过程中显微组织变化有关,可以利用η在一定变形温度和应变速率下的典型值来对这些显微组织的变化微观机制进行解释,并且通过显微组织观察进一步得到验证,从而在加工图中确定与单个微观成形机制相关的特征区域的大致范围。

图3 由真应力和应变速率得到的3次插值样条曲线

Fig. 3 Three times interpolating curves obtained from values of true stress and strain rate

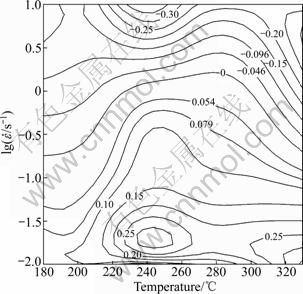

加工图是能量耗散图(见图4)与失稳图的叠加,能量耗散图确定以后,还需要确定稳定变形(或失稳)图,因为在加工失稳区(变形中可能出现的裂纹)能量耗散效率也可能较大。Murty准则[19]是以动态材料模型理论为基础,在加工图中用于确定流变失稳区域的一种方法。

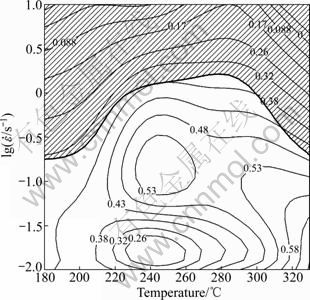

图4 应变为0.7时合金的能量耗散图

Fig. 4 Power dissipation map of alloy calculated at strain of 0.7

按照ZIEGLER[20]提出的应用于大塑性流变连续介质力学的不可逆热力学极值原理,当 <

< (D为给定温度下表征材料本征行为的耗散函数)时,材料会出现流变失稳。MURTY等[21-24]认为能量耗散协量J与变形过程的微观组织演变有关,因此,用J代替耗散函数D,从而导出

(D为给定温度下表征材料本征行为的耗散函数)时,材料会出现流变失稳。MURTY等[21-24]认为能量耗散协量J与变形过程的微观组织演变有关,因此,用J代替耗散函数D,从而导出

η>2m (4)

满足该判据条件时材料可能发生流变失稳。图5所示的流变失稳图中级数为负值的区域为根据该判据计算得到的流变失稳区。

图6所示为能量耗散图和流变失稳图叠加在一起得到的ZnAl10Cu2合金在应变为0.7的热加工图。结合微观组织观察可以更加深入理解图中各区域的特征,并分析不同区域的变形机制,有助于优化高温变形工艺参数,通过微观组织观察还可确定流变失稳现象和验证加工图。

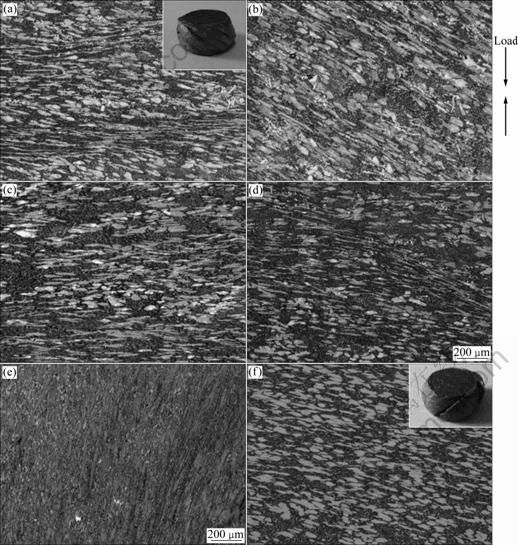

从图6可以看出,流变失稳区出现在高应变速率条件下,在此条件下变形时,能量耗散率η值出现最小值8.8%,且随着应变速率的增加,η值显著降低,表明合金的热加工性能急剧恶化。图7所示为ZnAl10Cu2合金在失稳区变形时对应的显微组织,图7(a)中的插图所示为变形温度为180 ℃、应变速率为10 s-1时压缩试样的宏观照片,可以清楚地观察到试样表面与压缩轴线接近45°角的宏观剪切裂纹,并通过显微照片发现存在大量绝热剪切带,如图7(a)所示,此变形条件位于加工图的左上角,η值出现局部极小值,8.8%。这可能是变形温度低、应变速率高、变形热效应大及ZnAl10Cu2合金的导热性较差造成大量塑性功所转换的热量来不及向周围较冷的部分传递,致使局部温度升高。而试样压缩时在与压缩轴线成45°角的方向对变形最有利,故此局部区域的温度高、流动应力小,变形主要集中在此局部区域,变形非常不均匀,产生宏观剪切裂纹及绝热剪切带。另外,从图7(a)还可以看出,粗大的α1晶粒沿着垂直于压缩轴线方向被拉长,造成材料的各向异性,显然,无论是45°剪切裂纹还是拉长的晶粒对合金的性能均是不利的,而剪切带的形成消耗了大部分能量,使其转化为热 能,故能量耗散率η较低,因此,这个较小的区域是非常有害的变形热力参数区域。

图5 根据失稳判据得到的流变失稳图

Fig. 5 Flow instability map obtained from flow instability criterion

图6 ZnAl10Cu2合金在应变为0.7时的热加工图

Fig.6 Hot processing map of ZnAl10Cu2 alloy at strain of 0.7

图7(f)中的插图所示为变形温度为330 ℃、应变速率为10 s-1时压缩试样的宏观照片,同样可观察到45°剪切裂纹,并通过显微组织观察发现伴随着局部塑性流动现象,如图7(f)所示,此变形条件位于加工图的右上角,即在高温、高应变速率区,此时η值达到最小值,几乎接近于0。在此小区域变形时,由于温度较高,氧化现象严重,此区的流动失稳区随温度升高有所扩大,可能与温度升高氧化加速有关。局部塑性流动的变形机理和剪切变形带一样,试样承受局部变形,只不过局部变形程度比绝热剪切带的低,同样对变形不利。

图7(b)~(e)所示分别为应变速率为0.1~1.0 s-1、变形温度为240~270 ℃时压缩试样的显微照片。从 图中可以明显地观察到绝热剪切带及局部塑性流动,但没有引起宏观剪切裂纹。

可见,ZnAl10Cu2合金在热变形过程中的主要缺陷为宏观剪切裂纹、绝热剪切带及局部塑性流动。周军等[12]指出,在绝热剪切带内的热软化区域容易出现空穴形核、长大和连接,易导致裂纹的产生,使得材料性能不均匀并下降,因此,这些区域在热变形时应尽量避开。

从图6可以看出,在变形温度为240~270 ℃、应变速率为0.1~1 s-1的区域,能量耗散率η出现峰值,为0.53。组织观察发现,合金在此区域变形时,片状α1和α2相均发生了不同程度的球化和弯折,同时基体β相发生了动态再结晶。片状组织的球化及基体β相的动态再结晶是ZnAl10Cu2合金热变形的主要特征,球化和动态再结晶都会引起流动应力的软化,其软化作用有利于合金的均匀塑性变形。

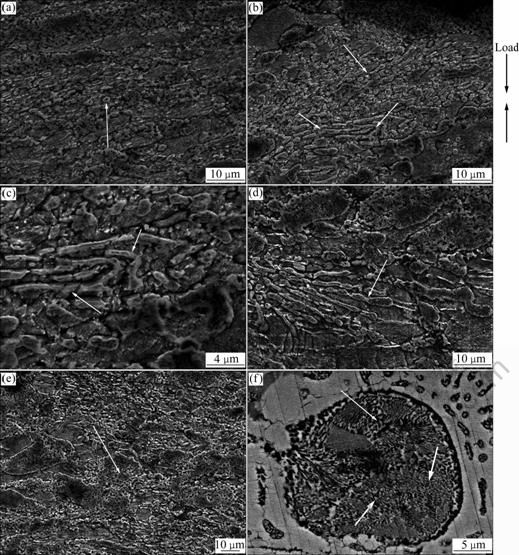

图8所示为热加工图中安全区域所对应变形条件下的显微组织。从图8中可以看出,α2相呈球状和短棒状分布在Zn基体中,晶粒尺寸细小,如图8(a)所示。这是由于在变形时,与应力轴平行的片状α2相发生弯折、扭折,然后在弯角附近断裂、破碎,形成与应力轴垂直的短棒状组织,并沿变形方向排列,断裂后部分较短的α2相完成球化,而初始位向与应力轴垂直的α2棒状直接发生断裂,如图8(b)~(d)中箭头所指,即在变形过程中所有片状α2相都力图使其位向与应力轴垂直,初步分析认为,垂直于应力轴方向可能会使片状α2相所受剪切应力增大,从而有利于发生剪切变形,使其断裂。

图7 ZnAl10Cu2合金在不同变形条件下的绝热剪切带和局部塑性流动

Fig. 7 Microstructures exhibiting adiabatic shear bands and local plastic flow for ZnAl10Cu2 alloy compressed under different conditions (Compressing axis is vertical in all micrographs): (a) t=270 ℃, =0.1 s-1;(b) t=240 ℃,

=0.1 s-1;(b) t=240 ℃, =0.1 s-1;(c) t=270 ℃,

=0.1 s-1;(c) t=270 ℃, =0.1 s-1;(d) t=270 ℃,

=0.1 s-1;(d) t=270 ℃, =1.0 s-1;(e) t=270 ℃,

=1.0 s-1;(e) t=270 ℃, =1.0 s-1;(f) t=240 ℃,

=1.0 s-1;(f) t=240 ℃, =0.1 s-1

=0.1 s-1

同时,原始初生相α1在变形过程中逐渐沿着与压缩轴垂直的方向上被拉长,α1晶粒内的片层由于承受大量变形而发生扭折、弯曲,随着变形时晶粒和片层的弯曲和拉长,发生片状组织向球状组织的转变,在变形过程中,长片层分解为若干小片层,小片层最初一般不呈等轴状,还需要进一步的球化才能最终完成等轴化,并伴随短片状旋转到与压缩轴垂直方向,最后在温度和表面张力驱动下完成等轴球化过程,如图8(e)和(f)箭头中所指。

ZnAl10Cu2合金在变形中的组织观察表明,初生枝晶α1相为若干相互平行的层片状共析团组成的集束,在层片组织的变形球化过程中,不同方位层片状共析团的球化状态不同,有的共析团球化较充分,有的共析团球化进程较慢。与此同时,初生枝晶内不同位向的共析团也被压弯变形或破碎而球化。片层组织的球化过程首先开始于不同方向共析团的交界处,如图8(f)中的细箭头所指。说明在变形条件下,该处的强度较低,变形阻力较小,而共析团则具有相对较高的强度,所以,共析团作为一个整体发生变形。随着变形的进行,球化过程逐步向共析团内扩展,共析团边界处球化组织增多,片层组织减少。同时,共析团发生转动,片层方向逐渐转到垂直于压缩轴的方向。组织观察还发现,由于层片组织方位的多样性,在变形过程中,不同方位共析团处于不同的局部应力状态,造成不同方位共析团的球化进程不同,某些处于有利于球化的局部应力状态共析团的球化进程较快,如图8(f)中的粗箭头所指。

图8 不同变形条件下稳定区压缩试样微观组织中的球化与弯析(压缩轴方向为垂直方向)

Fig. 8 Microstructures exhibiting globularization and kinking of lamellar for ZnAl10Cu2 specimens in stable area compressed under different conditions (Compression axis is vertical in all micrographs): (a) t=270 ℃, =0.1 s-1;(b) t=240 ℃,

=0.1 s-1;(b) t=240 ℃, =0.1 s-1; (c) t=270 ℃,

=0.1 s-1; (c) t=270 ℃, =0.1 s-1;(d) t=270 ℃,

=0.1 s-1;(d) t=270 ℃, =1.0 s-1;(e) t=270 ℃,

=1.0 s-1;(e) t=270 ℃, =1.0 s-1;(f) t=240 ℃,

=1.0 s-1;(f) t=240 ℃, =0.1 s-1

=0.1 s-1

图9所示为稳定区域不同变形条件下压缩试样的显微组织。从图中可以看出,基体β相发生了动态再结晶,且随着应变速率的增加动态再结晶越完全,当应变速率为0.01 s-1时,晶粒被拉长,只有局部小区域出现动态再结晶晶粒,如图9(a)和(b)中箭头所指,可能是因为再结晶的驱动力一般是由变形金属的储存能提供,当应变速率较低时,变形时间长,金属变形比较均匀,金属原子可充分扩散,位错也有足够的时间来攀移和对消,因此,位错密度较低,易于发生动态回复而使合金中的储存能降低,再结晶驱动力减小,因而只能在某些具有高能量起伏的区域(如变形量大的区域)首先形核,再结晶形核率较低;当应变速率为 1 s-1时,进入稳态变形区,组织为细小均匀的再结晶晶粒,如图9(d)所示,这与热加工图中安全区域相对应。但进一步增大应变速率时,热加工图中能量耗散效率η值降低,结合微观组织发现,再结晶晶粒出现不均匀现象,大变形区晶粒细小,小变形区晶粒较为粗大,如图10所示,这是因为变形速率较大,产生同样变形程度所需的时间较短,导致部分区域位错来不及抵消和合并,位错增多,能够发生再结晶的形核区域增多,导致晶粒细化。但当应变速率继续升高时,容易造成变形不均匀,这种组织对塑性产生严重的影响。

图9 不同变形条件下稳态区压缩试样显微组织中β相的动态再结晶(压缩轴方向为垂直方向)

Fig. 9 Microstructures exhibiting dynamic recrystallization of β phase for ZnAl10Cu2 specimens in stable area compressed under different conditions (Compression axis is vertical in all micrographs): (a), (b) t=270 ℃, =0.01 s-1;(c) t=270 ℃,

=0.01 s-1;(c) t=270 ℃, =0.1 s-1; (d) t=270 ℃,

=0.1 s-1; (d) t=270 ℃, =1 s-1

=1 s-1

从加工图中还可以看出,在变形温度为330 ℃、应变速率为0.01 s-1变形时,尽管能量耗散效率η值较大,但此区域不适合工业生产,一般不在此区域进行热变形。此外,在温度为220~280 ℃、以较高应变速率变形时,能量耗散效率变化较为平缓,其值为0.28~0.38,在280 ℃附近,能量耗散效率的等值线出现了明显的弯折,这种弯折可能是由于发生了相转变,这同该温度为Zn-10Al合金的相变点是吻合的。

综上所述,通过加工图分析和微观组织观察,最大η值出现在高温、低应变速率区,最小η值出现在高应变速率区,即流动失稳区域变形温度为 180~ 330 ℃、应变速率为0.5~10 s-1,变形缺陷主要为45°宏观剪切裂纹、绝热剪切带及局部塑性流动,这个区域在热变形时尽量避开;较佳加工区域温度为240~270 ℃、应变速率约为0.1 s-1,此区域为α1棒状和α2片层球化和扭折及基体β相动态再结晶共同起作用的区域。

图10 温度为270 ℃、应变速率为10 s-1时ZnAl10Cu2合金的显微组织

Fig. 10 Microstructures of ZnAl10Cu2 alloy at deformation temperature of 270 ℃ and strain rate of 10 s-1

3 结论

1) 通过热压缩实验,基于动态材料模型的Murty失稳准则并结合组织观察绘制了ZnAl10Cu2合金的热变形加工图,为研究该合金热变形加工提供了一种便捷、有效的工具。

2) 在变形温度为240~270 ℃、应变速率为0.1~1 s-1时为高耗散效率区域,此区域为安全区,是ZnAl10Cu2合金片状α2相及初生α1相球化的理想区域,最佳的变形参数在240 ℃、0.1 s-1附近,此时对应的最大能量耗散率为53%,可进行热变形。

3) 在高应变速率区域,温度为180~330 ℃,能量耗散率η出现最小值,此区域为非安全区,此区域内ZnAl10Cu2合金加工易发生流变失稳现象,产生宏观剪切裂纹、绝热剪切带、局部塑性流动等缺陷,这些区域在热变形时应尽量避开。

REFERENCES

[1] 孙连超, 田荣璋. 锌及锌合金物理冶金学[M]. 长沙: 中南工业大学出版社, 1994: 1-38.

SUN Lian-chao, TIAN Rong-zhang. Zinc and zinc alloy physical metallurgy[M]. Changsha: Central South University Press, 1994: 1-38.

[2] 石志强, 叶以富, 李世春, 郗学奎, 韩 彬. Zn-5Al共晶合金的表面效应对超塑变形的影响[J]. 机械工程材料, 2003, 27(1): 18-21.

SHI Zhi-qiang, YE Yi-fu, LI Shi-chun, XI Xue-kui, HAN Bin. Surface effect and superplasticity of Zn-5Al eutectic alloy[J]. Mechanical Engineering, 2003, 27(1): 18-21.

[3] AL-MAHARBI M, KARAMAN I, PURCEK G. Flow response of a severe plastically deformed two-phase zinc-aluminum alloy[J]. Materials Science and Engineering A, 2010, 527: 518-525.

[4] HA T A, SON J R, LEE W B. Superplastic deformation of a fine-grained Zn-0.3wt%Al alloy at room temperature[J]. Materials Science and Engineering A, 2001, 307: 98-106.

[5] MALEK P. The deformation structure of the superplastic Zn-Al alloy[J]. Materials Science and Engineering A, 1999, 268: 132-140.

[6] SARKAR J, PRASAD Y V R K, SURAPPA M K. Optimization of hot workability of an Al-Mg-Si alloy using processing maps[J]. Journal of Materials Science, 1995, 39: 2843-2848.

[7] PRASAD Y V R K, RAO K P. Processing maps for hot deformation of rolled AZ31 magnesium alloy plate: Anisotropy of hot workability[J]. Materials Science and Engineering A, 2008, 487: 316-327.

[8] 曹金荣, 刘正东, 程式长, 杨 刚, 谢建新. T122耐热钢热变形加工图及热成形性[J]. 北京科技大学学报, 2007, 29(12): 1204-1208.

CAO Jin-rong, LIU Zheng-dong, CHENG Shi-chang, YANG Gang, XIE Jian-xin. Processing maps and hot formability of T122 heat resistant steel[J]. Journal of University of Science and Technology Beijing, 2007, 29(12): 1204-1208.

[9] 李 鑫, 鲁世强, 王克鲁, 赵卫刚, 李臻熙, 曹春晓. 应用Murty准则优化TC11钛合金高温变形参数[J]. 金属学报, 2007, 43(12): 1268-1274.

LI Xin, LU Shi-qiang, WANG Ke-lu, ZHAO Wei-gang, LI Zhen-xi, CAO Chun-xiao. Optimization of high temperature deformation parameters of titanium alloy TC11 by using Murty criterion[J]. Acta Metallurgica Sinica, 2007, 43(12): 1268-1274.

[10] 单德彬, 史 科, 徐文臣, 吕 燕. TC11钛合金热变形机制及其热加工图[J]. 稀有金属材料与工程, 2009, 38(4): 632-636.

SHAN De-bin, SHI Ke, XUE Wen-chen, L? Yan. Hot deformation mechanism and processing of TC11 alloy[J]. Rare Metal Materials and Engineering, 2009, 38(4): 632-636.

[11] 鞠 泉, 李殿国, 刘国权. 15Cr-25Ni-Fe 基合金高温塑性变形行为的加工图[J]. 金属学报, 2006, 42(2): 218-224.

JU Quan, LI Dian-guo, LIU Guo quan. The processing map of hot plastic deformation of 15Cr-25Ni-Fe base superalloy[J]. Acta Metallurgica Sinica, 2006, 42(2): 218-224.

[12] 周 军, 曾卫东, 舒 滢, 周义刚. 应用加工图研究TC17 合金片状组织球化规律[J]. 稀有金属材料与工程, 2006, 35(2): 265-269.

ZHOU Jun, ZENG Wei-dong, SHU Ying, ZHOU Yi-gang. Study on globularization of lamellar structure in TC17 titanium alloy during hot deformation using processing map[J]. Rare Metal Materials and Engineering, 2006, 35(2): 265-269.

[13] 王 艳, 王明家, 蔡大勇, 熊青银, 王青峰. 高强度奥氏体不锈钢的热变形行为及其热加工图[J]. 材料热处理学报, 2005, 26(4): 65-69.

WANG Yan, WANG Ming-jia, CAI Da-yong, XIONG Liang-yin, WANG Qing-feng. Hot deformation behaviour and its processing map of a new austenitic stainless steel[J]. Transactions of Materials and Heat Treatment, 2005, 26(4): 65-69.

[14] 李 鑫, 鲁世强, 王克鲁, 丁林海. 金属热变形过程中的耗散结构探讨[J]. 材料导报, 2008, 22(1): 17-20.

LI Xin, LU Shi-qiang, WANG Ke-lu, DING Lin-hai. Discussion on dissipative structure formed during metal hot deformation[J]. Materials Review, 2008, 22(1): 17-20.

[15] 李 梁, 蒋 鹏. 钛合金热加工图与显微组织的对应关系[J].稀有金属材料与工程, 2008, 37(s3): 346-349.

LI Liang, JIANG Peng. The relationship between microstructure and hot processing map of titanium alloy[J]. Rare Metal Materials and Engineering, 2008, 37(s3): 346-349.

[16] PRASAD Y V R K, SASIDHARA S. Hot working guide: A compendium of processing maps[M]. Ohio: ASM International, 1997: 5-12.

[17] BOZZINI B, CERRI E. Numerical reliability of hot working processing maps[J]. Materials Science and Engineering A, 2002, 328: 344-347.

[18] PRASAD Y V R K, SESHACHARYULU T. Processing maps for hot working of titanium alloy[J]. Materials Science and Engineering A, 1998, 243: 82-88.

[19] MURTY S V S N, RAO B N. Communication: On the evaluation of efficiency of efficiency parameters in processing maps[J]. Metallurgical and Materials Transactions A, 1997, 28: 1581- 1582.

[20] ZIEGLER H. An introduction to thermomechanics[M]. New York: North-Holland Publishing Company, 1983: 60-88.

[21] MURTY S V S N, RAO B N. On the flow localization concepts in the processing maps of titanium alloy Ti-24Al-20Nb[J]. Journal of Materials Processing Technology, 2000: 103-109.

[22] MURTY S V S N, RAO B N. On the flow localization concepts in the processing maps of IN718[J]. Materials Science and Engineering A, 1999, 267: 159-161.

[23] MURTY S V S N, RAO B N, KASHYAP B P. Instability criteria for hot deformation of materials[J]. International Materials Reviews, 2000, 45(1): 15-26.

[24] MURTY S V S N, RAO B N, KASHYAP B P. Identification of flow instabilities in the processing maps of AISI 304 stainless steel[J]. Journal of Materials Processing Technology, 2005, 166: 268-278.

(编辑 陈卫萍)

基金项目:国家“十一五”科技支撑计划资助项目(2009BAE71B03)

收稿日期:2010-12-14;修订日期:2011-04-06

通信作者:李德富,教授,博士;电话:010-82241264; E-mail: lidf@mail.grinm.com