TiB2颗粒对7075铝合金流变成形显微组织的影响

甘贵生1,杨滨2,杜长华1,甘树德1

(1. 重庆理工大学 材料科学与工程学院,重庆,400054;

2. 北京科技大学 新金属材料国家重点实验室,北京,100083)

摘要:采用原位反应制得纯净的TiB2/7075复合材料,并经保温弯通道挤压成形制备半固态TiB2/7075复合材料。研究结果表明:随着颗粒质量分数的增加,原位反应放热量增加,生成TiB2颗粒粒径减小;在增强颗粒、冲刷搅拌和对流的共同作用下,熔体迅速形核并球化;670 ℃的熔体经三弯石墨通道流变挤压成形,颗粒质量分数为3%时,7075铝合金晶粒尺寸达到32.09 μm,形状因子为0.85;颗粒含量为4.5%时,晶粒尺寸达到23.90 μm,形状因子为0.96;颗粒含量为6%时,晶粒尺寸达到29.98 μm,形状因子为0.95。

关键词:原位反应;半固态复合材料;流变成形;冲刷搅拌

中图分类号:TG146.2+1 文献标志码:A 文章编号:1672-7207(2014)12-4168-07

Effect of TiB2 particle on microstructure of 7075 Al alloy in rheological forming

GAN Guisheng1, YANG Bin2, DU Changhua1, GAN Shude1

(1. School of Materials Science and Engineering, Chongqing University of Technology, Chongqing 400054, China;

2. State Key Laboratory for Advanced Metals and Materials, University of Science & Technology Beijing, Beijing 100083, China)

Abstract: Novel reactive technique was employed in the synthesis of 7075 Al matrix composites, and TiB2/7075 semi-solid composites were prepared by extruding technology after flowed through serpentine graphite channel. The results show that the more the heat quantity is created, when the TiB2 particle size is small, the mass fraction of particles in-situ reaction increases. The combination of particles, scouring and convection lead to nucleating and globurizing of the grain. After the extruding forming with three curved channels of molten at 670 ℃, the mean grain sizes and shape factors of the 3% TiB2/7075 composite are 32.09 μm and 0.85. The mean grain sizes and shape factors of 4.5% TiB2/7075 composite are 23.90 μm and 0.96 respectively, and those of 6% TiB2/7075 composite are 29.98 μm and 0.95 respectively.

Key words: in-situ reactive; semi-solid composites; rheological forming; scouring and stirring

自Flemings创立半固态成形技术以来,半固态技术飞速发展,被认为是21世纪最具有发展前途的材料成型技术之一[1]。传统的半固态成形方法如机械搅拌、电磁搅拌、双螺旋等都是需要较大的剪切速率或较长剪切时间,这样给半固态成型带来了诸如效率低、能耗高等问题。近期,提出了一系列不需太大剪切速率的半固态成型工艺,如倾斜槽法[2-4]、蛇形管法[5-7]和剪切低温浇铸法(LSPSF)[8-10]等。7075铝合金由于枝晶发达,固相率随温度变化敏感,使用现有半固态成型方法难以得到较为理想的半固态材料。TiC,TiB2和Al2O3陶瓷颗粒具有强度高、比刚度高、耐磨性好、热膨胀系数小等优异的综合性能,同时与Al具有较好的错配关系,常作为铝合金的细化剂[11-18]。本文作者早前研究了TiB2颗粒对7075铝合金半固态浆料组织的影响,但对其流变成形及其组织的影响尚未进行深入研究[19]。本文通过在7075中生成TiB2颗粒来细化7075铝合金的组织,通过简易的弯曲通道系统后,直接挤压成形,研究TiB2颗粒和弯道数量对7075铝合金半固态组织的影响。

1 实验

实验材料为7075铝合金,液相线635 ℃,固相线477 ℃,表1所示为其主要化学成分。

表1 7075铝合金的主要化学成分(质量分数)

Table 1 Main chemical composition of 7075 Al alloy %

在电阻炉中将7075铝合金加热至(850±5) ℃,加入按化学比配好并经混匀、烘干、预热好的K2TiF6(质量分数>97%)和KBF4(质量分数>97%)混合盐,用石墨搅拌器充分搅拌,反应结束后降温至720 ℃,扒除表面残余盐,加入精炼剂进行精炼和除气。于670 ℃时将复合材料熔体注入1个垂直放置直径为20 mm、高度均为390 mm 弯或3个弯的石墨通道(保温400 ℃),流进直径为50 mm、高度为50 mm的型腔(材料为H13,保温400 ℃)后,立即进行挤压成形。压力机为青岛即墨市兴宇汽车保修设备厂生产的四柱液压机,额定压力为10 kN,额定压强为30 MPa,压头下压速度为1.5 mm/s,保压10 s。

将流变挤压后的试样经475 ℃保温4 h后水淬,然后在120 ℃时效24 h。截取挤压试样中部进行组织观察,并用金相分析软件Image-Pro测出初生晶的平均面积然后再算出等效直径,其计算公式为 ,

, (其中:D为晶粒直径,S为晶粒面积;C为晶粒周长;l为形状因子,l=0~1,当l=1时,说明晶粒最圆整,为球形)。

(其中:D为晶粒直径,S为晶粒面积;C为晶粒周长;l为形状因子,l=0~1,当l=1时,说明晶粒最圆整,为球形)。

2 结果与讨论

2.1 TiB2颗粒对7075铝合金显微组织的影响

采用K2TiF6和KBF4混合盐法制备TiB2/7075铝基复合材料,在严格控制熔体中Ti和B物质的量的比为1:2时,可以用方程式描述最终反应:

(1)

(1)

图1所示为铸态7075铝合金和670 ℃直接水淬7075铝合金及TiB2/7075复合材料的组织。其中,图1(a)所示为7075合金在720 ℃条件下浇注在石墨模具中的显微组织。由图7可以看到:7075铝合金主要由粗大的树枝晶组成,最大晶粒尺寸约为250 μm。7075铝合金670 ℃直接水淬,仍以树枝晶为主,见图1(b)。添加质量分数为3%的TiB2颗粒、于670 ℃直接水淬后,获得明显细小的蔷薇状组织(图1(c))。添加6%TiB2后组织又转化为树枝晶,晶粒明显粗化(图1(d))。

图1 铸态7075铝合金和670 ℃直接水淬7075铝合金及TiB2/7075复合材料的显微组织

Fig. 1 Microstructures of as-cast 7075 Al alloy, 7075 Al alloy and TiB2/7075 composites after quenching at 670 ℃

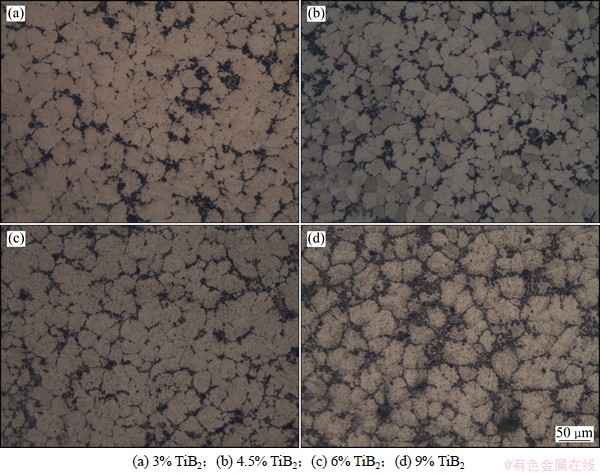

图2所示为670℃的TiB2/7075复合材料直接浇铸在型腔(保温400 ℃)挤压后并热处理的显微组织。由图2可以看到:添加质量分数为3%为TiB2能获得蔷薇状组织;达到4.5%时,晶粒尺寸到达最小,多在30 μm左右,形状趋于球形;添加6%TiB2后组织又转化为树枝晶,晶粒粗大;添加9%TiB2时晶界明显宽化。

2.2 TiB2颗粒对流变挤压7075铝合金显微组织的影响

图3所示为670 ℃的TiB2/7075复合材料经一弯石墨通道(保温400 ℃)流进直径为50 cm的型腔(保温400 ℃)挤压成形并热处理的显微组织,TiB2/7075复合材料显微组织均趋于球形。经计算,颗粒含量为3%时,7075铝合金晶粒尺寸达到32.10 μm,形状因子为0.87;颗粒含量为4.5%时,晶粒尺寸达到23.92 μm,形状因子为0.97;颗粒含量为6%时,晶粒尺寸达到35.47 μm,形状因子为0.91;颗粒含量为9%时,晶粒尺寸达到38.00 μm,形状因子为0.89。

图4所示为670 ℃的TiB2/7075复合材料经三弯石墨通道(保温400 ℃)流进d50的型腔(保温400 ℃)挤压成形并热处理后的显微组织。颗粒含量为3%时,7075铝合金晶粒尺寸达到32.09 μm,形状因子为0.85;当颗粒含量为4.5%时,晶粒尺寸达到23.90 μm,形状因子为0.96;当颗粒含量为6%时,晶粒尺寸达到29.98 μm,形状因子为0.95;当颗粒含量为9%时,晶粒尺寸达到31.94 μm,形状因子为0.95。

2.3 TiB2颗粒与弯道数量对7075铝合金形核能力的影响

2.3.1 TiB2颗粒对7075铝合金形核能力的影响

从图1~4可以看到:无论是水淬组织、直接挤压、还是经过弯道挤压,7075铝合金晶粒尺寸随颗粒含量变化呈现相同规律,即随着颗粒含量增加,晶粒尺寸先减小,随后增大。

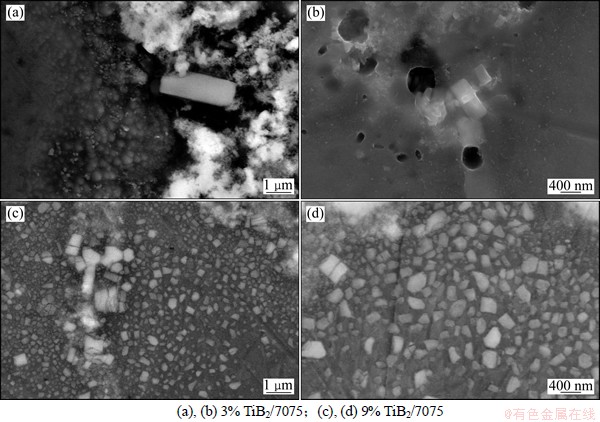

图5所示为7075铝基复合材料铸态(未挤压)组织中TiB2的形貌和分布。由图5可见:3% TiB2/7075合金的晶界处TiB2颗粒尺寸多为500~800 nm,个别能达到1 μm,TiB2颗粒大致呈六边形或四方形,弥散分布在晶界处。当颗粒含量达到9%时,少量大尺寸TiB2颗粒分布在晶界处,晶界附近的晶核内大量弥散分布着细小的TiB2颗粒,尺寸为100~300 nm,形状为不规则的多边形。

图2 670 ℃时TiB2/7075复合材料直接挤压并热处理后的显微组织

Fig. 2 Microstructures of 7075 Al alloy and TiB2/7075 composites by die casting at 670 ℃

图3 670 ℃时TiB2/7075复合材料经一弯通道后挤压并热处理的显微组织

Fig. 3 Microstructures of 7075 Al alloy and TiB2/7075 composites by die casting after flowed through one serpentine graphite channel at 670 ℃

图4 670 ℃的TiB2/7075复合材料经三弯通道后挤压并热处理的显微组织

Fig. 4 Microstructures of 7075 Al alloy and TiB2/7075 composites by die casting after flowed through three serpentine graphite channels at 670 ℃

图5 铝基复合材料铸态(未挤压)组织中TiB2的形貌和分布

Fig. 5 Micrograph and distribution of TiB2 particles in cast aluminum based composite materials

图6所示为7075铝基复合材料挤压并热处理后拉伸断口中TiB2的形貌。由图6可见:在拉伸断口TiB2颗粒的形貌多成片状。在同样放大倍数下,3% TiB2/7075合金的晶界处TiB2颗粒尺寸多为500~800 nm,9% TiB2/7075合金的晶界处TiB2颗粒尺寸多为200 nm左右。

文献[20-21]研究表明:平均颗粒尺寸为400 nm,所含活性TiB2颗粒的数量最多,因此,细化效果最好。当颗粒尺寸小于400 nm时,活性颗粒含量直线下降,晶粒开始粗化。由此看出:正是由于添加颗粒含量的增加,原位反应放热量越剧烈,生成TiB2颗粒尺寸减小,形貌也发生改变,形核能力发生改变。小尺寸颗粒由于具有极高的表面能,容易在晶界附近被捕获,最终造成复合材料的组织随添加颗粒含量而发生变化。

2.3.2 弯道数量对7075铝合金形核能力的影响

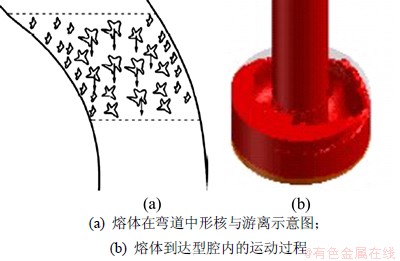

金属液在冷却管外壁上形成的晶核随即被高速旋转的金属液冲刷而脱落,成为液相中的游离晶核,因此,可以看成金属熔体在过冷条件下具有足够多的形核质点(见图7(a))。熔体在高温通道内流动的作用具体表现在:1) 流动过程中的自搅拌和冲刷作用;2) 缓慢的降温作用;3) 足够的形核核心(外加颗粒),使得熔体下落到管内一瞬间迅速形核。

在管壁凝固的晶核不断的被卷入熔体中,部分重熔,部分保留下来。熔体到达型腔内,在较大的冲击作用下,沿腔壁上升后下落。由于存在的对流作用(见图7(b)),有效过冷层和流动边界层的对流过程中液固相生长界面的形貌起决定性作用。

图6 铝基复合材料经弯道挤压成形并热处理后拉伸断口TiB2的形貌

Fig. 6 Micrograph and distribution of TiB2 particles in tensile fracture of TiB2/7075 composites by die casting after flowed through serpentine graphite channel at 670 ℃

图7 熔体在弯道中形核与游离示意图和熔体到达型腔内的运动过程

Fig. 7 Nucleation and peeling away diagrams in curve and filling process of melt

正是在增强颗粒,冲刷和对流共同作用下,熔体迅速形核并球化。随着弯道数量的增加,搅拌冲刷作用增强,产生更多的形核核心,晶粒得到细化。由于一弯和三弯通道,高度相同但有限,只是弯道数量由1个增大到3个,因此细化效果有限。

3 结论

1) 7075铝合金水淬后主要由树枝晶组成,添加3% TiB2后转化为蔷薇状组织,添加6%TiB2后组织又转化为树枝晶,晶粒粗大。经一弯石墨通道流变挤压成形,当颗粒含量为3%时,7075铝合金晶粒尺寸达到32.10 μm,形状因子为0.87;当颗粒含量等于4.5%时,晶粒尺寸达到23.92 μm,形状因子为0.97;当颗粒含量为6%时,晶粒尺寸达到35.47 μm,形状因子为0.91;当颗粒含量等于9%时,晶粒尺寸达到38.00 μm,形状因子为0.89。

2) 经三弯石墨通道流变挤压成形,颗粒含量为3%时,7075铝合金晶粒尺寸达到32.09 μm,形状因子为0.85;当颗粒含量等于4.5%时,晶粒尺寸达到23.90 μm,形状因子为0.96;当颗粒含量等于6%时,晶粒尺寸达到29.98 μm,形状因子为0.95;当颗粒含量等于9%时,晶粒尺寸达到31.94 μm,形状因子为0.95。

3) 颗粒含量的增加,原位反应放热量越剧烈,生成TiB2颗粒尺寸减小,形貌也发生改变。小尺寸颗粒形核能力发生改变,容易在晶界附近被捕获,最终造成复合材料的组织随添加颗粒含量而发生变化。

4) 熔体在高温弯曲通道的冲刷和自搅拌作用下,在管壁凝固的晶核不断的被卷入熔体中,部分重熔,部分保留下来。熔体到达型腔内,在较大的冲击作用下,沿腔壁上升后下落,产生对流。正是在增强颗粒,冲刷搅拌和对流的共同作用下,熔体迅速形核并球化。

参考文献:

[1] Flemings M C. Behavior of metal alloys in the semi-solid state[J]. Metall Trans A, 1991, 22(5): 957-981.

[2] Haga T, Suzuki S. Casting of aluminum alloy ingots for thixoforming using a cooling slope[J]. Journal of Materials Science and Technology, 2001, 118: 169-172.

[3] GUAN Renguo, ZHAO Zhengyong, DAI Chunguan, et al. A novel semisolid rheo-rolling process of AZ31 alloy with vibrating sloping plate[J]. Materials and Manufacturing Processes, 2013, 28(3): 299-305.

[4] 刘卫东.半固态浆料的冷却速率对组织的影响[J]. 铸造, 2013, 62(1): 10-12.

LIU Weidong. Effect of cooling rate of semi-solid slurry on its microstructure[J]. Foundry, 2013, 62(1): 10-12.

[5] CHEN Zhengzhou, MAO Weimin, WU Zongchuang. Influence of serpentine channel pouring process parameters on semi-solid A356 aluminum alloy slurry[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(5): 985-990.

[6] 杨小容, 毛卫民, 高冲. 采用蛇形管道浇注法制备半固态浆料[J]. 中国有色金属学报, 2009, 19(5): 869-873.

YANG Xiaorong, MAO Weimin, GAO Chong. Preparation of semi-solid feedstock by serpentine pipe pouring[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(5): 869-873.

[7] YANG Xiaorong, MAO Weimin, SUN Binyu. Preparation of semisolid A356 alloy slurry with larger capacity cast by serpentine channel[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(3): 455-460.

[8] GUO Hongmin, YANG Xiangjie, HU Bin. Rheocasting of A356 alloy by low superheat pouring with a hearing field[J]. Acta Metallurgica Sinica (English Letter), 2006, 19(5): 328-334.

[9] GUO Hongmin, YANG Xiangjie, HU Bin. Low superheat pouring with a shear field in rheocasting of aluminum alloys[J]. Journal of Wuhan University of Technology-Materials Science Edition, 2008, 23(1): 54-59.

[10] 王群, 杨湘杰, 刘勇, 等. LSPSF工艺对A356铝合金大体积半固态组织的影响[J]. 特种铸造及有色合金, 2011, 31(2): 133-136.

WANG Qun, YANG Xiangjie, LIU Yong, et al. Effects of LSPSF (Low Superheat Pouring Semi-solid Forming) process on microstructure of semi-solid A356 aluminum alloy with large volume[J]. Special Casting & Nonferrous Alloys, 2011, 31(2): 133-136.

[11] YANG Bin, WANG Feng, ZHANG Jishan. Microstructural characterization of in situ TiC/Al and TiC/Al-20Si-5Fe- 3Cu-1Mg composites prepared by spray deposition[J]. Acta Materialia, 2003, 51(17): 4977-4989.

[12] YANG Bin, GAN Guisheng, LU Yang, et al. Microstructural characterization and wear behavior of in situ TiC/7075 composites synthesized by displacement reactions and spray forming[J]. Materials Science and Engineering A, 2011, 528(18): 5649-5655.

[13] GAN Guisheng, ZHANG Lei, BEI Shuyu, et al. Effect of TiB2 additions on the microstructure of spray-formed Si-30Al composite[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(10): 2242-2247.

[14] YANG Bin, SUN Miao, GAN Guisheng, et al. In situ Al2O3 particle-reinforced Al and Cu matrix composites synthesized by displacement reactions[J]. Journal of Alloys and Compounds, 2010, 494(1/2): 261-265.

[15] Michael Rajan H B, Ramabalan S, Dinaharan I, et al. Synthesis and characterization of in situ formed titanium diboride particulate reinforced AA7075 aluminum alloy cast composites[J]. Materials and Design, 2013, 44: 438-445.

[16] LI Pengting, LI Yunguo, NIE Jinfeng, et al. Influence of forming process on three-dimensional morphology of TiB2 particles in Al-Ti-B alloys[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(3): 564-570.

[17] Rajasekaran N R, Sampath V. Effect of In-Situ TiB2 particle addition on the mechanical properties of AA 2219 Al alloy composite[J]. Journal of Minerals & Materials Characterization & Engineering, 2011, 10(6): 527-534.

[18] CHEN Dengbin, ZHAO Yutao, LI Guirong, et al. Mechanism and kinetic model of In-situ TiB2/7055Al nanocomposites synthesized under high intensity ultrasonic field[J]. Journal of Wuhan University of Technology, 2011, 26(5): 920-925.

[19] GAN Guisheng, YANG Bin, WU Huanchun, et al. The effect of TiB2 particles on the microstructure of semi-solid 7075 alloy slurry[J]. Materials Transactions, 2012, 53(6): 1178-1183.

[20] Quested T E, Greer A L, Cooper P S. The variable potency of TiB2 nucleant particles in the grain refinement of aluminium by Al-Ti-B additions[J]. Mater Sci Forum, 2002, 369/397/398/399/400/401/402: 53-58.

[21] Quested T E, Greer A L. The effect of the size distribution of inoculant parties on as-cast grains in aluminium alloy[J]. Acta Materialia, 2004, 52: 3859-3868.

(编辑 陈爱华)

收稿日期:2014-02-10;修回日期:2014-05-23

基金项目(Foundation item):重庆理工大学科研启动基金资助项目(2012ZD12);重庆市教委科技研究一般项目(KJ130813);国家高技术研究发展计划(863计划)项目(2009AA03Z523)(Project (2012ZD12)supported by the Scientific Research Staring Foundation of Chongqing University of Technology; Project (KJ130813) supported by Scientific and Technological Research Program of Chongqing Municipal Education Commission;Project (2009AA03Z523) supported by National High Technology Research and Development Program of China (863 Program))

通信作者:甘贵生(1982-),男,湖北孝感人,博士,讲师,从事复合材料研究;电话:023-62563178;E-mail:ggs@cqut.edu.cn